|

市場調查報告書

商品編碼

1851158

熱感列印:市場佔有率分析、行業趨勢、統計數據和成長預測(2025-2030 年)Thermal Printing - Market Share Analysis, Industry Trends & Statistics, Growth Forecasts (2025 - 2030) |

||||||

※ 本網頁內容可能與最新版本有所差異。詳細情況請與我們聯繫。

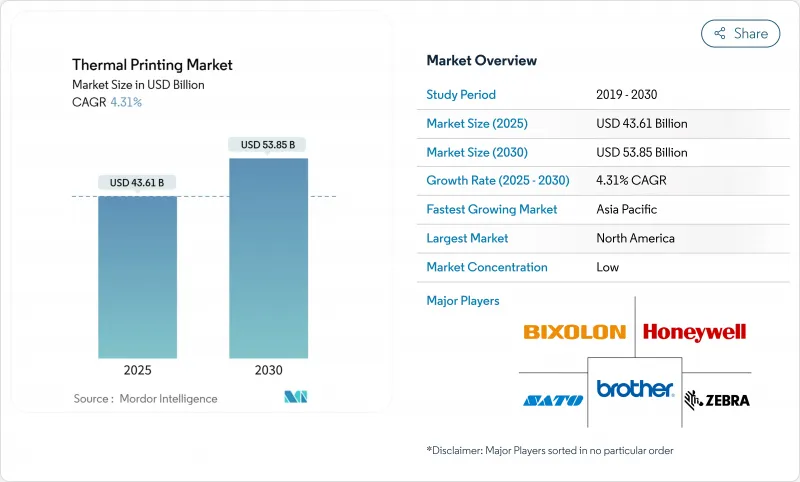

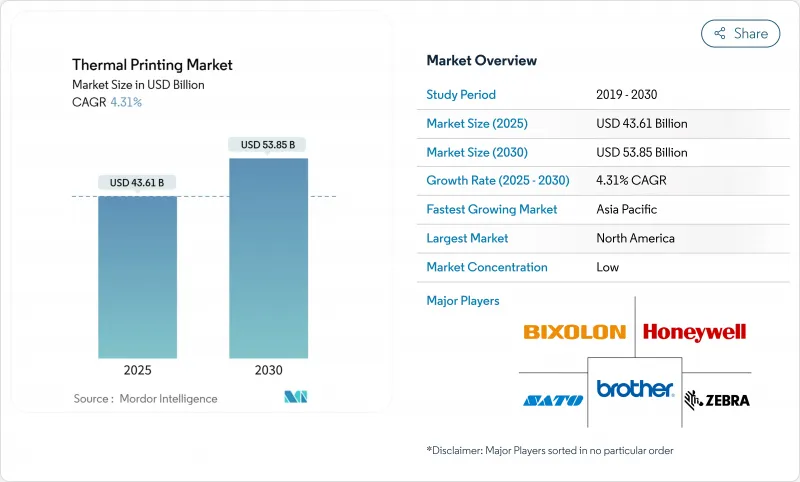

預計到 2025 年,熱感列印市場規模將達到 436.1 億美元,到 2030 年將達到 538.5 億美元,在此期間的複合年成長率為 4.31%。

醫療保健序列化法規、電子商務小包裹量以及依賴按需標籤的工業自動化專案共同推動了熱敏標籤技術的持續發展。禁止使用雙酚A和其他酚類物質的監管措施加速了配方轉變,但由於相容介質的選擇不斷增加,整體列印量並未下降。物聯網列印頭、遠端車隊管理軟體以及嵌入式RFID標籤工作流程的進步,正在增強該技術在互聯供應鏈中的重要性。同時,噴墨和雷射系統的高能耗和耗材成本使得熱感列印對每年需要運輸、儲存和追蹤數百萬件商品的大批量企業更具吸引力。主要供應商在亞太地區工廠的投資,標誌著全球產能正向該地區發生決定性轉移,因為跨國客戶正在尋求更具韌性的供應鏈網路。

全球熱感列印市場趨勢與洞察

AIDC(自動辨識與資料擷取)的普及與電子商務物流的蓬勃發展

小包裹業者在2027年GS1標準實施截止日期前,正積極遷移至2D條碼,並更新其設備以支援更高解析度的2D碼輸出,從而在推行無標籤退貨計劃的同時,維持硬體銷售。承運商的試驗表明,在訂單量激增的旺季,熱感標籤的使用量也隨之飆升,訂單量成長高達200%,而即時生成標籤則避免了人工操作造成的瓶頸。零售商還在門市等光線昏暗的場所部署雲端連接行動印表機,批量列印揀貨標籤,從而彌合線上訂購系統與末端宅配業者之間的資料鴻溝。這些市場發展趨勢已將熱感列印市場牢牢融入全通路物流工作流程。最後,物流中心正在將列印伺服器與倉庫執行軟體整合,以實現基於訂單路線的自動印表機分配,從而降低停機風險。

無線和行動式熱敏印表機的擴展

新款支援 Wi-Fi 6 的機型可將資料吞吐量提高一倍,並減少漫遊斷線,使揀貨員在數千平方公尺的倉庫中穿梭時也能不間斷地存取標籤。持續運作的電池現在可以支援整個雙班次,無需像以前那樣在中午充電,從而避免了出庫碼頭的停機。無襯紙功能可減少 50% 的介質浪費,這不僅令永續性審核滿意,還提高了可用捲筒容量。遠端系統管理儀表板(例如 SATO 的行動管理系統)可提醒 IT 團隊介質不足和頭部溫度異常,從而減少現場巡檢的頻率。車隊數據還可用於預測分析模型,可在故障發生前安排更換,從而提高物流中心的整體設備效率指標。

高昂的維修和頭部更換成本

熱感印表機頭仍是最昂貴的耗材,其售價通常佔新機價格的30%。複雜的智慧印表機整合了安全元件和物聯網模組,需要經過工廠培訓的技術人員進行維護,推高了人事費用。小型零售商往往等到故障發生才進行維護,迫使他們緊急採購,導致更新周期延長。供應商正在透過硬塗層和快速更換卡盒來應對這一問題,使操作人員無需工具即可更換印表頭,從而將停機時間縮短至幾分鐘。設備韌體中內建的預測服務演算法還可以在條碼顏色低於掃描器閾值之前預測故障,但此類升級會增加領先購置成本,可能會減緩預算緊張地區的採用速度。

細分市場分析

由於零售商、製造商和物流中心依賴標準化的一維和2D條碼在自動化工作流程中運輸貨物,條碼列印將繼續保持其最大地位,到 2024 年將佔熱感列印市場佔有率的 40.21%。 GS1 全球一致性、監管序列化要求和低廉的耗材成本保障了該細分市場的規模,即使數位轉型將部分交易轉移到線上,也能保持條碼更新需求的穩定性。

在整個熱感列印市場規模中,行動手持列印預計將從 2025 年到 2030 年以 7.34% 的複合年成長率成長。 Wi-Fi 6 連線、長壽命電池和無底紙媒體選項正在鼓勵企業用腰帶式設備取代固定式自助服務終端,從而減少停機時間和浪費,縮短行程,並提高員工生產力。

到2024年,直接熱感將佔據47.54%的市場佔有率,鞏固其在有效期不足12個月的短期運輸標籤領域的領先地位。染料擴散熱轉印目前仍處於小眾市場,但隨著醫療器材和高階包裝對清晰色彩漸層和照片級影像的需求日益成長,預計到2030年,其複合年成長率將達到5.54%。

直接熱感熱感採用無色帶設計,活動部件較少,購置和維護成本低,且能在極少人工干預下維持高列印量。然而,由於影像在紫外線照射下可能會變暗,在冷凍庫中可能會褪色,因此其在戶外和零下環境中的應用受到限制。熱轉印列印將蠟、蠟樹脂或樹脂墨水塗覆到薄膜狀的基材上,從而提供鋼製倉庫、電子標籤和高壓釜小瓶等管瓶所需的耐刮擦性和耐化學性。新型混合設備提供軟體可切換模式,使倉庫能夠使用經濟實惠的直接熱敏熱感列印出小包裹,並使用耐用的樹脂色帶列印五年期資產標籤。經機器學習輔助的墨水塗覆調整技術,其準確率檢驗R²=0.9916,可減少列印錯誤並延長列印頭壽命。同時,對無酚面塗層的研究促進了介質製造商和印表機原始設備製造商之間的合作,以校準熱曲線,防止印字頭過早磨損。這些技術創新使得熱感列印市場得以保持廣闊,其應用範圍涵蓋從快速消費品到關鍵工業領域。

熱感列印市場報告按應用(條碼、標籤、POS/收據、其他)、列印技術(直接熱感、熱轉印、染料擴散熱轉印)、格式類型(工業、其他)、最終用途行業(零售/電子商務、運輸/物流、製造/倉儲、其他)和地區(北美、歐洲、亞太、南美、中東/非洲)進行細分。

區域分析

北美地區佔2024年銷售額的35.65%,這主要得益於嚴格的醫療保健法規、廣泛的倉儲自動化以及數據豐富的2D碼和RFID標籤的廣泛應用。聯邦政府的可追溯性要求促使醫院和製藥公司隨著標準的演變更新印表機,而連鎖零售商則採用企業級管理套件來最佳化覆蓋數百家門市的設備。自疫情爆發以來,電子商務交易量持續成長。

受生態設計法規和消費者對酚類物質抵制情緒的推動,歐洲正在大力投資無雙酚介質的研發,並佔據了相當大的市場佔有率。該地區傾向於採用無底紙列印技術,以滿足減少廢棄物和碳足跡的目標。德國和北歐國家的製造商正在利用 OPC-UA 閘道器將印表機整合到工業 4.0 系統中,將標籤資料直接傳輸到數位雙胞胎,並創建批次系譜。對印字頭健康狀況的即時監控與該地區智慧工廠普遍採用的預測性維護策略相契合。

這是因為中國、印度和東協的物流業者正在建立密集的末端物流網路,需要即時產生標籤。例如,Epson將其秋田列印頭工廠的產能擴大三倍,這表明日本正在整合上游零件以滿足不斷成長的區域需求。日本本土印表機品牌正利用較低的人事費用吸引對價格敏感的中小型企業,而跨國第三方物流公司則正在進口企業級設備以滿足全球客戶的服務等級協定 (SLA)。印度的統一物流介面平台 (ULIP) 等政府計劃正在推動港口和鐵路的條碼標準化,進一步擴大了潛在用戶群。中東/非洲和南美洲在規模上相對落後,但隨著零售業現代化和公共機構資產追蹤數位化,這些地區的市場正在穩步成長。然而,外匯波動正在減緩續約速度,促使供應商提供訂閱模式,將資本支出分攤到多年合約中。

其他福利:

- Excel格式的市場預測(ME)表

- 3個月的分析師支持

目錄

第1章 引言

- 研究假設和市場定義

- 調查範圍

第2章調查方法

第3章執行摘要

第4章 市場情勢

- 市場概覽

- 市場促進因素

- AIDC(自動辨識與資料擷取)應用與電子商務物流蓬勃發展

- 無線和行動式熱敏印表機熱敏印表機的興起

- 與噴墨/雷射印表機相比,大批量標籤列印具有成本優勢。

- 醫療保健合規標籤需求日益成長

- 採用無襯紙和無BPAA的介質,促進永續性

- 低溫運輸物聯網整合實現即時追蹤

- 市場限制

- 高昂的維修和頭部更換成本

- 來自RFID和數位收據普及的競爭

- 雙酚A/苯酚法規增加媒體成本

- 紙漿價格波動擾亂紙張供應

- 供應鏈分析

- 監管環境

- 技術展望

- 波特五力分析

- 新進入者的威脅

- 買方的議價能力

- 供應商的議價能力

- 替代品的威脅

- 競爭對手之間的競爭

- 投資分析

第5章 市場規模與成長預測

- 透過使用

- 條碼

- POS/收據

- 標籤

- 卡片

- RFID

- 自助售票機和門票

- 行動裝置(手持裝置)

- 透過印刷技術

- 直接熱感(DT)

- 熱傳遞(TT)

- 染料擴散熱轉移(D2T2)

- 按格式

- 產業

- 桌面

- 移動的

- 按最終用途行業分類

- 零售與電子商務

- 運輸與物流

- 製造和倉儲

- 醫療保健和製藥

- 政府/公共

- 飯店及娛樂

- 銀行和金融服務

- 地區

- 北美洲

- 美國

- 加拿大

- 墨西哥

- 歐洲

- 德國

- 英國

- 法國

- 義大利

- 西班牙

- 俄羅斯

- 其他歐洲地區

- 亞太地區

- 中國

- 日本

- 印度

- 韓國

- ASEAN

- 亞太其他地區

- 中東和非洲

- 中東

- 沙烏地阿拉伯

- 阿拉伯聯合大公國

- 土耳其

- 其他中東地區

- 非洲

- 南非

- 奈及利亞

- 其他非洲地區

- 南美洲

- 巴西

- 阿根廷

- 其他南美洲

- 北美洲

第6章 競爭情勢

- 市場集中度

- 策略趨勢

- 市佔率分析

- 公司簡介

- Zebra Technologies

- SATO Holdings

- Toshiba TEC

- Honeywell International

- Brother Industries

- Star Micronics

- Seiko Instruments

- Citizen Systems

- Fujitsu Frontech

- Epson

- BIXOLON

- TSC Auto ID

- Printronix Auto ID

- Avery Dennison

- Evolis

- Axiohm

- CognitiveTPG

- Dymo(Newell)

- Posiflex Technology

- Xiamen Rongta Technology

第7章 市場機會與未來展望

The thermal printing market size is valued at USD 43.61 billion in 2025 and is projected to reach USD 53.85 billion by 2030, translating into a 4.31% CAGR across the period.

Sustained momentum comes from healthcare serialization rules, e-commerce parcel volumes, and industrial automation programs that rely on on-demand labels. Regulatory moves banning bisphenol-A and other phenols have triggered accelerated formulation shifts but have not diminished overall print volumes because compliant media options continue to expand. Advancements in IoT-ready printheads, remote fleet management software, and RFID-embedded label workflows strengthen the technology's relevance inside connected supply chains. Meanwhile, the higher cost of energy and consumables for inkjet or laser systems keeps thermal output attractive for high-volume businesses that ship, stock, or track millions of items annually. Investments by leading vendors in Asia-Pacific factories underline a decisive tilt of global capacity toward the region as multinational customers search for resilient supply networks.

Global Thermal Printing Market Trends and Insights

Adoption of AIDC and E-commerce Logistics Boom

Parcel operators shifting to two-dimensional barcodes ahead of the 2027 GS1 deadline are refreshing fleets to support higher-resolution QR output, sustaining hardware sales even as label-free returns programs roll out. Carrier trials show that thermal label volumes spike during peak seasons when order counts climb by 200% and real-time label generation prevents manual bottlenecks. Retailers also deploy cloud-linked mobile printers inside dark stores to print batch pick labels, closing data gaps between online order systems and last-mile couriers. These developments keep the thermal printing market firmly embedded in omnichannel logistics workflows. Finally, logistics hubs integrate print servers with warehouse execution software, allowing automatic printer allocation based on order routes and mitigating downtime risk.

Expansion of Wireless and Mobile Thermal Printers

New Wi-Fi 6-enabled models double data-throughput and reduce roaming drops, giving pickers uninterrupted label access while traveling across yards that span thousands of square meters. Continuous-run batteries now support an entire double shift, cutting mid-day recharge breaks that once halted outbound docks. Linerless capability trims media waste by 50%, pleasing sustainability auditors and raising effective roll capacity. Remote-management dashboards, such as SATO's Mobile Management System, alert IT teams to low media levels and head temperature anomalies, lowering field visit frequency. Fleet data also feeds predictive analytics models that schedule swap-outs before failures occur, raising overall equipment effectiveness metrics inside distribution centers.

High Repair and Head-replacement Costs

Thermal heads remain the most expensive consumable, often priced at 30% of a new unit, and intensive industrial users still swap them yearly. Complex smart printers embed secure elements and IoT modules that require factory-trained technicians, inflating labor bills. Smaller retailers defer maintenance until failures force emergency purchases, dampening refresh schedules. Vendors answer with harder coatings and quick-swap cassettes that let operators change heads without tools, reducing downtime to minutes. Predictive service algorithms embedded in device firmware also forecast failures before barcode darkness falls below scanner thresholds, though such upgrades increase upfront acquisition prices and may slow adoption in budget-constrained sectors.

Other drivers and restraints analyzed in the detailed report include:

- Cost-advantage Over Inkjet/Laser for High-volume Labels

- Growing Healthcare Compliance Labelling Needs

- Competition from RFID and Digital Receipt Adoption

For complete list of drivers and restraints, kindly check the Table Of Contents.

Segment Analysis

Barcode printing retained the largest position, accounting for 40.21% of thermal printing market share in 2024 as retailers, manufacturers, and logistics hubs relied on standardized one- and two-dimensional codes to move goods through automated workflows. The segment's scale is protected by global GS1 alignment, regulatory serialization mandates, and the low cost of consumables, keeping refresh demand stable even as digital transformation shifts some transactions online.

Within the overall thermal printing market size, mobile hand-held printing is projected to expand at a 7.34% CAGR from 2025 to 2030 because warehouse pickers, field technicians, and curbside grocery runners need real-time labels at the item level. Wi-Fi 6 connectivity, longer-life batteries, and linerless media options reduce downtime and waste, encouraging enterprises to replace fixed kiosks with belt-worn units that shorten travel paths and boost task productivity.

Direct thermal claimed 47.54% share in 2024, reinforcing its central place in short-life shipping labels where scannability under 12 months is acceptable. Dye-diffusion thermal transfer, although niche today, posts a 5.54% CAGR through 2030 as healthcare devices and luxury packaging require crisp color gradients and photo-quality graphics.

Direct thermal's simplicity-no ribbon, fewer moving parts-keeps acquisition and maintenance costs low, supporting high print cycles with minimal oversight. However, images can darken under UV exposure or fade in freezers, limiting usage in outdoor or sub-zero settings. Thermal transfer applies wax, wax-resin, or resin ink to filmic facestocks, achieving scratch and chemical resistance needed in steel stockrooms, electrical labeling, and laboratory vials that undergo autoclave sterilization. Emerging hybrid devices switch between modes via software, allowing warehouses to use economical direct thermal for outbound parcels and rugged resin ribbons for asset tags with 5-year life mandates. Machine-learning-assisted ink laydown tuning, verified by an R2 = 0.9916 accuracy score, reduces misprints and extends head life. Meanwhile, research into phenol-free top-coats spurs collaboration between media mills and printer OEMs to calibrate heat profiles that prevent premature head wear. These innovations ensure the thermal printing market maintains breadth across fast-moving consumer goods and mission-critical industrial contexts alike.

The Thermal Printing Market Report is Segmented by Application (Barcode, Label, POS / Receipt, and More ), Printing Technology (Direct Thermal, Thermal Transfer, Dye Diffusion Thermal Transfer), Format Type (Industrial, and More), End-Use Industry (Retail and E-Commerce, Transportation and Logistics, Manufacturing and Warehouse and More), and Geography (North America, Europe, Asia-Pacific, South America, Middle-East and Africa).

Geography Analysis

North America accounted for 35.65% of revenue in 2024 thanks to strict healthcare regulations, extensive warehouse automation, and high adoption of data-rich QR and RFID labelling. Federal traceability mandates ensure hospitals and pharmaceutical firms refresh printers as soon as standards evolve, and multi-site retailers standardize on enterprise-class management suites that optimize fleets across hundreds of stores. E-commerce volumes remain elevated post-pandemic, keeping parcel hubs focussed on rugged high-throughput units.

Europe follows with a sizable share, underpinned by eco-design regulations and consumer pushback against phenols, propelling R&D investments in bisphenol-free media. The region champions linerless adoption to satisfy waste-reduction directives and carbon-footprint goals. Manufacturers in Germany and the Nordic countries integrate printers with Industry 4.0 stacks, using OPC-UA gateways to feed label data directly into digital twins for batch genealogy. Real-time monitoring of printhead health aligns with predictive maintenance strategies prevalent in the region's smart factories.

Asia-Pacific is the fastest-growing slice, forecast at a 6.25% CAGR, as Chinese, Indian, and ASEAN logistics carriers build dense last-mile networks that require on-the-spot label generation. Investments like Epson's Akita printhead plant, tripling capacity, indicate upstream component consolidation in Japan serving rising regional demand. Domestic printer brands leverage lower labor costs to capture price-sensitive SMEs, while multinational 3PLs import enterprise-grade devices to satisfy global customer SLAs. Government projects such as India's Unified Logistics Interface Platform (ULIP) encourage barcode standardization across ports and railroads, further widening the addressable base. Middle East and Africa and South America trail in scale but register steady expansion as retail modernizes and public safety digitizes asset tracking; currency volatility, however, slows refresh cadence, prompting vendors to offer subscription models that spread capex over multi-year contracts.

List of Companies Covered in this Report:

- Zebra Technologies

- SATO Holdings

- Toshiba TEC

- Honeywell International

- Brother Industries

- Star Micronics

- Seiko Instruments

- Citizen Systems

- Fujitsu Frontech

- Epson

- BIXOLON

- TSC Auto ID

- Printronix Auto ID

- Avery Dennison

- Evolis

- Axiohm

- CognitiveTPG

- Dymo (Newell)

- Posiflex Technology

- Xiamen Rongta Technology

Additional Benefits:

- The market estimate (ME) sheet in Excel format

- 3 months of analyst support

TABLE OF CONTENTS

1 INTRODUCTION

- 1.1 Study Assumptions and Market Definition

- 1.2 Scope of the Study

2 RESEARCH METHODOLOGY

3 Executive Summary

4 Market Landscape

- 4.1 Market Overview

- 4.2 Market Drivers

- 4.2.1 Adoption of AIDC and e-commerce logistics boom

- 4.2.2 Expansion of wireless and mobile thermal printers

- 4.2.3 Cost-advantage over inkjet/laser for high-volume labels

- 4.2.4 Growing healthcare compliance labelling needs

- 4.2.5 Sustainability push for liner-less and BPA-free media

- 4.2.6 Cold-chain IoT integration for real-time tracking

- 4.3 Market Restraints

- 4.3.1 High repair and head-replacement costs

- 4.3.2 Competition from RFID and digital receipt adoption

- 4.3.3 BPA/phenol regulations raising media costs

- 4.3.4 Pulp-price volatility disrupting paper supply

- 4.4 Supply-Chain Analysis

- 4.5 Regulatory Landscape

- 4.6 Technological Outlook

- 4.7 Porter's Five Forces Analysis

- 4.7.1 Threat of New Entrants

- 4.7.2 Bargaining Power of Buyers

- 4.7.3 Bargaining Power of Suppliers

- 4.7.4 Threat of Substitutes

- 4.7.5 Competitive Rivalry

- 4.8 Investment Analysis

5 MARKET SIZE AND GROWTH FORECASTS (VALUE)

- 5.1 By Application

- 5.1.1 Barcode

- 5.1.2 POS / Receipt

- 5.1.3 Label

- 5.1.4 Card

- 5.1.5 RFID

- 5.1.6 Kiosk and Ticket

- 5.1.7 Mobile (hand-held)

- 5.2 By Printing Technology

- 5.2.1 Direct Thermal (DT)

- 5.2.2 Thermal Transfer (TT)

- 5.2.3 Dye Diffusion Thermal Transfer (D2T2)

- 5.3 By Format Type

- 5.3.1 Industrial

- 5.3.2 Desktop

- 5.3.3 Mobile

- 5.4 By End-Use Industry

- 5.4.1 Retail and E-commerce

- 5.4.2 Transportation and Logistics

- 5.4.3 Manufacturing and Warehouse

- 5.4.4 Healthcare and Pharma

- 5.4.5 Government and Public Safety

- 5.4.6 Hospitality and Entertainment

- 5.4.7 Banking and Financial Services

- 5.5 Geography

- 5.5.1 North America

- 5.5.1.1 United States

- 5.5.1.2 Canada

- 5.5.1.3 Mexico

- 5.5.2 Europe

- 5.5.2.1 Germany

- 5.5.2.2 United Kingdom

- 5.5.2.3 France

- 5.5.2.4 Italy

- 5.5.2.5 Spain

- 5.5.2.6 Russia

- 5.5.2.7 Rest of Europe

- 5.5.3 Asia-Pacific

- 5.5.3.1 China

- 5.5.3.2 Japan

- 5.5.3.3 India

- 5.5.3.4 South Korea

- 5.5.3.5 ASEAN

- 5.5.3.6 Rest of Asia-Pacific

- 5.5.4 Middle East and Africa

- 5.5.4.1 Middle East

- 5.5.4.1.1 Saudi Arabia

- 5.5.4.1.2 United Arab Emirates

- 5.5.4.1.3 Turkey

- 5.5.4.1.4 Rest of Middle East

- 5.5.4.2 Africa

- 5.5.4.2.1 South Africa

- 5.5.4.2.2 Nigeria

- 5.5.4.2.3 Rest of Africa

- 5.5.5 South America

- 5.5.5.1 Brazil

- 5.5.5.2 Argentina

- 5.5.5.3 Rest of South America

- 5.5.1 North America

6 COMPETITIVE LANDSCAPE

- 6.1 Market Concentration

- 6.2 Strategic Moves

- 6.3 Market Share Analysis

- 6.4 Company Profiles (includes Global level Overview, Market level overview, Core Segments, Financials as available, Strategic Information, Market Rank/Share for key companies, Products and Services, and Recent Developments)

- 6.4.1 Zebra Technologies

- 6.4.2 SATO Holdings

- 6.4.3 Toshiba TEC

- 6.4.4 Honeywell International

- 6.4.5 Brother Industries

- 6.4.6 Star Micronics

- 6.4.7 Seiko Instruments

- 6.4.8 Citizen Systems

- 6.4.9 Fujitsu Frontech

- 6.4.10 Epson

- 6.4.11 BIXOLON

- 6.4.12 TSC Auto ID

- 6.4.13 Printronix Auto ID

- 6.4.14 Avery Dennison

- 6.4.15 Evolis

- 6.4.16 Axiohm

- 6.4.17 CognitiveTPG

- 6.4.18 Dymo (Newell)

- 6.4.19 Posiflex Technology

- 6.4.20 Xiamen Rongta Technology

7 MARKET OPPORTUNITIES AND FUTURE OUTLOOK

- 7.1 White-space and Unmet-need Assessment