|

市場調查報告書

商品編碼

1852082

功率半導體:市場佔有率分析、產業趨勢、統計數據和成長預測(2025-2030 年)Power Semiconductor - Market Share Analysis, Industry Trends & Statistics, Growth Forecasts (2025 - 2030) |

||||||

※ 本網頁內容可能與最新版本有所差異。詳細情況請與我們聯繫。

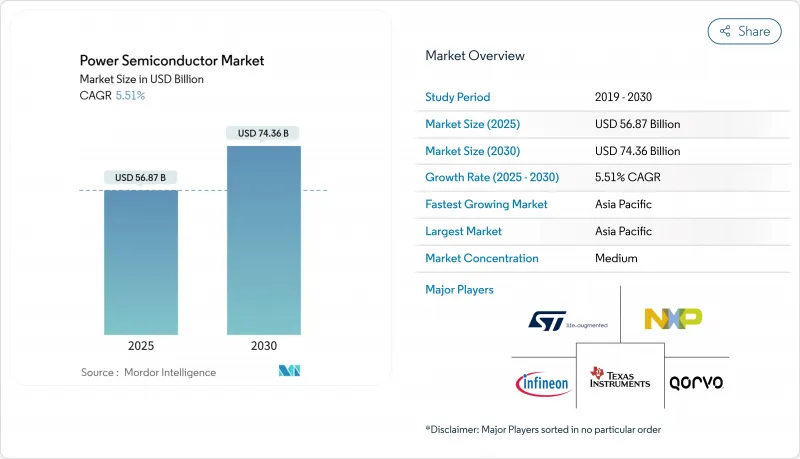

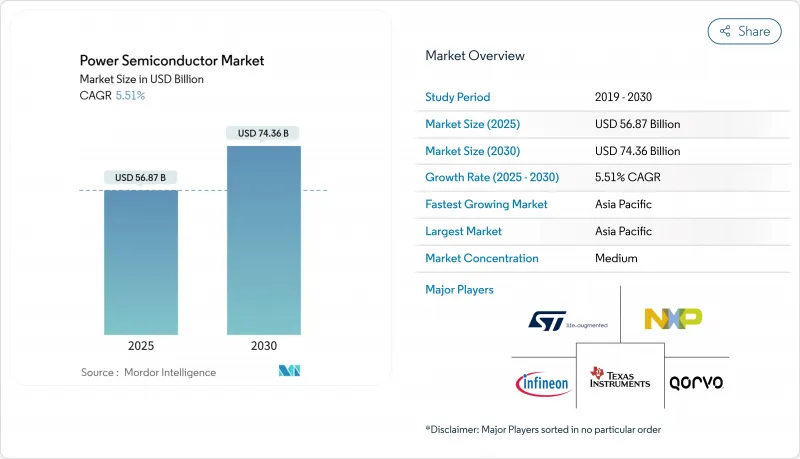

預計到 2025 年,功率半導體市場規模將達到 568.7 億美元,到 2030 年將達到 743.6 億美元,年複合成長率為 5.51%。

儘管其他領域週期性放緩,但對高效功率轉換的強勁需求,包括電動車、可再生能源系統和數據密集型電子產品,使功率半導體市場保持了韌性。寬能能隙(WBG)材料,主要是碳化矽(SiC)和氮化鎵(GaN),由於其在高電壓和高頻率下性能優於矽,因此價格也更高。汽車電氣化支撐了產量成長,而太陽能+儲能設施的安裝、5G基礎設施的部署以及工廠自動化升級才是推動快速成長的主要動力。區域供應鏈政策,例如美國的《晶片和工業產品法案》(CHIPS Act)和歐洲的《晶片和工業產品法案》,正在推動對國內製造業的投資,而亞太地區則憑藉其端到端的製造規模優勢,保持著領先地位。

全球功率半導體市場趨勢與洞察

電動車和充電基礎設施的需求激增

電動車越來越依賴碳化矽(SiC)MOSFET,這種元件能夠提高動力傳動系統的效率並縮短充電時間。汽車製造商在過渡到800V系統時,會指定使用SiC來降低逆變器損耗,例如FORVIA HELLA為其下一代車載充電器選擇了1200V CoolSiC裝置。像安森美半導體與大眾汽車簽訂的多年供貨協議,確保了從晶片到模組的垂直整合交付,並降低了分配風險。並聯直流快速充電器的部署需要8kW至1MW的功率模組,光是汽車應用就使SiC的需求量加倍。由於車規級產量比率仍面臨挑戰,整合元件製造商(IDM)正在增加專屬式基板能,以穩定成本曲線並保護利潤率。

5G基地台部署

在低於 6 GHz 和毫米波頻段,GaN高電子移動性電晶體的增益和效率均高於 LDMOS。由於小型基地台尺寸縮小,到本世紀末 GaN 的出貨量將增加四倍。恩智浦半導體 (NXP) 將 Si LDMOS 和 GaN晶粒整合到多晶片大規模 MIMO 模組中,以整合天線陣列並簡化散熱設計。此外,該公司還提供了一種燒結晶粒黏接材料,適用於能夠承受超過 225°C 熱點溫度的功率半導體。電訊業注重整體擁有成本,將效率提升轉化為營運成本的節省,從而鞏固 GaN 在未來部署中的應用。

矽晶圓供應週期

目前晶圓總需求超過合格能,記憶體供應商的庫存削減正在扭曲近期的採購行為。地緣政治摩擦推高了晶圓廠的建造成本,而水資源限制措施則限制了乾旱地區的待開發區位置。中國參與企業正競相進行價格戰,擠壓了整個產業鏈的利潤空間。儘管前端產能預訂顯示市場正在復甦,但個人電腦和智慧型手機終端市場的疲軟限制了銷售的恢復,暴露出的結構性而非週期性失衡問題。

細分市場分析

到2025年,功率積體電路將成為功率半導體市場規模的重要組成部分,預計到2030年將以6.12%的複合年成長率成長。汽車電池管理單元需要多軌穩壓器和功能安全診斷功能,而這些功能都整合在緊湊的電源管理積體電路(PMIC)封裝中。英飛凌符合ISO 26262標準的OPTIREG TLF35585為安全相關的電控系統供電,這標誌著單晶片電源管理的發展趨勢。分立元件在高電流路徑中仍然至關重要,佔據45%的市場。然而,在空間受限的子系統中,由於設計人員更傾向於成本最佳化的模組或積體電路解決方案,分立元件的市場佔有率正在下降。

供應商的藍圖正在將GaN或SiC晶粒整合到智慧功率模組中,這些模組整合了閘極驅動、感測和保護功能,從而加快了逆變器和充電器組件的上市速度。模組整合使缺乏內部封裝技術的中型批量工業和住宅能源客戶受益。另一方面,家用電子電器ODM廠商正在為其適配器設計採購分離式MOSFET,以利用基板級彈性和價格優勢。分離式、模組和積體電路形式的共存豐富了功率半導體市場,實現了性能和成本之間的客製化權衡。

區域分析

亞太地區將在2024年佔據51.7%的功率半導體市場佔有率,並在2030年之前維持6.86%的複合年成長率。中國在國家補貼和垂直整合的供應鏈的推動下,正引領碳化矽(SiC)和氮化鎵(GaN)產能的擴張。印度正在加速建造一座投資760億盧比的OSAT園區,目標日產量為1,500萬顆,顯示其有意在國內進行組裝。台灣和韓國將分別在先進封裝和記憶體領域主導,而日本將加強其在上游材料方面的控制。

北美將受益於《晶片製造和創新法案》(CHIPS Act)提供的500億美元激勵措施,這將推動棕地斯皮德(Wolfspeed)、博世(Bosch)等國際參與企業進行現有工廠改造和待開發區項目。汽車、國防和資料中心叢集將集中需求,並推動在地化生產的要求。 SEMI預測,2027年,區域工廠資本支出將翻倍,達到247億美元,強調長期規模發展。

歐洲將利用其汽車和可再生能源政策的協調一致,推動碳化矽(SiC)和氮化鎵(GaN)技術的應用。德國核准在德勒斯登建造價值50億歐元的工廠,便是公私合作提高能源自給率的範例。法國和義大利正在提供額外的津貼方案,以維持其在組件和基板的尖端技術。中東、非洲和拉丁美洲等新興市場則更注重價值,並採用成熟的矽平台,同時逐步試驗寬禁帶(WBG)技術,用於太陽能發電和鐵路電氣化。

其他福利:

- Excel格式的市場預測(ME)表

- 3個月的分析師支持

目錄

第1章 引言

- 研究假設和市場定義

- 調查範圍

第2章調查方法

第3章執行摘要

第4章 市場情勢

- 市場概覽

- 市場促進因素

- 電動車和充電基礎設施的需求正在快速成長

- 5G基地台的分佈

- 可再生能源推動電力轉換成長

- 工業自動化和電機驅動升級

- 高空平台系統與全電動式飛機動力傳動系統

- 面向亞洲的快速充電兩輪/三輪電動車架構

- 市場限制

- 矽晶圓供應週期

- WBG設備高成本且設計複雜

- 高密度電動車逆變器的熱極限

- 氮化鎵外延設備的出口限制

- 價值/供應鏈分析

- 監管環境

- 技術展望

- 波特五力分析

- 供應商的議價能力

- 買方的議價能力

- 新進入者的威脅

- 競爭對手之間的競爭

- 替代品的威脅

- 投資分析

第5章 市場規模與成長預測

- 按組件

- 離散的

- 整流器

- 雙極

- MOSFET

- IGBT

- 其他分立元件(閘流體、HEMT 等)

- 模組

- 閘流體模組

- IGBT模組

- MOSFET模組

- 智慧型電源模組(IPM)

- 功率積體電路

- PMIC(多通道)

- 開關穩壓器(AC/DC、DC/DC、ISO/非ISO)

- 線性穩壓器

- 電池管理積體電路

- 其他電源積體電路

- 離散的

- 材料

- 矽

- 碳化矽(SiC)

- 氮化鎵(GaN)

- 其他

- 按最終用戶行業分類

- 車

- 消費性電子產品和家用電器

- 資訊通訊技術(資訊科技和電信)

- 工業和製造業

- 能源與電力(可再生能源、電網)

- 航太/國防

- 醫療設備

- 其他(鐵路、船)

- 按地區

- 北美洲

- 美國

- 加拿大

- 墨西哥

- 歐洲

- 德國

- 法國

- 英國

- 義大利

- 其他歐洲地區

- 亞太地區

- 中國

- 日本

- 韓國

- 印度

- 亞太其他地區

- 南美洲

- 巴西

- 阿根廷

- 其他南美洲國家

- 中東

- 以色列

- 沙烏地阿拉伯

- 阿拉伯聯合大公國

- 其他中東地區

- 非洲

- 南非

- 埃及

- 其他非洲地區

- 北美洲

第6章 競爭情勢

- 市場集中度

- 策略趨勢

- 市佔率分析

- 公司簡介

- Infineon Technologies AG

- Texas Instruments Incorporated

- Qorvo Inc.

- STMicroelectronics NV

- NXP Semiconductors NV

- ON Semiconductor Corporation

- Renesas Electronics Corporation

- Broadcom Inc.

- Toshiba Corporation

- Mitsubishi Electric Corporation

- Fuji Electric Co., Ltd.

- Semikron Danfoss GmbH and Co. KG

- Wolfspeed Inc.

- ROHM Co., Ltd.

- Vishay Intertechnology Inc.

- Nexperia BV

- Alpha and Omega Semiconductor Ltd.

- Magnachip Semiconductor Corp.

- Microchip Technology Inc.

- Littelfuse Inc.

- Navitas Semiconductor Corp.

- Power Integrations Inc.

- Monolithic Power Systems Inc.

第7章 市場機會與未來展望

The power semiconductor market size stands at USD 56.87 billion in 2025 and is on track to reach USD 74.36 billion by 2030, advancing at a 5.51% CAGR .

Strong demand for efficient power conversion across electric vehicles, renewable energy systems, and data-intensive electronics keeps the power semiconductor market resilient even as cyclical slowdowns emerge elsewhere. Wide-bandgap (WBG) materials-chiefly silicon carbide (SiC) and gallium nitride (GaN)-command premium pricing because they outperform silicon in high-voltage and high-frequency conditions. Automotive electrification anchors volume, yet rapid growth stems from solar-plus-storage installations, 5G infrastructure rollouts, and factory automation upgrades. Regional supply-chain policies such as the U.S. CHIPS Act and the European Chips Act intensify domestic fabrication investments, while the Asia Pacific leverages its end-to-end manufacturing scale to maintain leadership.

Global Power Semiconductor Market Trends and Insights

Surging Demand for EVs and Charging Infrastructure

Electric vehicles increasingly rely on SiC MOSFETs that raise drivetrain efficiency and shorten charging times . Automakers shifting to 800 V systems specify SiC to trim inverter losses, evidenced by FORVIA HELLA selecting 1,200 V CoolSiC devices for next-gen on-board chargers. Multi-year supply pacts, such as onsemi's agreement with Volkswagen, secure vertically integrated chip-to-module deliveries, mitigating allocation risks. Parallel DC fast-charger roll-outs require 8 kW to 1 MW power blocks, effectively doubling SiC demand from vehicle content alone. Automotive-grade yields stay challenging, so IDMs add captive substrate capacity to stabilize cost curves and safeguard margins.

Proliferation of 5G Base-Stations

GaN high-electron-mobility transistors deliver higher gain and efficiency than LDMOS at sub-6 GHz and mmWave frequencies. Small-cell densification pushes GaN shipments to quadruple by decade-end as operators combat escalating energy bills. NXP couples Si LDMOS with GaN die in multichip massive-MIMO modules that integrate antenna arrays and simplify thermal design. Power semiconductor suppliers add sintered die-attach materials to cope with hot-spot temperatures above 225 °C. The telecom sector's focus on total-cost-of-ownership converts incremental efficiency gains into reduced opex, cementing GaN adoption in next-phase rollouts.

Silicon Wafer Supply Tightness Cycles

Total wafer demand now eclipses qualified capacity, and inventory drawdown at memory suppliers distorts short-term purchasing behavior . Geopolitical friction inflates fab-construction costs, while water-usage limits restrict greenfield sites in drought-prone zones. Chinese entrants pursue price competition that compresses margins across the chain. Although front-end equipment bookings hint at recovery, end-market weakness in PCs and smartphones tempers volume pick-up, exposing structural rather than cyclical imbalances.

Other drivers and restraints analyzed in the detailed report include:

- Renewables-Led Power Conversion Growth

- Industrial Automation and Motor-Drive Upgrades

- High Cost / Design Complexity of WBG Devices

For complete list of drivers and restraints, kindly check the Table Of Contents.

Segment Analysis

Power integrated circuits contributed significantly to the power semiconductor market size in 2025 and will climb at a 6.12% CAGR through 2030. Automotive battery-management units require multi-rail regulators and functional-safety diagnostics delivered in a compact PMIC footprint. Infineon's ISO 26262-compliant OPTIREG TLF35585 underpins safety-related electronic control units, illustrating the trend toward single-chip power management . Discrete devices remain indispensable for high-current paths, preserving 45% revenue share; nevertheless, the discrete share edges lower as designers favor cost-optimized module or IC solutions in space-constrained subsystems.

Supplier roadmaps bundle GaN or SiC dies within intelligent power modules that integrate gate drive, sensing, and protection, shortening time-to-market for inverter and charger assemblies. Module consolidation benefits mid-volume industrial and residential energy customers who lack in-house packaging expertise. Conversely, consumer-electronics ODMs still procure discrete MOSFETs for adapter designs to exploit board-level flexibility and price advantages. The coexistence of discrete, module, and IC formats enriches the power semiconductor market, enabling tailored performance-cost trade-offs.

The Power Semiconductor Market Report is Segmented by Component (Discrete, Modules, Power IC), Material (Silicon, Silicon Carbide, Gallium Nitride, Others), End-User Industry (Automotive, Consumer Electronics and Appliances, ICT, Industrial and Manufacturing, Energy and Power, Aerospace and Defense, Healthcare and Equipment, Others), and Geography. The Market Forecasts are Provided in Terms of Value (USD).

Geography Analysis

Asia Pacific accounted for 51.7% of the power semiconductor market share in 2024 and sustained a 6.86% CAGR through 2030. China spearheads SiC and GaN capacity ramps, aided by state subsidies and vertically integrated supply chains. India fast-tracks an INR 7,600 crore OSAT campus targeting 15 million units per day, signaling intent to onshore assembly. Taiwan and South Korea guard leadership in advanced packaging and memory, respectively, while Japan fortifies upstream materials command.

North America benefits from USD 50 billion in CHIPS Act incentives that unlock brownfield conversions and greenfield fabs by Wolfspeed, Bosch, and overseas entrants. Automotive, defense, and data-center clusters concentrate demand, boosting local content requirements. SEMI projects regional fab-equipment outlays doubling to USD 24.7 billion by 2027, underscoring long-term scale-up .

Europe leverages its automotive and renewable energy policy alignment to catalyze SiC and GaN uptake. Germany's EUR 5 billion Dresden fab approval exemplifies public-private alignment to elevate self-sufficiency. France and Italy offer additional grant packages to preserve leading-edge module and substrate know-how. Emerging markets across the Middle East, Africa, and Latin America stay value-conscious, adopting mature silicon platforms while gradually trialing WBG for utility-scale solar and railway electrification.

- Infineon Technologies AG

- Texas Instruments Incorporated

- Qorvo Inc.

- STMicroelectronics N.V.

- NXP Semiconductors N.V.

- ON Semiconductor Corporation

- Renesas Electronics Corporation

- Broadcom Inc.

- Toshiba Corporation

- Mitsubishi Electric Corporation

- Fuji Electric Co., Ltd.

- Semikron Danfoss GmbH and Co. KG

- Wolfspeed Inc.

- ROHM Co., Ltd.

- Vishay Intertechnology Inc.

- Nexperia B.V.

- Alpha and Omega Semiconductor Ltd.

- Magnachip Semiconductor Corp.

- Microchip Technology Inc.

- Littelfuse Inc.

- Navitas Semiconductor Corp.

- Power Integrations Inc.

- Monolithic Power Systems Inc.

Additional Benefits:

- The market estimate (ME) sheet in Excel format

- 3 months of analyst support

TABLE OF CONTENTS

1 INTRODUCTION

- 1.1 Study Assumptions and Market Definition

- 1.2 Scope of the Study

2 RESEARCH METHODOLOGY

3 EXECUTIVE SUMMARY

4 MARKET LANDSCAPE

- 4.1 Market Overview

- 4.2 Market Drivers

- 4.2.1 Surging demand for EVs and charging infrastructure

- 4.2.2 Proliferation of 5G base-stations

- 4.2.3 Renewables-led power conversion growth

- 4.2.4 Industrial automation and motor-drive upgrades

- 4.2.5 HAPS and all-electric aircraft powertrains

- 4.2.6 Fast-charging 2-/3-wheeler EV architectures in Asia

- 4.3 Market Restraints

- 4.3.1 Silicon wafer supply tightness cycles

- 4.3.2 High cost / design complexity of WBG devices

- 4.3.3 Thermal limits in high-density EV inverters

- 4.3.4 Export controls on GaN epitaxy tools

- 4.4 Value / Supply-Chain Analysis

- 4.5 Regulatory Landscape

- 4.6 Technological Outlook

- 4.7 Porters Five Forces Analysis

- 4.7.1 Bargaining Power of Suppliers

- 4.7.2 Bargaining Power of Buyers

- 4.7.3 Threat of New Entrants

- 4.7.4 Intensity of Competitive Rivalry

- 4.7.5 Threat of Substitutes

- 4.8 Investment Analysis

5 MARKET SIZE AND GROWTH FORECASTS (VALUE)

- 5.1 By Component

- 5.1.1 Discrete

- 5.1.1.1 Rectifier

- 5.1.1.2 Bipolar

- 5.1.1.3 MOSFET

- 5.1.1.4 IGBT

- 5.1.1.5 Other Discrete Components (Thyristor, HEMT, etc.)

- 5.1.2 Modules

- 5.1.2.1 Thyristor Module

- 5.1.2.2 IGBT Module

- 5.1.2.3 MOSFET Module

- 5.1.2.4 Intelligent Power Module (IPM)

- 5.1.3 Power IC

- 5.1.3.1 PMIC (Multichannel)

- 5.1.3.2 Switching Regulators (AC/DC, DC/DC, Iso/Non-iso)

- 5.1.3.3 Linear Regulators

- 5.1.3.4 Battery Management IC

- 5.1.3.5 Other Power ICs

- 5.1.1 Discrete

- 5.2 By Material

- 5.2.1 Silicon

- 5.2.2 Silicon Carbide (SiC)

- 5.2.3 Gallium Nitride (GaN)

- 5.2.4 Others

- 5.3 By End-user Industry

- 5.3.1 Automotive

- 5.3.2 Consumer Electronics and Appliances

- 5.3.3 ICT (IT and Telecom)

- 5.3.4 Industrial and Manufacturing

- 5.3.5 Energy and Power (Renewables, Grid)

- 5.3.6 Aerospace and Defense

- 5.3.7 Healthcare Equipment

- 5.3.8 Others (Rail, Marine)

- 5.4 By Geography

- 5.4.1 North America

- 5.4.1.1 United States

- 5.4.1.2 Canada

- 5.4.1.3 Mexico

- 5.4.2 Europe

- 5.4.2.1 Germany

- 5.4.2.2 France

- 5.4.2.3 United Kingdom

- 5.4.2.4 Italy

- 5.4.2.5 Rest of Europe

- 5.4.3 Asia Pacific

- 5.4.3.1 China

- 5.4.3.2 Japan

- 5.4.3.3 South Korea

- 5.4.3.4 India

- 5.4.3.5 Rest of Asia Pacific

- 5.4.4 South America

- 5.4.4.1 Brazil

- 5.4.4.2 Argentina

- 5.4.4.3 Rest of South America

- 5.4.5 Middle East

- 5.4.5.1 Israel

- 5.4.5.2 Saudi Arabia

- 5.4.5.3 United Arab Emirates

- 5.4.5.4 Rest of Middle East

- 5.4.6 Africa

- 5.4.6.1 South Africa

- 5.4.6.2 Egypt

- 5.4.6.3 Rest of Africa

- 5.4.1 North America

6 COMPETITIVE LANDSCAPE

- 6.1 Market Concentration

- 6.2 Strategic Moves

- 6.3 Market Share Analysis

- 6.4 Company Profiles (includes Global level Overview, Market level overview, Core Segments, Financials as available, Strategic Information, Market Rank/Share for key companies, Products and Services, and Recent Developments))

- 6.4.1 Infineon Technologies AG

- 6.4.2 Texas Instruments Incorporated

- 6.4.3 Qorvo Inc.

- 6.4.4 STMicroelectronics N.V.

- 6.4.5 NXP Semiconductors N.V.

- 6.4.6 ON Semiconductor Corporation

- 6.4.7 Renesas Electronics Corporation

- 6.4.8 Broadcom Inc.

- 6.4.9 Toshiba Corporation

- 6.4.10 Mitsubishi Electric Corporation

- 6.4.11 Fuji Electric Co., Ltd.

- 6.4.12 Semikron Danfoss GmbH and Co. KG

- 6.4.13 Wolfspeed Inc.

- 6.4.14 ROHM Co., Ltd.

- 6.4.15 Vishay Intertechnology Inc.

- 6.4.16 Nexperia B.V.

- 6.4.17 Alpha and Omega Semiconductor Ltd.

- 6.4.18 Magnachip Semiconductor Corp.

- 6.4.19 Microchip Technology Inc.

- 6.4.20 Littelfuse Inc.

- 6.4.21 Navitas Semiconductor Corp.

- 6.4.22 Power Integrations Inc.

- 6.4.23 Monolithic Power Systems Inc.

7 MARKET OPPORTUNITIES AND FUTURE OUTLOOK

- 7.1 White-space and Unmet-Need Assessment