|

市場調查報告書

商品編碼

1910931

印度紙和紙板包裝市場:市場佔有率分析、行業趨勢與統計、成長預測(2026-2031)India Paper And Paperboard Packaging - Market Share Analysis, Industry Trends & Statistics, Growth Forecasts (2026 - 2031) |

||||||

※ 本網頁內容可能與最新版本有所差異。詳細情況請與我們聯繫。

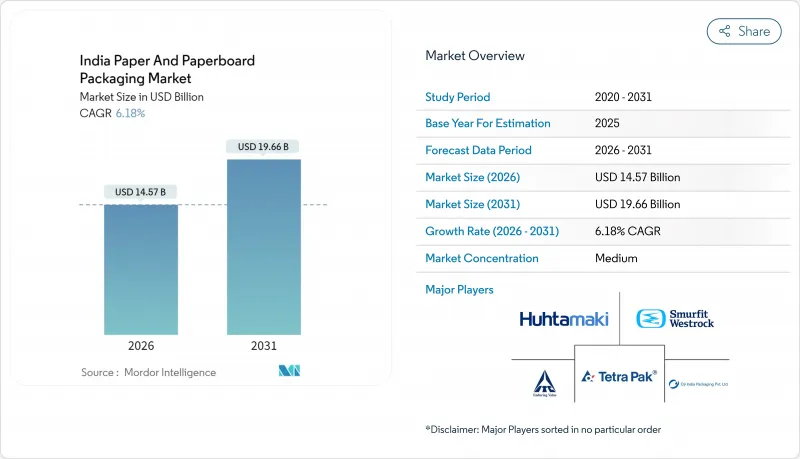

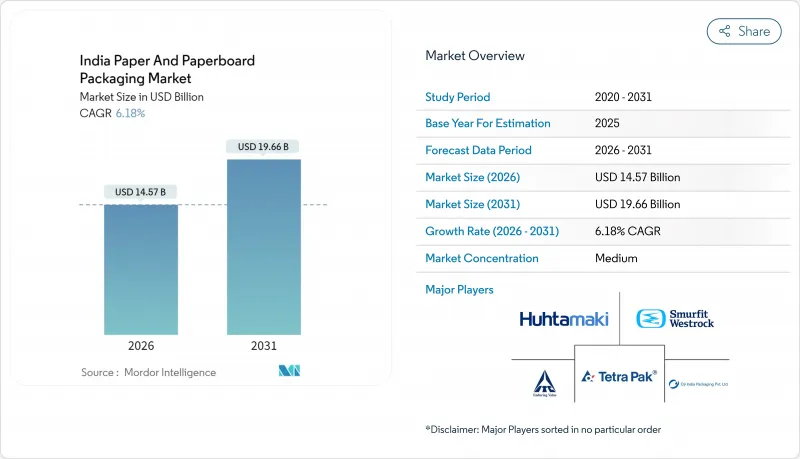

預計到 2026 年,印度紙和紙板包裝市場規模將達到 145.7 億美元,高於 2025 年的 137.2 億美元。

預計到 2031 年將達到 196.6 億美元,2026 年至 2031 年的複合年成長率為 6.18%。

需求動能反映了全國逐步淘汰一次性塑膠製品、電子商務物流的快速擴張以及品牌對循環經濟包裝的承諾。瓦楞紙箱因其抗震且輕巧的運輸需求,在網路零售領域佔據主導地位。同時,液體紙盒受益於高階飲料的成長和無菌填充技術的投資。食品飲料品牌正在加速採用可回收的單一材料包裝,而一二線城市快速商業中心的擴張也擴大了小型二次包裝的潛在市場。在供應方面,再生纖維產能、農業廢棄物紙漿生產線和高速柔版印刷機的擴建工作正在取得進展,但由於能源價格上漲和進口再生紙價格波動,利潤率仍面臨壓力。

印度紙和紙板包裝市場趨勢及展望

電子商務對瓦楞紙包裝的需求不斷成長

訂單量的快速成長以及電商快遞35公斤的新重量限制促使加工商尋求兼顧強度和紙張重量的瓦楞紙板設計,以提高最後一公里配送效率。 Flipkart 淘汰塑膠包裝的舉措已導致數百萬小包裹轉為紙質包裝。像 Adani Wilmar 這樣的快速消費品供應商正在為線上通路推出更大容量的 SKU,從而推動了瓦楞紙板使用量的成長。位於班加羅爾和德里的區域樞紐網路加快了補貨速度,同時增加了觸點,並推動了對能夠維護品牌價值的高品質印刷圖案的需求。因此,瓦楞紙板製造商正在採用在線連續柔版摺頁機和數位印刷模組來縮短準備時間並減少廢棄物。因此,在電子商務滲透率和材料中性永續性要求的交匯點,印度紙和紙板包裝市場正經歷結構性成長。

食品品牌正逐步轉向可再生單一材料包裝

隨著都市區消費者越來越關注包裝標籤的最終使用壽命,可回收性已成為影響購買決策的重要因素。領先的食品加工企業正在重新設計複合材料,採用水性或生物聚合物塗層的單基材紙板,無需多層塑膠即可提供防油防潮性能。 Huhtamaki 與印度工業聯合會合作創建了一份開放原始碼設計指南,展示了單一材料形式如何促進機械回收流程。由於品牌所有者的目標是在 2026 年實現更高的生產者延伸責任 (EPR) 目標,因此能夠保證纖維純度和可追溯性的供應商將優先考慮。塗層化學品可以大規模在線連續應用,為加工商帶來利潤率和速度方面的優勢,從而增強印度紙和紙板包裝市場的長期發展動力。

進口再生紙價格波動

印度約30%的再生紙板原料依賴海運,而運輸中斷和競標戰推高了現貨價格,擠壓了造紙廠的利潤空間。印度造紙工業協會已要求對從中國和智利進口的多層紙板徵收關稅,理由是價格暴跌。 JK Paper公司2024會計年度獲利下降58%就是一個鮮明的例子,說明成本飆升如何直接影響利潤。雖然北美一條新的紙漿生產線在2025年中期有助於抑制全球紙價,但外匯波動和紅海航運風險仍導致市場波動性居高不下,減緩了印度紙和紙板包裝市場近期的成長速度。

細分市場分析

到2025年,瓦楞紙板將佔總收入的48.23%,這主要得益於履約中心對緩衝和托盤效率的重視。液體紙盒雖然尺寸較小,但預計將以7.28%的複合年成長率成長,這主要得益於高階乳製品、果汁和無菌預製食品解決方案的需求。印度瓦楞紙和紙板包裝市場預計在2026年至2031年間將成長22.9億美元,主要得益於在線連續印刷和模切技術的投資,這些技術降低了換線成本。在利樂公司突破性地推出5% ISCC PLUS認證的再生聚合物層的引領下,UFlex等液體紙盒產業的領導者計畫將年產量擴大到120億包。同時,由於符合單一材料標準的水性阻隔塗層的改進,折疊紙盒在消費品領域保持著穩固的地位。小眾市場保護要求和環保意識品牌推廣帶來了溢價差異,從而緩衝了特種紙板和模塑纖維原料價格的波動。

從競爭角度來看,像ITC這樣的大型集團掌控著從農場到成品紙板的整個流程,這使它們能夠對沖原料成本並縮短產品開發週期。瓦楞紙板製造商則透過將印刷工序設在更靠近數位市場的地區來應對,從而實現當日補貨。隨著印度紙和紙板包裝市場朝向超本地化配送模式發展,這成為一項營運優勢。

預計到2025年,食品飲料品牌將佔總收入的39.35%,這主要得益於嚴格的衛生標準和不斷擴展的低溫運輸。同時,個人護理和化妝品領域預計將以7.72%的複合年成長率實現更高成長。在餐飲服務業,速食店正在採用由再生纖維和PLA分散體製成的防油翻蓋式容器,以遵守一次性塑膠禁令。預計到2031年,印度個人保健產品紙和紙板包裝市場規模將成長5.68億美元,主要得益於高階品牌從塑膠容器轉向硬紙板和膠印紙套。

在醫療保健領域,由於國內藥品產量增加,對泡殼包裝內襯和醫用紙盒的需求保持穩定。電子產品製造商雖然在尋求防靜電織物托盤,但由於其與發泡材的功能等效性存在成本差異,因此成長速度受到限制。在工業和汽車領域,多層瓦楞紙箱以及「印度製造」計劃帶來的採購量增加,確保了在廣泛的終端用戶領域擁有均衡的收入基礎。

其他福利

- Excel格式的市場預測(ME)表

- 分析師支持(3個月)

目錄

第1章 引言

- 研究假設和市場定義

- 調查範圍

第2章調查方法

第3章執行摘要

第4章 市場情勢

- 市場概覽

- 市場促進因素

- 電子商務的擴張帶動了對瓦楞紙包裝需求的成長。

- 食品品牌正逐步轉向可再生單一材料包裝

- 政府禁止使用一次性塑膠製品

- 快速商業區域中心的崛起

- 投資自動化高速柔版印刷

- 提高農業廢棄物紙漿生產能力

- 市場限制

- 進口再生紙價格波動

- 貨櫃紙板能源成本持續上漲

- 中小加工商的消費稅退稅延遲

- 計費和出版領域的數位化替代方案

- 工業供應鏈分析

- 監管環境

- 技術展望

- 波特五力分析

- 新進入者的威脅

- 供應商的議價能力

- 買方的議價能力

- 替代品的威脅

- 產業間競爭

第5章 市場規模與成長預測

- 依產品類型

- 可折疊瓦楞紙箱

- 紙板包裝

- 液體紙盒

- 其他

- 按最終用戶行業分類

- 飲食

- 處方藥

- 個人護理及化妝品

- 電氣和電子設備

- 工業與汽車

- 按包裝類型

- 主要零售包裝

- 二級運輸包裝

- 可直接上架/展示包裝

- 保護性襯墊和緩衝墊

- 按材料等級

- 原生紙漿

- 再生纖維

- 混紡/混合纖維

第6章 競爭情勢

- 市場集中度

- 策略趨勢

- 市佔率分析

- 公司簡介

- TCPL Packaging Limited

- Parksons Packaging Limited

- Smurfit WestRock plc

- KCL Limited

- Borkar Packaging Private Limited

- Canpac Trends Private Limited

- Trident Paper Box Industries

- Tetra-Pak India Private Limited

- UFlex Ltd

- Oji India Packaging Private Limited

- ITC Limited-Paperboards and Specialty Papers Division

- JK Paper Limited

- Horizon Packs Private Limited

- Astron Packaging Limited

- ANY Graphics Private Limited

- Meghna Packaging Private Limited

- GPA Global India

- Huhtamaki India Limited

- Mayur Uniquoters Limited

第7章 市場機會與未來展望

India paper and paperboard packaging market size in 2026 is estimated at USD 14.57 billion, growing from 2025 value of USD 13.72 billion with 2031 projections showing USD 19.66 billion, growing at 6.18% CAGR over 2026-2031.

Demand momentum reflects the nationwide shift away from single-use plastics, the rapid scale-up of e-commerce logistics, and brand commitments to circular-economy packaging.Corrugated boxes dominate because online retail requires impact-resistant yet lightweight transit formats, while liquid cartons are benefiting from premium beverage growth and aseptic filling investments. Food and beverage brands accelerate the adoption of recyclable mono-material packs, and quick-commerce hubs in Tier-1 and Tier-2 cities enlarge the addressable base for small-format secondary packs. On the supply side, recycled fiber capacity, agro-residue pulp lines, and high-speed flexo presses are expanding, yet margin pressure persists due to energy inflation and volatile imported waste-paper prices.

India Paper And Paperboard Packaging Market Trends and Insights

Rising E-commerce Corrugated Demand

Order-volume surges and heavier quick-commerce shipments now permitted up to 35 kg are pushing converters to engineer corrugated designs that balance strength and grammage for last-mile efficiency. Flipkart's commitment to eliminating plastic cushioning has already converted millions of parcels to paper-based formats. FMCG suppliers such as Adani Wilmar have introduced larger stock-keeping units tailored for online channels, fueling incremental box tonnage. Regional hub networks in Bengaluru and Delhi enable faster replenishment but also multiply touch-points, widening demand for high-print graphics that preserve brand equity. As a result, corrugators are installing inline flexo folders and digital print modules to shorten make-ready times and cut waste. The India paper and paperboard packaging market, therefore, derives a structural uplift from the intersection of e-commerce penetration and material-neutral sustainability mandates.

Food Brand Shift to Recyclable Mono-Material Packs

Recyclability is now a purchase driver as urban consumers scrutinize pack labels for end-of-life credentials. Large food processors are reformulating laminates toward single-substrate paperboard combined with aqueous or biopolymer coatings that deliver grease and moisture barriers without multi-layer plastics. Huhtamaki's partnership with the Confederation of Indian Industry created open-source design guides that clarify how mono-material formats ease mechanical recycling workflows. As brand owners chase Extended Producer Responsibility targets that ramp up in 2026, vendors able to guarantee fiber purity and traceability gain preference.Because coating chemistries can be applied in-line at scale, converters capture both margin and speed advantages, reinforcing the long-run tailwind on the India paper and paperboard packaging market.

Price Volatility of Imported Waste Paper

India relies on seaborne recovered fiber for roughly 30% of recycled-board furnish; freight disruptions and bidding wars push spot prices, squeezing mill margins. The Indian Paper Manufacturers Association has petitioned for duties on multi-layer board imports from China and Chile, citing price undercutting. JK Paper's FY 2024 profit drop of 58% exemplifies how cost spikes flow through earnings. Although new North American pulp lines tempered global prices in mid-2025, currency swings and Red Sea routing risks keep volatility elevated, dampening the near-term growth tempo of the India paper and paperboard packaging market.

Other drivers and restraints analyzed in the detailed report include:

- Government Ban on Single-Use Plastics

- Emergence of Quick-Commerce Regional Hubs

- Chronic Containerboard Energy-Cost Inflation

For complete list of drivers and restraints, kindly check the Table Of Contents.

Segment Analysis

Corrugated stock generated 48.23% of 2025 revenue, buoyed by e-commerce fulfillment centers that prize cushioning and pallet efficiency. Liquid cartons, though smaller, are slated for a 7.28% CAGR on the back of premium dairy, juice, and aseptic meal solutions. The India paper and paperboard packaging market size for corrugated grades is projected to increase by an additional USD 2.29 billion between 2026 and 2031, driven by investments in inline print-and-die-cut technology that lowers changeover costs. Liquid-carton leaders such as UFlex plan to lift output to 12 billion packs annually, helped by Tetra Pak's landmark rollout of 5% ISCC PLUS certified recycled-polymer layers. In parallel, folding cartons maintain a stable FMCG base, upgraded by water-based barrier coats that meet mono-material guidelines. Specialty paperboards and molded fiber trade on niche protection requirements and ecological branding, commanding premium spreads that cushion input volatility.

From a competitive stance, large groups like ITC control the full chain from agro-forestry to finished board, enabling raw-material hedging and shorter product-development cycles. Corrugators respond by co-locating print cells near digital marketplaces to deliver same-day box replenishment, an operational edge as the India paper and paperboard packaging market pivots toward hyperlocal delivery.

Food and beverage brands captured 39.35% revenue in 2025 due to stringent hygiene codes and an expanding cold chain, while personal care and cosmetics outperformed with an 7.72% CAGR forecast. Within food-service, quick-serve restaurants adopt grease-resistant clamshells built from recycled fiber plus PLA dispersion, aligning with the single-use-plastic ban. The India paper and paperboard packaging market size for personal-care items is slated to advance by USD 568 million through 2031 as premium labels trade plastic jars for rigid paperboard tubes and offset-printed sleeves.

On the healthcare front, blister backing and medical-grade cartons enjoy secure demand as domestic pharma output climbs. Electronics brands seek static-safe fiber trays but weigh cost against functional parity with foam, damping runaway growth. Industrial and automotive parts rely on multi-wall corrugated crates that dovetail with the Make in India sourcing expansion, ensuring a broad, balanced revenue footprint across end-use bands.

The India Paper and Paperboard Packaging Market Report is Segmented by Product Type (Folding Cartons, Corrugated Packaging, Liquid Cartons, and More), End-User Vertical (Food and Beverage, Healthcare and Pharma, Automotive, and More), Packaging Format (Primary Retail Packs, Secondary Transit Packs, and More), Material Grade (Virgin Fiber, Recycled Fiber, and More). The Market Forecasts are Provided in Terms of Value (USD).

List of Companies Covered in this Report:

- TCPL Packaging Limited

- Parksons Packaging Limited

- Smurfit WestRock plc

- KCL Limited

- Borkar Packaging Private Limited

- Canpac Trends Private Limited

- Trident Paper Box Industries

- Tetra-Pak India Private Limited

- UFlex Ltd

- Oji India Packaging Private Limited

- ITC Limited - Paperboards and Specialty Papers Division

- JK Paper Limited

- Horizon Packs Private Limited

- Astron Packaging Limited

- A N Y Graphics Private Limited

- Meghna Packaging Private Limited

- GPA Global India

- Huhtamaki India Limited

- Mayur Uniquoters Limited

Additional Benefits:

- The market estimate (ME) sheet in Excel format

- 3 months of analyst support

TABLE OF CONTENTS

1 INTRODUCTION

- 1.1 Study Assumptions and Market Definition

- 1.2 Scope of the Study

2 RESEARCH METHODOLOGY

3 EXECUTIVE SUMMARY

4 MARKET LANDSCAPE

- 4.1 Market Overview

- 4.2 Market Drivers

- 4.2.1 Rising e-commerce corrugated demand

- 4.2.2 Food brand shift to recyclable mono-material packs

- 4.2.3 Government ban on single-use plastics

- 4.2.4 Emergence of quick-commerce regional hubs

- 4.2.5 Automated high-speed flexo printing investments

- 4.2.6 Agro-residue pulp capacity additions

- 4.3 Market Restraints

- 4.3.1 Price volatility of imported waste paper

- 4.3.2 Chronic containerboard energy-cost inflation

- 4.3.3 Delayed GST refunds for SME converters

- 4.3.4 Digital substitution in billing and publishing

- 4.4 Industry Supply-Chain Analysis

- 4.5 Regulatory Landscape

- 4.6 Technological Outlook

- 4.7 Porter's Five Forces Analysis

- 4.7.1 Threat of New Entrants

- 4.7.2 Bargaining Power of Suppliers

- 4.7.3 Bargaining Power of Buyers

- 4.7.4 Threat of Substitutes

- 4.7.5 Industry Rivalry

5 MARKET SIZE AND GROWTH FORECASTS (VALUE)

- 5.1 By Product Type

- 5.1.1 Folding Cartons

- 5.1.2 Corrugated Packaging

- 5.1.3 Liquid Cartons

- 5.1.4 Other Product Types

- 5.2 By End-User Vertical

- 5.2.1 Food and Beverage

- 5.2.2 Healthcare and Pharma

- 5.2.3 Personal Care and Cosmetics

- 5.2.4 Electrical and Electronics

- 5.2.5 Industrial and Automotive

- 5.3 By Packaging Format

- 5.3.1 Primary Retail Packs

- 5.3.2 Secondary Transit Packs

- 5.3.3 Shelf-ready / Display Packs

- 5.3.4 Protective Inserts and Cushioning

- 5.4 By Material Grade

- 5.4.1 Virgin Fiber

- 5.4.2 Recycled Fiber

- 5.4.3 Hybrid/Mixed Fiber

6 COMPETITIVE LANDSCAPE

- 6.1 Market Concentration

- 6.2 Strategic Moves

- 6.3 Market Share Analysis

- 6.4 Company Profiles (includes Global level Overview, Market level overview, Core Segments, Financials as available, Strategic Information, Market Rank/Share for key companies, Products and Services, and Recent Developments)

- 6.4.1 TCPL Packaging Limited

- 6.4.2 Parksons Packaging Limited

- 6.4.3 Smurfit WestRock plc

- 6.4.4 KCL Limited

- 6.4.5 Borkar Packaging Private Limited

- 6.4.6 Canpac Trends Private Limited

- 6.4.7 Trident Paper Box Industries

- 6.4.8 Tetra-Pak India Private Limited

- 6.4.9 UFlex Ltd

- 6.4.10 Oji India Packaging Private Limited

- 6.4.11 ITC Limited - Paperboards and Specialty Papers Division

- 6.4.12 JK Paper Limited

- 6.4.13 Horizon Packs Private Limited

- 6.4.14 Astron Packaging Limited

- 6.4.15 A N Y Graphics Private Limited

- 6.4.16 Meghna Packaging Private Limited

- 6.4.17 GPA Global India

- 6.4.18 Huhtamaki India Limited

- 6.4.19 Mayur Uniquoters Limited

7 MARKET OPPORTUNITIES AND FUTURE OUTLOOK

- 7.1 White-space and Unmet-need Assessment