|

市場調查報告書

商品編碼

1851624

奈米纖維素:全球市場佔有率分析、行業趨勢、統計數據和成長預測(2025-2030 年)Global Nanocellulose - Market Share Analysis, Industry Trends & Statistics, Growth Forecasts (2025 - 2030) |

||||||

※ 本網頁內容可能與最新版本有所差異。詳細情況請與我們聯繫。

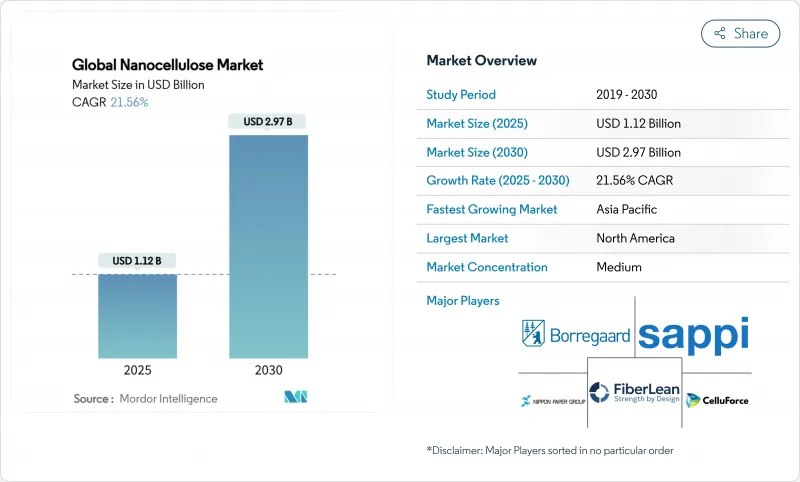

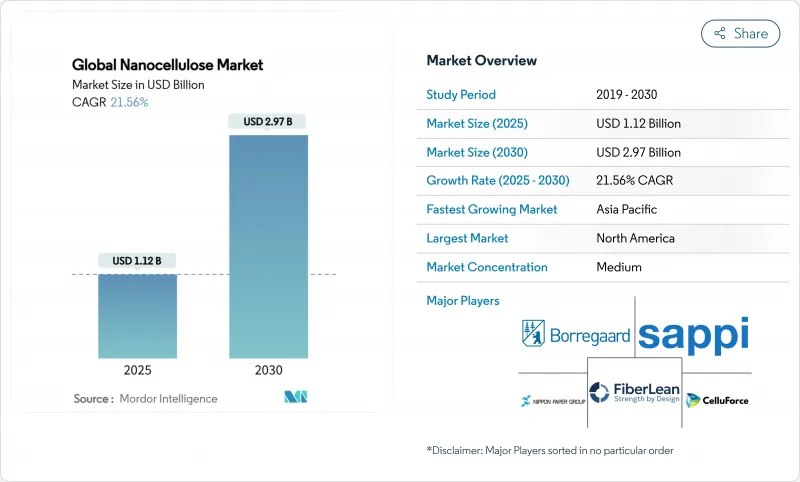

2025 年全球奈米纖維素市場規模估計為 11.2 億美元,預計到 2030 年將達到 29.7 億美元,預測期(2025-2030 年)複合年成長率為 21.56%。

日益成長的永續性需求、動態的石化產品價格以及材料科學的快速突破,共同為兩位數成長鋪平了道路。汽車輕量化、回收阻隔薄膜和生物醫學支架將推動近期需求,而酵素法低能耗製程將釋放未來成本競爭力。北美現有企業憑藉著成熟的中試生產線和與目標商標產品製造商 (OEM) 的緊密合作關係,正憑藉更低的轉化成本和接近性電子及包裝叢集的優勢,縮小與北美企業的差距。原料來源從木漿轉向農業廢棄物,進一步降低了供應鏈風險,並支持了循環經濟經營模式。在競爭激烈的市場環境下,現有大型紙漿企業不斷擴大產能,而生物技術新興企業專注於高階治療領域,由此形成了一個充滿活力的夥伴關係與許可生態系統,加速了應用推廣。

全球奈米纖維素市場趨勢與洞察

優異的機械性質和阻隔性能

奈米纖維素的拉伸強度為 4.9–7.5 GPa(吉帕),彈性模量為 100–200 GPa,使其在對重量要求嚴格的部件中性能接近碳纖維,因此在汽車車身面板和飛機內飾領域極具吸引力。橡樹嶺國家實驗室 (ONL) 於 2025 年檢驗了奈米纖維素的潛力,結果表明,碳奈米纖維增強奈米纖維素複合複合材料的拉伸強度比傳統玻璃纖維替代品高 50%,韌性幾乎是後者的兩倍。其高長寬比和表面積有助於與聚合物基體形成牢固的結合,從而最大限度地降低分層風險並提高疲勞壽命。日本汽車製造商預計,當奈米纖維素取代某些金屬和塑膠零件時,每輛車可減重 20 公斤,從而顯著節省燃油並減少生命週期排放。除了承重零件外,超薄奈米纖維素薄膜還比乙烯-乙烯醇共聚物 (EVOH) 和聚偏二氯乙烯 (PVDC) 具有更好的氧氣和水蒸氣阻隔性能,並且可回收和可堆肥。這種材料的機械性能和阻隔性能的雙重優勢,使其能夠應用於廣泛的市場,從家電外殼到藥品泡殼包裝。

對永續包裝的需求激增

零售商、電商公司和食品品牌正迅速取代石油基薄膜,迅速推高了對生物基阻隔材料的需求。在2024年的R3PACK試驗中,比利時、法國和盧森堡的歐洲連鎖店用纖維素包裝取代了試驗規模的塑膠托盤,減少了數千噸一次性塑膠的使用。歐盟指令要求到2030年所有包裝都必須可重複使用或可回收,這促使加工商對奈米纖維素塗層進行認證,以升級傳統的紙板。細菌纖維素薄膜具有優異的紫外線阻隔性能和拉伸強度,既能減少光敏食品的腐敗,又能承受低溫運輸物流的考驗。瑞典一家Start-Ups公司透過最佳化乾燥能耗和捲對卷塗佈速度,實現了與低密度聚乙烯(LDPE)包裝膜的成本持平,從而消除了最後一個經濟障礙。美國食品藥物管理局(FDA)核准原纖化纖維素作為食品接觸的公認安全物質(GRAS),進一步加速了北美供應商對這種材料的採用。隨著品牌所有者簽訂多年供應協議,奈米纖維素市場為產能擴張提供了可預測的收入基礎。

生產成本高且規模化風險

即使採用最佳化的水解工藝,最低銷售價格仍高於大宗聚合物基準價格-酸法製程每幹噸10,031美元,而以目前的酵素法產率計算,每幹噸可達65,740美元。連續造紙試點計畫可將每公斤產量的資本支出減半,但持續的品管仍面臨挑戰,品質維持率最高僅為73%。高昂的資本支出限制了大型工廠的建設,使其僅限於大型紙漿企業和國有企業,從而疏遠了缺乏資本資源的新興市場創新者。生命週期評估表明,年產量超過2萬噸的工廠可提供6.5倍的環境回報,但此類工廠的建設需要強勁的下游用戶需求,而目前很少有下游用戶具備這樣的能力。這種先有雞還是先有蛋的難題抑制了其他強勁的需求訊號,並促使企業採取逐步消除瓶頸的策略,而不是待開發區工廠。

細分市場分析

奈米纖維素(NFC)預計到2024年將佔據41.93%的市場佔有率,這反映了其成熟的生產基礎設施以及在造紙和複合材料應用領域的廣泛適用性。然而,細菌纖維素憑藉其超高的純度以及在醫藥和生物醫學應用領域的高階定位,成為成長最快的細分市場,預計到2030年將以37.02%的複合年成長率成長。這種生產模式的分化揭示了細菌纖維素的策略定位,其目標應用領域是能夠抵消發酵成本的高價值應用,而NFC則利用了機械加工的可擴展性。

由於其優異的結晶結構,奈米晶纖維素(NCC)的應用持續穩定成長,尤其是在對尺寸穩定性和耐熱性要求較高的增強材料領域。微纖化纖維素(MFC)是一種過渡性技術,它在紙張和包裝應用中,在提供優於傳統纖維素的性能的同時,也能保持與傳統添加劑的成本競爭力。

憑藉數十年來紙漿和造紙行業發展所建立的供應鏈和加工基礎設施,木漿將在2024年繼續保持其主導地位,市場佔有率將達到58.36%。然而,農業廢棄物作為一種原料,將展現出最強勁的成長勢頭,年複合成長率將達到23.68%,其成本優勢和與循環經濟的契合度將從根本上挑戰木漿的長期主導地位。農業廢棄物轉型反映了經濟最佳化和永續性的要求,即優先考慮有效利用廢棄物而非消耗原生資源。

微藻類、海藻和細菌宿主為化妝品精華液和眼科溶液提供特定數量的原料,在這些產品中,絕對純度比成本更為重要。這些生物資源能夠實現閉合迴路培養,最大限度地減少農藥殘留,並有助於獲得非基因改造認證。歐洲的聯盟正在探索大麻秸稈和亞麻為原料,利用當地纖維作物來解決紙漿木材短缺的問題。然而,殘渣的物流仍然複雜,利用季節性殘渣需要濕式儲存筒倉和緻密化顆粒,這會帶來隱性的資本投資。木漿生產商則透過監管鏈認證和全年供應保證來應對,強調其散裝包裝的可靠性。這種競爭確保了技術的不斷創新,並引領奈米纖維素市場走向多元化原料的未來。

區域分析

北美在奈米纖維素市場佔據領先地位,預計2024年將佔43.92%的市場佔有率。這得益於美國和能源部早期提供的津貼,推出試點生產線,以及汽車和航太目標商標產品製造商(OEM)的強勁需求。該地區高度一體化的紙漿和造紙物流使造紙廠能夠快速改造蒸煮器,用於纖維素奈米纖維,而無需新增資本支出(CAPEX)。一級供應商正與州立大學合作,最佳化汽車片狀成型化合物,以滿足美國公路安全保險協會(IIHS)的碰撞測試標準。雖然永續包裝的法律規範不如美國嚴格,但大型零售商的品牌承諾確保了穩定的供應。因此,北美奈米纖維素市場規模仍是全球生產商設定價格目標的重要參考。

亞太地區預計到2030年將以24.36%的複合年成長率成長,挑戰北美市場的領先地位。日本企業正透過改造利用折舊免稅額造紙設備,率先實現纖維素奈米纖維的商業化;而中國新興企業則部署國產低成本高壓均質機,以避免進口關稅。深圳的電子組裝指定使用奈米纖維素阻隔膜來保護有機發光二極體(OLED)模組免受氧氣滲入,這催生了強勁的需求,並縮短了供應商的資質認證週期。在印度和泰國,豐富的農業殘餘物使原料成本降低了40%,而酵素許可協議則加速了奈米纖維素技術的應用。因此,奈米纖維素市場正吸引東協港口周邊地區(出口物流集中地)不斷湧現新的工廠。

儘管歐洲對一次性塑膠製品實施了全球最嚴格的禁令,但仍保持著兩位數以上的成長。比利時和北歐的加工商已證實,奈米纖維素塗層符合95%的紙張可回收標準。雖然能源價格上漲擠壓了利潤淨利率,但歐盟的創新津貼降低了試點投資的風險,展現了其在循環生物經濟領域的領先地位。南美洲擁有豐富的甘蔗渣資源,一旦其CelOCE酶工廠實現商業化,南美洲正崛起為低成本出口中心。中東和非洲正在轉向使用奈米纖維素增強水泥複合材料來抑製沙漠建築揚塵,跨國水泥巨頭正在資助海灣地區計劃附近的試點建設。這種地域上的多元化發展反映了政策、資源和產業結構的差異,從而支撐了奈米纖維素市場的全球均衡成長。

其他福利:

- Excel格式的市場預測(ME)表

- 3個月的分析師支持

目錄

第1章 引言

- 研究假設和市場定義

- 調查範圍

第2章調查方法

第3章執行摘要

第4章 市場情勢

- 市場概覽

- 市場促進因素

- 優異的機械性質和阻隔性

- 對永續包裝的需求激增

- 監管部門呼籲尋找一次性塑膠的替代品

- 增加研發試點設施和資金

- 酵素低能耗生產取得突破

- 市場限制

- 生產成本高且規模化風險

- 與其他生物奈米材料的競爭

- 食品接觸安全與吸入問題

- 價值鏈分析

- 波特五力模型

- 供應商的議價能力

- 買方的議價能力

- 新進入者的威脅

- 替代品的威脅

- 競爭程度

第5章 市場規模與成長預測

- 依產品類型

- 奈米纖維素(NFC)

- 奈米晶纖維素(NCC)

- 細菌纖維素

- 微纖化纖維素(MFC)

- 其他

- 按原料

- 木漿

- 農業殘餘物

- 微藻類和其他生物資源

- 其他

- 按形式

- 乾粉

- 凝膠

- 暫停

- 按最終用途行業分類

- 紙張加工

- 油漆和塗料

- 石油和天然氣

- 飲食

- 合成的

- 藥品和化妝品

- 其他終端用戶產業

- 按地區

- 亞太地區

- 中國

- 印度

- 日本

- 韓國

- 馬來西亞

- 泰國

- 印尼

- 越南

- 亞太其他地區

- 北美洲

- 美國

- 加拿大

- 墨西哥

- 歐洲

- 德國

- 英國

- 法國

- 義大利

- 西班牙

- 北歐國家

- 土耳其

- 俄羅斯

- 其他歐洲地區

- 南美洲

- 巴西

- 阿根廷

- 哥倫比亞

- 南美洲其他地區

- 中東和非洲

- 沙烏地阿拉伯

- 南非

- 奈及利亞

- 卡達

- 埃及

- 阿拉伯聯合大公國

- 其他中東和非洲地區

- 亞太地區

第6章 競爭情勢

- 市場集中度

- 策略趨勢

- 市佔率分析

- 公司簡介

- Axcelon Biopolymers Corporation

- Borregaard AS

- CelluComp

- CelluForce

- Chuetsu Pulp & Paper Co., Ltd.

- Daicel Corporation

- FiberLean

- GranBio Technologies

- Melodea

- NIPPON PAPER INDUSTRIES CO., LTD.

- Norske Skog ASA

- Oji Holdings Corporation

- Sappi Ltd

- Stora Enso

- UPM

第7章 市場機會與未來展望

The Global Nanocellulose Market size is estimated at USD 1.12 Billion in 2025, and is expected to reach USD 2.97 Billion by 2030, at a CAGR of 21.56% during the forecast period (2025-2030).

Escalating sustainability mandates, volatile petrochemical prices, and rapid material science breakthroughs converge to create a clear runway for double-digit expansion. Automotive lightweighting, recyclable barrier films, and biomedical scaffolds headline near-term demand, while enzymatic low-energy processes unlock future cost competitiveness. North American incumbents leverage mature pilot lines and close original equipment manufacturer (OEM) ties, yet Asian producers narrow the gap through lower conversion costs and proximity to electronics and packaging clusters. Raw-material flexibility shifting from wood pulp to agricultural residues further de-risks supply chains and anchors circular-economy business models. Established pulp majors expand tonnage on the competitive front, whereas biotech start-ups chase premium therapeutic niches, resulting in an active partnership and licensing landscape that accelerates application rollout.

Global Nanocellulose Market Trends and Insights

Superior Mechanical and Barrier Properties

Nanocellulose's tensile strength of 4.9-7.5 GPa (Gigapascals) and elastic modulus of 100-200 GPa position it close to carbon fiber in weight-sensitive components, making it attractive for automotive body panels and aircraft interiors. Oak Ridge National Laboratory validated this potential in 2025 by showing 50% higher tensile strength and nearly double toughness in carbon-nanofiber-enhanced nanocellulose composites versus conventional glass-fiber alternatives. The high aspect ratio and surface area foster tight bonding with polymer matrices, minimizing delamination risk and boosting fatigue life. Japanese automakers project a 20 kg per-vehicle weight cut when nanocellulose substitutes selected metal and plastic parts, translating into meaningful fuel savings and lower lifecycle emissions. Beyond load-bearing parts, ultrathin nanocellulose films block oxygen and water vapor better than Ethylene Vinyl Alcohol (EVOH) or Polyvinylidene Chloride (PVDC), yet remain recyclable and compostable. These dual mechanical and barrier advantages underpin the material's broad addressable market, from consumer electronics casings to pharmaceutical blister packs.

Sustainable Packaging Demand Surge

Retail, e-commerce, and food brands rush to replace petroleum films, driving a steep demand curve for bio-based barriers. European chains in Belgium, France, and Luxembourg replaced pilot-scale plastic trays with cellulose packs in the 2024 R3PACK trial, eliminating thousands of tonnes of single-use plastics. European Union (EU) directives mandate that all packaging be reusable or recyclable by 2030, prompting converters to qualify nanocellulose coatings that upgrade ordinary paperboard. Bacterial cellulose films show superior ultraviolet (UV) shielding and tensile strength, reducing spoilage in light-sensitive foods while holding up under cold-chain logistics. Swedish start-up lines achieved cost parity with Low Density Polyethylene (LDPE) wrap by optimizing drying energy and roll-to-roll coating speeds, removing the final economic roadblock. Food and Drug Administration (FDA)'s Generally Recognized As Safe (GRAS) nod for fibrillated cellulose in food contact further derisks adoption for North American suppliers . As brand owners lock in multi-year supply contracts, the nanocellulose market secures a predictable revenue base for capacity expansions.

High Production Cost and Scale-up Risk

Even with hydrolysis optimization, minimum selling prices hover at USD 10,031 per dry tonne for acid routes, and USD 65,740 per dry tonne for current enzymatic yields, dwarfing commodity polymer benchmarks. Continuous papermaking pilots halve capex per output kilogram, yet sustained quality control remains elusive as retention tops out at 73%. Capex intensity restricts large-scale units to pulp majors and state-backed entities, marginalizing innovators in emerging markets that lack patient capital. Life-cycle assessments show a 6.5-fold environmental win once plants exceed 20,000 tpa, but financing such nameplates requires off-take certainty that few downstream users can underwrite today. This chicken-and-egg dynamic tempers otherwise strong demand signals and prompts phased debottlenecking rather than greenfield mega-mills.

Other drivers and restraints analyzed in the detailed report include:

- Regulatory Push to Replace Single-use Plastics

- Rising R&D Pilot Facilities and Funding

- Competition From Other Bio-nanomaterials

For complete list of drivers and restraints, kindly check the Table Of Contents.

Segment Analysis

Nanofibrillated Cellulose (NFC) commands 41.93% market share in 2024, reflecting its established production infrastructure and broad applicability across paper processing and composites applications. However, Bacterial Cellulose is the fastest-growing segment with 37.02% CAGR through 2030, driven by its ultra-pure properties and premium positioning in pharmaceuticals and biomedical applications. The production dichotomy reveals strategic positioning where NFC leverages mechanical processing scalability, while bacterial cellulose targets high-value applications, justifying fermentation costs.

Nanocrystalline Cellulose (NCC) maintains steady growth through its crystalline structure advantages in reinforcement applications, particularly where dimensional stability and thermal resistance prove critical. Microfibrillated Cellulose (MFC) is a bridge technology, offering enhanced properties over conventional cellulose while remaining cost-competitive with traditional additives in paper and packaging applications.

Wood Pulp maintains its dominant position with 58.36% market share in 2024, leveraging established supply chains and processing infrastructure developed over decades of pulp and paper industry evolution. Yet, Agricultural Residues as a source demonstrate the strongest growth trajectory at 23.68% CAGR, fundamentally challenging wood pulp's long-term dominance through cost advantages and circular economy alignment. The shift toward agricultural residues reflects economic optimization and sustainability mandates favoring waste valorization over virgin resource consumption.

Micro-algae, seaweed, and bacterial hosts supply specialty volumes for cosmetic serums and ophthalmic solutions where absolute purity trumps cost. These bio-sources allow closed-loop cultivation, minimizing pesticide carry-over and easing Genetically Modified Organism (GMO)-free certification. European consortiums study hemp hurd and flax shive feedstocks, leveraging regional fiber crops to offset pulpwood shortages. However, residue logistics remain complex: seasonal availability demands wet-storage silos or densification pellets, adding hidden capex. Wood pulp producers counter with chain-of-custody certification and guaranteed year-round supply, arguing reliability for mass-market packaging volumes. The competitive dance ensures continuous innovation and locks the nanocellulose market into a multi-feedstock future.

The Nanocellulose Market Report is Segmented by Product Type (Nanofibrillated Cellulose, Bacterial Cellulose, and More), Source (Wood Pulp, Agricultural Residues, and More), Form (Dry, Gel, and Suspension), End-Use Industry (Paper Processing, Oil and Gas, Composites, and More), and Geography (Asia-Pacific, North America, Europe, South America, and Middle East and Africa). The Market Forecasts are Provided in Terms of Value (USD)

Geography Analysis

North America leads the Nanocellulose market with a 43.92% revenue share in 2024, backed by early USDA and DOE grants that underwrote pilot lines and strong pull from automotive and aerospace original equipment manufacturers (OEMs). The region enjoys deeply integrated pulp-and-paper logistics, letting mills quickly pivot digesters toward cellulose nanofibrils without greenfield capital expenditure (CAPEX). Tier-1 suppliers collaborate with state universities to optimize automotive sheet-molding compounds that meet Insurance Institute for Highway Safety (IIHS) crash standards. Regulatory frameworks on sustainable packaging are less stringent than in the European Union (EU), yet brand commitments by big box retailers ensure stable offtake. As a result, the nanocellulose market size across North America remains the anchor against which global producers benchmark pricing.

Asia-Pacific records a 24.36% CAGR that challenges North America's leadership by 2030. Japanese corporations commercialized cellulose nanofiber years ahead of rivals by repurposing depreciated paper machines, while Chinese start-ups deploy low-cost, high-pressure homogenizers built domestically to evade import duties. Electronics assemblers in Shenzhen specify nanocellulose barrier films to protect Organic Light Emitting Diode (OLED) modules from oxygen ingress, creating captive demand and shortening supplier qualification cycles. Agricultural residue abundance in India and Thailand cuts feedstock bills by 40%, and enzyme licensing deals accelerate adoption. Consequently, the Nanocellulose market attracts continuous plant announcements around ASEAN ports where export logistics converge.

Europe secures mid-teen growth on the back of the world's strictest single-use-plastic bans. Converters in Belgium and the Nordics qualify Nanocellulose coatings to meet 95% paper recyclability thresholds. While higher energy prices squeeze margins, EU innovation grants de-risk pilot investments that showcase circular-bioeconomy leadership. South America, buoyed by sugarcane bagasse supplies, emerges as a low-cost export hub once CelOCE enzyme plants go commercial. Middle East and Africa start from a small base yet eye nanocellulose enhanced cement composites to curb desert construction dust, with multinational cement majors funding test pours near Gulf megaprojects. This geographic mosaic mirrors differing policy, resource, and industrial profiles, underpinning a balanced global growth picture for the nanocellulose market.

- Axcelon Biopolymers Corporation

- Borregaard AS

- CelluComp

- CelluForce

- Chuetsu Pulp & Paper Co., Ltd.

- Daicel Corporation

- FiberLean

- GranBio Technologies

- Melodea

- NIPPON PAPER INDUSTRIES CO., LTD.

- Norske Skog ASA

- Oji Holdings Corporation

- Sappi Ltd

- Stora Enso

- UPM

Additional Benefits:

- The market estimate (ME) sheet in Excel format

- 3 months of analyst support

TABLE OF CONTENTS

1 Introduction

- 1.1 Study Assumptions & Market Definition

- 1.2 Scope of the Study

2 Research Methodology

3 Executive Summary

4 Market Landscape

- 4.1 Market Overview

- 4.2 Market Drivers

- 4.2.1 Superior Mechanical and Barrier Properties

- 4.2.2 Sustainable Packaging Demand Surge

- 4.2.3 Regulatory Push to Replace Single-use Plastics

- 4.2.4 Rising R&D Pilot Facilities and Funding

- 4.2.5 Enzymatic Low-energy Production Breakthroughs

- 4.3 Market Restraints

- 4.3.1 High Production Cost and Scale-up Risk

- 4.3.2 Competition From Other Bio-nanomaterials

- 4.3.3 Food-contact Safety and Inhalation Concerns

- 4.4 Value Chain Analysis

- 4.5 Porter's Five Forces

- 4.5.1 Bargaining Power of Suppliers

- 4.5.2 Bargaining Power of Buyers

- 4.5.3 Threat of New Entrants

- 4.5.4 Threat of Substitutes

- 4.5.5 Degree of Competition

5 Market Size & Growth Forecasts (Value)

- 5.1 By Product Type

- 5.1.1 Nanofibrillated Cellulose (NFC)

- 5.1.2 Nanocrystalline Cellulose (NCC)

- 5.1.3 Bacterial Cellulose

- 5.1.4 Microfibrillated Cellulose (MFC)

- 5.1.5 Others

- 5.2 By Source

- 5.2.1 Wood Pulp

- 5.2.2 Agricultural Residues

- 5.2.3 Micro-algae & Other Bio-sources

- 5.2.4 Others

- 5.3 By Form

- 5.3.1 Dry (Powder)

- 5.3.2 Gel

- 5.3.3 Suspension

- 5.4 By End-use Industry

- 5.4.1 Paper Processing

- 5.4.2 Paints and Coatings

- 5.4.3 Oil and Gas

- 5.4.4 Food and Beverage

- 5.4.5 Composites

- 5.4.6 Pharmaceuticals and Cosmetics

- 5.4.7 Other End-user Industries

- 5.5 By Geography

- 5.5.1 Asia-Pacific

- 5.5.1.1 China

- 5.5.1.2 India

- 5.5.1.3 Japan

- 5.5.1.4 South Korea

- 5.5.1.5 Malaysia

- 5.5.1.6 Thailand

- 5.5.1.7 Indonesia

- 5.5.1.8 Vietnam

- 5.5.1.9 Rest of Asia-Pacific

- 5.5.2 North America

- 5.5.2.1 United States

- 5.5.2.2 Canada

- 5.5.2.3 Mexico

- 5.5.3 Europe

- 5.5.3.1 Germany

- 5.5.3.2 United Kingdom

- 5.5.3.3 France

- 5.5.3.4 Italy

- 5.5.3.5 Spain

- 5.5.3.6 NORDIC Countries

- 5.5.3.7 Turkey

- 5.5.3.8 Russia

- 5.5.3.9 Rest of Europe

- 5.5.4 South America

- 5.5.4.1 Brazil

- 5.5.4.2 Argentina

- 5.5.4.3 Colombia

- 5.5.4.4 Rest of South America

- 5.5.5 Middle East and Africa

- 5.5.5.1 Saudi Arabia

- 5.5.5.2 South Africa

- 5.5.5.3 Nigeria

- 5.5.5.4 Qatar

- 5.5.5.5 Egypt

- 5.5.5.6 United Arab Emirates

- 5.5.5.7 Rest of Middle East and Africa

- 5.5.1 Asia-Pacific

6 Competitive Landscape

- 6.1 Market Concentration

- 6.2 Strategic Moves

- 6.3 Market Share Analysis

- 6.4 Company Profiles (includes Global level Overview, Market level overview, Core Segments, Financials as available, Strategic Information, Market Rank/Share for key companies, Products & Services, and Recent Developments)

- 6.4.1 Axcelon Biopolymers Corporation

- 6.4.2 Borregaard AS

- 6.4.3 CelluComp

- 6.4.4 CelluForce

- 6.4.5 Chuetsu Pulp & Paper Co., Ltd.

- 6.4.6 Daicel Corporation

- 6.4.7 FiberLean

- 6.4.8 GranBio Technologies

- 6.4.9 Melodea

- 6.4.10 NIPPON PAPER INDUSTRIES CO., LTD.

- 6.4.11 Norske Skog ASA

- 6.4.12 Oji Holdings Corporation

- 6.4.13 Sappi Ltd

- 6.4.14 Stora Enso

- 6.4.15 UPM

7 Market Opportunities & Future Outlook

- 7.1 White-space & Unmet-need Assessment

- 7.2 Enzymatic and Biological Methods for Nanocellulose Production