|

市場調查報告書

商品編碼

1906930

壓力感測器產業:市場佔有率分析、產業趨勢與統計、成長預測(2026-2031)Pressure Sensors Industry - Market Share Analysis, Industry Trends & Statistics, Growth Forecasts (2026 - 2031) |

||||||

※ 本網頁內容可能與最新版本有所差異。詳細情況請與我們聯繫。

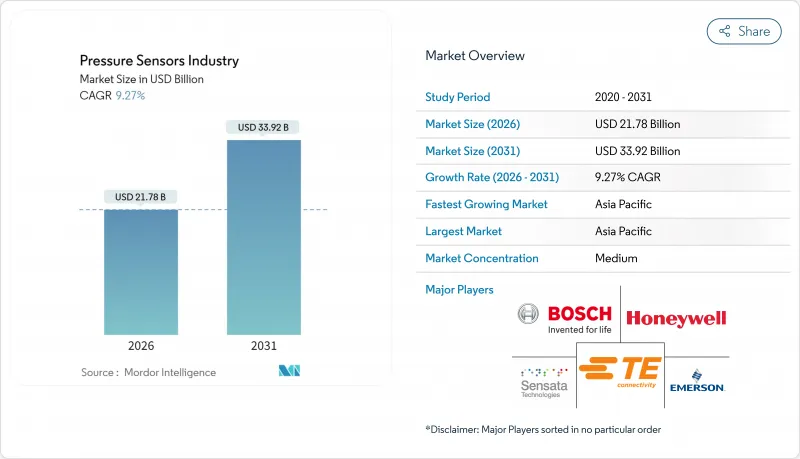

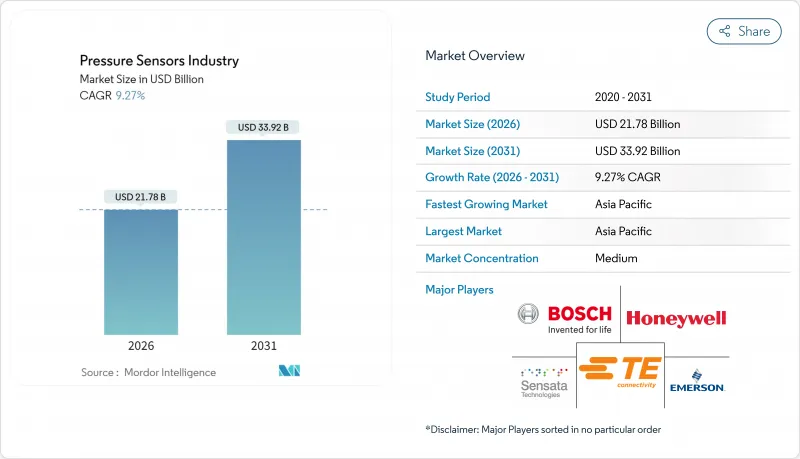

2025年壓力感測器市值為199.3億美元,預計到2031年將達到339.2億美元,而2026年為217.8億美元。

預計在預測期(2026-2031 年)內,複合年成長率將達到 9.27%。

強勁的需求源自於電動動力傳動系統控制、智慧工廠維修和一次性醫療設備,這些都需要精確的壓力監測以確保安全性和效率。亞太地區的電氣化政策正在加速xEV電池溫度控管系統中高精度氣壓感測器的應用。同時,歐洲和北美向工業4.0的升級也促使無線節點的普及,以降低安裝成本。醫療設備的小型化,尤其是在心血管導管領域,為符合滅菌標準的一次性MEMS設計創造了巨大的機會。此外,在LNG運輸船隊等嚴苛環境下的探勘應用,也推動了對能夠承受超過175°C製程溫度的碳化矽(SiC)和光學技術的高階需求。競爭日趨激烈:現有企業正在邊緣整合人工智慧引擎以保護利潤率,而中國白牌MEMS代工廠則在擴大生產規模並降低平均售價。

全球壓力感測器產業趨勢與洞察

xEV動力傳動系統控制系統的快速電氣化推動了高精度氣壓感測技術的發展

在電動車領域,精密氣壓感知器用於檢測電池膨脹並進行溫度控管,從而避免熱失控事件的發生。熱失控事件可能導致汽車製造商每輛車損失高達 3000 美元。隨著碳化矽驅動逆變器的滲透率預計到 2027 年將達到 50%,感測器供應商正在改進其設計,使其能夠承受 175°C 以上的工作溫度。中國、日本和韓國的汽車需求最為強勁,這些國家憑藉超級工廠的產能和政府補貼,正加速碳化矽驅動逆變器的普及應用。

智慧工廠維修的擴展將推動對無線感測器節點的需求。

歐洲和北美的製造商正在對現有設備進行改造,加裝 LoRaWAN 和 NB-IoT 壓力節點,以實現預測性維護。預計到 2030 年,低功耗廣域網路連線數將超過 35 億。例如,WIKA 的儀器生產線在一個自動化單元中整合了超過 10,000 種不同的感測器。在維修計劃中,電池供電節點被優先考慮,以避免昂貴的管道工程,這也是無線技術應用年複合成長率 (CAGR) 達到 12.8% 的關鍵因素。

中國白牌MEMS代工廠平均售價(ASP)下降

儘管像MEMSensing這樣的公司預計到2024年營收將成長28.8%至36.85%,但仍持續虧損,這凸顯了激進的定價策略正在擠壓全球現有企業的利潤空間。西方供應商正透過轉向高溫碳化矽和人工智慧封裝技術來應對這一局面。

細分市場分析

到2025年,有線設備仍將佔總收入的71.32%,這主要得益於引擎控制單元和手術室等高耗電環境中確定性資料傳輸的需求。然而,隨著工廠採用工業4.0,無線節點將以12.61%的複合年成長率超越有線設備。智慧控制改造套件可將安裝成本降低40%,並支援壓力容器的預測性停機維護。乙太網路供電(PoE)升級透過將電源和資料復用到單一線路上,保持了有線感測器的效用。無線節點利用能源採集和邊緣運算技術,使其能夠安裝在以前無法觸及的位置,例如旋轉軸和密封腔室。

到2025年,絕對壓力式感測器將佔據45.58%的市場佔有率,這主要得益於歧管壓力、氣象記錄和無人機高度測量等對真空參考測量的需求。差壓式感測器的年複合成長率將達到10.23%,主要成長動力來自暖通空調維修和無塵室過濾監測。近年來,濕式蝕刻蝕矽製造技術的進步顯著提升了感測器的靈敏度(5.07 mV/V/MPa)和線性度(0.67% FS)。壓力表仍是液壓系統中的關鍵裝置,但其成長率較為溫和,僅為個位數。

區域分析

亞太地區以35.62%的市佔率主導,主要歸功於中國的MEMS晶圓廠和印度強制實施的胎壓監測系統(TPMS)。國家高速公路網路的擴張和5293個電動車充電站的建設正在推動每輛車感測器數量的成長。本土製造商正在縮小技術差距,主要廠商指出,國內供應商正在將人工智慧整合到其汽車感知系統中。歐洲憑藉其工業自動化傳統優勢,英飛凌投資50億歐元的德勒斯登智慧功率工廠代表了其在半導體領域的戰略自主性。北美在航太和醫療領域表現卓越,DARPA資助的研究推動了感測技術的尖端發展。中東和非洲的複合年成長率(CAGR)最高,達到12.08%,這主要得益於液化天然氣(LNG)計劃對海底儀器的需求,以及智慧城市基礎設施為無線部署提供的基礎。

其他福利:

- Excel格式的市場預測(ME)表

- 分析師支持(3個月)

目錄

第1章 引言

- 研究假設和市場定義

- 調查範圍

第2章調查方法

第3章執行摘要

第4章 市場情勢

- 市場概覽

- 市場促進因素

- xEV動力傳動系統控制系統的快速電氣化推動了高精度氣壓感測技術的發展(亞洲)

- 智慧工廠維修的擴展將推動對無線感測器節點的需求(歐洲和北美)。

- 印度和東協掀起摩托車強制安裝胎壓監測裝置的浪潮

- 加速部署5G毫米波無線技術需要精確的熱機械壓力控制。

- 門診循環系統診所採用一次性MEMS壓力導管(美國)

- LNG裝運船隻的增加推動了對用於惡劣環境(中東)的海底壓力測量設備的需求。

- 市場限制

- 中國白牌MEMS代工廠平均售價(ASP)下降

- 無線通訊協定環境碎片化推高了整合成本。

- 人們擔心在溫度超過 175°C 的生產線上使用光壓晶片的可靠性

- 大壓電壓阻晶片短缺影響供應鏈

- 價值/供應鏈分析

- 監理與技術展望

- 波特五力分析

- 供應商的議價能力

- 買方的議價能力

- 新進入者的威脅

- 替代品的威脅

- 競爭對手之間的競爭

- 宏觀趨勢如何影響市場

- 投資分析

第5章 市場規模與成長預測

- 依感測器類型

- 有線

- 無線的

- 依產品類型

- 絕對

- 不同之處

- 測量

- 透過技術

- 壓電元件

- 電磁學

- 電容式

- 共振固體

- 光學

- 其他壓力感測器

- 透過使用

- 車

- 醫療保健

- 家用電子電器

- 產業

- 航太/國防

- 食品/飲料

- HVAC

- 按地區

- 北美洲

- 美國

- 加拿大

- 墨西哥

- 歐洲

- 英國

- 德國

- 法國

- 義大利

- 其他歐洲地區

- 亞太地區

- 中國

- 日本

- 印度

- 韓國

- 亞太其他地區

- 中東

- 以色列

- 沙烏地阿拉伯

- 阿拉伯聯合大公國

- 土耳其

- 其他中東地區

- 非洲

- 南非

- 埃及

- 其他非洲地區

- 南美洲

- 巴西

- 阿根廷

- 南美洲其他地區

- 北美洲

第6章 競爭情勢

- 市場集中度

- 策略趨勢

- 市佔率分析

- 公司簡介

- ABB Ltd

- All Sensors Corporation

- Bosch Sensortec GmbH

- Endress+Hauser AG

- TE Connectivity

- Honeywell International Inc.

- Schneider Electric SE

- Kistler Group

- Rockwell Automation Inc.

- Emerson Electric Co.

- Sensata Technologies Inc.

- Siemens AG

- Yokogawa Electric Corp.

- Infineon Technologies AG

- STMicroelectronics NV

- Sensirion AG

- NXP Semiconductors NV

- Texas Instruments Inc.

- Omron Corporation

- Murata Manufacturing Co., Ltd.

- Amphenol(SSI Technologies)

- BD Sensors GmbH

- Keller AG fur Druckmesstechnik

第7章 市場機會與未來展望

The pressure sensors market was valued at USD 19.93 billion in 2025 and estimated to grow from USD 21.78 billion in 2026 to reach USD 33.92 billion by 2031, at a CAGR of 9.27% during the forecast period (2026-2031).

Strong demand stems from electrified power-train control, smart-factory retrofits, and disposable medical devices that require precise pressure monitoring for safety and efficiency. Electrification mandates in Asia-Pacific are accelerating adoption of high-accuracy barometric sensors in xEV battery-thermal systems, while Industry 4.0 upgrades across Europe and North America favor wireless nodes that cut installation cost. Medical device miniaturization, especially in cardiovascular catheters, is opening a sizeable opportunity for single-use MEMS designs that meet sterilization standards. At the same time, harsh-environment exploration-such as LNG carrier fleets-creates premium demand for silicon-carbide and optical technologies capable of surviving >175 °C process lines. Competitive intensity is rising: incumbents embed AI engines at the edge to defend margins, whereas Chinese white-label MEMS foundries scale volume and depress average selling prices.

Global Pressure Sensors Industry Trends and Insights

Rapid electrification of xEV power-train control systems driving high-accuracy barometric sensing

Electric vehicles use precision barometric sensors to detect cell swelling and manage heat, avoiding thermal runaway events that can cost OEMs up to USD 3,000 per vehicle. Sensor suppliers are hardening designs for >175 °C operation because silicon-carbide traction inverters will reach 50% penetration by 2027. Automotive demand is strongest in China, Japan, and South Korea where gigafactory capacity and government subsidies intersect to accelerate adoption.

Expansion of smart-factory retrofits boosting wireless sensor node demand

European and North American manufacturers are layering LoRaWAN and NB-IoT pressure nodes onto legacy equipment to enable predictive maintenance; low-power wide-area connections are forecast to exceed 3.5 billion by 2030. Assembly lines such as WIKA's gauge facility now incorporate more than 10,000 sensor variants in a single automated cell. Retrofit projects prioritize battery-powered nodes to avoid expensive conduit runs, a key factor behind the 12.8% CAGR in wireless uptake.

ASP erosion from Chinese white-label MEMS foundries

Firms such as MEMSensing posted 28.8%-36.85% revenue growth in 2024 while still running at a loss, underscoring aggressive pricing tactics that compress margins for global incumbents. Western vendors answer by pivoting toward high-temperature silicon-carbide and AI-enabled packages.

Other drivers and restraints analyzed in the detailed report include:

- Mandatory tyre-pressure monitoring adoption waves in India & ASEAN two-wheelers

- Accelerated rollout of 5G mmWave radios requiring precision thermo-mechanical pressure control

- Fragmented wireless protocol landscape inflating integration cost

For complete list of drivers and restraints, kindly check the Table Of Contents.

Segment Analysis

Wired devices retained 71.32% revenue in 2025 due to deterministic data delivery in power-rich settings such as engine control units and surgical theaters. However, wireless nodes will outpace with a 12.61% CAGR as factories retrofit to Industry 4.0. Smart Control retrofit kits cut installation expense by 40% while enabling predictive shutdowns for pressure vessels. Power-over-Ethernet upgrades are keeping wired sensors relevant by multiplexing power and data on a single line. Wireless nodes leverage energy harvesting and edge compute, allowing placement on rotating shafts or sealed chambers once considered unreachable.

Absolute designs held 45.58% share in 2025 because manifold pressure, weather logging, and drone altimetry require vacuum-referenced readings. Differential units will see a 10.23% CAGR thanks to HVAC retrofits and filtration monitoring in cleanrooms. Recent wet-etch silicon fabrication pushed sensitivity to 5.07 mV/V/MPa with 0.67% FS linearity. Gauge units remain staple devices in hydraulics but exhibit only mid-single-digit growth.

The Pressure Sensors Market Report is Segmented by Type of Sensor (Wired, Wireless), Product Type (Absolute, Differential, Gauge), Technology (Piezoresistive, Electromagnetic, Optical, Capacitive, Resonant Solid-State, and More), Application (Automotive, Medical, Industrial, Aerospace and Defense, HVAC, and More), and Geography. The Market Forecasts are Provided in Terms of Value (USD).

Geography Analysis

Asia-Pacific's 35.62% leadership stems from China's MEMS fabs and India's TPMS mandates. The National Highways expansion and 5,293 EV charging stations catalyze sensor content per vehicle. Local producers are closing the technology gap; Major players notes domestic suppliers are integrating AI into automotive perception stacks. Europe leverages its industrial automation heritage; Infineon's EUR 5 billion Dresden Smart Power Fab underscores strategic semiconductor self-reliance. North America excels in aerospace and medical segments, with DARPA-funded research pushing sensing frontiers. The Middle East & Africa posts the fastest 12.08% CAGR on LNG projects needing subsea instrumentation, complemented by smart-city infrastructure that seeds wireless deployments.

- ABB Ltd

- All Sensors Corporation

- Bosch Sensortec GmbH

- Endress+Hauser AG

- TE Connectivity

- Honeywell International Inc.

- Schneider Electric SE

- Kistler Group

- Rockwell Automation Inc.

- Emerson Electric Co.

- Sensata Technologies Inc.

- Siemens AG

- Yokogawa Electric Corp.

- Infineon Technologies AG

- STMicroelectronics N.V.

- Sensirion AG

- NXP Semiconductors N.V.

- Texas Instruments Inc.

- Omron Corporation

- Murata Manufacturing Co., Ltd.

- Amphenol (S S I Technologies)

- BD Sensors GmbH

- Keller AG fur Druckmesstechnik

Additional Benefits:

- The market estimate (ME) sheet in Excel format

- 3 months of analyst support

TABLE OF CONTENTS

1 INTRODUCTION

- 1.1 Study Assumptions and Market Definition

- 1.2 Scope of the Study

2 RESEARCH METHODOLOGY

3 EXECUTIVE SUMMARY

4 MARKET LANDSCAPE

- 4.1 Market Overview

- 4.2 Market Drivers

- 4.2.1 Rapid electrification of xEV power-train control systems driving high-accuracy barometric sensing (Asia)

- 4.2.2 Expansion of smart factory retrofits boosting wireless sensor node demand (Europe and NA)

- 4.2.3 Mandatory tyre-pressure monitoring adoption waves in India and ASEAN two-wheelers

- 4.2.4 Accelerated rollout of 5G mmWave radios requiring precision thermo-mechanical pressure control

- 4.2.5 Adoption of disposable MEMS pressure catheters in outpatient cardiovascular clinics (US)

- 4.2.6 LNG carrier fleet build-up elevating harsh-environment subsea pressure instrumentation (Middle East)

- 4.3 Market Restraints

- 4.3.1 ASP erosion from Chinese white-label MEMS foundries

- 4.3.2 Fragmented wireless protocol landscape inflating integration cost

- 4.3.3 Reliability concerns in optical pressure chips beyond 175 degree C process lines

- 4.3.4 Supply-chain exposure to bulk piezoresistive wafer shortages

- 4.4 Value / Supply-Chain Analysis

- 4.5 Regulatory and Technological Outlook

- 4.6 Porter's Five Forces Analysis

- 4.6.1 Bargaining Power of Suppliers

- 4.6.2 Bargaining Power of Buyers

- 4.6.3 Threat of New Entrants

- 4.6.4 Threat of Substitutes

- 4.6.5 Intensity of Competitive Rivalry

- 4.7 Impact of Macro Trends on the Market

- 4.8 Investment Analysis

5 MARKET SIZE AND GROWTH FORECASTS (VALUE)

- 5.1 By Type of Sensor

- 5.1.1 Wired

- 5.1.2 Wireless

- 5.2 By Product Type

- 5.2.1 Absolute

- 5.2.2 Differential

- 5.2.3 Gauge

- 5.3 By Technology

- 5.3.1 Piezoresistive

- 5.3.2 Electromagnetic

- 5.3.3 Capacitive

- 5.3.4 Resonant Solid-State

- 5.3.5 Optical

- 5.3.6 Other Pressure Sensors

- 5.4 By Application

- 5.4.1 Automotive

- 5.4.2 Medical

- 5.4.3 Consumer Electronics

- 5.4.4 Industrial

- 5.4.5 Aerospace and Defense

- 5.4.6 Food and Beverage

- 5.4.7 HVAC

- 5.5 By Geography

- 5.5.1 North America

- 5.5.1.1 United States

- 5.5.1.2 Canada

- 5.5.1.3 Mexico

- 5.5.2 Europe

- 5.5.2.1 United Kingdom

- 5.5.2.2 Germany

- 5.5.2.3 France

- 5.5.2.4 Italy

- 5.5.2.5 Rest of Europe

- 5.5.3 Asia-Pacific

- 5.5.3.1 China

- 5.5.3.2 Japan

- 5.5.3.3 India

- 5.5.3.4 South Korea

- 5.5.3.5 Rest of Asia-Pacific

- 5.5.4 Middle East

- 5.5.4.1 Israel

- 5.5.4.2 Saudi Arabia

- 5.5.4.3 United Arab Emirates

- 5.5.4.4 Turkey

- 5.5.4.5 Rest of Middle East

- 5.5.5 Africa

- 5.5.5.1 South Africa

- 5.5.5.2 Egypt

- 5.5.5.3 Rest of Africa

- 5.5.6 South America

- 5.5.6.1 Brazil

- 5.5.6.2 Argentina

- 5.5.6.3 Rest of South America

- 5.5.1 North America

6 COMPETITIVE LANDSCAPE

- 6.1 Market Concentration

- 6.2 Strategic Moves

- 6.3 Market Share Analysis

- 6.4 Company Profiles (includes Global- and Market-level Overview, Core Segments, Financials, Strategic Information, Market Rank/Share, Products and Services, Recent Developments)

- 6.4.1 ABB Ltd

- 6.4.2 All Sensors Corporation

- 6.4.3 Bosch Sensortec GmbH

- 6.4.4 Endress+Hauser AG

- 6.4.5 TE Connectivity

- 6.4.6 Honeywell International Inc.

- 6.4.7 Schneider Electric SE

- 6.4.8 Kistler Group

- 6.4.9 Rockwell Automation Inc.

- 6.4.10 Emerson Electric Co.

- 6.4.11 Sensata Technologies Inc.

- 6.4.12 Siemens AG

- 6.4.13 Yokogawa Electric Corp.

- 6.4.14 Infineon Technologies AG

- 6.4.15 STMicroelectronics N.V.

- 6.4.16 Sensirion AG

- 6.4.17 NXP Semiconductors N.V.

- 6.4.18 Texas Instruments Inc.

- 6.4.19 Omron Corporation

- 6.4.20 Murata Manufacturing Co., Ltd.

- 6.4.21 Amphenol (S S I Technologies)

- 6.4.22 BD Sensors GmbH

- 6.4.23 Keller AG fur Druckmesstechnik

7 MARKET OPPORTUNITIES AND FUTURE OUTLOOK

- 7.1 White-space and Unmet-Need Assessment