|

市場調查報告書

商品編碼

1873710

工業自動化趨勢:中美半導體5.0之爭Industrial Automation Trends: China-US Competition in Semiconductor Industry 5.0 |

|||||||

美國半導體製造回流政策促使供應商加強在美投資,加速工廠建設。美國市場勞動成本上升和技術人才短缺,促使供應商專注於為半導體生產引入自動化解決方案。人工智慧和數位孿生技術有助於提高生產效率和良率,並被視為智慧製造的核心技術。此外,隨著智慧物流設備的覆蓋範圍和部署靈活性不斷提升,預計獨立工廠將演變為多個工廠互聯的生態系統。台灣供應商如德科曼(Techman)和肯邁克(Kenmec)正積極運用其技術實力和系統整合經驗,掌握美國半導體自動化市場的機會。

樣品預覽

主要亮點:

- 美國半導體退貨政策鼓勵供應商在美國投資和擴張。

- 勞動成本上升和勞動力短缺促使自動化解決方案成為主流。

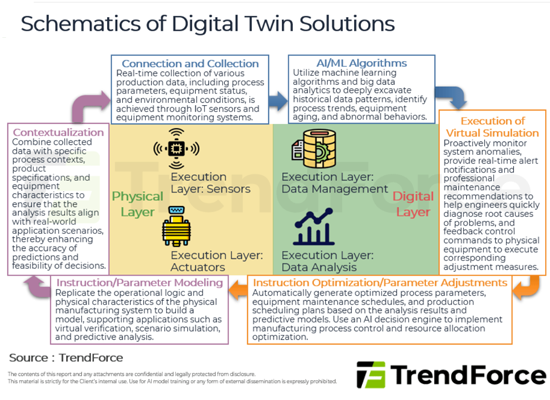

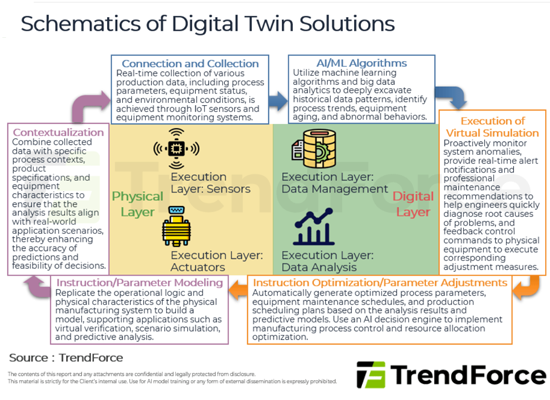

- 人工智慧和數位孿生技術是智慧製造的核心,可提高效率和良率。

- 先進的智慧物流將促進多個設施互聯互通的生態系統的發展。

- 台灣供應商正利用其技術和整合能力積極開拓美國市場。

目錄

第一章:中美智慧半導體製造的發展

第二章:在半導體製造中應用人工智慧和數位孿生技術以提高生產效率和良率

第三章:在半導體工廠發展 "工業5.0" :用於增強人機互動、韌性和永續性的自動化解決方案

第四章:TRI的視角

The repatriation policy of the US semiconductor manufacturing is spurring suppliers to increase investment in the US and accelerate plans for plant establishment. Due to the high labor costs and scarcity of technical talent in the US market, suppliers are striving to introduce solutions of automated semiconductor production. AI and digital twin technology are becoming the core of smart manufacturing by benefiting production efficiency and yield improvement. Moreover, with the upgrade in coverage rate and deployment flexibility of smart logistics equipment, it is expected to develop from single equipment to a multi-equipment collaborative ecosystem. Taiwanese suppliers such as Techman and KENMEC are actively seizing opportunities in the US semiconductor automation market through their technological prowess and system integration experience.

Sample preview

Key Highlights:

- The US semiconductor repatriation policy drives suppliers to invest and expand their presence in the US.

- High labor costs and talent shortages make automation solutions mainstream.

- AI and digital twin technologies become the core of smart manufacturing, enhancing efficiency and yield.

- Upgrades in smart logistics enable development toward a multi-equipment collaborative ecosystem.

- Taiwanese suppliers leverage technological and integration strengths to actively explore the US market.

Table of Contents

1. Development of Smart Semiconductor Production between China and the US

2. AI and Digital Twin Incorporated to Semiconductor Production for Improvement of Production Efficiency and Yield

- Figure 1: Schematics of Digital Twin Solutions

- Table 1: Development Progress of Smart Production Solutions

3. Development of "Industry 5.0" at Semiconductor Fabs: Automated Solutions for Enhanced Human-Machine Interaction, Resilience, and Sustainability

- Table 2: Overview of Automated Products and Services from Taiwan-Based Companies for Semiconductor Manufacturing