|

市場調查報告書

商品編碼

1693371

印度黏合劑:市場佔有率分析、行業趨勢和統計數據、成長預測(2025-2030 年)India Adhesives - Market Share Analysis, Industry Trends & Statistics, Growth Forecasts (2025 - 2030) |

||||||

價格

※ 本網頁內容可能與最新版本有所差異。詳細情況請與我們聯繫。

簡介目錄

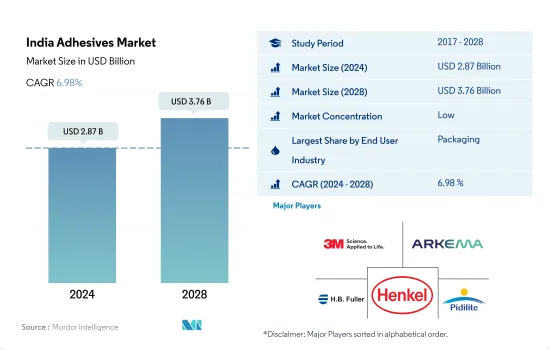

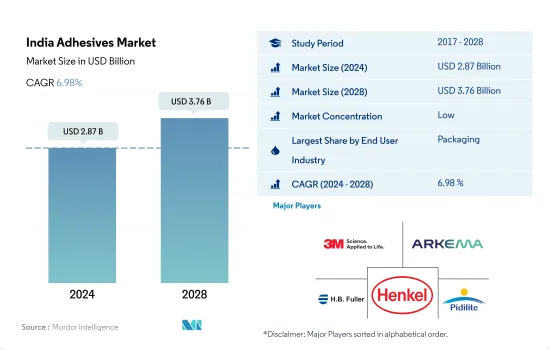

印度黏合劑市場規模預計在 2024 年為 28.7 億美元,預計到 2028 年將達到 37.6 億美元,預測期內(2024-2028 年)的複合年成長率為 6.98%。

汽車市場的崛起和不斷發展的技術主導包裝趨勢預計將推動印度黏合劑的消費

- 受新冠疫情影響,2020年印度膠合劑消費量呈下降趨勢。與2019年相比,當年的產量以金額為準下降了9.94%。生產設施關閉近三個月以及原料短缺是印度黏合劑消費量下降的主要因素。

- 包裝是印度經濟第五大產業,也是該國成長最快的產業之一。根據印度包裝產業協會(PIAI)的數據,該產業的複合年成長率為 22% 至 25%。過去幾年,包裝產業在推動國家技術和創新發展以及為農業和快速消費品等其他製造業增值方面發揮了關鍵作用。根據印度包裝協會(IIP)的數據,印度的包裝消費量在過去十年中飆升了200%,從2010年的人均每年4.3公斤增加到2020年的8.6公斤。

- 印度也是一個重要的汽車出口國,預計在不久的將來出口將實現快速成長。此外,隨著印度政府和各大汽車公司在印度市場採取各種舉措,預計未來幾年印度將成為二輪車和四輪車市場的領導者。 2021 年印度乘用車市場價值為 327 億美元,預計到 2027 年將達到 548.4 億美元,2022 年至 2027 年的複合年成長率將超過 9%。預計到 2025 年印度電動車 (EV) 產業價值將達到 70.9 億美元。這往往會增加對黏合劑的需求。

印度黏合劑市場趨勢

更便宜、更輕的包裝趨勢日益成長,推動了對軟質和硬質塑膠包裝的需求

- 包裝是設計和工程方面成長最快的行業之一,旨在保護和提高產品的安全性和壽命。人們對清潔水、乾淨的新鮮食品和藥品的需求日益增加,先進技術的快速採用也推動了包裝產業的發展。包裝業已連續多年成為日本經濟第五大產業。過去十年,包裝產品的使用量增加了200%以上,預計到2020年底,人均年消費量將從4.3公斤增加到8.6公斤。由於農業生產和快速消費品領域的應用不斷增加,印度很可能在不久的將來見證顯著的成長。

- 新冠疫情導致全國停工和部分製造工廠關閉,擾亂了供應鏈管道和進出口貿易。因此,該國的包裝產量在 2020 年下降了 5%,但由於公共衛生問題導致需求增加,2021 年產量輕鬆回升。該國的包裝生產主要由塑膠包裝驅動,約佔 2021 年包裝產量的 82%。由於對廉價、輕質軟性和剛性包裝的需求不斷增加,塑膠生產部門預計在預測期內將以約 6.88% 的複合年成長率快速成長。

- 印度包裝產業的成長主要得益於近年來中階人口的增加、供應鏈系統的改善以及電子商務活動的興起。此外,全國對食品安全和品質的關注度日益提高,推動了食品加工行業的發展並刺激了包裝需求。

政府推出的 e-AMRIT 等措施以及汽車貸款利率降低 2-3% 將推動汽車製造業

- 預計到2020年,印度汽車產業將成為亞太地區第四大汽車生產國。政府在2021年撥款4.32兆印度盧比擴建道路等措施也導致道路上車輛數量的增加。預計這一成長趨勢將持續到2028年。

- 由於全國範圍內的封鎖、供應鏈中斷和整體經濟放緩,新冠疫情導致乘用車銷售量從 2019 年的 338 萬輛下降到 2021 年的 239 萬輛。然而,由於政府為支持汽車製造業所做的努力,例如將汽車貸款利率降低 2-3%,這一數字在 2022 年 3 月上升至 272 萬輛。在乘用車領域,瑪魯蒂鈴木是最大的品牌,2021 年的市場佔有率為 52%。預計這一成長趨勢將在預測期內(2022-2028 年)持續下去。

- 商用車方面,塔塔汽車銷售量最大,2022年3月市場佔有率接近43%。商用車銷量從2021年的568,560輛增加至2022年3月的716,570輛,這得益於2020年新冠疫情引發的虧損經濟復甦。商用車銷量從2021年的568,560輛增加至2022年3月的716,570輛,這得益於2020年新冠疫情引發的虧損經濟復甦。

- 印度政府透過 e-AMRIT 等舉措推動電動車製造業的發展,這將推動 2028 年前電動車產量的增加。與 2020 年相比,2021 年印度的電動車銷量將成長 108%。

印度膠黏劑產業概況

印度黏合劑市場較為分散,前五大公司佔27.19%的市場。市場的主要企業有:3M、阿科瑪集團、HB Fuller Company、漢高股份公司和 Pidilite Industries Ltd.。

其他福利

- Excel 格式的市場預測 (ME) 表

- 3個月的分析師支持

目錄

第1章執行摘要和主要發現

第2章 報告要約

第3章 引言

- 研究假設和市場定義

- 研究範圍

- 調查方法

第4章 產業主要趨勢

- 最終用戶趨勢

- 航太

- 車

- 建築與施工

- 鞋類皮革

- 包裝

- 木製品和配件

- 法律規範

- 印度

- 價值鍊和通路分析

第5章市場區隔

- 最終用戶產業

- 航太

- 車

- 建築與施工

- 鞋類和皮革

- 醫療保健

- 包裝

- 木製品和配件

- 其他

- 科技

- 熱熔膠

- 反應性

- 溶劑型

- 紫外線固化膠合劑

- 水性

- 樹脂

- 丙烯酸纖維

- 氰基丙烯酸酯

- 環氧樹脂

- 聚氨酯

- 矽膠

- VAE,EVA

- 其他

第6章競爭格局

- 關鍵策略趨勢

- 市場佔有率分析

- 商業狀況

- 公司簡介

- 3M

- Arkema Group

- ASTRAL ADHESIVES

- AVERY DENNISON CORPORATION

- HB Fuller Company

- Henkel AG & Co. KGaA

- Huntsman International LLC

- Jubilant Industries Ltd.

- Pidilite Industries Ltd.

- Sika AG

第7章:CEO面臨的關鍵策略問題

第 8 章 附錄

- 全球黏合劑和密封劑產業概況

- 概述

- 五力分析框架(產業吸引力分析)

- 全球價值鏈分析

- 促進因素、限制因素和機會

- 資訊來源及延伸閱讀

- 圖片列表

- 關鍵見解

- 數據包

- 詞彙表

簡介目錄

Product Code: 92426

The India Adhesives Market size is estimated at 2.87 billion USD in 2024, and is expected to reach 3.76 billion USD by 2028, growing at a CAGR of 6.98% during the forecast period (2024-2028).

Emerging automotive market and evolving trend of technology driven packaging expected to boost the consumption of adhesives in India

- The consumption of adhesives in India has shown a downward trend in 2020 due to the impact of COVID-19. The production was reduced by 9.94% in terms of value in the same year compared to 2019. The lockdown in the country for nearly three months, due to which production facilities were shut down, and raw material shortages are some of the major reasons for the decline in adhesives consumption in India.

- Packaging is the fifth-largest industry in India's economy and one of the fastest-growing sectors in the country. The sector is developing at a CAGR of 22% to 25%, according to the Packaging Industry Association of India (PIAI). Over the last several years, the packaging industry has played a vital role in driving technology and innovation growth in the country and delivering value to other manufacturing sectors like agriculture and FMCG. According to the Indian Institute of Packaging (IIP), packaging consumption in India has surged 200% over the last decade, reaching 8.6 kg per person per year in 2020 from 4.3 kilograms per person per year in 2010.

- India is also a significant vehicle exporter, with high export growth expected in the near future. Furthermore, various efforts by the Government of India and key automobile firms in the Indian market will likely propel India to the forefront of the two- and four-wheeler markets in the coming periods. The Indian passenger vehicle market was valued at USD 32.70 billion in 2021, and it is predicted to reach USD 54.84 billion by 2027, with a CAGR of more than 9% between 2022 and 2027. The electric vehicle (EV) industry in India is expected to reach USD 7.09 billion by 2025. This tends to increase the demand for adhesives.

India Adhesives Market Trends

Rising trend of cheap and lightweight packaging to drive the demand for flexible and rigid plastic packaging

- Packaging is one of the fast-growing industries in terms of design and technology for protecting and enhancing products' safety and longevity. The rising demand for clean water, clean and fresh food, and pharmaceuticals, along with the rapid adoption of advanced technologies driving the packaging industry. Packaging has registered as the fifth-largest sector in the country's economy over the past few years. The usage of packaging products has increased by over 200% in the past decade, which has registered consumption from 4.3 Kg per person per annum to 8.6 Kg per person per annum by the end of 2020. Owing to rising applications in agriculture production and the FMCG sector, India is likely to gain significant growth in the near future.

- Due to the COVID-19 pandemic, the country-wide lockdowns and partial suspension of manufacturing facilities caused disrupted supply-chain channels and imports and exports trade. As a result, the country's packaging production declined by 5% in 2020 but readily recovered in 2021, owing to rising demand for public health concerns. Packaging production is majorly driven by plastic packaging in the country, which nearly accounts for around 82% of the packaging produced in 2021. With the increasing demand for cheap and lightweight flexible and rigid packaging, the plastic production segment is likely to register the fastest growth of around 6.88% CAGR during the forecast period.

- The growth of the Indian packaging industry is mainly attributed to the rising middle-class population, improvement of the supply-chain system, and emerging e-commerce activities in recent years. Furthermore, the growing attention to food safety and quality across the nation is likely to drive the food processing industry, thus, propelling the packaging demand.

Rising government initiatives such as e-AMRIT and auto loan interest rates decrease by 2-3% to lead the automotive manufacturing

- The Indian automotive industry was the fourth largest in the Asia-Pacific by volume in 2020. With the government initiatives such as the expansion of roads in 2021 by allocation of funds of INR 4.32 trillion, the number of vehicles has also increased on roads. This trend of growth is expected to sustain in the coming years up to 2028.

- Due to the COVID-19 pandemic, there was a dip in sales of passenger vehicles from 3.38 million in 2019 to 2.39 million in 2021 because of nationwide lockdown, supply chain disruptions, and overall economic slowdown. But, with the government initiatives to support the automobile manufacturing sector, such as decreasing interest rates for auto loans by 2-3%, it moved up to 2.72 million vehicles by March 2022. Maruti Suzuki is the largest in the passenger vehicles segment, with a market share of 52% in 2021. This growth trend is expected to sustain in the forecast period, which is 2022-2028.

- In the case of commercial vehicles, Tata Motors is the largest vehicle producer by number, with a market share of nearly 43% in March 2022. The commercial vehicle sales increased from 568,560 in 2021 to 716570 by March 2022 because of recovering loss-ridden economy due to the impact of COVID-19 in 2020. With this growing post-pandemic economy, it is expected to increase in the mentioned period.

- The electric vehicle manufacturing push by the Indian government with initiatives such as e-AMRIT will lead increase in the production of electric vehicles in years up to 2028. The increase in the number of electric vehicles being sold in India increased by 108% in 2021 compared to 2020.

India Adhesives Industry Overview

The India Adhesives Market is fragmented, with the top five companies occupying 27.19%. The major players in this market are 3M, Arkema Group, H.B. Fuller Company, Henkel AG & Co. KGaA and Pidilite Industries Ltd. (sorted alphabetically).

Additional Benefits:

- The market estimate (ME) sheet in Excel format

- 3 months of analyst support

TABLE OF CONTENTS

1 EXECUTIVE SUMMARY & KEY FINDINGS

2 REPORT OFFERS

3 INTRODUCTION

- 3.1 Study Assumptions & Market Definition

- 3.2 Scope of the Study

- 3.3 Research Methodology

4 KEY INDUSTRY TRENDS

- 4.1 End User Trends

- 4.1.1 Aerospace

- 4.1.2 Automotive

- 4.1.3 Building and Construction

- 4.1.4 Footwear and Leather

- 4.1.5 Packaging

- 4.1.6 Woodworking and Joinery

- 4.2 Regulatory Framework

- 4.2.1 India

- 4.3 Value Chain & Distribution Channel Analysis

5 MARKET SEGMENTATION (includes market size in Value in USD and Volume, Forecasts up to 2028 and analysis of growth prospects)

- 5.1 End User Industry

- 5.1.1 Aerospace

- 5.1.2 Automotive

- 5.1.3 Building and Construction

- 5.1.4 Footwear and Leather

- 5.1.5 Healthcare

- 5.1.6 Packaging

- 5.1.7 Woodworking and Joinery

- 5.1.8 Other End-user Industries

- 5.2 Technology

- 5.2.1 Hot Melt

- 5.2.2 Reactive

- 5.2.3 Solvent-borne

- 5.2.4 UV Cured Adhesives

- 5.2.5 Water-borne

- 5.3 Resin

- 5.3.1 Acrylic

- 5.3.2 Cyanoacrylate

- 5.3.3 Epoxy

- 5.3.4 Polyurethane

- 5.3.5 Silicone

- 5.3.6 VAE/EVA

- 5.3.7 Other Resins

6 COMPETITIVE LANDSCAPE

- 6.1 Key Strategic Moves

- 6.2 Market Share Analysis

- 6.3 Company Landscape

- 6.4 Company Profiles (includes Global Level Overview, Market Level Overview, Core Business Segments, Financials, Headcount, Key Information, Market Rank, Market Share, Products and Services, and Analysis of Recent Developments).

- 6.4.1 3M

- 6.4.2 Arkema Group

- 6.4.3 ASTRAL ADHESIVES

- 6.4.4 AVERY DENNISON CORPORATION

- 6.4.5 H.B. Fuller Company

- 6.4.6 Henkel AG & Co. KGaA

- 6.4.7 Huntsman International LLC

- 6.4.8 Jubilant Industries Ltd.

- 6.4.9 Pidilite Industries Ltd.

- 6.4.10 Sika AG

7 KEY STRATEGIC QUESTIONS FOR ADHESIVES AND SEALANTS CEOS

8 APPENDIX

- 8.1 Global Adhesives and Sealants Industry Overview

- 8.1.1 Overview

- 8.1.2 Porter's Five Forces Framework (Industry Attractiveness Analysis)

- 8.1.3 Global Value Chain Analysis

- 8.1.4 Drivers, Restraints, and Opportunities

- 8.2 Sources & References

- 8.3 List of Tables & Figures

- 8.4 Primary Insights

- 8.5 Data Pack

- 8.6 Glossary of Terms

02-2729-4219

+886-2-2729-4219