|

市場調查報告書

商品編碼

1844360

金屬製造餘熱回收系統市場機會、成長動力、產業趨勢分析及2025-2034年預測Metal Manufacturing Waste Heat Recovery System Market Opportunity, Growth Drivers, Industry Trend Analysis, and Forecast 2025 - 2034 |

||||||

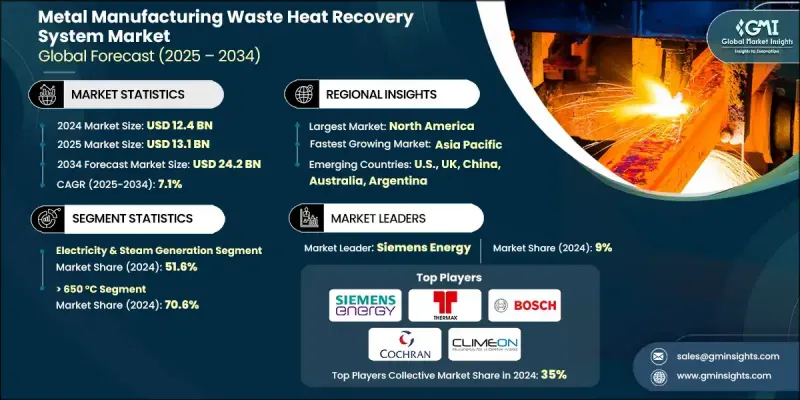

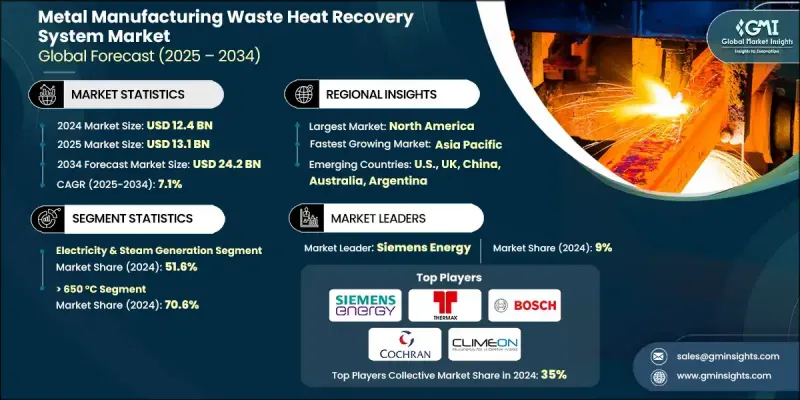

2024 年全球金屬製造廢熱回收系統市場價值為 124 億美元,預計到 2034 年將以 7.1% 的複合年成長率成長至 242 億美元。

隨著製造商更加重視營運效率、永續性和降低整體能源支出,市場持續穩定成長。軋製、鍛造、冶煉和鑄造等高溫製程會產生大量過剩熱能。廢熱回收系統旨在捕獲這些能量,並將其轉化為電能、蒸汽或製程熱等可用形式,重新投入運作。這顯著降低了能耗,減少了排放,並幫助企業遵守日益嚴格的環境標準。隨著全球監管機構推動碳減排和清潔生產,金屬製造等能源密集產業面臨的壓力日益增大。這些系統也能幫助企業減少對一次能源投入的依賴,同時推動其永續發展目標。熱交換器技術、有機朗肯循環和熱電材料的最新進展提高了廢熱回收系統的性能和可靠性,進一步支持了產業成長和長期應用。

| 市場範圍 | |

|---|---|

| 起始年份 | 2024 |

| 預測年份 | 2025-2034 |

| 起始值 | 124億美元 |

| 預測值 | 242億美元 |

| 複合年成長率 | 7.1% |

2024年,電力和蒸汽發電佔51.6%,預計到2034年將以8.1%的複合年成長率成長。再生能源計畫和政府支持的新興地區電氣化進程中廢熱回收系統(WHRS)的日益普及,正在加速對電力和蒸汽發電的需求。人們越來越重視將工業廢能重新用於電力和蒸汽發電,這也對市場發展產生了正面的影響,尤其是在基礎設施薄弱的地區。

2024年,650°C以上高溫領域佔據70.6%的市場佔有率,預計到2034年將以7%的複合年成長率成長。專為高溫應用而設計的系統正變得越來越重要,尤其是在冶煉和鑄造生產線的直接回收裝置中。這些系統直接從極端廢氣流中回收熱量,無需額外的加熱階段,並提高了熱效率。其堅固的結構使其能夠承受轉爐和高爐中常見的高塵高熱環境,非常適合在密集的工業環境中持續使用。

預計到2034年,歐洲金屬製造餘熱回收系統市場將以6.6%的複合年成長率成長,這得益於嚴格的環境指令、不斷發展的鋼鐵行業實踐以及對廢物能源基礎設施投資的不斷擴大。這些系統在應對城市地區能源挑戰方面發揮著至關重要的作用,尤其是在公用事業成本不斷上漲、垃圾掩埋場空間有限的情況下,對先進的回收解決方案的需求強勁。

全球金屬製造餘熱回收系統市場的領導企業包括西門子能源、IHI公司、Echogen Power Systems、Climeon、Thermax、博世、Promec Engineering、Kanin Energy、三菱重工、AURA、Forbes Marshall、Turboden、CMR Green Technologies Ltd.、FirstEof India Pvt. Ltd.、川崎重、板、曼、C、Cran、Cran、C羅、STP TEAM。為了提升市場影響力,各企業正專注於策略性產品開發、跨產業合作和技術創新。他們正在投資更緊湊、更有效率的回收系統,以滿足各種工業需求,包括惡劣的環境條件和高粉塵應用。

目錄

第1章:方法論與範圍

第2章:執行摘要

第3章:行業洞察

- 產業生態系統分析

- 監管格局

- 產業衝擊力

- 成長動力

- 產業陷阱與挑戰

- 成長潛力分析

- 波特的分析

- 供應商的議價能力

- 買家的議價能力

- 新進入者的威脅

- 替代品的威脅

- PESTEL分析

- 新興機會和趨勢

- 數位化和物聯網整合

- 新興市場滲透

第4章:競爭格局

- 介紹

- 按地區分析公司市場佔有率

- 北美洲

- 歐洲

- 亞太地區

- 中東和非洲

- 拉丁美洲

- 策略舉措

- 競爭基準測試

- 戰略儀表板

- 創新與技術格局

第5章:市場規模與預測:按應用,2021 - 2034

- 主要趨勢

- 預熱

- 電力和蒸汽發電

- 蒸汽朗肯循環

- 有機朗肯循環

- 卡林納循環

- 其他

第6章:市場規模與預測:按溫度,2021-2034 年

- 主要趨勢

- < 230 攝氏度

- 230°C - 650°C

- > 650 攝氏度

第7章:市場規模及預測:依地區,2021 - 2034

- 主要趨勢

- 北美洲

- 美國

- 加拿大

- 墨西哥

- 歐洲

- 德國

- 英國

- 法國

- 義大利

- 西班牙

- 亞太地區

- 中國

- 澳洲

- 印度

- 日本

- 韓國

- 中東和非洲

- 沙烏地阿拉伯

- 阿拉伯聯合大公國

- 南非

- 拉丁美洲

- 巴西

- 阿根廷

第8章:公司簡介

- AURA

- Bosch

- Climeon

- CMR Green Technologies Ltd.

- Cochran

- CTP TEAM

- Echogen Power Systems

- FirstESCO India Pvt. Ltd.

- Forbes Marshall

- IHI Corporation

- John Wood Group

- Kanin Energy

- Kawasaki Heavy Industries

- Mitsubishi Heavy Industries

- Primetals Technologies

- Promec Engineering

- Siemens Energy

- Sofinter

- Thermax

- Turboden

The Global Metal Manufacturing Waste Heat Recovery System Market was valued at USD 12.4 billion in 2024 and is estimated to grow at a CAGR of 7.1% to reach USD 24.2 billion by 2034.

The market continues to experience steady growth as manufacturers place greater emphasis on operational efficiency, sustainability, and reducing overall energy expenses. High-temperature processes such as rolling, forging, smelting, and casting generate large volumes of excess thermal energy. Waste heat recovery systems are engineered to capture this energy and convert it into usable forms such as electricity, steam, or process heat, reintegrating it into operations. This significantly reduces energy consumption, lowers emissions, and helps companies adhere to tightening environmental standards. With global regulatory bodies pushing for carbon reduction and clean production, the pressure is increasing on energy-intensive industries like metal manufacturing. These systems also help companies reduce reliance on primary energy inputs while advancing their sustainability goals. Recent improvements in heat exchanger technology, organic Rankine cycles, and thermoelectric materials have enhanced the performance and dependability of waste heat recovery systems, further supporting industry growth and long-term adoption.

| Market Scope | |

|---|---|

| Start Year | 2024 |

| Forecast Year | 2025-2034 |

| Start Value | $12.4 Billion |

| Forecast Value | $24.2 Billion |

| CAGR | 7.1% |

The electricity and steam generation accounted for a 51.6% share in 2024 and is projected to grow at a CAGR of 8.1% through 2034. Growing deployment of waste heat recovery systems (WHRS) within renewable initiatives and government-backed electrification efforts across emerging regions is accelerating the demand. The rising focus on repurposing industrial waste energy for power and steam applications is also positively influencing market momentum, particularly in infrastructure-challenged regions.

The temperatures above 650 °C segment held a 70.6% share in 2024 and is anticipated to grow at a CAGR of 7% by 2034. Systems designed for high-temperature applications are becoming increasingly critical, especially in direct recovery setups within smelting and casting lines. These systems recover heat directly from extreme exhaust streams, eliminating the need for additional heating stages and improving thermal efficiency. Their robust construction enables them to endure the high-dust and high-heat environments typically seen in converters and blast furnaces, making them ideal for continuous use in intensive industrial settings.

Europe Metal Manufacturing Waste Heat Recovery System Market is expected to grow at a CAGR of 6.6% through 2034, fueled by stringent environmental directives, evolving steel industry practices, and expanded investment in waste-to-energy infrastructure. These systems play a vital role in addressing the energy challenges of urban areas, facing rising utility costs and limited landfill availability, creating strong demand for advanced recovery solutions.

Companies leading the Global Metal Manufacturing Waste Heat Recovery System Market include Siemens Energy, IHI Corporation, Echogen Power Systems, Climeon, Thermax, Bosch, Promec Engineering, Kanin Energy, Mitsubishi Heavy Industries, AURA, Forbes Marshall, Turboden, CMR Green Technologies Ltd., FirstESCO India Pvt. Ltd., Kawasaki Heavy Industries, John Wood Group, Cochran, Primetals Technologies, Sofinter, and CTP TEAM. To enhance their presence, companies are focusing on strategic product development, cross-sector collaborations, and technological innovations. They are investing in more compact and high-efficiency recovery systems that meet a wide range of industrial requirements, including harsh environmental conditions and high-dust applications.

Table of Contents

Chapter 1 Methodology & Scope

- 1.1 Research design

- 1.2 Base estimates & calculations

- 1.3 Forecast calculation

- 1.4 Data sources

- 1.4.1 Primary

- 1.4.2 Secondary

- 1.4.2.1 Paid

- 1.4.2.2 Public

- 1.5 Market definitions

Chapter 2 Executive Summary

- 2.1 Industry synopsis, 2021 - 2034

Chapter 3 Industry Insights

- 3.1 Industry ecosystem analysis

- 3.2 Regulatory landscape

- 3.3 Industry impact forces

- 3.3.1 Growth drivers

- 3.3.2 Industry pitfalls & challenges

- 3.4 Growth potential analysis

- 3.5 Porter's analysis

- 3.5.1 Bargaining power of suppliers

- 3.5.2 Bargaining power of buyers

- 3.5.3 Threat of new entrants

- 3.5.4 Threat of substitutes

- 3.6 PESTEL analysis

- 3.6.1 Political factors

- 3.6.2 Economic factors

- 3.6.3 Social factors

- 3.6.4 Technology factors

- 3.6.5 environmental factors

- 3.6.6 Legal factors

- 3.7 Emerging opportunities & trends

- 3.7.1 Digitalization and IoT integration

- 3.7.2 Emerging market penetration

Chapter 4 Competitive landscape, 2025

- 4.1 Introduction

- 4.2 Company market share analysis, by region, 2024

- 4.2.1 North America

- 4.2.2 Europe

- 4.2.3 Asia Pacific

- 4.2.4 Middle East and Africa

- 4.2.5 Latin America

- 4.3 Strategic initiatives

- 4.4 Competitive benchmarking

- 4.5 Strategic dashboard

- 4.6 Innovation & technology landscape

Chapter 5 Market Size and Forecast, By Application, 2021 - 2034 (USD Million)

- 5.1 Key trends

- 5.2 Pre-heating

- 5.3 Electricity & steam generation

- 5.3.1 Steam rankine cycle

- 5.3.2 Organic rankine cycle

- 5.3.3 Kalina cycle

- 5.4 Others

Chapter 6 Market Size and Forecast, By Temperature, 2021 - 2034 (USD Million)

- 6.1 Key trends

- 6.2 < 230 °C

- 6.3 230°C - 650 °C

- 6.4 > 650 °C

Chapter 7 Market Size and Forecast, By Region, 2021 - 2034 (USD Million)

- 7.1 Key trends

- 7.2 North America

- 7.2.1 U.S.

- 7.2.2 Canada

- 7.2.3 Mexico

- 7.3 Europe

- 7.3.1 Germany

- 7.3.2 UK

- 7.3.3 France

- 7.3.4 Italy

- 7.3.5 Spain

- 7.4 Asia Pacific

- 7.4.1 China

- 7.4.2 Australia

- 7.4.3 India

- 7.4.4 Japan

- 7.4.5 South Korea

- 7.5 Middle East & Africa

- 7.5.1 Saudi Arabia

- 7.5.2 UAE

- 7.5.3 South Africa

- 7.6 Latin America

- 7.6.1 Brazil

- 7.6.2 Argentina

Chapter 8 Company Profiles

- 8.1 AURA

- 8.2 Bosch

- 8.3 Climeon

- 8.4 CMR Green Technologies Ltd.

- 8.5 Cochran

- 8.6 CTP TEAM

- 8.7 Echogen Power Systems

- 8.8 FirstESCO India Pvt. Ltd.

- 8.9 Forbes Marshall

- 8.10 IHI Corporation

- 8.11 John Wood Group

- 8.12 Kanin Energy

- 8.13 Kawasaki Heavy Industries

- 8.14 Mitsubishi Heavy Industries

- 8.15 Primetals Technologies

- 8.16 Promec Engineering

- 8.17 Siemens Energy

- 8.18 Sofinter

- 8.19 Thermax

- 8.20 Turboden