|

市場調查報告書

商品編碼

1876544

汽車噴塗機器人系統市場機會、成長促進因素、產業趨勢分析及預測(2025-2034年)Automotive Paint Robot System Market Opportunity, Growth Drivers, Industry Trend Analysis, and Forecast 2025 - 2034 |

||||||

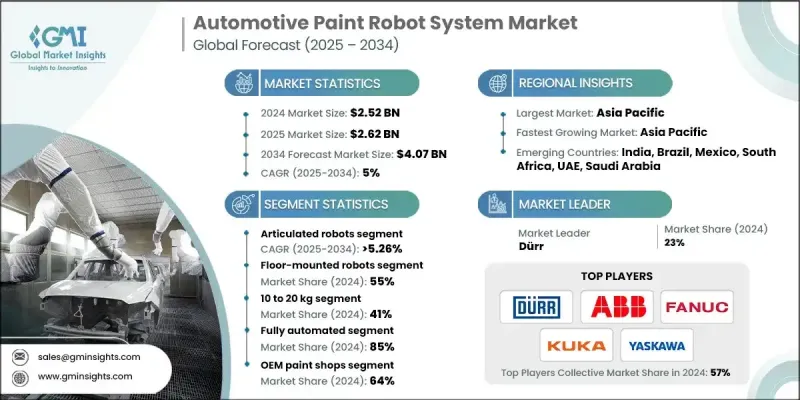

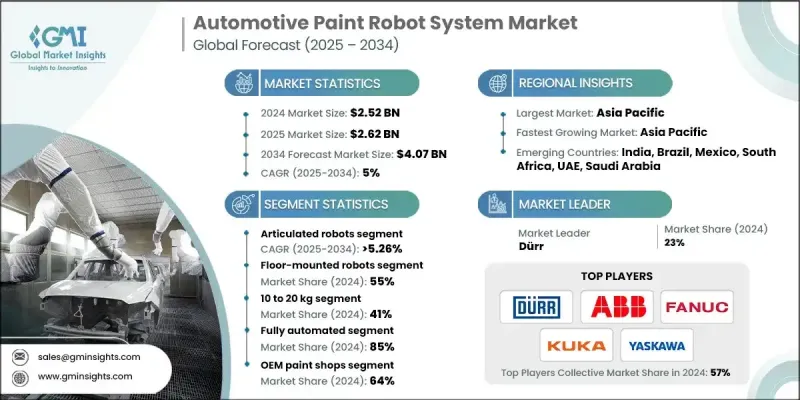

2024 年全球汽車噴漆機器人系統市場價值為 25.2 億美元,預計到 2034 年將以 5% 的複合年成長率成長至 40.7 億美元。

汽車生產設施中自動化程度的不斷提高正在推動這一市場的發展,因為製造商正在尋求在車輛噴塗作業中實現更高的精度、均勻性和永續性。旨在實現車身搬運、塗裝和精加工自動化的汽車噴塗機器人系統已成為現代汽車生產線不可或缺的一部分。全球汽車產量的成長、電動車的加速轉型以及對客製化塗裝日益成長的需求,都是推動市場擴張的主要因素。機器人噴塗能夠提供一致的塗層厚度、卓越的表面品質和最小的材料浪費,同時確保更快的循環時間和更高的效率。這些系統還能透過減少排放和提高能源效率來支持製造商的永續發展目標。此外,更嚴格的環境法規、降低營運成本的壓力以及數位化和綠色製造的持續發展趨勢,都進一步推動了對自動化噴塗車間的投資。由於機器人噴塗技術能夠提供可重複的結果並消除人工操作帶來的不一致性,汽車製造商正在優先考慮採用先進的噴塗機器人技術,以在每個生產階段實現更高的生產效率和精度。

| 市場範圍 | |

|---|---|

| 起始年份 | 2024 |

| 預測年份 | 2025-2034 |

| 起始值 | 25.2億美元 |

| 預測值 | 40.7億美元 |

| 複合年成長率 | 5% |

2024年,關節型機器人市佔率達到69%,預計2025年至2034年將以5.26%的複合年成長率成長。其主導地位歸功於關節型機器人的多功能性、遠距離作業能力以及輕鬆應對複雜車輛幾何形狀的能力。這些機器人配備多個關節,通常擁有六個或更多軸,能夠像人臂一樣提供流暢精準的運動,使其成為對精度和適應性要求極高的汽車噴漆應用的理想選擇。它們能夠處理複雜的噴塗角度和輪廓,從而在保持大規模生產線效率的同時,提升整體噴塗品質。

2024年,落地式機器人市佔率達到55%,預計到2034年將以5.63%的複合年成長率成長。由於其穩定性、易於整合以及與現有生產佈局的兼容性,落地式機器人仍然是製造工廠中最常用的配置。這些機器人直接固定在基座或車間地面上,為機械手臂和塗漆器提供穩固的支撐,從而在高速噴塗循環中實現精確控制和穩定運行。其堅固的結構和適應性使其成為大型汽車裝配線不可或缺的一部分。

亞太地區汽車噴塗機器人系統市場佔50%的市場佔有率,預計2024年市場規模將達到12.5億美元。該地區強勁的市場地位得益於快速的工業化進程、大規模的汽車製造以及對自動化技術日益成長的投資。中國、日本、韓國和印度等國家正透過戰略舉措引領這一成長,這些舉措旨在推動智慧製造、機器人技術和工業4.0的普及應用。這些政府支持的項目以及高水準的技術創新,使該地區成為先進製造和自動化發展的重要中心。

全球汽車噴塗機器人系統市場的主要參與者包括庫卡(KUKA)、發那科(FANUC)、ABB、杜爾(Durr)、科茂(Comau)、川崎重工、史陶比爾機器人(Staubli Robotics)、安川電機和歐姆龍。這些領先企業正透過創新、合作和拓展技術能力來鞏固其競爭地位。他們專注於研發,致力於推出更高精度、更高能源效率和更數位化整合的智慧機器人噴塗解決方案。與汽車製造商的合作,使得他們能夠開發出滿足特定生產需求的客製化自動化系統。此外,各公司也持續擴大產能和服務網路,以滿足新興市場日益成長的需求。

目錄

第1章:方法論

- 市場範圍和定義

- 研究設計

- 研究方法

- 資料收集方法

- 資料探勘來源

- 全球的

- 地區/國家

- 基準估算和計算

- 基準年計算

- 市場估算的關鍵趨勢

- 初步研究和驗證

- 原始資料

- 預報

- 研究假設和局限性

第2章:執行概要

第3章:行業洞察

- 產業生態系分析

- 供應商格局

- 利潤率分析

- 成本結構

- 每個階段的價值增加

- 影響價值鏈的因素

- 中斷

- 產業影響因素

- 成長促進因素

- 汽車客製化需求不斷成長

- 大批量車輛生產要求

- 勞動成本削減壓力

- 環境法規

- 機器人技術的進步

- 製造商的永續發展舉措

- 產業陷阱與挑戰

- 高昂的初始投資成本

- 複雜的維護要求

- 市場機遇

- 新興市場的擴張

- 電動車產量成長

- 協作機器人開發

- 人工智慧與物聯網的融合

- 成長促進因素

- 成長潛力分析

- 專利分析

- 波特的分析

- PESTEL 分析

- 成本細分分析

- 技術格局

- 當前技術趨勢

- 新興技術

- 監管環境

- 價格趨勢

- 按地區

- 由機器人

- 生產統計

- 生產中心

- 消費中心

- 進出口

- 永續性和環境方面

- 永續實踐

- 減少廢棄物策略

- 生產中的能源效率

- 環保舉措

- 碳足跡考量

- 投資和供應鏈分析

- 投資和融資趨勢分析

- 供應鏈動態和原料影響

- 卓越營運、永續性和勞動力管理

- 品質標準和績效基準

- 環境影響與永續發展舉措

- 勞動力影響和技能需求分析

- 培訓和發展計劃評估

- 供應商和風險管理

- 供應商評估標準與選擇框架

- 風險評估和緩解策略

- 自動化對取得高規格合約的影響

第4章:競爭格局

- 介紹

- 公司市佔率分析

- 北美洲

- 歐洲

- 亞太地區

- 拉丁美洲

- 中東和非洲

- 主要市場參與者的競爭分析

- 競爭定位矩陣

- 戰略展望矩陣

- 關鍵進展

- 併購

- 合作夥伴關係與合作

- 新安裝項目啟動

- 擴張計劃和資金

第5章:市場估算與預測:依機器人分類,2021-2034年

- 主要趨勢

- 關節機器人

- 笛卡兒機器人

- Scara機器人

- 協作機器人

第6章:市場估算與預測:以年計算,2021-2034年

- 主要趨勢

- 落地式機器人

- 壁掛式機器人

- 軌道式機器人

第7章:市場估計與預測:依有效載荷分類,2021-2034年

- 主要趨勢

- 最多 5 公斤

- 5至10公斤

- 10至20公斤

- 體重超過20公斤

第8章:市場估算與預測:依自動化程度分類,2021-2034年

- 主要趨勢

- 全自動

- 半自動

第9章:市場估算與預測:依最終用途分類,2021-2034年

- 主要趨勢

- OEM噴漆車間

- 一級供應商設施

- 售後市場和碰撞維修中心

- 特種車輛製造

第10章:市場估計與預測:依地區分類,2021-2034年

- 主要趨勢

- 北美洲

- 美國

- 加拿大

- 歐洲

- 德國

- 英國

- 法國

- 義大利

- 西班牙

- 北歐

- 俄羅斯

- 亞太地區

- 中國

- 印度

- 日本

- 澳洲

- 印尼

- 菲律賓

- 泰國

- 韓國

- 新加坡

- 拉丁美洲

- 巴西

- 墨西哥

- 阿根廷

- 中東和非洲

- 沙烏地阿拉伯

- 南非

- 阿拉伯聯合大公國

第11章:公司簡介

- 全球參與者

- ABB

- Comau

- Denso

- Durr

- Epson Robots

- FANUC

- Kawasaki Heavy Industries

- KUKA

- Mitsubishi Electric

- Nachi-Fujikoshi

- Omron

- Panasonic

- Staubli Robotics

- Yaskawa Electric

- 區域玩家

11.2.1. 3M公司

- 斗山機器人

- 精英機器人

- 現代機器人

- 里斯機器人

- 優傲機器人

- 新興參與者/顛覆者

- 弗蘭卡·埃米卡

- 精確自動化

- 重新思考機器人技術

- 標準機器人

- 泰克曼機器人

The Global Automotive Paint Robot System Market was valued at USD 2.52 billion in 2024 and is estimated to grow at a CAGR of 5% to reach USD 4.07 billion by 2034.

The growing adoption of automation across automotive production facilities is driving this market, as manufacturers seek enhanced precision, uniformity, and sustainability in vehicle painting operations. Automotive paint robot systems, designed to automate body handling, coating, and finishing, have become essential to modern vehicle manufacturing lines. Rising global vehicle output, the accelerating transition toward electric vehicles, and increasing demand for customized finishes are major factors contributing to market expansion. Robotic painting offers consistent coating thickness, superior finish quality, and minimal material waste while ensuring faster cycle times and higher efficiency. These systems also support manufacturers' sustainability goals by reducing emissions and improving energy efficiency. Moreover, stricter environmental regulations, pressure to reduce operational costs, and the ongoing trend toward digital and green manufacturing are further fueling investments in automated paint shops. With robotic painting technology delivering repeatable results and eliminating inconsistencies associated with manual operations, automakers are prioritizing advanced paint robotics to achieve higher productivity and precision in every production stage.

| Market Scope | |

|---|---|

| Start Year | 2024 |

| Forecast Year | 2025-2034 |

| Start Value | $2.52 billion |

| Forecast Value | $4.07 billion |

| CAGR | 5% |

The articulated robots segment held 69% share in 2024 and is projected to grow at a CAGR of 5.26% from 2025 to 2034. This dominance is attributed to their versatility, extended reach, and ability to handle complex vehicle geometries with ease. These robots, equipped with multiple joints and typically six or more axes, provide smooth and precise motion like that of a human arm, making them ideal for automotive paint applications that demand accuracy and adaptability. Their capability to manage intricate painting angles and contours enhances the overall finish quality while maintaining efficiency on large-scale production lines.

The floor-mounted robots segment held a 55% share in 2024 and is expected to grow at a CAGR of 5.63% through 2034. Floor-mounted configurations remain the most adopted setup in manufacturing facilities due to their stability, ease of integration, and compatibility with existing production layouts. These robots are fixed directly onto pedestals or plant floors, providing a solid base for the robotic arm and paint applicator, which allows for precise control and steady operation during high-speed painting cycles. Their robust structure and adaptability make them an essential part of large automotive assembly lines.

Asia Pacific Automotive Paint Robot System Market held a 50% share and generated USD 1.25 billion in 2024. The region's strong position is supported by rapid industrialization, large-scale automotive manufacturing, and rising investment in automation technologies. Countries including China, Japan, South Korea, and India are leading this growth through strategic initiatives that promote smart manufacturing, robotics, and Industry 4.0 adoption. These government-backed programs and high levels of technological innovation have positioned the region as a major hub for advanced manufacturing and automation development.

Key players operating in the Global Automotive Paint Robot System Market include KUKA, FANUC, ABB, Durr, Comau, Kawasaki Heavy Industries, Staubli Robotics, Yaskawa Electric, and Omron. Leading companies in the Automotive Paint Robot System Market are strengthening their competitive position through innovation, collaboration, and expansion of technological capabilities. They are focusing on research and development to introduce intelligent robotic painting solutions with higher accuracy, energy efficiency, and digital integration. Partnerships with automotive manufacturers are enabling tailored automation systems designed to meet specific production requirements. Companies are also expanding their manufacturing capacity and service networks to cater to rising demand in emerging markets.

Table of Contents

Chapter 1 Methodology

- 1.1 Market scope and definition

- 1.2 Research design

- 1.2.1 Research approach

- 1.2.2 Data collection methods

- 1.3 Data mining sources

- 1.3.1 Global

- 1.3.2 Regional/Country

- 1.4 Base estimates and calculations

- 1.4.1 Base year calculation

- 1.4.2 Key trends for market estimation

- 1.5 Primary research and validation

- 1.5.1 Primary sources

- 1.6 Forecast

- 1.7 Research assumptions and limitations

Chapter 2 Executive Summary

- 2.1 Industry 3600 synopsis, 2021 - 2034

- 2.2 Key market trends

- 2.2.1 Regional

- 2.2.2 Robot

- 2.2.3 Mounting

- 2.2.4 Pay load

- 2.2.5 Automation level

- 2.2.6 End use

- 2.3 TAM analysis, 2025-2034

- 2.4 CXO perspectives: Strategic imperatives

- 2.4.1 Executive decision points

- 2.4.2 Critical success factors

- 2.5 Future-outlook and strategic recommendations

Chapter 3 Industry Insights

- 3.1 Industry ecosystem analysis

- 3.1.1 Supplier landscape

- 3.1.2 Profit margin analysis

- 3.1.3 Cost structure

- 3.1.4 Value addition at each stage

- 3.1.5 Factors affecting the value chain

- 3.1.6 Disruptions

- 3.2 Industry impact forces

- 3.2.1 Growth drivers

- 3.2.1.1 Rising demand for automotive customization

- 3.2.1.2 High-volume vehicle production requirements

- 3.2.1.3 Labor cost reduction pressures

- 3.2.1.4 Environmental regulations

- 3.2.1.5 Technological advancements in robotics

- 3.2.1.6 Sustainability initiatives by manufacturers

- 3.2.2 Industry pitfalls and challenges

- 3.2.2.1 High initial investment costs

- 3.2.2.2 Complex maintenance requirements

- 3.2.3 Market opportunities

- 3.2.3.1 Expansion in emerging markets

- 3.2.3.2 Electric vehicle production growth

- 3.2.3.3 Collaborative robotics development

- 3.2.3.4 Integration of AI and IoT

- 3.2.1 Growth drivers

- 3.3 Growth potential analysis

- 3.4 Patent analysis

- 3.5 Porter's analysis

- 3.6 PESTEL analysis

- 3.7 Cost breakdown analysis

- 3.8 Technology landscape

- 3.8.1 Current technological trends

- 3.8.2 Emerging technologies

- 3.9 Regulatory landscape

- 3.9.1 North America

- 3.9.2 Europe

- 3.9.3 Asia Pacific

- 3.9.4 Latin America

- 3.9.5 Middle East and Africa

- 3.10 Price trends

- 3.10.1 By region

- 3.10.2 By robot

- 3.11 Production statistics

- 3.11.1 Production hubs

- 3.11.2 Consumption hubs

- 3.11.3 Export and import

- 3.12 Sustainability and environmental aspects

- 3.12.1 Sustainable practices

- 3.12.2 Waste reduction strategies

- 3.12.3 Energy efficiency in production

- 3.12.4 Eco-friendly initiatives

- 3.13 Carbon footprint considerations

- 3.14 Investment and supply chain analysis

- 3.14.1 Investment and funding trends analysis

- 3.14.2 Supply chain dynamics and raw material impact

- 3.15 Operational excellence, sustainability, and workforce management

- 3.15.1 Quality standards and performance benchmarking

- 3.15.2 Environmental impact and sustainability initiatives

- 3.15.3 Workforce impact and skills requirements analysis

- 3.15.4 Training and development programs assessment

- 3.16 Vendor and risk management

- 3.16.1 Vendor evaluation criteria and selection framework

- 3.16.2 Risk assessment and mitigation strategies

- 3.17 Impact of Automation on Securing High-Specification Contracts

Chapter 4 Competitive Landscape, 2024

- 4.1 Introduction

- 4.2 Company market share analysis

- 4.2.1 North America

- 4.2.2 Europe

- 4.2.3 Asia Pacific

- 4.2.4 Latin America

- 4.2.5 Middle East & Africa

- 4.3 Competitive analysis of major market players

- 4.4 Competitive positioning matrix

- 4.5 Strategic outlook matrix

- 4.6 Key developments

- 4.6.1 Mergers & acquisitions

- 4.6.2 Partnerships & collaborations

- 4.6.3 New mounting launches

- 4.6.4 Expansion plans and funding

Chapter 5 Market Estimates & Forecast, By Robot, 2021 - 2034 (USD Bn, Units)

- 5.1 Key trends

- 5.2 Articulated robots

- 5.3 Cartesian robots

- 5.4 Scara robots

- 5.5 Collaborative robots

Chapter 6 Market Estimates & Forecast, By Mounting, 2021 - 2034 (USD Bn, Units)

- 6.1 Key trends

- 6.2 Floor-mounted robots

- 6.3 Wall-mounted robots

- 6.4 Rail-mounted robots

Chapter 7 Market Estimates & Forecast, By Pay Load, 2021 - 2034 (USD Bn, Units)

- 7.1 Key trends

- 7.2 Up to 5 kg

- 7.3 5 to 10 kg

- 7.4 10 to 20 kg

- 7.5 Above 20 kg

Chapter 8 Market Estimates & Forecast, By Automation Level, 2021 - 2034 (USD Bn, Units)

- 8.1 Key trends

- 8.2 Fully automated

- 8.3 Semi-automated

Chapter 9 Market Estimates & Forecast, By End Use, 2021 - 2034 (USD Bn, Units)

- 9.1 Key trends

- 9.2 OEM paint shops

- 9.3 Tier-1 supplier facilities

- 9.4 Aftermarket and collision repair centers

- 9.5 Specialty vehicle manufacturing

Chapter 10 Market Estimates & Forecast, By Region, 2021 - 2034 (USD Bn, Units)

- 10.1 Key trends

- 10.2 North America

- 10.2.1 US

- 10.2.2 Canada

- 10.3 Europe

- 10.3.1 Germany

- 10.3.2 UK

- 10.3.3 France

- 10.3.4 Italy

- 10.3.5 Spain

- 10.3.6 Nordics

- 10.3.7 Russia

- 10.4 Asia Pacific

- 10.4.1 China

- 10.4.2 India

- 10.4.3 Japan

- 10.4.4 Australia

- 10.4.5 Indonesia

- 10.4.6 Philippines

- 10.4.7 Thailand

- 10.4.8 South Korea

- 10.4.9 Singapore

- 10.5 Latin America

- 10.5.1 Brazil

- 10.5.2 Mexico

- 10.5.3 Argentina

- 10.6 Middle East and Africa

- 10.6.1 Saudi Arabia

- 10.6.2 South Africa

- 10.6.3 UAE

Chapter 11 Company Profiles

- 11.1 Global Players

- 11.1.1 ABB

- 11.1.2 Comau

- 11.1.3 Denso

- 11.1.4 Durr

- 11.1.5 Epson Robots

- 11.1.6 FANUC

- 11.1.7 Kawasaki Heavy Industries

- 11.1.8 KUKA

- 11.1.9 Mitsubishi Electric

- 11.1.10 Nachi-Fujikoshi

- 11.1.11 Omron

- 11.1.12 Panasonic

- 11.1.13 Staubli Robotics

- 11.1.14 Yaskawa Electric

- 11.2 Regional Players

11.2.1. 3 M Company

- 11.2.2 Doosan Robotics

- 11.2.3 Elite Robots

- 11.2.4 Hyundai Robotics

- 11.2.5 Reis Robotics

- 11.2.6 Universal Robots

- 11.3 Emerging Players / Disruptors

- 11.3.1 Franka Emika

- 11.3.2 Precise Automation

- 11.3.3 Rethink Robotics

- 11.3.4 Standard Bots

- 11.3.5 Techman Robot