|

市場調查報告書

商品編碼

1934714

立式袋:市場佔有率分析、產業趨勢與統計、成長預測(2026-2031)Stand-Up Pouches - Market Share Analysis, Industry Trends & Statistics, Growth Forecasts (2026 - 2031) |

||||||

※ 本網頁內容可能與最新版本有所差異。詳細情況請與我們聯繫。

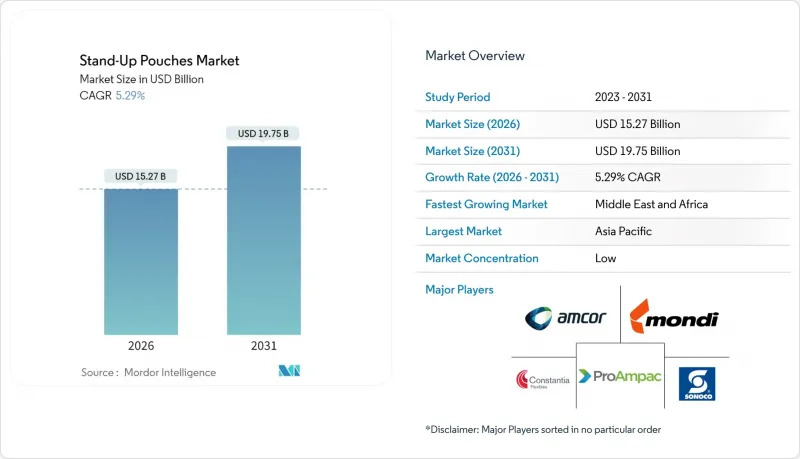

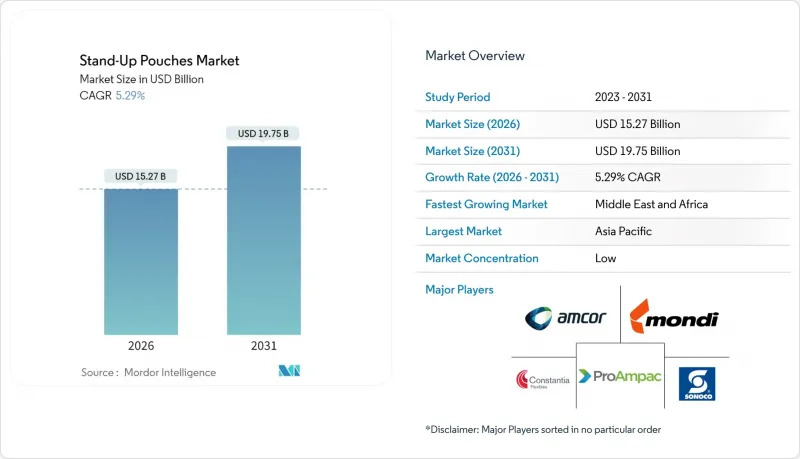

預計到 2026 年,立式袋市場價值將達到 152.7 億美元,高於 2025 年的 145 億美元。

預計到 2031 年,該產業規模將達到 197.5 億美元,2026 年至 2031 年的複合年成長率為 5.29%。

對輕巧、可重複密封且外觀精美的包裝的需求不斷成長,推動了這一成長勢頭。歐洲的監管改革、東亞機能飲料的創新以及北美寵物食品品牌從硬質包裝轉向軟包裝,都在加速這一趨勢的普及。早期採用單一材料、可回收包裝形式,為製造商帶來了成本和聲譽優勢;同時,熱填充和高溫蒸餾性能的提升,也為食品、飲料和家居用品等品類開闢了新的終端應用前景。亞太地區的生產規模擴大、拉丁美洲的技術升級,以及以安姆科、蒙迪和索諾科主導的積極併購活動,正在重塑競爭格局,協助企業追求效率和循環經濟。

全球立式袋市場趨勢與洞察

歐盟快速過渡到單一材料可回收包裝袋結構

將於2025年2月生效的歐盟包裝和包裝廢棄物法規要求所有消費品包裝到2030年必須可回收,且塑膠包裝必須至少含有30%的再生塑膠。製造商正迅速從多層鋁箔結構過渡到單層聚乙烯薄膜,後者與家庭回收系統相容。 Amco公司的Liquiflex Amprima包裝袋符合這些標準,據報道,與傳統複合材料相比,可減少79%的碳排放和84%的用水量。率先採用者將受益於更低的生產者延伸責任(EPR)成本和更高的貨架吸引力,而落後者則面臨更高的研發成本和貨架空間損失的風險。隨著加工商獲得新的密封技術許可,並在不影響阻隔性能的前提下實現更薄的薄膜厚度,這種轉變將增強傾倒式包裝袋市場。

東亞地區攜帶式機能飲料的蓬勃發展推動了熱填充裝袋的發展。

東亞消費者正逐漸接受攜帶式分裝蛋白奶昔、維生素凝膠和代餐飲料。耐熱溫度超過85°C的產品使加工商能夠省去防腐劑,延長保存期限,並提供營養豐富的配方。森永株式會社(Morinaga & Co.)的五年保存期限「果凍 Energy Long Life」軟包裝在日本的防災用品貨架上備受矚目,展現了其卓越的阻隔性和蒸餾性能。一家韓國Start-Ups瞄準千禧世代女性,推出單份包裝的蛋白粉,銷量較去年同期成長三倍。這些創新產品正在推動東南亞各地便利商店和高階健身房的普及,為立式袋市場開闢了新的需求。

美國多層複合材料的回收途徑有限

在美國,需要360億至430億美元的基礎建設投資才能在2030年前將塑膠回收再利用提高到61%。品牌商對擴大多層包裝袋的使用持謹慎態度,直到材料回收設施能夠識別和分離柔軟性材料。因此,製造商正在加速開發單一材料,但轉型成本和對現有設施的風險暫時減緩了立式袋市場的成長。

細分市場分析

截至2025年,塑膠材質的立式袋佔比高達71.17%,這主要得益於加工商優先考慮聚乙烯的密封性、聚丙烯的耐熱性和PET的透明度。受法規和消費者需求的推動,預計到2031年,可生物分解包裝袋的複合年成長率將達到6.78%,但小批量SKU的支持仍面臨挑戰。 Acredo Packaging公司生產的甘蔗基包裝袋,每單位可減少43克二氧化碳排放,並可在現有設備上進行加工。

同時,Amco公司的AmFiber紙基阻隔複合材料瞄準了尋求無鋁保存期限的零食生產商。特種EVOH阻隔層和尼龍紮帶層持續保護對氧氣敏感的填充物,但成本上升正促使這些產品重新定位,轉向更高價值的營養保健產品線。預計到2029年,可生物分解級立式袋市場規模將超過10.8億美元,但塑膠仍是食品飲料產業的主導材料。不斷完善的回收設計指南正在推動快速的實驗,使塑膠既成為立式袋市場中一項成熟的技術,也成為創新的平台。

到2025年,圓底包裝袋將佔據38.11%的收入佔有率,這主要得益於成熟的成型設備和廣泛的應用。同時,由於底部穩定性較佳,方底包裝袋無需二次包裝即可支援更大的填充量,預計其複合年成長率將達到5.52%。 K型密封和Delta密封規格因其防篡改特性而受到製藥填充商的青睞。餐飲服務採購商則傾向於選擇2公升和5公升的角底包裝袋來盛裝醬料和調味品,他們認為這種包裝袋能夠提高托盤利用率,並且與高密度聚乙烯(HDPE)瓶相比,排放可減少79%。

然而,技術挑戰依然存在,例如容量超過1公升的產品在蒸餾過程中如何控制頂部空間,以及歐洲湯品生產線對自立袋的接受度較低。透過持續研發側邊折疊形狀和瓶蓋排氣孔,我們旨在最大限度地減少壓力差,並有望擴大我們在立式袋市場的佔有率。

區域分析

亞太地區預計在2025年佔據立式袋市場的領頭羊。這主要得益於中國的大規模加工廠、日本的熱填充技術發展以及韓國的優質化策略。聚乙烯供應過剩,預計2025年將新增500萬噸產能,將對薄膜價格構成壓力,使加工商在原料採購方面獲得優勢,但也擠壓了利潤空間。安姆科收購古吉拉突邦的Phoenix Flexibles公司,進一步拓展了其在印度價值2000萬美元的醫療包裝市場的業務,並加速了當地的生產。

在北美,完善的食品加工基礎設施和以寵物為中心的消費文化維持了穩定的需求。然而,基礎設施缺口龐大,到2030年需要400億美元用於材料回收設施的現代化。即將實施的25%樹脂關稅加劇了成本壓力,但也鼓勵了本地樹脂投資和再生樹脂試點計畫。加之加州2026年強制實施的再生材料含量要求,這些政策正推動立式袋市場轉型為單聚聚乙烯(PE)蒸餾形式。

歐洲在監管方面處於領先地位,強制要求立式袋市場採用可回收設計。安姆科 (Amcor)、蒙迪 (Mondi) 和比肖夫+克萊因 (Bischoff + Klein) 等領先企業已成功將符合 30% PCR 標準的 PP 和 PE 單層壁包裝袋商業化,與 PET/鋁/OPE 三層層級構造相比,可減少 79% 的二氧化碳排放。北歐國家的補充裝計劃表明,當低碳包裝與方便的線上購物相結合時,消費者接受度可以迅速提高。

拉丁美洲正在崛起為產能熱點。巴西食品產業成長了7.2%,百事公司投資2.4億美元的擴建計畫將於2025年運作三台八通道袋裝填充機。墨西哥和哥倫比亞已延長了循環包裝投資的稅額扣抵,以吸引跨國加工企業,並根據《美墨加協定》(USMCA)的規定開闢對美國的出口管道。

中東和非洲地區預計將以8.39%的複合年成長率實現最快成長,這主要得益於無菌奶粉、風味水和果汁等無鋁包裝產品的成長。 SIG在肯亞推出Prime 55以及利樂在奈及利亞的促銷宣傳活動降低了市場進入門檻。節能滅菌技術和價格合理的配件被認為是推動該地區立式袋市場成長的關鍵成功因素。

其他福利:

- Excel格式的市場預測(ME)表

- 3個月的分析師支持

目錄

第1章 引言

- 研究假設和市場定義

- 調查範圍

第2章調查方法

第3章執行摘要

第4章 市場情勢

- 市場概覽

- 市場促進因素

- 歐盟快速過渡到單一材料可回收包裝袋結構

- 東亞地區即機能飲料的蓬勃發展正在推動對熱填充吸嘴袋的需求。

- 北美寵物濕食品包裝從金屬罐過渡到殺菌袋

- 非洲無菌乳製品分銷的擴大推動了無鋁包裝袋的發展

- 北歐美妝電商引領易傾倒型填充用裝產品SKU擴張

- 巴西對軟包裝填充生產線的投資激增,加速了包裝從硬質轉向軟質的轉變。

- 市場限制

- 美國對多層複合材料回收途徑的限制

- EVOH和尼龍樹脂價格波動給亞太地區加工商帶來壓力

- 品牌所有者對再生材料轉型的擔憂

- 歐洲產1公升以上湯包裝在蒸餾滅菌過程中存在頂部空間不足的問題。

- 產業供應鏈分析

- 監理展望

- 技術展望

- 波特五力分析

- 新進入者的威脅

- 買方的議價能力

- 供應商的議價能力

- 替代品的威脅

- 競爭對手之間的競爭

- 地緣政治情境的影響評估

第5章 市場規模與成長預測

- 依材料類型

- 塑膠

- 聚對苯二甲酸乙二醇酯(PET)

- 聚乙烯(PE)

- 聚丙烯(PP)

- 乙烯 - 乙烯醇共聚物(EVOH)

- 其他塑膠

- 紙

- 金屬箔

- 可生物分解和可堆肥材料

- 塑膠

- 依產品類型

- 圓底/圓底

- K-Seal

- 犁/角底

- 其他產品類型

- 透過使用

- 食物

- 烘焙點心

- 零嘴零食

- 寵物食品

- 糖果甜點

- 其他食物

- 飲料

- 個人護理和化妝品

- 醫療和藥品

- 寵物護理

- 其他應用

- 食物

- 透過分銷管道

- 直銷

- 間接銷售

- 按地區

- 北美洲

- 美國

- 加拿大

- 墨西哥

- 歐洲

- 德國

- 英國

- 法國

- 義大利

- 西班牙

- 俄羅斯

- 其他歐洲地區

- 亞太地區

- 中國

- 印度

- 日本

- 韓國

- 澳洲和紐西蘭

- 亞太其他地區

- 中東和非洲

- 中東

- 阿拉伯聯合大公國

- 沙烏地阿拉伯

- 土耳其

- 其他中東地區

- 非洲

- 南非

- 奈及利亞

- 埃及

- 其他非洲地區

- 中東

- 南美洲

- 巴西

- 阿根廷

- 其他南美洲

- 北美洲

第6章 競爭情勢

- 市場集中度

- 策略趨勢

- 市佔率分析

- 公司簡介

- Amcor Plc

- Mondi plc

- Sonoco Products Company

- Constantia Flexibles GmbH

- ProAmpac LLC

- Smurfit WestRock

- Swiss Pac USA

- Winpak Ltd

- Uflex Limited

- Glenroy Inc.

- Flair Flexible Packaging Corp.

- Sealed Air Corp.

- Huhtamaki Oyj

- Bischof+Klein SE

- Interflex Group

- DoyPak Solutions

- Clondalkin Group

第7章 市場機會與未來展望

Stand-up pouches market size in 2026 is estimated at USD 15.27 billion, growing from 2025 value of USD 14.5 billion with 2031 projections showing USD 19.75 billion, growing at 5.29% CAGR over 2026-2031.

Rising demand for lightweight, resealable, and visually engaging packaging underpins this growth momentum. Regulatory reforms in Europe, functional-beverage innovation in East Asia, and a shift from rigid to flexible packaging among North American pet food brands are accelerating volume adoption. Early moves toward mono-material, recyclable formats provide manufacturers with cost and reputation advantages, while improvements in hot-fill and retort performance broaden end-use possibilities across the food, beverage, and household categories. Production scale in Asia-Pacific, technology upgrades in Latin America, and a vibrant M&A pipeline led by Amcor, Mondi, and Sonoco are redefining competitive boundaries as companies chase efficiency and circularity.

Global Stand-Up Pouches Market Trends and Insights

Rapid Shift to Mono-Material Recyclable Pouch Structures in EU

The European Union Packaging and Packaging Waste Regulation, effective as of February 2025, requires all consumer packs to be recyclable by 2030 and to contain at least 30% post-consumer recycled content for plastics. Producers are rapidly transitioning from multi-layer aluminum structures to mono-material polyethylene films, which remain compatible with curbside recycling streams. Amcor's Liquiflex AmPrima pouch meets these criteria and reports a 79% reduction in carbon emissions, alongside an 84% decrease in water use compared to legacy laminates. Brand owners who adopt early see lower extended producer responsibility fees and improved shelf-appeal messaging, while late movers face R&D cost spikes and possible loss of shelf space. The pivot strengthens the spouted pouches market as converters license new sealing technologies and downgauge films without compromising barrier integrity.

On-the-Go Functional Beverage Boom in East Asia Spurring Hot-Fill Pouches

East-Asian consumers are embracing protein shakes, vitamin gels, and meal-replacement drinks in portable portions. Hot-fill tolerance beyond 85 °C allows processors to skip preservatives, extend ambient shelf life, and deliver nutrient-dense formulas. Japan's disaster-preparedness aisle now features Morinaga Seika's five-year "in Jelly Energy Long Life" pouch, validating extreme barrier and retort performance expectations. Start-ups in South Korea triple their year-over-year sales by marketing single-serve spouts for protein mixes targeting female millennials. These breakthroughs inspire adoption in Southeast-Asian convenience stores and premium gyms, giving the stand-up pouches market fresh volume pipelines.

Limited Recycling Streams for Multi-Layer Laminates in United States

The U.S. requires USD 36-43 billion in infrastructure upgrades to lift plastics recycling rates to 61% by 2030. Until material recovery facilities can recognize and separate flexible laminates, brand owners hesitate to scale multilayer pouches. Producers are therefore accelerating the development of mono-materials, but transition costs and legacy equipment risks temporarily slow the growth of the stand-up pouches market.

Other drivers and restraints analyzed in the detailed report include:

- Migration from Metal Cans to Retort Pouches for Wet Pet Food in North America

- Growth of Aseptic Dairy Distribution in Africa Favoring Aluminum-Free Pouches

- Volatile EVOH & Nylon Resin Prices Squeezing APAC Converters

For complete list of drivers and restraints, kindly check the Table Of Contents.

Segment Analysis

Plastic structures controlled 71.17% of the stand-up pouches market in 2025 as processors valued polyethylene's sealability, polypropylene's heat stability, and PET's clarity. Biodegradable options are projected to record a 6.78% CAGR through 2031, driven by regulatory and consumer demand, while still addressing small-run SKUs. Accredo Packaging's sugarcane-derived resin pouch offsets 43 grams of CO2 per unit while offering drop-in machinability.

Meanwhile, Amcor's AmFiber paper-based barrier laminate targets snack producers searching for aluminum-free shelf life. Specialty EVOH barriers and nylon tie layers continue to protect oxygen-sensitive fillings, but cost spikes reposition them toward high-value nutraceutical lines. The stand-up pouches market size for biodegradable grades is projected to cross USD 1.08 billion by 2029, yet plastics will still anchor core food and beverage volumes. Evolving design-for-recycle guidelines stimulate rapid experimentation, positioning plastics as both incumbent and innovation canvas in the stand-up pouches market.

Round-bottom (Doyen) pouches accounted for a 38.11% revenue share in 2025, thanks to their mature forming equipment and broad application adoption. Corner-bottom designs, however, exhibit a 5.52% CAGR growth due to improved base stability, which supports larger fill volumes without requiring secondary cartons. K-Seal and Delta-Seal variants appeal to pharmaceutical fillers requiring tamper-evident integrity. Foodservice buyers are pursuing 2-L and 5-L corner-bottom pouches for sauces and condiments, citing pallet efficiency and 79% emission savings compared to HDPE bottles.

Nonetheless, technical challenges, chiefly headspace management during retort for SKUs exceeding 1 L, and slow migration in European soup lines, persist. Continuous R&D in gusset geometry and cap venting aims to minimize pressure differentials, promising to unlock new market share gains in the stand-up pouches market.

The Stand-Up Pouches Market Report is Segmented by Material Type (Plastic, Paper, and More), Product Type (Doyen/Round Bottom, K-Seal, and More), Application (Food, Beverage, Personal Care and Cosmetics, Healthcare and Pharmaceuticals, Pet Care, and Other Application), Distribution Channel (Direct Sales, and Indirect Sales), and Geography (North America, Europe, and More). The Market Forecasts are Provided in Terms of Value (USD).

Geography Analysis

Asia-Pacific dominated with 38.21% share of the stand-up pouches market in 2025, underpinned by China's large-scale converting facilities, Japan's hot-fill R&D, and South Korea's premiumization playbook. Expected polyethylene oversupply, with 5 million tons of new capacity in 2025, is pressuring film pricing, offering converters raw-material leverage but compressing their margins. Amcor's acquisition of Phoenix Flexibles in Gujarat expands its reach into India's USD 20 million medical packaging niche and accelerates localized production.

North America leverages entrenched food-processing infrastructure and a pets-first culture to anchor steady demand. Infrastructure gaps loom large, with a USD 40 billion funding requirement to modernize material recovery facilities before 2030. Imminent 25% resin tariffs amplify cost pressures, yet they are also stimulating regional resin investment and trials using recycled resin. Coupled with California's 2026 recyclable-content mandate, such policies push the stand-up pouches market toward mono-material PE retort formats.

Europe stands at the regulatory vanguard, compelling design-for-recycling across the stand-up pouches market. Early adopters, including Amcor, Mondi, and Bischof + Klein, have already commercialized PP and PE single-web pouches that meet the 30% PCR threshold and deliver 79% CO2 cuts compared to PET/Alu/OPE triplex structures. Nordic refill programmes prove that consumer uptake can be rapid when lower-carbon packaging meets online convenience.

Latin America emerges as a capacity hotspot. Brazil registers 7.2% growth in the food industry, and PepsiCo's USD 240 million plant upgrade will commission three eight-lane pouch fillers in 2025. Mexico and Colombia extend tax credits for circular-packaging investments, attracting multinational converters and opening export corridors into the United States under USMCA provisions.

The Middle East and Africa experience the fastest CAGR at 8.39%, led by aseptic milk, flavored water, and fruit nectar packed in aluminum-free pouches. SIG's Prime 55 installation in Kenya and Tetra Pak's promotional campaigns in Nigeria lower entry barriers. Energy-efficient sterilization and affordable fitment remain key success factors poised to drive regional growth within the stand-up pouches market.

- Amcor Plc

- Mondi plc

- Sonoco Products Company

- Constantia Flexibles GmbH

- ProAmpac LLC

- Smurfit WestRock

- Swiss Pac USA

- Winpak Ltd

- Uflex Limited

- Glenroy Inc.

- Flair Flexible Packaging Corp.

- Sealed Air Corp.

- Huhtamaki Oyj

- Bischof + Klein SE

- Interflex Group

- DoyPak Solutions

- Clondalkin Group

Additional Benefits:

- The market estimate (ME) sheet in Excel format

- 3 months of analyst support

TABLE OF CONTENTS

1 INTRODUCTION

- 1.1 Study Assumptions and Market Definition

- 1.2 Scope of the Study

2 RESEARCH METHODOLOGY

3 EXECUTIVE SUMMARY

4 MARKET LANDSCAPE

- 4.1 Market Overview

- 4.2 Market Drivers

- 4.2.1 Rapid Shift to Mono-material Recyclable Pouch Structures in EU

- 4.2.2 On-the-go Functional Beverage Boom in East Asia Spurring Hot-fill Spouted Pouches

- 4.2.3 Migration from Metal Cans to Retort Pouches for Wet Pet Food in North America

- 4.2.4 Growth of Aseptic Dairy Distribution in Africa Favouring Aluminium-free Pouches

- 4.2.5 Nordic Beauty E-commerce Driving Refill Pouch SKUs with Easy-pour Features

- 4.2.6 CapEx Surge in Brazilian Pouch-filling Lines Accelerating Rigid-to-flexible Switch

- 4.3 Market Restraints

- 4.3.1 Limited Recycling Streams for Multi-layer Laminates in the U.S.

- 4.3.2 Volatile EVOH and Nylon Resin Prices Squeezing Asia Pacific Converters

- 4.3.3 Brand-owner Concerns Over Recycled-content Migration

- 4.3.4 Retort Head-space Failures in >1-L European Soup Packs

- 4.4 Industry Supply Chain Analysis

- 4.5 Regulatory Outlook

- 4.6 Technological Outlook

- 4.7 Porter's Five Forces Analysis

- 4.7.1 Threat of New Entrants

- 4.7.2 Bargaining Power of Buyers

- 4.7.3 Bargaining Power of Suppliers

- 4.7.4 Threat of Substitutes

- 4.7.5 Intensity of Competitive Rivalry

- 4.8 Assessment of Geopolitical Scenario Impact

5 MARKET SIZE AND GROWTH FORECASTS (VALUE)

- 5.1 By Material Type

- 5.1.1 Plastic

- 5.1.1.1 Polyethylene Terephthalate (PET)

- 5.1.1.2 Polyethylene (PE)

- 5.1.1.3 Polypropylene (PP)

- 5.1.1.4 Ethylene Vinyl Alcohol Copolymer (EVOH)

- 5.1.1.5 Other Plastics

- 5.1.2 Paper

- 5.1.3 Metal Foil

- 5.1.4 Biodegradable and Compostable Materials

- 5.1.1 Plastic

- 5.2 By Product Type

- 5.2.1 Doyen / Round Bottom

- 5.2.2 K-Seal

- 5.2.3 Plow / Corner Bottom

- 5.2.4 Other Product Types

- 5.3 By Application

- 5.3.1 Food

- 5.3.1.1 Baked Food

- 5.3.1.2 Snacked Food

- 5.3.1.3 Pet Food

- 5.3.1.4 Confectionery

- 5.3.1.5 Other Food

- 5.3.2 Beverage

- 5.3.3 Personal Care and Cosmetics

- 5.3.4 Healthcare and Pharmaceuticals

- 5.3.5 Pet Care

- 5.3.6 Other Application

- 5.3.1 Food

- 5.4 By Distribution Channel

- 5.4.1 Direct Sales

- 5.4.2 Indirect Sales

- 5.5 By Geography

- 5.5.1 North America

- 5.5.1.1 United States

- 5.5.1.2 Canada

- 5.5.1.3 Mexico

- 5.5.2 Europe

- 5.5.2.1 Germany

- 5.5.2.2 United Kingdom

- 5.5.2.3 France

- 5.5.2.4 Italy

- 5.5.2.5 Spain

- 5.5.2.6 Russia

- 5.5.2.7 Rest of Europe

- 5.5.3 Asia-Pacific

- 5.5.3.1 China

- 5.5.3.2 India

- 5.5.3.3 Japan

- 5.5.3.4 South Korea

- 5.5.3.5 Australia and New Zealand

- 5.5.3.6 Rest of Asia-Pacific

- 5.5.4 Middle East and Africa

- 5.5.4.1 Middle East

- 5.5.4.1.1 United Arab Emirates

- 5.5.4.1.2 Saudi Arabia

- 5.5.4.1.3 Turkey

- 5.5.4.1.4 Rest of Middle East

- 5.5.4.2 Africa

- 5.5.4.2.1 South Africa

- 5.5.4.2.2 Nigeria

- 5.5.4.2.3 Egypt

- 5.5.4.2.4 Rest of Africa

- 5.5.4.1 Middle East

- 5.5.5 South America

- 5.5.5.1 Brazil

- 5.5.5.2 Argentina

- 5.5.5.3 Rest of South America

- 5.5.1 North America

6 COMPETITIVE LANDSCAPE

- 6.1 Market Concentration

- 6.2 Strategic Moves

- 6.3 Market Share Analysis

- 6.4 Company Profiles (includes Global level Overview, Market level overview, Core Segments, Financials as available, Strategic Information, Market Rank/Share for key companies, Products and Services, and Recent Developments)

- 6.4.1 Amcor Plc

- 6.4.2 Mondi plc

- 6.4.3 Sonoco Products Company

- 6.4.4 Constantia Flexibles GmbH

- 6.4.5 ProAmpac LLC

- 6.4.6 Smurfit WestRock

- 6.4.7 Swiss Pac USA

- 6.4.8 Winpak Ltd

- 6.4.9 Uflex Limited

- 6.4.10 Glenroy Inc.

- 6.4.11 Flair Flexible Packaging Corp.

- 6.4.12 Sealed Air Corp.

- 6.4.13 Huhtamaki Oyj

- 6.4.14 Bischof + Klein SE

- 6.4.15 Interflex Group

- 6.4.16 DoyPak Solutions

- 6.4.17 Clondalkin Group

7 MARKET OPPORTUNITIES AND FUTURE OUTLOOK

- 7.1 White-Space and Unmet-Need Assessment