|

市場調查報告書

商品編碼

1851545

飲料包裝:市場佔有率分析、行業趨勢、統計數據和成長預測(2025-2030 年)Beverage Packaging - Market Share Analysis, Industry Trends & Statistics, Growth Forecasts (2025 - 2030) |

||||||

※ 本網頁內容可能與最新版本有所差異。詳細情況請與我們聯繫。

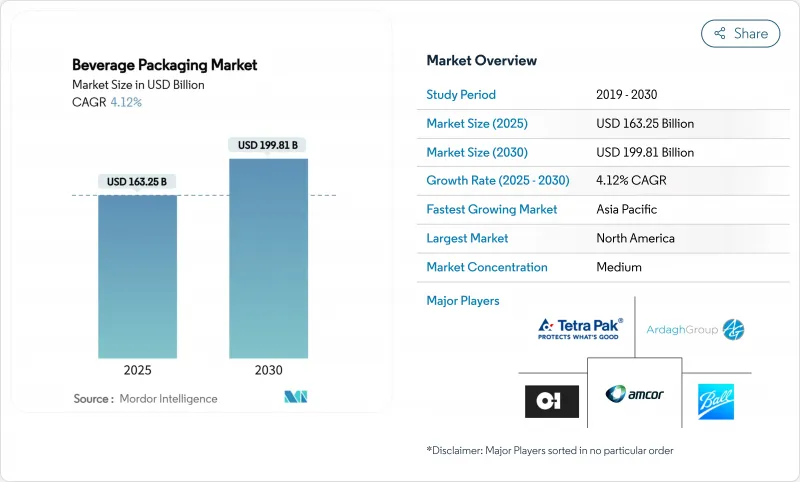

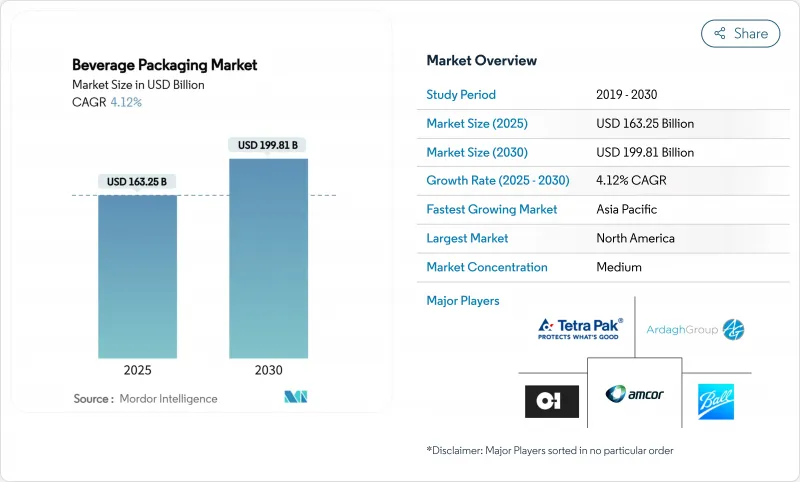

預計到 2025 年,飲料包裝市場價值將達到 1,632.5 億美元,到 2030 年將達到 1998.1 億美元,年複合成長率為 4.12%。

推動成長的因素包括全球範圍內對再生材料含量基準值制定的統一法規,以及高階飲料新品上市和鋁罐產能擴張等並行需求引擎。能夠應對再生材料含量強制性要求、不斷上漲的原生樹脂成本以及消費者偏好轉向低環境影響包裝形式的包裝供應商正在贏得市場佔有率。對閉合迴路回收、數位浮水印和適用於電商的多包裝產品進行策略性投資,正在使後進企業分開來。諸如安靠(Amkor)和貝裡全球(Berry Global)即將進行的合併等整合,持續重塑著競爭格局,為擁有多元化產品組合的公司帶來規模經濟效益。

全球飲料包裝市場趨勢與洞察

優質化即飲飲料

高階即飲飲料的推出正促使品牌商從普通塑膠包裝升級為玻璃或精製鋁包裝。在英國,價值168億英鎊(212億美元)的烈酒產業預計到2030年將以每年16.2%的速度成長,僅2023年就有超過50家新的釀酒廠開業。 92%的美國消費者將玻璃與品質和無限循環利用聯繫起來,玻璃供應商正利用這一高階趨勢。品牌商將晶瑩剔透的容器與智慧瓶蓋和QR碼標籤結合,提供產品來源資訊、會員獎勵和認證回收方式。飲料包裝市場正受惠於高階產品每公升包裝成本的增加,從而抵消了主流碳酸軟性飲料銷售疲軟的影響。

鋁罐產能快速擴張

鋁的無限可回收性和超過70%的閉合迴路回收率正在推動全球產能競賽。波爾公司正在佛羅裡達州增設一條生產線,並計劃於2024年在奧勒岡州破土動工興建一座工廠。諾貝麗斯公司正在阿拉巴馬州建造一座年產60萬噸的軋延,這是該公司與阿達格公司簽訂的長期供應協議的一部分,因為預計到2031年,紙板需求將以每年4%的速度成長。因此,在飲料包裝市場,綜合金屬供應商正在獲得成本競爭力和永續性通訊的優勢,對啤酒和發泡水的塑膠包裝構成壓力。

原生樹脂價格不穩定

2025年初,原油價格波動和煉油廠停產推高了PTA和MEG的成本,迫使中國和歐洲的聚酯瓶蓋生產商閒置產能以調整庫存。持有現貨樹脂合約的包裝加工商利潤空間受到壓縮,促使他們轉向遠期合約和機械回收。因此,飲料包裝市場正傾向於那些持有可回收原料庫存的供應商,以保護其客戶免受價格波動的影響。

細分市場分析

到2024年,塑膠將佔銷售額的42%,反映了其成熟的供應鏈和成本優勢。然而,再生材料含量強制要求和不斷擴大的押金返還政策對PET的主導地位構成了挑戰。儘管輕量化和化學回收計劃持續推進,但塑膠飲料包裝市場規模預計僅以4.12%的複合年成長率成長,市場佔有率仍在萎縮。紙板的複合年成長率高達6.65%,是所有材料中最高的。以鋁罐為代表的金屬包裝的復興,顯示監管機構和消費者對可再生或無限循環利用的基材的需求日益成長。 Graphic Packaging International推出的Boardio紙板罐和EnviroClip包裝盒,旨在取代先前使用收縮膜包裝的碳酸飲料多包裝。一體化工廠利用國內纖維供應和75%的回收率來應對原生樹脂價格的波動。

儘管物流排放不斷增加,飲料包裝產業也正在見證玻璃作為一種高階材料的重新定位。 OI Glass公司正投資1.5億美元對其位於英國阿洛阿的工廠進行現代化改造,採用混合熔爐和輕質瓶,目標是到2030年減少25%的二氧化碳排放。 Novelis公司的工廠鋁製封閉式回收率超過70%,顯示該公司對長期需求充滿信心。總而言之,這些轉變意味著到2030年,隨著材料組合的多樣化,塑膠在飲料包裝領域的市場佔有率將會下降,即使人口成長導致塑膠的絕對噸位增加。

由於瓶裝飲料用途廣泛,可用於盛裝碳酸飲料、水、乳製品替代品和酒精飲料,預計到2024年,瓶裝飲料將佔飲料市場銷售額的38%。在瓶裝飲料的推動下,預計到2030年,飲料包裝市場規模將以3.7%的年複合成長率溫和成長,同時包裝形式也將更加多樣化。瓶蓋支撐結構和先進的阻隔塗層(例如等離子塗層和二氧化矽塗層)進一步減輕了瓶身重量。然而,由於每公升包裝的材料重量比瓶裝飲料低60-80%,軟包裝將以7.23%的複合年成長率實現顯著成長,使其更適合電商銷售。

多包裝葡萄酒和雞尾酒袋採用單一材料複合材料,經受住了跌落測試,降低了運輸成本,並逐漸被路邊取貨計劃所接受。紙盒包裝繼續用於無菌乳製品、果汁以及現在的植物來源拿鐵,這得益於利樂公司的超高溫瞬時滅菌(UHT)灌裝生產線,該生產線可減少25%的能源消耗。罐裝產品在精釀啤酒、能量飲料和氣泡水中仍佔有一席之地,其快速冷卻的特性有助於提升品牌忠誠度。雖然啤酒桶的銷售量佔比不到3%,仍屬於小眾產品,但不銹鋼桶的循環利用周期超過25年,符合零廢棄物的概念。

區域分析

2024年,北美地區佔全球銷售額的27%,主要得益於較高的人均飲料消費量和優質化的發展空間。皇冠控股公司(Crown Holdings)2024年北美銷量成長5%,這主要得益於維吉尼亞和內華達州新增的易拉罐生產線。然而,各州關於繫繩瓶蓋和生產者延伸責任費的法律法規造成了合規的複雜性,這有利於多元化跨國公司。加拿大到2030年實現rPET(再生聚對苯二甲酸乙二醇酯)統一的目標將促進區域回收基礎設施的建設,並進一步加強飲料包裝市場中的循環供應商。來自亞太地區的輕質瓶進口給國內加工商帶來了競爭壓力和成本挑戰。

亞太地區預計到2030年將以5.61%的複合年成長率成長,主要受都市化和可支配所得成長的推動。在中國,2023年前10個月飲料產量增加了2.7%,其中啤酒產量激增22%。印度將於2025年4月起強制要求使用30%的再生PET(rPET),將對再生材料的需求產生影響,並對不合規者處以懲罰性課稅。擁有內部回收設施的跨國公司(例如可口可樂在菲律賓的PETValue工廠)將佔據市場優勢,而規模較小的加工商則面臨原料短缺的問題。日本加工商正專注於「即食」健康飲品,並推廣使用無菌包裝袋進行攜帶式營養補充。

歐洲在嚴格的法規方面展現了領導力,例如於2025年2月生效的《塑膠包裝和回收條例》(PPWR),該條例要求所有包裝材料在2028年前必須可回收, 寶特瓶在2030年前必須使用30%的再生PET(rPET)。因此,歐元區飲料包裝市場正在轉向可回收設計通訊協定,例如單一材料套筒和水性油墨。食品級rPET的供需失衡維持了其溢價,並促進了灌裝商和回收商之間的合作。在環境、社會和治理(ESG)限制下,玻璃產能正在合理化,導致區域葡萄酒和頂級烈酒的供應趨緊,有助於保持價值。隨著零售商在各成員國努力推進塑膠減量藍圖,軟性紙基解決方案正日益受到青睞。

其他福利:

- Excel格式的市場預測(ME)表

- 3個月的分析師支持

目錄

第1章 引言

- 研究假設和市場定義

- 調查範圍

第2章調查方法

第3章執行摘要

第4章 市場情勢

- 市場概覽

- 市場促進因素

- 優質化即飲飲料

- 鋁罐產能快速擴張

- PET輕量化和繫繩帽法規

- 電子商務多件裝商品(主要是酒類)的成長

- 數位浮水印在流通領域的興起

- 濃縮飲料和「家用汽水」生態系統

- 市場限制

- 原生樹脂價格不穩定

- 再生PET薄片供應瓶頸

- 加速推行反一次性塑膠政策

- 投資者對ESG的審查抑制了玻璃資本的投資

- 價值鏈分析

- 監管環境

- 技術展望

- 波特五力分析

- 供應商的議價能力

- 買方/消費者的議價能力

- 新進入者的威脅

- 替代品的威脅

- 競爭對手之間的競爭

- 評估市場宏觀經濟趨勢

第5章 市場規模與成長預測

- 依材料類型

- 塑膠

- 金屬

- 玻璃

- 紙板

- 依產品類型

- 瓶子

- 能

- 小袋

- 紙盒

- 啤酒桶

- 按包裝類型

- 無菌

- 熱填充

- 冷填充/碳酸化

- 蒸餾

- 可在常溫儲存

- 冷鏈配送

- 按飲料類型

- 碳酸飲料

- 酒精飲料

- 瓶裝水

- 牛奶

- 果菜汁

- 能量飲料

- 植物性飲料

- 其他飲料類型

- 按地區

- 北美洲

- 美國

- 加拿大

- 墨西哥

- 歐洲

- 英國

- 德國

- 法國

- 義大利

- 西班牙

- 奧地利

- 波蘭

- 俄羅斯

- 其他歐洲地區

- 亞太地區

- 中國

- 印度

- 日本

- 澳洲

- 亞太其他地區

- 南美洲

- 巴西

- 阿根廷

- 南美洲其他地區

- 中東

- 沙烏地阿拉伯

- 阿拉伯聯合大公國

- 土耳其

- 其他中東地區

- 非洲

- 南非

- 其他非洲地區

- 北美洲

第6章 競爭情勢

- 市場集中度

- 策略趨勢

- 市佔率分析

- 公司簡介

- Amcor plc

- Ball Corporation

- Tetra Laval International SA

- OI Glass Inc.

- Crown Holdings Inc.

- Ardagh Group SA

- Ardagh Metal Packaging SA

- Verallia SA

- Vidrala SA

- Vetropack Holding Ltd.

- Silgan Holdings Inc.

- Berry Global Group Inc.

- Mondi plc

- Sonoco Products Company

- CCL Industries Inc.

- Smurfit Kappa Group plc

- CANPACK SA

- Huhtamaki Oyj

- Toyo Seikan Group Holdings Ltd.

- Nampak Ltd.

- Krones AG

- Guala Closures Group

第7章 市場機會與未來展望

The beverage packaging market was valued at USD 163.25 billion in 2025 and is forecast to expand at a 4.12% CAGR, reaching USD 199.81 billion by 2030.

Growth is propelled by converging global regulations that standardize recycled-content thresholds, while premium ready-to-drink launches and a wave of aluminum-can capacity additions provide parallel demand engines. Packaging suppliers able to navigate recycled-material mandates, cost inflation for virgin resin, and shifting consumer preferences toward low-impact formats are capturing share. Strategic investments in closed-loop recycling, digital watermarking, and e-commerce-ready multipacks are differentiating leaders from laggards. Consolidation-exemplified by the pending Amcor-Berry Global merger-continues to reshape the competitive baseline, creating scale benefits for firms with multi-format portfolios.

Global Beverage Packaging Market Trends and Insights

Premiumisation in Ready-to-Drink Beverages

Premium RTD launches are prompting brands to upgrade from commoditized plastics to glass and sleek aluminum, enabling higher shelf price points while still meeting recycled-content requirements. In the United Kingdom, a spirits sector worth GBP 16.8 billion (USD 21.2 billion) in 2024 recorded more than 50 new distilleries during 2023, and RTD spirits are projected to expand 16.2% per year to 2030. Glass suppliers are capitalizing on premium cues, with 92% of US consumers associating glass with quality and infinite recyclability. Brand owners are pairing high-clarity containers with smart closures and QR-coded labels that unlock provenance data, loyalty rewards, and authenticated recycling instructions. The beverage packaging market benefits as premium SKUs carry higher packaging spend per liter, offsetting volume softness in mainstream carbonates.

Surge in Aluminium-Can Capacity Expansions

Aluminum's infinite recyclability and closed-loop recovery rates above 70% have spurred a global capacity race. Ball Corporation added a Florida line and broke ground on an Oregon plant in 2024. Novelis is building a 600,000-tonne rolling mill in Alabama under long-term supply agreements with Ardagh to accommodate forecast 4% annual can-sheet demand growth through 2031. The beverage packaging market therefore sees integrated metal suppliers gaining cost leverage and sustainability messaging advantages, pressuring plastics in beer and sparkling water.

Volatile Virgin-Resin Prices

Crude oil swings and refinery outages pushed PTA and MEG costs higher in early 2025, forcing polyester bottle-chip producers in China and Europe to idle capacity to re-balance inventories. Packaging converters on spot resin contracts saw margin compression, encouraging forward contracts or integration into mechanical recycling. The beverage packaging market therefore tilts toward suppliers holding equity stakes in recycle-ready feedstock, shielding customers from volatility.

Other drivers and restraints analyzed in the detailed report include:

- PET Lightweighting and Tethered-Cap Regulations

- Growth of E-commerce Multipacks

- Supply Bottlenecks for Recycled PET Flakes

For complete list of drivers and restraints, kindly check the Table Of Contents.

Segment Analysis

Plastic retained 42% of 2024 revenue, underlining entrenched supply chains and cost advantages. Yet recycled-content directives and deposit-return expansion are challenging PET's dominance. The beverage packaging market size for plastic is projected to advance only at the overall 4.12% CAGR, tempering its share despite ongoing lightweighting and chemical-recycling projects. Paperboard's 6.65% CAGR-highest among materials-and metal's comeback via aluminum cans illustrate regulatory pull and consumer push toward renewable or infinitely recyclable substrates. Graphic Packaging International's launch of Boardio paperboard canisters and EnviroClip carriers targets carbonated soft drink multipacks once controlled by shrink-film. Integrated mills leverage domestic fiber supply and 75% recycling rates, cushioning them against virgin-resin volatility.

The beverage packaging industry is also witnessing glass repositioned as a prestige material notwithstanding higher logistics emissions. O-I Glass committed USD 150 million to modernize its Alloa, UK plant with hybrid furnaces and lightweight bottles, aiming for a 25% CO2 cut by 2030. Aluminum enjoys a closed-loop rate above 70%, and Novelis' forthcoming mill signals confidence in long-term demand. Collectively, these shifts suggest a diversified material mix by 2030, with plastics losing points of beverage packaging market share even as absolute tonnage rises in line with population growth.

Bottles accounted for 38% of 2024 revenue thanks to versatility across carbonates, water, dairy alternates, and alcohol. The beverage packaging market size attributed to bottles is projected to grow modestly at 3.7% to 2030 amid format diversification. Tethered-cap compliance and advanced barrier coatings (e.g., plasma or silicon oxide) are unlocking incremental weight savings. However, pouches are set to capture outsized gains via a 7.23% CAGR, reflecting 60-80% lower material weight per liter and suitability for e-commerce.

Multipack wine and cocktail pouches withstand drop tests, reduce shipping costs, and utilize mono-material laminates increasingly accepted in curbside programs. Cartons continue to service aseptic dairy, juice, and now plant-based lattes, propelled by Tetra Pak's UHT filling lines with energy cuts of 25%. Cans sustain relevance through craft beer, energy drinks, and sparkling water, and their rapid chilling characteristics underpin brand loyalty. Beer kegs remain a niche at under 3% of volume, but stainless-steel re-use cycles of 25+ years align with zero-waste narratives.

The Beverage Packaging Market Report is Segmented by Material Type (Plastic, Metal, Glass, and Paperboard), Product Type (Bottles, Cans, Pouches, Cartons, and Beer Kegs), Packaging Format (Aseptic, Hot-Fill, Cold-Fill/Carbonated, Retortable, and More), Beverage Type (Carbonated Drinks, Alcoholic Beverages, Bottled Water, Milk, and More), and Geography. The Market Forecasts are Provided in Terms of Value (USD).

Geography Analysis

North America captured 27% of 2024 revenue due to to high per-capita beverage intake and premiumization headroom. Crown Holdings registered 5% North American volume growth in 2024, boosted by new Virginia and Nevada can lines. Yet state-level legislation on tethered caps and expanded-producer-responsibility fees creates compliance complexity that favors diversified multinationals. Canada's harmonized rPET targets to 2030 incent regional reclamation infrastructure, further bolstering circular-ready suppliers within the beverage packaging market. Competitive pressures arise from Asia-Pacific imports of lightweight bottles, challenging domestic converters on cost.

Asia-Pacific is forecast to post a 5.61% CAGR through 2030, underpinned by urbanization and rising disposable incomes. China recorded 2.7% output growth in beverages across the first ten months of 2023 while beer production jumped 22%. India's rPET mandate at 30% from April 2025 introduces both demand for recycled feedstock and punitive taxes for non-compliance. Multinationals with in-house recycling (e.g., Coca-Cola's PETValue facility in the Philippines) gain a foothold, whereas small converters face input scarcity. Japanese processors focus on "ready-to-eat" and healthy beverages, encouraging aseptic pouch uptake for portable nutrition.

Europe commands stringent regulatory leadership with the PPWR effective February 2025 mandating all packaging be recyclable by 2028 and 30% rPET in PET bottles by 2030. The beverage packaging market in the bloc therefore pivots toward design-for-recycling protocols such as monomaterial sleeves and water-based inks. Supply-demand imbalances in food-grade rPET keep premiums elevated, encouraging partnerships between fillers and recyclers. Glass capacity rationalization amid ESG constraints tightens supply for regional wine and premium spirits, supporting value retention. Flexible paper-based solutions gain traction as retailers commit to plastic reduction roadmaps across member states.

- Amcor plc

- Ball Corporation

- Tetra Laval International SA

- O-I Glass Inc.

- Crown Holdings Inc.

- Ardagh Group S.A.

- Ardagh Metal Packaging S.A.

- Verallia S.A.

- Vidrala S.A.

- Vetropack Holding Ltd.

- Silgan Holdings Inc.

- Berry Global Group Inc.

- Mondi plc

- Sonoco Products Company

- CCL Industries Inc.

- Smurfit Kappa Group plc

- CANPACK S.A.

- Huhtamaki Oyj

- Toyo Seikan Group Holdings Ltd.

- Nampak Ltd.

- Krones AG

- Guala Closures Group

Additional Benefits:

- The market estimate (ME) sheet in Excel format

- 3 months of analyst support

TABLE OF CONTENTS

1 INTRODUCTION

- 1.1 Study Assumptions and Market Definition

- 1.2 Scope of the Study

2 RESEARCH METHODOLOGY

3 EXECUTIVE SUMMARY

4 MARKET LANDSCAPE

- 4.1 Market Overview

- 4.2 Market Drivers

- 4.2.1 Premiumisation in ready-to-drink (RTD) beverages

- 4.2.2 Surge in aluminium-can capacity expansions

- 4.2.3 PET lightweighting and tethered-cap regulations

- 4.2.4 Growth of e-commerce multipacks (mainly alcohol)

- 4.2.5 Rise of digital watermarks for circularity (under-radar)

- 4.2.6 Beverage concentrates and "soda-at-home" ecosystems (under-radar)

- 4.3 Market Restraints

- 4.3.1 Volatile virgin-resin prices

- 4.3.2 Supply bottlenecks for recycled PET flakes

- 4.3.3 Anti-single-use plastics policy acceleration (under-radar)

- 4.3.4 Investor ESG scrutiny curbing cap-ex in glass (under-radar)

- 4.4 Value Chain Analysis

- 4.5 Regulatory Landscape

- 4.6 Technological Outlook

- 4.7 Porter's Five Forces Analysis

- 4.7.1 Bargaining Power of Suppliers

- 4.7.2 Bargaining Power of Buyers/Consumers

- 4.7.3 Threat of New Entrants

- 4.7.4 Threat of Substitutes

- 4.7.5 Intensity of Competitive Rivalry

- 4.8 Assessment of Macro Economic Trends on the Market

5 MARKET SIZE AND GROWTH FORECASTS (VALUES)

- 5.1 By Material Type

- 5.1.1 Plastic

- 5.1.2 Metal

- 5.1.3 Glass

- 5.1.4 Paperboard

- 5.2 By Product Type

- 5.2.1 Bottles

- 5.2.2 Cans

- 5.2.3 Pouches

- 5.2.4 Cartons

- 5.2.5 Beer Kegs

- 5.3 By Packaging Format

- 5.3.1 Aseptic

- 5.3.2 Hot-Fill

- 5.3.3 Cold-Fill/Carbonated

- 5.3.4 Retortable

- 5.3.5 Shelf-Stable Ambient

- 5.3.6 Chilled Distribution

- 5.4 By Beverage Type

- 5.4.1 Carbonated Drinks

- 5.4.2 Alcoholic Beverages

- 5.4.3 Bottled Water

- 5.4.4 Milk

- 5.4.5 Fruit and Vegetable Juices

- 5.4.6 Energy Drinks

- 5.4.7 Plant-based Drinks

- 5.4.8 Other Beverage Types

- 5.5 By Geography

- 5.5.1 North America

- 5.5.1.1 United States

- 5.5.1.2 Canada

- 5.5.1.3 Mexico

- 5.5.2 Europe

- 5.5.2.1 United Kingdom

- 5.5.2.2 Germany

- 5.5.2.3 France

- 5.5.2.4 Italy

- 5.5.2.5 Spain

- 5.5.2.6 Austria

- 5.5.2.7 Poland

- 5.5.2.8 Russia

- 5.5.2.9 Rest of Europe

- 5.5.3 Asia-Pacific

- 5.5.3.1 China

- 5.5.3.2 India

- 5.5.3.3 Japan

- 5.5.3.4 Australia

- 5.5.3.5 Rest of Asia-Pacific

- 5.5.4 South America

- 5.5.4.1 Brazil

- 5.5.4.2 Argentina

- 5.5.4.3 Rest of South America

- 5.5.5 Middle East

- 5.5.5.1 Saudi Arabia

- 5.5.5.2 United Arab Emirates

- 5.5.5.3 Turkey

- 5.5.5.4 Rest of Middle East

- 5.5.6 Africa

- 5.5.6.1 South Africa

- 5.5.6.2 Rest of Africa

- 5.5.1 North America

6 COMPETITIVE LANDSCAPE

- 6.1 Market Concentration

- 6.2 Strategic Moves

- 6.3 Market Share Analysis

- 6.4 Company Profiles (includes Global level Overview, Market level overview, Core Segments, Financials as available, Strategic Information, Market Rank/Share for key companies, Products and Services, and Recent Developments)

- 6.4.1 Amcor plc

- 6.4.2 Ball Corporation

- 6.4.3 Tetra Laval International SA

- 6.4.4 O-I Glass Inc.

- 6.4.5 Crown Holdings Inc.

- 6.4.6 Ardagh Group S.A.

- 6.4.7 Ardagh Metal Packaging S.A.

- 6.4.8 Verallia S.A.

- 6.4.9 Vidrala S.A.

- 6.4.10 Vetropack Holding Ltd.

- 6.4.11 Silgan Holdings Inc.

- 6.4.12 Berry Global Group Inc.

- 6.4.13 Mondi plc

- 6.4.14 Sonoco Products Company

- 6.4.15 CCL Industries Inc.

- 6.4.16 Smurfit Kappa Group plc

- 6.4.17 CANPACK S.A.

- 6.4.18 Huhtamaki Oyj

- 6.4.19 Toyo Seikan Group Holdings Ltd.

- 6.4.20 Nampak Ltd.

- 6.4.21 Krones AG

- 6.4.22 Guala Closures Group

7 MARKET OPPORTUNITIES AND FUTURE OUTLOOK

- 7.1 White-space and Unmet-Need Assessment