|

市場調查報告書

商品編碼

1871132

電動車半導體市場機會、成長促進因素、產業趨勢分析及預測(2025-2034年)Electric Vehicle Semiconductors Market Opportunity, Growth Drivers, Industry Trend Analysis, and Forecast 2025 - 2034 |

||||||

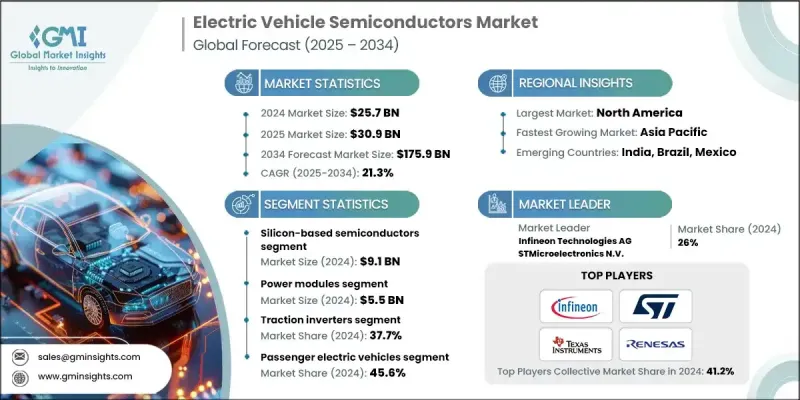

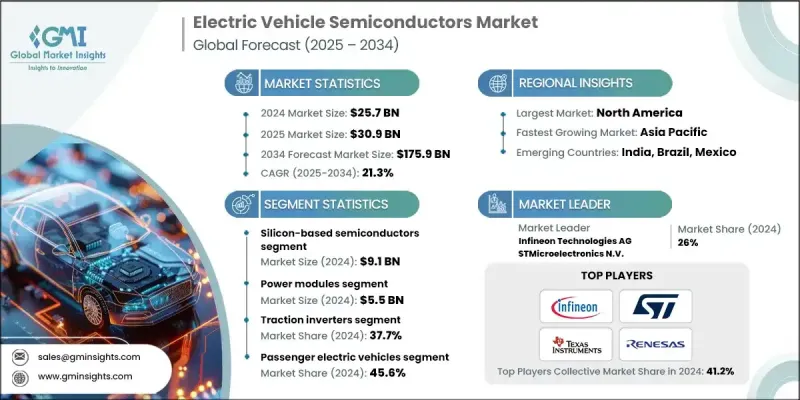

2024 年全球電動車半導體市場價值為 257 億美元,預計到 2034 年將以 21.3% 的複合年成長率成長至 1,759 億美元。

隨著全球向碳中和和降低溫室氣體排放轉型,電動車(EV)的普及推動了市場擴張。世界各國政府和監管機構在實施嚴格排放法規的同時,也推出了激勵措施、退稅和補貼,以促進電動車的使用。消費者越來越傾向於選擇永續的出行方式而非傳統的燃油車,這進一步刺激了市場需求。電動車的快速普及也帶動了對先進半導體的需求,而先進半導體正是電動車的技術支柱。它們能夠實現高效的動力系統控制、能量最佳化、資訊娛樂系統和安全系統。永續發展要求已成為推動電動車生態系統中半導體創新發展的主要動力。整個產業正經歷從傳統矽基半導體向碳化矽(SiC)和氮化鎵(GaN)等新一代材料的重大轉型。這些寬頻隙半導體具有更高的能量效率、更快的開關速度和更優異的熱管理性能,對於電動車的高功率運作至關重要。它們能夠使車輛動力系統更加緊湊、輕巧和高效,從而提升續航里程、充電速度和整體性能。汽車製造商和半導體公司正在迅速整合 SiC 和 GaN 技術來取代傳統材料,從而提高自身的競爭優勢,並滿足不斷變化的全球電動車需求。

| 市場範圍 | |

|---|---|

| 起始年份 | 2024 |

| 預測年份 | 2025-2034 |

| 起始值 | 257億美元 |

| 預測值 | 1759億美元 |

| 複合年成長率 | 21.3% |

2024年,矽基半導體市場規模預計將達91億美元。該市場的強勁表現得益於矽技術的成熟和成本效益,以及完善的全球製造能力。這些半導體裝置性能可靠、可擴展,並與現有汽車系統相容,因此成為量產電動車的首選。隨著電動車產業的規模化發展,它們在電源管理系統和車輛控制單元中的廣泛應用也進一步鞏固了其市場地位。

預計到2024年,功率模組市場規模將達到55億美元。市場對功率模組的需求源自於其能夠將多個功率元件整合到緊湊、高效的封裝中,從而提升能量轉換效率和散熱性能。這項功能對於混合動力和純電動車的動力傳動系統、充電系統和逆變器至關重要。持續致力於提高系統可靠性和降低熱損耗,使得功率模組始終處於電動車半導體創新領域的前沿。

到2034年,美國電動車半導體市場將以21.8%的複合年成長率成長。聯邦和州政府的激勵措施、電動車強制規定以及消費者對電動車日益成長的接受度,都為這一成長提供了強力的支撐。美國本土汽車製造商擴大採用基於碳化矽(SiC)的功率晶片,以提高動力傳動系統的效率、高性能運算能力以及自動駕駛系統的整合度。此外,美國也受惠於《晶片和半導體產業戰略法案》(CHIPS Act)支持的本地半導體生產,從而促進了創新並增強了供應鏈的韌性。汽車製造商、半導體公司和技術供應商之間的合作正在推動電池管理系統、自動駕駛處理器和高性能充電模組等領域的下一代發展,確保電動車生態系統的持續競爭力。

電動車半導體市場的主要參與者包括 Wolfspeed, Inc.、NXP Semiconductors NV、STMicroelectronics NV、Texas Instruments Inc.、Infineon Technologies AG、Microchip Technology Inc.、Analog Devices, Inc.、Renesas Electronics Corporation、ON Semchip Technology Inc.、Analog Devices, Inc.、Renesas Electronics Corporation、ON Semiconductor 電話公司Co., Ltd.、Toshiba Electronic Devices & Storage、Allegro MicroSystems, Inc.、ams OSRAM AG、StarPower Semiconductor Ltd.、Samsung Semiconductor, Inc.、Sanken Electric Co., Ltd. 與 BYD Semiconductor Co., Ltd.。這些電動車半導體市場的領導者正在實施策略性舉措,以增強其競爭優勢並擴大其技術影響力。他們正在加大研發投入,以加速碳化矽 (SiC) 和氮化鎵 (GaN) 等寬禁帶材料的研發,從而實現更高的性能和能源效率。各公司正與汽車原始設備製造商 (OEM) 建立長期供應合作夥伴關係,以確保半導體技術能夠整合到新型電動車平台中。在政府政策的支持下,製造業在地化正在增強供應穩定性並提升成本競爭力。

目錄

第1章:方法論與範圍

第2章:執行概要

第3章:行業洞察

- 產業生態系分析

- 供應商格局

- 利潤率

- 成本結構

- 每個階段的價值增加

- 影響價值鏈的因素

- 中斷

- 產業影響因素

- 成長促進因素

- 全球永續發展目標推動電動車快速普及

- 電力電子技術的進步(SiC 和 GaN 技術)

- 政府對電氣化的激勵措施和監管要求

- 自動駕駛和連網電動車的需求日益成長

- 擴大電動車充電基礎設施

- 產業陷阱與挑戰

- 先進半導體的高製造成本與研發成本

- 全球供應鏈受限及晶片短缺

- 成長促進因素

- 成長潛力分析

- 監管環境

- 北美洲

- 歐洲

- 亞太地區

- 拉丁美洲

- 中東和非洲

- 波特的分析

- PESTEL 分析

- 技術與創新格局

- 當前技術趨勢

- 新興技術

- 價格趨勢

- 歷史價格分析(2021-2024)

- 價格趨勢促進因素

- 區域價格差異

- 價格預測(2025-2034)

- 定價策略

- 新興商業模式

- 合規要求

- 永續性措施

- 永續材料評估

- 碳足跡分析

- 循環經濟實施

- 永續性認證和標準

- 永續性投資報酬率分析

- 全球消費者情緒分析

- 專利分析

第4章:競爭格局

- 介紹

- 公司市佔率分析

- 按地區

- 北美洲

- 歐洲

- 亞太地區

- 拉丁美洲

- 中東和非洲

- 市場集中度分析

- 按地區

- 對主要參與者進行競爭基準分析

- 財務績效比較

- 收入

- 利潤率

- 研發

- 產品組合比較

- 產品範圍廣度

- 科技

- 創新

- 地理位置比較

- 全球足跡分析

- 服務網路覆蓋

- 按地區分類的市場滲透率

- 競爭定位矩陣

- 領導人

- 挑戰者

- 追蹤者

- 小眾玩家

- 戰略展望矩陣

- 財務績效比較

- 2021-2024 年主要發展動態

- 併購

- 夥伴關係與合作

- 技術進步

- 擴張和投資策略

- 永續發展舉措

- 數位轉型計劃

- 新興/新創企業競爭對手格局

第5章:市場估算與預測:依技術類型分類,2021-2034年

- 主要趨勢

- 矽基半導體

- 碳化矽(SiC)半導體

- 氮化鎵(GaN)半導體

- 超寬頻隙半導體

第6章:市場估算與預測:依產品類型分類,2021-2034年

- 主要趨勢

- 電源模組

- 分離式功率元件

- 電源管理積體電路

- 微控制器和處理器

- 感測器積體電路

- 閘極驅動器積體電路

- 通訊與介面積體電路

- 記憶體和儲存積體電路

- 其他

第7章:市場估計與預測:依應用領域分類,2021-2034年

- 主要趨勢

- 牽引逆變器

- 車用充電器(OBC)

- 直流-直流轉換器

- 無線電力傳輸

- 超快速充電系統

- 其他

第8章:市場估算與預測:依最終用途分類,2021-2034年

- 主要趨勢

- 乘用電動車

- 商用電動車

- 專用電動車

- 電動車充電基礎設施

- 其他

第9章:市場估計與預測:依地區分類,2021-2034年

- 主要趨勢

- 北美洲

- 美國

- 加拿大

- 歐洲

- 德國

- 英國

- 法國

- 西班牙

- 義大利

- 荷蘭

- 亞太地區

- 中國

- 印度

- 日本

- 澳洲

- 韓國

- 拉丁美洲

- 巴西

- 墨西哥

- 阿根廷

- 中東和非洲

- 沙烏地阿拉伯

- 南非

- 阿拉伯聯合大公國

第10章:公司簡介

- Allegro MicroSystems, Inc.

- Alpha and Omega Semiconductor Ltd.

- ams OSRAM AG

- Analog Devices, Inc.

- BYD Semiconductor Co., Ltd.

- Diodes Incorporated

- Infineon Technologies AG

- IXYS Corporation

- Melexis NV

- Microchip Technology Inc.

- Monolithic Power Systems, Inc.

- NXP Semiconductors NV

- ON Semiconductor Corporation

- Power Integrations, Inc.

- Powerex, Inc.

- Qorvo, Inc.

- Renesas Electronics Corporation

- ROHM Co., Ltd.

- Samsung Semiconductor, Inc.

- Sanken Electric Co., Ltd.

- StarPower Semiconductor Ltd.

- STMicroelectronics NV

- Texas Instruments Inc.

- Toshiba Electronic Devices & Storage

- Wolfspeed, Inc.

The Global Electric Vehicle Semiconductors Market was valued at USD 25.7 Billion in 2024 and is estimated to grow at a CAGR of 21.3% to reach USD 175.9 Billion by 2034.

The market is expanding as the global shift toward carbon neutrality and lower greenhouse gas emissions drives widespread adoption of electric vehicles (EVs). Governments and regulatory authorities worldwide are enforcing strict emission regulations while introducing incentives, rebates, and subsidies to promote EV usage. Consumers increasingly prefer sustainable mobility alternatives over traditional combustion vehicles, further boosting demand. This surge in EV adoption has led to an accelerated requirement for advanced semiconductors, which serve as the technological backbone of electric vehicles. They enable efficient powertrain control, energy optimization, infotainment, and safety systems. Sustainability mandates have become a primary force shaping semiconductor innovation within the EV ecosystem. The industry is undergoing a major transition from conventional silicon-based semiconductors to next-generation materials such as silicon carbide (SiC) and gallium nitride (GaN). These wide-bandgap semiconductors provide superior energy efficiency, faster switching, and improved thermal management, essential for handling high-power operations in EVs. Their ability to make vehicle power systems more compact, lightweight, and efficient enhances range, charging speed, and overall performance. Automakers and semiconductor companies are rapidly integrating SiC and GaN technologies to replace legacy materials, increasing their competitive advantage and addressing the evolving global EV demand.

| Market Scope | |

|---|---|

| Start Year | 2024 |

| Forecast Year | 2025-2034 |

| Start Value | $25.7 Billion |

| Forecast Value | $175.9 Billion |

| CAGR | 21.3% |

The silicon-based semiconductors segment generated USD 9.1 Billion in 2024. The strong position of this segment is attributed to the maturity and cost-efficiency of silicon technology, supported by established global manufacturing capabilities. These semiconductors deliver reliable performance, scalability, and compatibility with current automotive systems, making them the preferred option for mass-produced EV models. Their extensive use in power management systems and vehicle control units continues to strengthen their market relevance as the EV industry scales.

The power modules segment generated USD 5.5 Billion in 2024. The demand for power modules stems from their ability to consolidate multiple power devices into compact, high-efficiency packages that enhance energy conversion and thermal regulation. This functionality is vital for powering electric drivetrains, charging systems, and inverters in both hybrid and fully electric vehicles. The continuous focus on achieving higher system reliability and reducing thermal losses keeps power modules at the forefront of EV semiconductor innovation.

U.S. Electric Vehicle Semiconductors Market will grow at a CAGR of 21.8% by 2034. Growth is strongly supported by federal and state-level incentives, EV mandates, and growing consumer adoption. Domestic automakers increasingly incorporate SiC-based power chips to enhance drivetrain efficiency, performance computing, and autonomous driving integration. The U.S. also benefits from local semiconductor production supported by the CHIPS Act, fostering innovation and supply chain resilience. Collaboration among automakers, semiconductor firms, and technology providers is driving next-generation developments in battery management systems, autonomous processors, and high-performance charging modules, ensuring sustained competitiveness within the EV ecosystem.

Key players active in the Electric Vehicle Semiconductors Market include Wolfspeed, Inc., NXP Semiconductors N.V., STMicroelectronics N.V., Texas Instruments Inc., Infineon Technologies AG, Microchip Technology Inc., Analog Devices, Inc., Renesas Electronics Corporation, ON Semiconductor Corporation, Power Integrations, Inc., Melexis N.V., Monolithic Power Systems, Inc., ROHM Co., Ltd., Toshiba Electronic Devices & Storage, Allegro MicroSystems, Inc., ams OSRAM AG, StarPower Semiconductor Ltd., Samsung Semiconductor, Inc., Sanken Electric Co., Ltd., and BYD Semiconductor Co., Ltd. Leading companies in the Electric Vehicle Semiconductors Market are implementing strategic initiatives to reinforce their competitive edge and expand their technological footprint. They are increasing R&D investment to accelerate advancements in wide-bandgap materials like SiC and GaN, targeting higher performance and energy efficiency. Firms are entering long-term supply partnerships with automotive OEMs to secure semiconductor integration across new EV platforms. Localization of manufacturing, supported by government policies, is enhancing supply stability and cost competitiveness.

Table of Contents

Chapter 1 Methodology and Scope

- 1.1 Market scope and definition

- 1.2 Research design

- 1.2.1 Research approach

- 1.2.2 Data collection methods

- 1.3 Data mining sources

- 1.3.1 Global

- 1.3.2 Regional/Country

- 1.4 Base estimates and calculations

- 1.4.1 Base year calculation

- 1.4.2 Key trends for market estimation

- 1.5 Primary research and validation

- 1.5.1 Primary sources

- 1.6 Forecast model

- 1.7 Research assumptions and limitations

Chapter 2 Executive Summary

- 2.1 Industry snapshot

- 2.2 Key market trends

- 2.2.1 Packaging type trends

- 2.2.2 Material trends

- 2.2.3 Application trends

- 2.2.4 Regional

- 2.3 TAM Analysis, 2025-2034 (USD Billion)

- 2.4 CXO perspectives: Strategic imperatives

- 2.4.1 Executive decision points

- 2.4.2 critical success factors

- 2.5 Future outlook and strategic recommendations

Chapter 3 Industry Insights

- 3.1 Industry ecosystem analysis

- 3.1.1 Supplier Landscape

- 3.1.2 Profit Margin

- 3.1.3 Cost structure

- 3.1.4 Value addition at each stage

- 3.1.5 Factor affecting the value chain

- 3.1.6 Disruptions

- 3.2 Industry impact forces

- 3.2.1 Growth drivers

- 3.2.1.1 Rapid EV adoption driven by global sustainability goals

- 3.2.1.2 Advancements in power electronics (SiC & GaN technologies)

- 3.2.1.3 Government incentives and regulatory mandates for electrification

- 3.2.1.4 Growing demand for autonomous and connected EVs

- 3.2.1.5 Expansion of EV charging infrastructure

- 3.2.2 Industry pitfalls and challenges

- 3.2.2.1 High manufacturing and R&D costs of advanced semiconductors

- 3.2.2.2 Global supply chain constraints & chip shortages

- 3.2.1 Growth drivers

- 3.3 Growth potential analysis

- 3.4 Regulatory landscape

- 3.4.1 North America

- 3.4.2 Europe

- 3.4.3 Asia Pacific

- 3.4.4 Latin America

- 3.4.5 Middle East & Africa

- 3.5 Porter's analysis

- 3.6 PESTEL analysis

- 3.7 Technology and innovation landscape

- 3.7.1 Current technological trends

- 3.7.2 Emerging technologies

- 3.8 Price trends

- 3.8.1 Historical price analysis (2021-2024)

- 3.8.2 Price trend drivers

- 3.8.3 Regional price variations

- 3.8.4 Price forecast (2025-2034)

- 3.9 Pricing strategies

- 3.10 Emerging business models

- 3.11 Compliance requirements

- 3.12 Sustainability measures

- 3.12.1 Sustainable materials assessment

- 3.12.2 Carbon footprint analysis

- 3.12.3 Circular economy implementation

- 3.12.4 Sustainability certifications and standards

- 3.12.5 Sustainability ROI analysis

- 3.13 Global consumer sentiment analysis

- 3.14 Patent analysis

Chapter 4 Competitive Landscape, 2024

- 4.1 Introduction

- 4.2 Company market share analysis

- 4.2.1 By region

- 4.2.1.1 North America

- 4.2.1.2 Europe

- 4.2.1.3 Asia Pacific

- 4.2.1.4 Latin America

- 4.2.1.5 Middle East & Africa

- 4.2.2 Market Concentration Analysis

- 4.2.1 By region

- 4.3 Competitive benchmarking of key players

- 4.3.1 Financial performance comparison

- 4.3.1.1 Revenue

- 4.3.1.2 Profit margin

- 4.3.1.3 R&D

- 4.3.2 Product portfolio comparison

- 4.3.2.1 Product range breadth

- 4.3.2.2 Technology

- 4.3.2.3 Innovation

- 4.3.3 Geographic presence comparison

- 4.3.3.1 Global footprint analysis

- 4.3.3.2 Service network coverage

- 4.3.3.3 Market penetration by region

- 4.3.4 Competitive positioning matrix

- 4.3.4.1 Leaders

- 4.3.4.2 Challengers

- 4.3.4.3 Followers

- 4.3.4.4 Niche players

- 4.3.5 Strategic outlook matrix

- 4.3.1 Financial performance comparison

- 4.4 Key developments, 2021-2024

- 4.4.1 Mergers and acquisitions

- 4.4.2 Partnerships and collaborations

- 4.4.3 Technological advancements

- 4.4.4 Expansion and investment strategies

- 4.4.5 Sustainability initiatives

- 4.4.6 Digital transformation initiatives

- 4.5 Emerging/ startup competitors landscape

Chapter 5 Market Estimates and Forecast, By Technology Type, 2021 - 2034 (USD Million)

- 5.1 Key trends

- 5.2 Silicon-based semiconductors

- 5.3 Silicon Carbide (SiC) semiconductors

- 5.4 Gallium Nitride (GaN) semiconductors

- 5.5 Ultra-wide bandgap semiconductors

Chapter 6 Market Estimates and Forecast, By Product Type, 2021 - 2034 (USD Million)

- 6.1 Key trends

- 6.2 Power modules

- 6.3 Discrete power devices

- 6.4 Power management ICs

- 6.5 Microcontrollers & processors

- 6.6 Sensor ICs

- 6.7 Gate driver ICs

- 6.8 Communication & interface ICs

- 6.9 Memory & storage ICs

- 6.10 Others

Chapter 7 Market Estimates and Forecast, By Application, 2021 - 2034 (USD Million)

- 7.1 Key trends

- 7.2 Traction inverters

- 7.3 Onboard Chargers (OBC)

- 7.4 DC-DC converters

- 7.5 Wireless power transfer

- 7.6 Ultra-fast charging systems

- 7.7 Others

Chapter 8 Market Estimates and Forecast, By End Use, 2021 - 2034 (USD Million)

- 8.1 Key trends

- 8.2 Passenger electric vehicles

- 8.3 Commercial electric vehicles

- 8.4 Specialized electric vehicles

- 8.5 EV charging infrastructure

- 8.6 Others

Chapter 9 Market Estimates and Forecast, By Region, 2021 - 2034 (USD Million)

- 9.1 Key trends

- 9.2 North America

- 9.2.1 U.S.

- 9.2.2 Canada

- 9.3 Europe

- 9.3.1 Germany

- 9.3.2 UK

- 9.3.3 France

- 9.3.4 Spain

- 9.3.5 Italy

- 9.3.6 Netherlands

- 9.4 Asia Pacific

- 9.4.1 China

- 9.4.2 India

- 9.4.3 Japan

- 9.4.4 Australia

- 9.4.5 South Korea

- 9.5 Latin America

- 9.5.1 Brazil

- 9.5.2 Mexico

- 9.5.3 Argentina

- 9.6 Middle East and Africa

- 9.6.1 Saudi Arabia

- 9.6.2 South Africa

- 9.6.3 UAE

Chapter 10 Company Profiles

- 10.1 Allegro MicroSystems, Inc.

- 10.2 Alpha and Omega Semiconductor Ltd.

- 10.3 ams OSRAM AG

- 10.4 Analog Devices, Inc.

- 10.5 BYD Semiconductor Co., Ltd.

- 10.6 Diodes Incorporated

- 10.7 Infineon Technologies AG

- 10.8 IXYS Corporation

- 10.9 Melexis N.V.

- 10.10 Microchip Technology Inc.

- 10.11 Monolithic Power Systems, Inc.

- 10.12 NXP Semiconductors N.V.

- 10.13 ON Semiconductor Corporation

- 10.14 Power Integrations, Inc.

- 10.15 Powerex, Inc.

- 10.16 Qorvo, Inc.

- 10.17 Renesas Electronics Corporation

- 10.18 ROHM Co., Ltd.

- 10.19 Samsung Semiconductor, Inc.

- 10.20 Sanken Electric Co., Ltd.

- 10.21 StarPower Semiconductor Ltd.

- 10.22 STMicroelectronics N.V.

- 10.23 Texas Instruments Inc.

- 10.24 Toshiba Electronic Devices & Storage

- 10.25 Wolfspeed, Inc.