|

市場調查報告書

商品編碼

1885896

人造肉配料市場機會、成長促進因素、產業趨勢分析及預測(2025-2034年)Cultivated Meat Ingredients Market Opportunity, Growth Drivers, Industry Trend Analysis, and Forecast 2025 - 2034 |

||||||

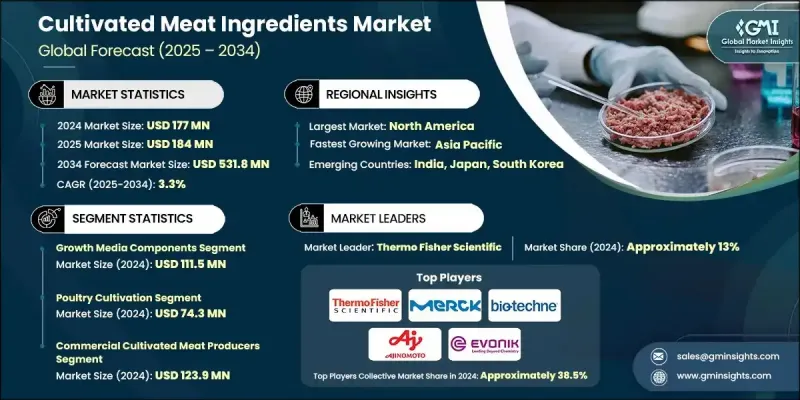

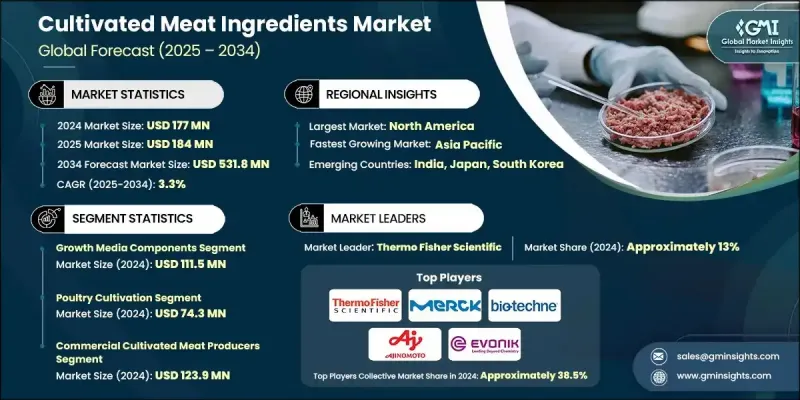

2024 年全球人造肉配料市場價值為 1.77 億美元,預計到 2034 年將以 3.3% 的複合年成長率成長至 5.318 億美元。

這些成分構成了細胞農業的基礎,使人們能夠透過可控的生物加工而非傳統養殖方式,利用動物細胞生產真正的肉類。它們包括生長培養基成分、支架材料和加工添加劑等關鍵組分,這些成分支持細胞的擴增、成熟和結構化組織的形成。先進的生物製程工程和精準發酵技術被用於開發食品級原料,以幫助在大型生物反應器系統中形成肌肉、脂肪和結締組織。隨著法規的日益明確和永續發展優先事項的加強,製造商正著力開發不含動物成分、成本更低的配方,以推動該行業的價格與傳統肉類持平。商業生產商是最大的需求群體,他們高度依賴高品質的培養基原料,包括基礎營養素、重組生長因子(如FGF2和IGF-1)、無血清替代品以及專為高密度細胞性能設計的微量營養素混合物。這種循環的生物加工方法旨在減少對昂貴的藥用級原料的依賴,並為能夠支持工業級人造肉生產的可擴展生產系統鋪平道路。

| 市場範圍 | |

|---|---|

| 起始年份 | 2024 |

| 預測年份 | 2025-2034 |

| 起始值 | 1.77億美元 |

| 預測值 | 5.318億美元 |

| 複合年成長率 | 3.3% |

2024年,培養基成分細分市場創造了1.115億美元的收入,預計2025年至2034年將以3.2%的複合年成長率成長,2024年市佔率將達到63%。這個類別佔據主導地位,因為這些成分為細胞在整個培養過程中的穩健生長、存活和分化提供了必要的生化基礎。基礎營養素、特化蛋白、胺基酸混合物和無血清替代品協同作用,共同創造了組織形成的最佳環境。

2024年,家禽養殖業市場規模達7,430萬美元,預計2025年至2034年間將以3.4%的複合年成長率成長,佔2024年市場總額的42%。家禽細胞培養技術憑藉其良好的生長特性、更有效率的培養基需求以及消費者對各種家禽產品的廣泛接受度,在該領域佔據領先地位。更快的細胞倍增時間和更低的複雜性有助於降低營運成本和縮短商業化週期,這對於專注於快速擴大規模並同時控制資金需求的早期生產設施尤其重要。

預計2025年至2034年,北美人造肉配料市場將以3.3%的複合年成長率成長。企業對永續蛋白質生產日益成長的興趣,以及人們對細胞農業在負責任的食品體系中作用的認知不斷提高,正推動著人造肉配料在商業、試點和研究領域的應用。對環境影響和符合倫理的食品生產的關注,促使人們投資於先進的生物程序技術,這些技術有望逐步補充傳統的畜牧業體系。

全球人造肉配料市場的主要企業包括賽默飛世爾科技(Thermo Fisher Scientific)、默克集團(Merck KGaA)、百奧泰克(Bio-Techne)、味之素(Ajinomoto)、贏創工業集團(Evonik Industries)、CJ Bio、瓦克化學(Wacker Chemie瓦克)、賽多利斯本(Sartori) Bio)、魯塞爾(Rousselot)、吉利達(GELITA)和帕爾斯加德(Palsgaard)。這些企業正透過大力投資研發來降低生產成本、提升功能性能,並開發適用於大規模生物加工的無動物性配料,從而增強自身的競爭優勢。許多公司正在推動重組蛋白技術,最佳化營養成分配比,並與人造肉品生產商建立合作關係,共同開發專用培養基配方。企業正透過新建生產基地、進行策略合作以及整合供應鏈來擴大其全球業務版圖,以確保配料的穩定供應。此外,包括轉向使用食品級非藥用成分在內的永續發展舉措,也為市場的長期擴張提供了支持。

目錄

第1章:方法論與範圍

第2章:執行概要

第3章:行業洞察

- 產業生態系分析

- 供應商格局

- 利潤率

- 每個階段的價值增加

- 影響價值鏈的因素

- 中斷

- 產業影響因素

- 促進要素

- 陷阱與挑戰

- 機會

- 成長潛力分析

- 監管環境

- 北美洲

- 歐洲

- 亞太地區

- 拉丁美洲

- 中東和非洲

- 波特的分析

- PESTEL 分析

- 價格趨勢

- 按地區

- 按成分

- 未來市場趨勢

- 技術與創新格局

- 當前技術趨勢

- 新興技術

- 專利格局

- 貿易統計(HS編碼)(註:僅提供重點國家的貿易統計資料)

- 主要進口國

- 主要出口國

- 永續性和環境方面

- 永續實踐

- 減少廢棄物策略

- 生產中的能源效率

- 環保舉措

- 碳足跡考量

第4章:競爭格局

- 介紹

- 公司市佔率分析

- 按地區

- 北美洲

- 歐洲

- 亞太地區

- 拉丁美洲

- MEA

- 按地區

- 公司矩陣分析

- 主要市場參與者的競爭分析

- 競爭定位矩陣

- 關鍵進展

- 併購

- 合作夥伴關係與合作

- 新產品發布

- 擴張計劃

第5章:市場估算與預測:依成分分類,2021-2034年

- 主要趨勢

- 生長培養基成分

- 基礎培養基

- 血清及血清替代品

- 重組生長因子

- 重組結構蛋白和功能蛋白

- 胺基酸和氮源

- 維生素、礦物質和能量來源

- 生長培養基成分

- 奈米纖維支架

- 可食用微載體

- 可食用膜和中空纖維系統

- 細胞外基質(ECM)蛋白

- 植物來源的支架

- 真菌和微生物支架

- 合成聚合物支架

- 3D生物墨水

- 加工助劑和配方成分

- 交聯酶

- 脂質和脂肪酸

- 乳化劑和穩定劑

- 脂肪替代品和油凝膠

- 風味系統和感官增強劑

第6章:市場估算與預測:依應用領域分類,2021-2034年

- 主要趨勢

- 家禽養殖

- 海鮮及魚類養殖

- 牛肉和紅肉養殖

- 豬肉養殖

- 異國風味和新奇肉類

- 其他

第7章:市場估算與預測:依最終用途分類,2021-2034年

- 主要趨勢

- 商業養殖肉品生產商

- 試點和示範設施

- 研究機構與學術界

- 其他

第8章:市場估算與預測:依地區分類,2021-2034年

- 主要趨勢

- 北美洲

- 美國

- 加拿大

- 歐洲

- 德國

- 英國

- 法國

- 西班牙

- 義大利

- 歐洲其他地區

- 亞太地區

- 中國

- 印度

- 日本

- 澳洲

- 韓國

- 亞太其他地區

- 拉丁美洲

- 巴西

- 墨西哥

- 阿根廷

- 拉丁美洲其他地區

- 中東和非洲

- 沙烏地阿拉伯

- 南非

- 阿拉伯聯合大公國

- 中東和非洲其他地區

第9章:公司簡介

- Thermo Fisher Scientific

- Merck KGaA

- Bio-Techne

- Ajinomoto

- Evonik Industries

- CJ Bio

- Wacker Chemie

- Sartorius

- ADM

- Cargill

- GenScript

- Takara Bio

- Rousselot

- GELITA

- Palsgaard

The Global Cultivated Meat Ingredients Market was valued at USD 177 million in 2024 and is estimated to grow at a CAGR of 3.3% to reach USD 531.8 million by 2034.

These ingredients form the foundation of cellular agriculture, enabling the creation of real meat from animal cells through controlled bioprocessing rather than traditional farming. They include essential components such as growth media ingredients, scaffolding materials, and processing additives that support cell expansion, maturation, and structured tissue formation. Advanced bioprocess engineering and precision fermentation are used to develop food-grade inputs that help form muscle, fat, and connective tissue within large-scale bioreactor systems. As regulations become clearer and sustainability priorities strengthen, manufacturers are emphasizing animal-free, lower-cost formulations to push the industry toward price parity with conventional meat. Commercial producers represent the largest demand base, relying heavily on high-quality media inputs including basal nutrients, recombinant growth factors like FGF2 and IGF-1, serum-free replacements, and micronutrient blends designed for high-density cell performance. This circular approach to bioprocessing aims to reduce dependence on costly pharmaceutical-grade ingredients and builds the path toward scalable production systems capable of supporting industrial-level cultivated meat operations.

| Market Scope | |

|---|---|

| Start Year | 2024 |

| Forecast Year | 2025-2034 |

| Start Value | $177 million |

| Forecast Value | $531.8 million |

| CAGR | 3.3% |

The growth media components segment generated USD 111.5 million in 2024 and is expected to grow at a CAGR of 3.2% from 2025 to 2034, accounting for a 63% share in 2024. This category plays a dominant role because these components provide the biochemical foundation necessary for robust cell growth, survival, and differentiation throughout cultivation. Basal nutrients, specialized proteins, amino acid blends, and serum-free substitutes all work together to create the optimal environment for tissue formation.

The poultry cultivation segment generated USD 74.3 million in 2024 and is expected to grow at a CAGR of 3.4% between 2025 and 2034, representing 42% of the total market in 2024. Poultry cells hold a leading position in this sector due to their favorable growth behavior, more efficient media requirements, and broad consumer acceptance of various poultry-based products. Faster cell doubling times and reduced complexity contribute to lower operating costs and shorter commercialization timelines, which are especially important for early-stage production facilities focused on scaling rapidly while managing capital demands.

North America Cultivated Meat Ingredients Market is projected to grow at a CAGR of 3.3% from 2025 to 2034. Rising corporate interest in sustainable protein production and growing recognition of cellular agriculture's role in responsible food systems are contributing to increased adoption across commercial, pilot, and research environments. Concerns surrounding environmental impact and ethical food production are motivating investment into advanced bioprocess technologies that may gradually complement traditional livestock-based systems.

Leading companies in the Global Cultivated Meat Ingredients Market include Thermo Fisher Scientific, Merck KGaA, Bio-Techne, Ajinomoto, Evonik Industries, CJ Bio, Wacker Chemie, Sartorius, ADM, Cargill, GenScript, Takara Bio, Rousselot, GELITA, and Palsgaard. Companies in the Cultivated Meat Ingredients Market are strengthening their competitive positioning by investing heavily in R&D to lower production costs, improve functional performance, and develop animal-free ingredients tailored for large-scale bioprocessing. Many firms are advancing recombinant protein technologies, optimizing nutrient blends, and building partnerships with cultivated meat manufacturers to co-develop specialized media formulations. Businesses are expanding their global footprint through new production sites, strategic collaborations, and supply-chain integration to ensure reliable ingredient availability. Sustainability initiatives, including the shift toward food-grade, non-pharmaceutical components, also support long-term market expansion.

Table of Contents

Chapter 1 Methodology & Scope

- 1.1 Market scope and definition

- 1.2 Research design

- 1.2.1 Research approach

- 1.2.2 Data collection methods

- 1.3 Data mining sources

- 1.3.1 Global

- 1.3.2 Regional/Country

- 1.4 Base estimates and calculations

- 1.4.1 Base year calculation

- 1.4.2 Key trends for market estimation

- 1.5 Primary research and validation

- 1.5.1 Primary sources

- 1.6 Forecast model

- 1.7 Research assumptions and limitations

Chapter 2 Executive Summary

- 2.1 Industry 3600 synopsis

- 2.2 Key market trends

- 2.2.1 Ingredients trends

- 2.2.2 Application trends

- 2.2.3 End use trends

- 2.2.4 Regional trends

- 2.3 TAM Analysis, 2025-2034

- 2.4 CXO perspectives: Strategic imperatives

- 2.4.1 Executive decision points

- 2.4.2 Critical success factors

- 2.5 Future Outlook and Strategic Recommendations

Chapter 3 Industry Insights

- 3.1 Industry ecosystem analysis

- 3.1.1 Supplier landscape

- 3.1.2 Profit margin

- 3.1.3 Value addition at each stage

- 3.1.4 Factor affecting the value chain

- 3.1.5 Disruptions

- 3.2 Industry impact forces

- 3.2.1 Drivers

- 3.2.2 Pitfalls & Challenges

- 3.2.3 Opportunities

- 3.3 Growth potential analysis

- 3.4 Regulatory landscape

- 3.4.1 North America

- 3.4.2 Europe

- 3.4.3 Asia Pacific

- 3.4.4 Latin America

- 3.4.5 Middle East & Africa

- 3.5 Porter's analysis

- 3.6 PESTEL analysis

- 3.7 Price trends

- 3.7.1 By region

- 3.7.2 By ingredients

- 3.8 Future market trends

- 3.9 Technology and Innovation landscape

- 3.9.1 Current technological trends

- 3.9.2 Emerging technologies

- 3.10 Patent Landscape

- 3.11 Trade statistics (HS code) ( Note: the trade statistics will be provided for key countries only)

- 3.11.1 Major importing countries

- 3.11.2 Major exporting countries

- 3.12 Sustainability and environmental aspects

- 3.12.1 Sustainable practices

- 3.12.2 Waste reduction strategies

- 3.12.3 Energy efficiency in production

- 3.12.4 Eco-friendly initiatives

- 3.13 Carbon footprint consideration

Chapter 4 Competitive Landscape, 2024

- 4.1 Introduction

- 4.2 Company market share analysis

- 4.2.1 By region

- 4.2.1.1 North America

- 4.2.1.2 Europe

- 4.2.1.3 Asia Pacific

- 4.2.1.4 LATAM

- 4.2.1.5 MEA

- 4.2.1 By region

- 4.3 Company matrix analysis

- 4.4 Competitive analysis of major market players

- 4.5 Competitive positioning matrix

- 4.6 Key developments

- 4.6.1 Mergers & acquisitions

- 4.6.2 Partnerships & collaborations

- 4.6.3 New Product Launches

- 4.6.4 Expansion Plans

Chapter 5 Market Estimates and Forecast, By Ingredients, 2021-2034 (USD Million & Kilo Tons)

- 5.1 Key trends

- 5.2 Growth media components

- 5.2.1 Basal media

- 5.2.2 Serum & serum alternatives

- 5.2.3 Recombinant growth factors

- 5.2.4 Recombinant structural & functional proteins

- 5.2.5 Amino acids & nitrogen sources

- 5.2.6 Vitamins, minerals & energy sources

- 5.3 Growth media components

- 5.3.1 Nanofibrous scaffolds

- 5.3.2 Edible microcarriers

- 5.3.3 Edible membranes & hollow fiber systems

- 5.3.4 Extracellular matrix (ECM) proteins

- 5.3.5 Plant-derived scaffolds

- 5.3.6 Fungal & microbial scaffolds

- 5.3.7 Synthetic polymer scaffolds

- 5.3.8 3D bioinks

- 5.4 Processing aids & formulation ingredients

- 5.4.1 Crosslinking enzymes

- 5.4.2 Lipids & fatty acids

- 5.4.3 Emulsifiers & stabilizers

- 5.4.4 Fat substitutes & oleogels

- 5.4.5 Flavor systems & sensory enhancers

Chapter 6 Market Estimates and Forecast, By Application, 2021-2034 (USD Million & Kilo Tons)

- 6.1 Key trends

- 6.2 Poultry cultivation

- 6.3 Seafood & fish cultivation

- 6.4 Beef & red meat cultivation

- 6.5 Pork cultivation

- 6.6 Exotic & novel meats

- 6.7 Others

Chapter 7 Market Estimates and Forecast, By End Use, 2021-2034 (USD Million & Kilo Tons)

- 7.1 Key trends

- 7.2 Commercial Cultivated Meat Producers

- 7.3 Pilot & Demonstration Facilities

- 7.4 Research Institutions & Academia

- 7.5 Others

Chapter 8 Market Estimates and Forecast, By Region, 2021-2034 (USD Million & Kilo Tons)

- 8.1 Key trends

- 8.2 North America

- 8.2.1 U.S.

- 8.2.2 Canada

- 8.3 Europe

- 8.3.1 Germany

- 8.3.2 UK

- 8.3.3 France

- 8.3.4 Spain

- 8.3.5 Italy

- 8.3.6 Rest of Europe

- 8.4 Asia Pacific

- 8.4.1 China

- 8.4.2 India

- 8.4.3 Japan

- 8.4.4 Australia

- 8.4.5 South Korea

- 8.4.6 Rest of Asia Pacific

- 8.5 Latin America

- 8.5.1 Brazil

- 8.5.2 Mexico

- 8.5.3 Argentina

- 8.5.4 Rest of Latin America

- 8.6 Middle East and Africa

- 8.6.1 Saudi Arabia

- 8.6.2 South Africa

- 8.6.3 UAE

- 8.6.4 Rest of Middle East and Africa

Chapter 9 Company Profiles

- 9.1 Thermo Fisher Scientific

- 9.2 Merck KGaA

- 9.3 Bio-Techne

- 9.4 Ajinomoto

- 9.5 Evonik Industries

- 9.6 CJ Bio

- 9.7 Wacker Chemie

- 9.8 Sartorius

- 9.9 ADM

- 9.10 Cargill

- 9.11 GenScript

- 9.12 Takara Bio

- 9.13 Rousselot

- 9.14 GELITA

- 9.15 Palsgaard