|

市場調查報告書

商品編碼

1693611

歐洲機器狀態監測:市場佔有率分析、產業趨勢與統計、成長預測(2025-2030 年)Europe Machine Condition Monitoring - Market Share Analysis, Industry Trends & Statistics, Growth Forecasts (2025 - 2030) |

||||||

※ 本網頁內容可能與最新版本有所差異。詳細情況請與我們聯繫。

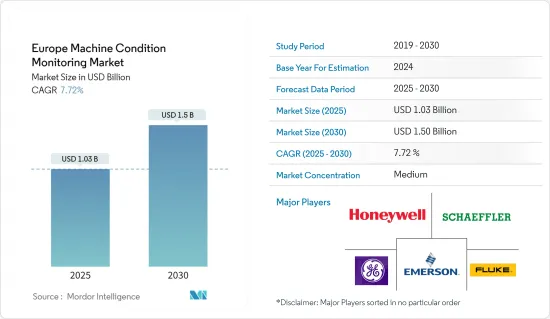

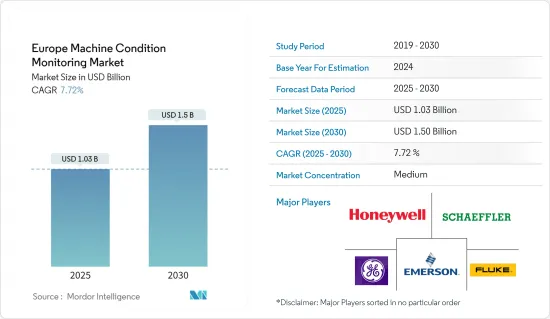

預計 2025 年歐洲機器狀態監測市場規模為 10.3 億美元,到 2030 年將達到 15 億美元,預測期內(2025-2030 年)的複合年成長率為 7.72%。

低成本、大量生產的前景使得維修專業人員轉向狀態監測。主動的機器狀態監控可以幫助多個行業防止機器故障。

主要亮點

- 任何企業的主要目標之一是延長其資產的生命週期並確保其長期有效運作。這可以透過使用狀態監測來實現。對於機械來說,維護保養極為重要。由於許多公司都專注於提高資產利用率和生產力,因此機器狀態監測是維護的重要組成部分。

- 預測維修系統可以透過狀態監控工具幫助組織追蹤任何設備或機械在空閒、正常和尖峰時段的表現。從各種條件下運作的機器獲得的數據有助於規劃未來的維護,以防止突然故障和停機。

- 自動化機器監控是實現智慧工廠的第一步。在智慧工廠中,機器與基於物聯網和網路的感測器互連,以促進即時機器資料提取。互聯機器網路可協助您深入了解機器效能,從而提高連續生產能力並分析預計產量與實際產量的比率。

- 智慧製造和工業4.0的興起增加了監控工廠生產設備狀況的可能性。可以部署實體感測器來收集工廠車間的數據,然後在工作站的儀表板上進行處理和視覺化。這可以讓您概覽機器的狀況並提高正常運作和效率。

- 所有歐洲企業都擁有生產商品和服務以創造收益的關鍵資產,但由於新冠疫情,這些資產都在迅速下滑。這類公司經營團隊感受到了極度的危機感和恐慌,越來越重視削減成本。由於製造業活動疲軟,公司可能會傾向於跳過維護,這可能會導致預測期內高成本。

歐洲機器狀態監測市場趨勢

工業 4.0 和製造業及製程工業的新興產業應用

- 工業 4.0 將改變企業製造、改進和分銷產品的方式。製造商擴大將物聯網、雲端運算和分析、人工智慧和機器學習等新興技術融入他們的生產設施和業務中。

- 此外,過去,預防性維護有助於減少機器停機時間並避免意外停機。工業 4.0 帶來了一種確保機器可用性的新方法,稱為狀態監控。它持續監控機器數據以檢測磨損情況,從而更容易安排維修並減少停機時間。由於只需要更換磨損的零件,因此它還具有降低維護成本的潛力。

- 工業 4.0 將使工廠從舊有系統轉變為智慧組件和智慧機器,實現數位化工廠並最終實現工廠和企業生態系統的互聯。這種智慧工廠通常配備先進的感測器、嵌入式軟體和機器人,可以收集和分析數據,從而做出更好的決策。

- 自動化機器狀態監測是實現智慧工廠的第一步。在智慧工廠中,機器與基於物聯網和網路的感測器互連,以促進即時機器資料提取。互聯機器網路可協助您深入了解機器效能,從而提高連續生產能力並分析預計產量與實際產量的比率。根據ETNO預測,到2027年,歐洲汽車產業將擁有2.23億個活躍的物聯網(IoT)連接,工業領域將擁有1,900萬個活躍的物聯網(IoT)連接。

- 透過機器監控還可以改善車間和工廠車間的溝通。生產車間的製造商和操作員可以透過分析、警報和其他通知來了解機器行為,從而擴大生產過程的可見性,激發相關人員更好的意識和參與。機器監控對於為所有相關人員創造機會連接獨立的車間操作至關重要,以考慮智慧工廠所必需的更廣泛的性能和流程結果。

- 總體而言,當生產過程中的機器或資產受到即時監控且人工干預最少時,智慧工廠是有效的。透過追蹤壓力、振動、溫度和噪音等幾個參數,機械監控可以確定資產的健康狀況。也會識別機器性能指標,並立即報告任何劣化或有缺陷的零件。

德國擁有龐大的市場佔有率

- 汽車工業是德國最大的工業之一。該公司在自動駕駛技術等高科技汽車產品方面也擁有世界領先的實力。據德國貿易投資署 (GTAI) 稱,德國是歐洲最大的汽車市場,佔所有乘用車產量的 25% 左右,佔新註冊汽車的 20% 左右。

- 據 GTAI 稱,德國汽車製造商去年生產了超過 1560 萬輛汽車。德國工廠生產了超過310萬輛乘用車和351,000輛商用車。因此,該行業對狀態監測解決方案的需求龐大,以確保車輛的安全運作。

- 根據OICA的數據,德國新車銷售和註冊量有所成長,2019年達到402萬輛。疫情期間製造業停擺導致隔年銷售量降至約327萬輛。新車銷量和註冊量下降,2021 年年比 2019 年下降 26% 至 297 萬輛。

- 該市場也受益於該國強大的海運業。德國是世界上最大的航運國家之一。據聯邦數位事務和運輸部稱,該國在貨櫃航運領域的國際佔有率約為 30%。德國航運業的年營業額超過500億歐元(525.1億美元)。

- 在船舶的日常運作中,結構和機械故障可能導致嚴重事故,損壞船舶,危及船員和乘客安全,威脅環境並造成重大經濟損失。狀態監測作為一種經濟高效且可以使船舶免受此類風險的維護策略,在船舶工業中越來越受歡迎。船上狀態監測有助於監測關鍵船上資產,如主引擎、推進器、發電機、壓縮機、泵浦等。

- 此外,2022 年 4 月,總部位於德國的旋轉機械狀態監測解決方案全球供應商 Bruel&Kjaer Vibro(B&K Vibro)宣布對其 VCM-3/SETPOINT 產品進行一系列增強,以提供單一、整合的 SETPOINT 狀態監測系統 (CMS) 解決方案。 VCM-3 資料與 VC-8000 資料完全整合,可以直接匯入 SETPOINT CMS。

歐洲機器狀態監測產業概況

歐洲機器狀態監測市場較為分散,包括Honeywell國際公司、舍弗勒技術股份公司、通用電氣公司、艾默生電氣公司和福祿克公司。市場參與者正在採取夥伴關係、創新、合併和收購等策略來增強其產品供應並獲得永續的競爭優勢。

2022年7月,通用電氣宣布計畫成為三家獨立的上市公司,專注於醫療保健、能源和航空。 GE的醫療保健業務將被稱為GE醫療集團。 GE現有的能源組合,包括可再生能源、電力、數位和能源金融服務,將合併到GE Vernova品牌下。 GE Aerospace 將成為 GE 航空業務的名稱。

2022年5月,NI宣布推出ActiveUptime,這是一款用於測試設備和設施狀態監控和預測性維護的即服務解決方案。此承包解決方案根據您的環境進行客製化,並提供您所需的資訊以主動監控系統健康狀況並防止關鍵測試設備發生故障。作為持續服務的一部分,NI 維護團隊的專職技術人員將遠端監控系統健康狀況、提供支援並根據客戶需求調整解決方案。此解決方案可主動預測故障發生之前的情況。

其他福利:

- Excel 格式的市場預測 (ME) 表

- 3個月的分析師支持

目錄

第1章 引言

- 研究假設和市場定義

- 研究範圍

第2章調查方法

第3章執行摘要

第4章 市場洞察

- 市場概覽

- 產業吸引力-波特五力分析

- 供應商的議價能力

- 買家的議價能力

- 新進入者的威脅

- 替代品的威脅

- 競爭對手之間的競爭強度

- COVID-19 市場影響評估

第5章市場動態

- 市場促進因素

- 透過預測性維護提高設備性能和生產力

- 工業4.0及製造業及製程工業的新興產業應用

- 市場挑戰/限制

- 改裝的成本影響

- 歐洲宏觀經濟與地緣政治因素

第6章市場區隔

- 按類型

- 硬體

- 振動狀態監測裝置

- 熱成像設備

- 潤滑劑分析

- 軟體

- 服務

- 硬體

- 按行業

- 石油和天然氣

- 發電

- 工藝與製造

- 航太與國防

- 汽車與運輸

- 其他產業(海洋、採礦、金屬等)

- 按國家

- 英國

- 德國

- 法國

- 義大利

- 其他歐洲國家國家(東歐和西歐)

第7章競爭格局

- 公司簡介

- Honeywell International Inc.

- Schaeffler Technologies AG & Co. KG

- General Electric Company

- Emerson Electric Co.

- Fluke Corporation

- Ametek Spectro Scientific

- Parker Hannifin Corporation

- Rockwell Automation Inc.

- SKF AB

- Als Limited

- National Instruments Corporation

- Flirn Systems Inc.

第8章投資分析

第9章:市場的未來

The Europe Machine Condition Monitoring Market size is estimated at USD 1.03 billion in 2025, and is expected to reach USD 1.50 billion by 2030, at a CAGR of 7.72% during the forecast period (2025-2030).

An outlook toward low-cost mass production has led maintenance professionals to turn to condition monitoring. With active machine condition monitoring, multiple industries can prevent machine failures, which is an added capital investment.

Key Highlights

- One of the primary goals of any business is to prolong an asset's lifecycle and ensure that the asset functions efficiently for an extended period. This can be accomplished through the use of condition monitoring. Maintenance is crucial to machines. Machine condition monitoring is an important part of maintenance, and thus, many companies have been focusing more on asset utilization and increasing productivity.

- Predictive maintenance systems can help organizations with condition-monitoring tools to track the performance of any equipment or machine in idle, normal, and peak performances. The data from machines operating at different conditions helps plan maintenance in the future to prevent sudden failure or downtime.

- Automated machine monitoring forms the first step toward achieving smart factories. In a smart factory, machines are interconnected with IoT-enabled, web-based sensors that facilitate real-time machine data extraction. The network of connected machines helps obtain valuable insights into machine performance, enhances ongoing production, and analyzes estimated versus actual production ratios.

- The rise of smart manufacturing and Industry 4.0 increased the possibility of monitoring the condition of the production equipment in a factory. Physical sensors can be deployed to collect data from the factory floor, and they can be processed and visualized on a dashboard on a workstation. This provides an overview of the condition of the machines and enables increased uptime and efficiency.

- All European businesses have crucial assets for manufacturing goods and services offering revenue, experiencing a rapid decline due to the COVID-19 pandemic. The management of such companies has been feeling extreme urgency and panic, increasing the emphasis on cutting costs. Since manufacturing activity is low, companies are tempted to eliminate maintenance, which can result in high costs during the forecast period.

Europe Machine Condition Monitoring Market Trends

Industry 4.0 and Emerging Industrial Applications Across Manufacturing and Process Industries

- Industry 4.0 transforms how organizations manufacture, improve, and distribute their products. Manufacturers are increasingly integrating emerging technologies, such as IoT, cloud computing and analytics, and AI and machine learning, into their production facilities and operations.

- Moreover, in the past, preventive maintenance helped reduce machine downtime and avoid unscheduled outages. Industry 4.0 brought a new method of ensuring machine availability called condition monitoring. It involves continuous monitoring of machine data to detect wear, making it easier to schedule repairs and reduce downtime. The method also has the potential to lower maintenance costs, as only worn-out parts need replacing.

- Industry 4.0 is transitioning factories from legacy systems to smart components and machines, enabling digital factories and, eventually, an ecosystem of connected factories and enterprises. These smart factories are commonly equipped with advanced sensors, embedded software, and robotics that collect and analyze data, allowing for better decision-making.

- Automated machine monitoring forms the first step toward achieving smart factories. In a smart factory, machines are interconnected with IoT-enabled, web-based sensors that facilitate real-time machine data extraction. The network of connected machines helps obtain valuable insights into machine performance, enhances ongoing production, and analyzes estimated versus actual production ratios. According to ETNO, the active Internet of Things (IoT) connections in the automotive sector would be 223 million, and industries would be 19 million across Europe by 2027.

- Shop or factory floor communications can also be improved with machine monitoring. Manufacturers and operators across the shop floor are informed on machine behavior through analytics, warnings, and other notifications that expand production process visibility, creating a catalyst for better stakeholder awareness and engagement. Machine monitoring is vital for creating an opportunity for all stakeholders to connect individual, independent shop floor operations to account for broader performance and process outcomes that are essential for a smart factory.

- Overall, a smart factory is effective when machines or assets in the production process are monitored in real-time with minimal manual intervention. By tracking several parameters like pressure, vibration, temperature, and noise, machine monitoring determines asset health conditions. Machine performance metrics are also identified, and any deterioration or faulty part is immediately reported.

Germany Holds the Highest Market Share

- The automotive sector is one of the largest industries in Germany. The country is also one of the strongest in the world when it comes to high-tech automotive products, including autonomous driving technology. Germany is Europe's largest automotive market, accounting for around 25% of all passenger cars manufactured and almost 20% of all new registrations, according to the Germany Trade and Invest (GTAI).

- Also, as per GTAI, German automobile manufacturers produced more than 15.6 million vehicles the previous year. Over 3.1 million passenger cars and 351,000 commercial vehicles were manufactured in German plants. Consequently, there was a significant demand for condition monitoring solutions from this sector to ensure the safe operation of vehicles.

- According to OICA, new car sales and registrations in Germany increased, reaching 4.02 million in 2019. Due to the manufacturing halt during the pandemic, the sales decreased to approximately 3.27 million the following year. New sales and registrations decreased, with 2.97 million in 2021, a 26% decrease from 2019.

- The market also benefits from a strong maritime industry in the country. Germany is among the largest seafaring nations globally. According to the Federal Ministry for Digital and Transport, the country has an international market share of around 30% in the container shipping sector. The German shipping industry generates an annual turnover of over EUR 50 billion (USD 52.51 billion).

- In day-to-day ship operations, structural and mechanical failures might result in serious accidents, inflicting ship damage, placing the crew and passengers on board in danger, posing a threat to the environment, and causing substantial financial losses. As a cost-efficient and effective maintenance strategy that can save ships from such risks, condition monitoring is gaining popularity in the marine industry. Condition monitoring in onboard ships helps monitor critical onboard assets, such as main engines, thrusters, generators, compressors, and pumps.

- Moreover, in April 2022, Germany-based Bruel& Kjaer Vibro(B&K Vibro), a global supplier of condition monitoring solutions for rotating machinery, introduced an array of product enhancements for its VCM-3/SETPOINT offerings to provide a single, integrated SETPOINT condition monitoring system (CMS) solution. The data from VCM-3 can be fully integrated with VC-8000 data and fed directly into SETPOINT CMS, creating a plant-wide solution that encompasses machine protection and condition monitoring for critical and BOP machinery assets.

Europe Machine Condition Monitoring Industry Overview

The European machine condition monitoring market is moderately fragmented, with key players like Honeywell International Inc., Schaeffler Technologies AG & Co. KG, General Electric Company, Emerson Electric Co., and Fluke Corporation, among others. Players in the market are adopting strategies such as partnerships, innovations, mergers, and acquisitions to enhance their product offerings and gain sustainable competitive advantage.

In July 2022, GE announced plans to become three independent and publicly traded businesses focusing on healthcare, energy, and aviation, where new names also reflect a new beginning. GE's healthcare business would be called GE HealthCare. GE's existing portfolio of energy businesses, including renewable energy, power, digital, and energy financial services, would sit together under the brand name GE Vernova. GE Aerospace would be the name of GE's aviation business.

In May 2022, NI announced the launch of ActiveUptime, its maintenance-as-a-service solution for condition monitoring and predictive maintenance of test equipment and facilities. This turnkey solution is tailored to the user's environment and provides the information needed to proactively monitor system health and prevent critical test equipment from failing. As part of the ongoing service, a dedicated technician from NI's maintenance team is expected to remotely monitor system health, provide support, and adapt the solution based on the customer's needs. This solution advances the user's capabilities to predict outages before they happen proactively.

Additional Benefits:

- The market estimate (ME) sheet in Excel format

- 3 months of analyst support

TABLE OF CONTENTS

1 INTRODUCTION

- 1.1 Study Assumptions and Market Definition

- 1.2 Scope of the Study

2 RESEARCH METHODOLOGY

3 EXECUTIVE SUMMARY

4 MARKET INSIGHTS

- 4.1 Market Overview

- 4.2 Industry Attractiveness - Porter's Five Forces Analysis

- 4.2.1 Bargaining Power of Suppliers

- 4.2.2 Bargaining Power of Buyers

- 4.2.3 Threat of New Entrants

- 4.2.4 Threat of Substitutes

- 4.2.5 Intensity of Competitive Rivalry

- 4.3 Assessment of the Impact of COVID-19 on the Market

5 MARKET DYNAMICS

- 5.1 Market Drivers

- 5.1.1 Increasing Equipment Performance and Productivity through Predictive Maintenance

- 5.1.2 Industry 4.0 and Emerging Industrial Applications Across Manufacturing and Process Industries

- 5.2 Market Challenges/Restraints

- 5.2.1 Cost Implications In Line With Retrofits

- 5.2.2 European Macroeconomic and Geopolitical Factors

6 MARKET SEGMENTATION

- 6.1 By Type

- 6.1.1 Hardware

- 6.1.1.1 Vibration Condition Monitoring Equipment

- 6.1.1.2 Thermography Equipment

- 6.1.1.3 Lubricating Oil Analysis

- 6.1.2 Software

- 6.1.3 Services

- 6.1.1 Hardware

- 6.2 By End-user Vertical

- 6.2.1 Oil and Gas

- 6.2.2 Power Generation

- 6.2.3 Process and Manufacturing

- 6.2.4 Aerospace and Defense

- 6.2.5 Automotive and Transportation

- 6.2.6 Other End-user Verticals (marine, Mining, Metal, Etc.)

- 6.3 By Country

- 6.3.1 United Kingdom

- 6.3.2 Germany

- 6.3.3 France

- 6.3.4 Italy

- 6.3.5 Rest of Europe (Eastern Europe and Western European Countries)

7 COMPETITIVE LANDSCAPE

- 7.1 Company Profiles

- 7.1.1 Honeywell International Inc.

- 7.1.2 Schaeffler Technologies AG & Co. KG

- 7.1.3 General Electric Company

- 7.1.4 Emerson Electric Co.

- 7.1.5 Fluke Corporation

- 7.1.6 Ametek Spectro Scientific

- 7.1.7 Parker Hannifin Corporation

- 7.1.8 Rockwell Automation Inc.

- 7.1.9 SKF AB

- 7.1.10 Als Limited

- 7.1.11 National Instruments Corporation

- 7.1.12 Flirn Systems Inc.