|

市場調查報告書

商品編碼

1871082

用於包裝應用的纖維素奈米晶體市場機會、成長促進因素、產業趨勢分析及預測(2025-2034年)Cellulose Nanocrystals for Packaging Applications Market Opportunity, Growth Drivers, Industry Trend Analysis, and Forecast 2025 - 2034 |

||||||

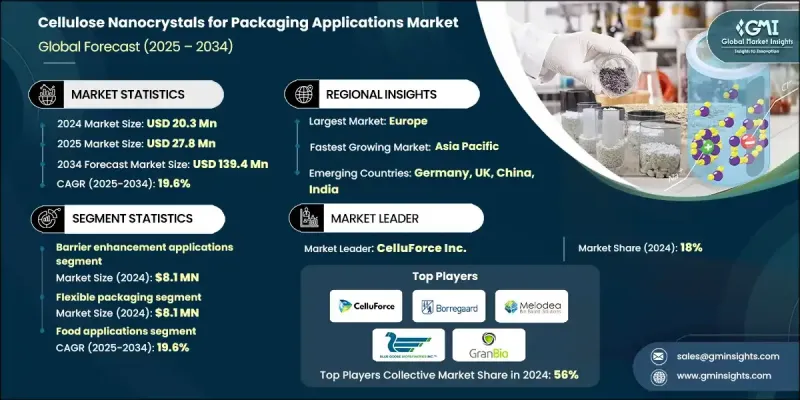

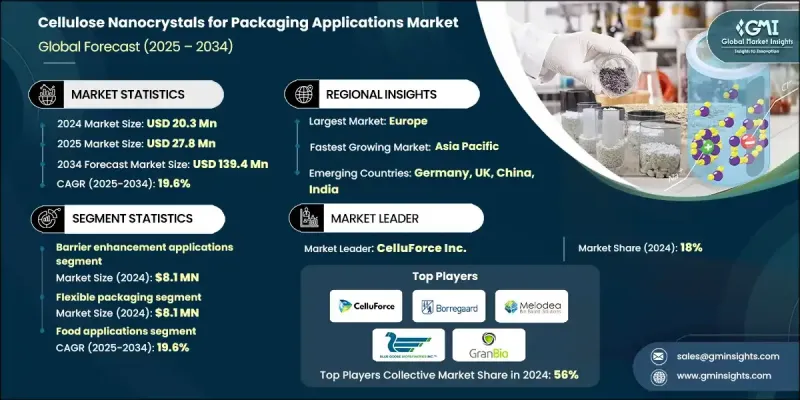

2024 年全球包裝應用纖維素奈米晶體市場價值為 2,030 萬美元,預計到 2034 年將以 19.6% 的複合年成長率成長至 1.394 億美元。

由於其卓越的機械強度、生物分解性和優異的阻隔性能,包裝產業對奈米纖維素(CNC)的需求正在迅速成長。這些奈米材料顯著提高了包裝薄膜的抗氧性和抗油性,為石油基塗料提供了環保替代品。包裝和造紙應用約佔微奈米纖維素產品市場佔有率的60%。酶法和機械加工方法的技術創新已將能源需求降低了近90%,使大規模CNC生產更加可行且經濟高效。全球向永續和循環包裝解決方案的轉型仍然是關鍵的成長動力,消費者和企業越來越重視環保材料。增強型阻隔塗層已顯示出可衡量的性能提升,在CNC含量為5-10%時,氧氣透過率降低了21-36%。這種永續性和性能的平衡使CNC基塗層成為食品、藥品和消費品包裝的首選材料,這些行業都需要延長產品壽命並防止環境因素的影響。

| 市場範圍 | |

|---|---|

| 起始年份 | 2024 |

| 預測年份 | 2025-2034 |

| 起始值 | 2030萬美元 |

| 預測值 | 1.394億美元 |

| 複合年成長率 | 19.6% |

2024年,阻隔增強應用領域佔39.9%的市場佔有率,凸顯了CNC材料相比傳統材料在阻隔氧氣、水分和紫外線輻射方面的卓越性能。由於高阻隔性能對於維持產品新鮮度和安全性至關重要,尤其是在食品、消費品和藥品包裝領域,因此該領域將繼續保持領先地位。

2024年,軟包裝品類佔39.9%的市場佔有率,涵蓋薄膜、包裝膜、軟包裝袋及其他軟包裝容器。此品類受惠於數控加工技術在提升阻隔性能的同時,也能維持產品的柔韌性與加工性能。食品包裝、吸塑包裝和永續消費品包裝等應用都依賴數控加工技術,在不影響產品功能性和設計靈活性的前提下,實現產品的耐用性、防護性和環保優勢。

2024年,北美纖維素奈米晶體包裝應用市場佔據27.6%的市場佔有率,預計到2034年將以19%的複合年成長率成長。該地區受益於強大的研究生態系統、成熟的包裝產業以及企業對永續發展日益成長的承諾。美國和加拿大是領先的應用市場,這得益於各大學和國家實驗室的積極研究計畫。奈米材料應用領域的監管進步和行業專業知識進一步鞏固了北美在該新興市場的領先地位。

全球包裝用纖維素奈米晶體市場的主要企業包括 FiberLean Technologies、GranBio、Kruger Inc.、CelluForce Inc.、Anomera Inc.、Blue Goose Biorefineries、Melodea Ltd.、Reinste Nano Ventures Pvt. Ltd.、Borregaard ASA 和 Nanoverse。這些領先企業正透過創新、合作和技術進步不斷鞏固其市場地位。許多企業正在投資先進的奈米纖維素加工技術,以提高規模化生產能力、降低能源成本並改善材料品質。包裝生產商與研究機構之間的策略合作正在加速產品開發,並擴大纖維素奈米晶體在食品、藥品和消費品包裝領域的應用。

目錄

第1章:方法論與範圍

第2章:執行概要

第3章:行業洞察

- 產業生態系分析

- 供應商格局

- 利潤率

- 每個階段的價值增加

- 影響價值鏈的因素

- 中斷

- 產業影響因素

- 成長促進因素

- 對永續包裝解決方案的需求日益成長

- 監理機關大力推動生物基食品接觸包裝材料的發展

- 加大包裝奈米技術研究的投資

- 產業陷阱與挑戰

- 生產成本高,商業規模有限。

- 疏水包裝聚合物整合的技術挑戰

- 包裝應用中的濕度敏感度限制

- 市場機遇

- 用於增強包裝相容性的表面改質技術

- 多層封裝架構開發

- 主動式和智慧包裝應用成長

- 成長促進因素

- 成長潛力分析

- 監管環境

- 北美洲

- 歐洲

- 亞太地區

- 拉丁美洲

- 中東和非洲

- 波特的分析

- PESTEL 分析

- 價格趨勢

- 按地區

- 包裝功能

- 包裝規格

- 終端包裝產業

- 未來市場趨勢

- 專利格局

- 貿易統計(HS編碼)(註:僅提供重點國家的貿易統計資料)

- 主要進口國

- 主要出口國

- 永續性和環境方面

- 永續實踐

- 減少廢棄物策略

- 生產中的能源效率

- 環保舉措

- 碳足跡考量

第4章:競爭格局

- 介紹

- 公司市佔率分析

- 按地區

- 北美洲

- 歐洲

- 亞太地區

- 拉丁美洲

- MEA

- 按地區

- 公司矩陣分析

- 主要市場參與者的競爭分析

- 競爭定位矩陣

- 關鍵進展

- 併購

- 合作夥伴關係與合作

- 新產品發布

- 擴張計劃

第5章:市場估價與預測:依包裝功能分類,2021-2034年

- 主要趨勢

- 屏障增強應用

- 氧氣阻隔應用

- 防潮層應用

- 油脂阻隔應用

- 氣體阻隔應用

- 機械加固應用

- 拉伸強度增強

- 剛度和尺寸穩定性

- 抗撕裂性能提升

- 塗層應用

- 表面阻隔塗層

- 功能塗層

- 保護塗層

- 主動包裝功能

- 抗菌包裝應用

- 抗氧化包裝應用

- 控釋系統

- 智慧包裝功能

- 感測器整合應用

- 指標系統

- 響應式包裝材料

第6章:市場估價與預測:依包裝形式分類,2021-2034年

- 主要趨勢

- 軟包裝

- 薄膜和片材

- 收納袋和包包

- 包膜和襯墊

- 多層軟性結構

- 硬質包裝

- 容器和瓶子

- 罐子和瓶子

- 結構包裝組件

- 紙和紙板包裝

- 折疊紙盒

- 食品包裝

- 瓦楞紙包裝

- 紙板容器

- 多層複合包裝

- 屏障層應用

- 黏合層整合

- 複雜的多層結構

第7章:市場估計與預測:依最終用途包裝產業分類,2021-2034年

- 主要趨勢

- 食品包裝

- 直接食品接觸應用

- 間接食品接觸應用

- 新鮮食品包裝

- 加工食品包裝

- 冷凍食品包裝

- 飲料包裝

- 非酒精飲料包裝

- 酒精飲料包裝

- 乳製品飲料包裝

- 藥品包裝

- 藥品初級包裝

- 二級藥品包裝

- 醫療器材包裝

- 消費品包裝

- 個人護理包裝

- 家居用品包裝

- 電子封裝

第8章:市場估算與預測:依地區分類,2021-2034年

- 主要趨勢

- 北美洲

- 美國

- 加拿大

- 歐洲

- 德國

- 英國

- 法國

- 西班牙

- 義大利

- 歐洲其他地區

- 亞太地區

- 中國

- 印度

- 日本

- 澳洲

- 韓國

- 亞太其他地區

- 拉丁美洲

- 巴西

- 墨西哥

- 阿根廷

- 拉丁美洲其他地區

- 中東和非洲

- 沙烏地阿拉伯

- 南非

- 阿拉伯聯合大公國

- 中東和非洲其他地區

第9章:公司簡介

- CelluForce Inc.

- Borregaard ASA

- Reinste Nano Ventures Pvt. Ltd.

- Melodea Ltd.

- Blue Goose Biorefineries

- FiberLean Technologies

- Anomera Inc.

- Kruger Inc

- GranBio

- Nanoverse

The Global Cellulose Nanocrystals for Packaging Applications Market was valued at USD 20.3 million in 2024 and is estimated to grow at a CAGR of 19.6% to reach USD 139.4 million by 2034.

The demand for CNCs in the packaging industry is rapidly increasing due to their exceptional mechanical strength, biodegradability, and advanced barrier performance. These nanomaterials significantly improve resistance to oxygen and oil in packaging films, providing an eco-friendly substitute for petroleum-based coatings. Packaging and paper applications represent around 60% share for micro and nanocellulose products. Technological innovations in enzymatic and mechanical processing methods have lowered energy requirements by nearly 90%, making large-scale CNC production more feasible and cost-efficient. The global shift toward sustainable and circular packaging solutions remains the key growth drive, with consumers and corporations increasingly prioritizing environmentally friendly materials. Enhanced barrier coatings have shown measurable performance improvements, with oxygen transmission rates reduced by 21-36% at 5-10% CNC loadings. This balance of sustainability and performance positions CNC-based coatings as a preferred material in food, pharmaceutical, and consumer goods packaging, all requiring extended product life and protection against environmental factors.

| Market Scope | |

|---|---|

| Start Year | 2024 |

| Forecast Year | 2025-2034 |

| Start Value | $20.3 Million |

| Forecast Value | $139.4 Million |

| CAGR | 19.6% |

The barrier enhancement applications segment held 39.9% share in 2024, highlighting CNC's superior ability to protect against oxygen, moisture, and UV radiation compared to conventional materials. This segment continues to dominate as high-barrier properties are essential for maintaining product freshness and safety, especially in food, consumer goods, and pharmaceutical packaging.

The flexible packaging category held a 39.9% share in 2024, covering films, wraps, pouches, and other flexible containers. This segment benefits from CNC's ability to improve barrier performance while maintaining flexibility and processability. Applications such as food packaging, blister packs, and sustainable consumer goods packaging rely on CNCs to deliver durability, protection, and environmental advantages without compromising functionality or design versatility.

North America Cellulose Nanocrystals for Packaging Applications Market held 27.6% share in 2024 and is expected to grow at a CAGR of 19% through 2034. The region benefits from a strong research ecosystem, a mature packaging sector, and growing corporate commitments to sustainability. The United States and Canada are leading adopters, supported by active research programs across universities and national laboratories. Regulatory advancements and industry expertise in nanomaterial applications have further reinforced North America's leadership in this emerging market.

Key companies operating in the Global Cellulose Nanocrystals for Packaging Applications Market include FiberLean Technologies, GranBio, Kruger Inc., CelluForce Inc., Anomera Inc., Blue Goose Biorefineries, Melodea Ltd., Reinste Nano Ventures Pvt. Ltd., Borregaard ASA, and Nanoverse. Leading companies in the cellulose nanocrystals for packaging applications market are strengthening their market foothold through innovation, collaborations, and technological advancement. Many are investing in advanced nanocellulose processing technologies to enhance scalability, reduce energy costs, and improve material quality. Strategic partnerships between packaging producers and research institutions are accelerating product development and expanding CNC applications across food, pharmaceutical, and consumer goods packaging.

Table of Contents

Chapter 1 Methodology & Scope

- 1.1 Market scope and definition

- 1.2 Research design

- 1.2.1 Research approach

- 1.2.2 Data collection methods

- 1.3 Data mining sources

- 1.3.1 Global

- 1.3.2 Regional/Country

- 1.4 Base estimates and calculations

- 1.4.1 Base year calculation

- 1.4.2 Key trends for market estimation

- 1.5 Primary research and validation

- 1.5.1 Primary sources

- 1.6 Forecast model

- 1.7 Research assumptions and limitations

Chapter 2 Executive Summary

- 2.1 Industry 360° synopsis

- 2.2 Key market trends

- 2.2.1 Regional

- 2.2.2 Packaging function

- 2.2.3 Packaging format

- 2.2.4 End use packaging sector

- 2.3 TAM Analysis, 2025-2034

- 2.4 CXO perspectives: Strategic imperatives

- 2.4.1 Executive decision points

- 2.4.2 Critical success factors

- 2.5 Future Outlook and Strategic Recommendations

Chapter 3 Industry Insights

- 3.1 Industry ecosystem analysis

- 3.1.1 Supplier Landscape

- 3.1.2 Profit Margin

- 3.1.3 Value addition at each stage

- 3.1.4 Factor affecting the value chain

- 3.1.5 Disruptions

- 3.2 Industry impact forces

- 3.2.1 Growth drivers

- 3.2.1.1 Growing Demand for Sustainable Packaging Solutions

- 3.2.1.2 Regulatory Push for Bio-based Food Contact Packaging Materials

- 3.2.1.3 Increasing Investment in Packaging Nanotechnology Research

- 3.2.2 Industry pitfalls and challenges

- 3.2.2.1 High production costs & limited commercial scale

- 3.2.2.2 Technical challenges in hydrophobic packaging polymer integration

- 3.2.2.3 Moisture sensitivity limitations in packaging applications

- 3.2.3 Market opportunities

- 3.2.3.1 Surface modification technologies for enhanced packaging compatibility

- 3.2.3.2 Multilayer packaging architecture development

- 3.2.3.3 Active & smart packaging applications growth

- 3.2.1 Growth drivers

- 3.3 Growth potential analysis

- 3.4 Regulatory landscape

- 3.4.1 North America

- 3.4.2 Europe

- 3.4.3 Asia Pacific

- 3.4.4 Latin America

- 3.4.5 Middle East & Africa

- 3.5 Porter's analysis

- 3.6 PESTEL analysis

- 3.6.1 Technology and Innovation Landscape

- 3.6.2 Current technological trends

- 3.6.3 Emerging technologies

- 3.7 Price trends

- 3.7.1 By region

- 3.7.2 Packaging Function

- 3.7.3 Packaging Format

- 3.7.4 End use Packaging Sector

- 3.8 Future market trends

- 3.9 Patent Landscape

- 3.10 Trade statistics (HS code) (Note: the trade statistics will be provided for key countries only)

- 3.10.1 Major importing countries

- 3.10.2 Major exporting countries

- 3.11 Sustainability and environmental aspects

- 3.11.1 Sustainable practices

- 3.11.2 Waste reduction strategies

- 3.11.3 Energy efficiency in production

- 3.11.4 Eco-friendly initiatives

- 3.12 Carbon footprint considerations

Chapter 4 Competitive Landscape, 2024

- 4.1 Introduction

- 4.2 Company market share analysis

- 4.2.1 By region

- 4.2.1.1 North America

- 4.2.1.2 Europe

- 4.2.1.3 Asia Pacific

- 4.2.1.4 LATAM

- 4.2.1.5 MEA

- 4.2.1 By region

- 4.3 Company matrix analysis

- 4.4 Competitive analysis of major market players

- 4.5 Competitive positioning matrix

- 4.6 Key developments

- 4.6.1 Mergers & acquisitions

- 4.6.2 Partnerships & collaborations

- 4.6.3 New product launches

- 4.6.4 Expansion plans

Chapter 5 Market Estimates and Forecast, By Packaging Function, 2021 - 2034 (USD Million) (Kilo Tons)

- 5.1 Key trends

- 5.2 Barrier enhancement applications

- 5.2.1 Oxygen barrier applications

- 5.2.2 Moisture barrier applications

- 5.2.3 Grease & oil barrier applications

- 5.2.4 Gas barrier applications

- 5.3 Mechanical reinforcement applications

- 5.3.1 Tensile strength enhancement

- 5.3.2 Stiffness & dimensional stability

- 5.3.3 Tear resistance improvement

- 5.4 Coating applications

- 5.4.1 Surface barrier coatings

- 5.4.2 Functional coatings

- 5.4.3 Protective coatings

- 5.5 Active packaging functions

- 5.5.1 Antimicrobial packaging applications

- 5.5.2 Antioxidant packaging applications

- 5.5.3 Controlled release systems

- 5.6 Smart packaging functions

- 5.6.1 Sensor integration applications

- 5.6.2 Indicator systems

- 5.6.3 Responsive packaging materials

Chapter 6 Market Estimates and Forecast, By Packaging Format, 2021 - 2034 (USD Million) (Kilo Tons)

- 6.1 Key trends

- 6.2 Flexible packaging

- 6.2.1 Films & sheets

- 6.2.2 Pouches & bags

- 6.2.3 Wraps & liners

- 6.2.4 Multilayer flexible structures

- 6.3 Rigid packaging

- 6.3.1 Containers & bottles

- 6.3.2 Jars & cans

- 6.3.3 Structural packaging components

- 6.4 Paper & paperboard packaging

- 6.4.1 Folding cartons

- 6.4.2 Food service packaging

- 6.4.3 Corrugated packaging

- 6.4.4 Paperboard containers

- 6.5 Multilayer & laminated packaging

- 6.5.1 Barrier layer applications

- 6.5.2 Adhesive layer integration

- 6.5.3 Complex multilayer structures

Chapter 7 Market Estimates and Forecast, By End Use Packaging Sector, 2021 - 2034 (USD Million) (Kilo Tons)

- 7.1 Key trends

- 7.2 Food packaging

- 7.2.1 Direct food contact applications

- 7.2.2 Indirect food contact applications

- 7.2.3 Fresh food packaging

- 7.2.4 Processed food packaging

- 7.2.5 Frozen food packaging

- 7.3 Beverage packaging

- 7.3.1 Non-alcoholic beverage packaging

- 7.3.2 Alcoholic beverage packaging

- 7.3.3 Dairy beverage packaging

- 7.4 Pharmaceutical packaging

- 7.4.1 Primary pharmaceutical packaging

- 7.4.2 Secondary pharmaceutical packaging

- 7.4.3 Medical device packaging

- 7.5 Consumer goods packaging

- 7.5.1 Personal care packaging

- 7.5.2 Household products packaging

- 7.5.3 Electronics packaging

Chapter 8 Market Estimates and Forecast, By Region, 2021 - 2034 (USD Million) (Kilo Tons)

- 8.1 Key trends

- 8.2 North America

- 8.2.1 U.S.

- 8.2.2 Canada

- 8.3 Europe

- 8.3.1 Germany

- 8.3.2 UK

- 8.3.3 France

- 8.3.4 Spain

- 8.3.5 Italy

- 8.3.6 Rest of Europe

- 8.4 Asia Pacific

- 8.4.1 China

- 8.4.2 India

- 8.4.3 Japan

- 8.4.4 Australia

- 8.4.5 South Korea

- 8.4.6 Rest of Asia Pacific

- 8.5 Latin America

- 8.5.1 Brazil

- 8.5.2 Mexico

- 8.5.3 Argentina

- 8.5.4 Rest of Latin America

- 8.6 Middle East and Africa

- 8.6.1 Saudi Arabia

- 8.6.2 South Africa

- 8.6.3 UAE

- 8.6.4 Rest of Middle East and Africa

Chapter 9 Company Profiles

- 9.1 CelluForce Inc.

- 9.2 Borregaard ASA

- 9.3 Reinste Nano Ventures Pvt. Ltd.

- 9.4 Melodea Ltd.

- 9.5 Blue Goose Biorefineries

- 9.6 FiberLean Technologies

- 9.7 Anomera Inc.

- 9.8 Kruger Inc

- 9.9 GranBio

- 9.10 Nanoverse