|

市場調查報告書

商品編碼

1773399

商用車柴油引擎排氣門市場機會、成長動力、產業趨勢分析及2025-2034年預測Commercial Vehicle Diesel Engine Exhaust Valve Market Opportunity, Growth Drivers, Industry Trend Analysis, and Forecast 2025 - 2034 |

||||||

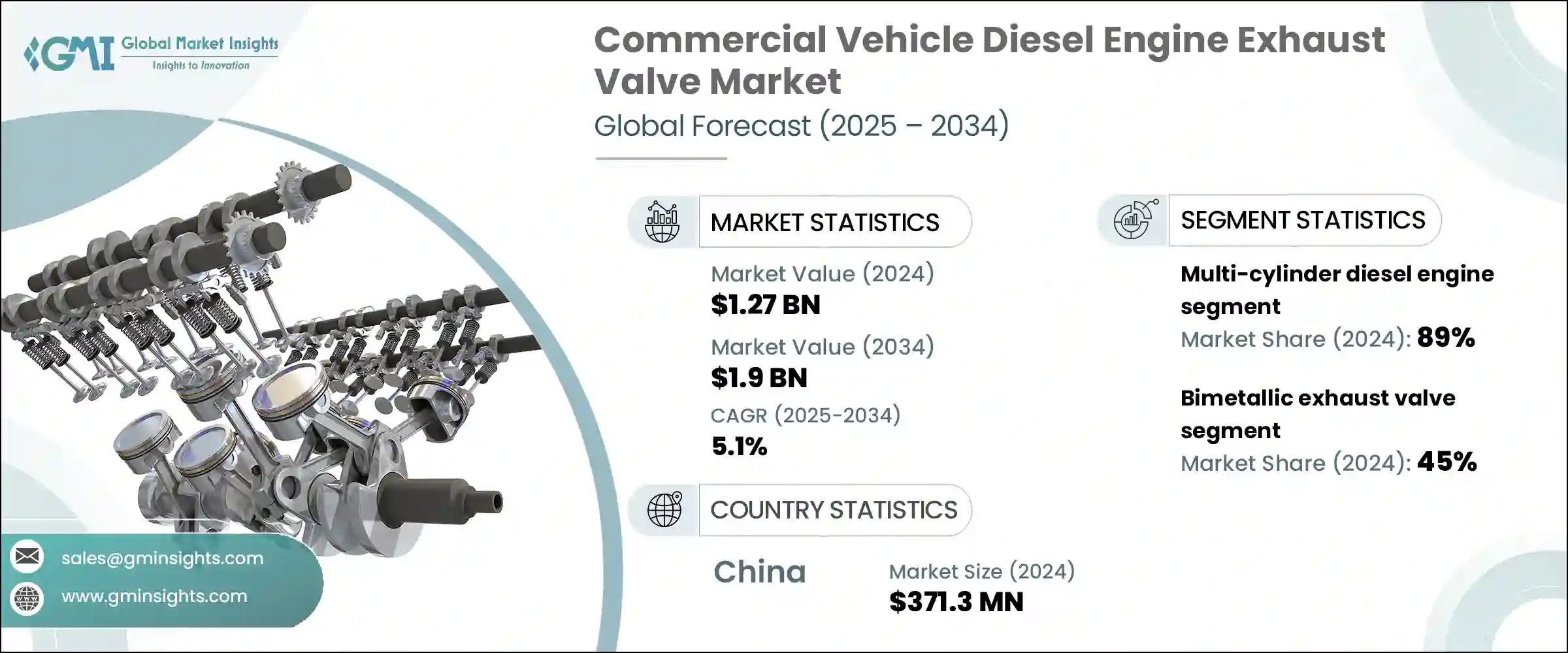

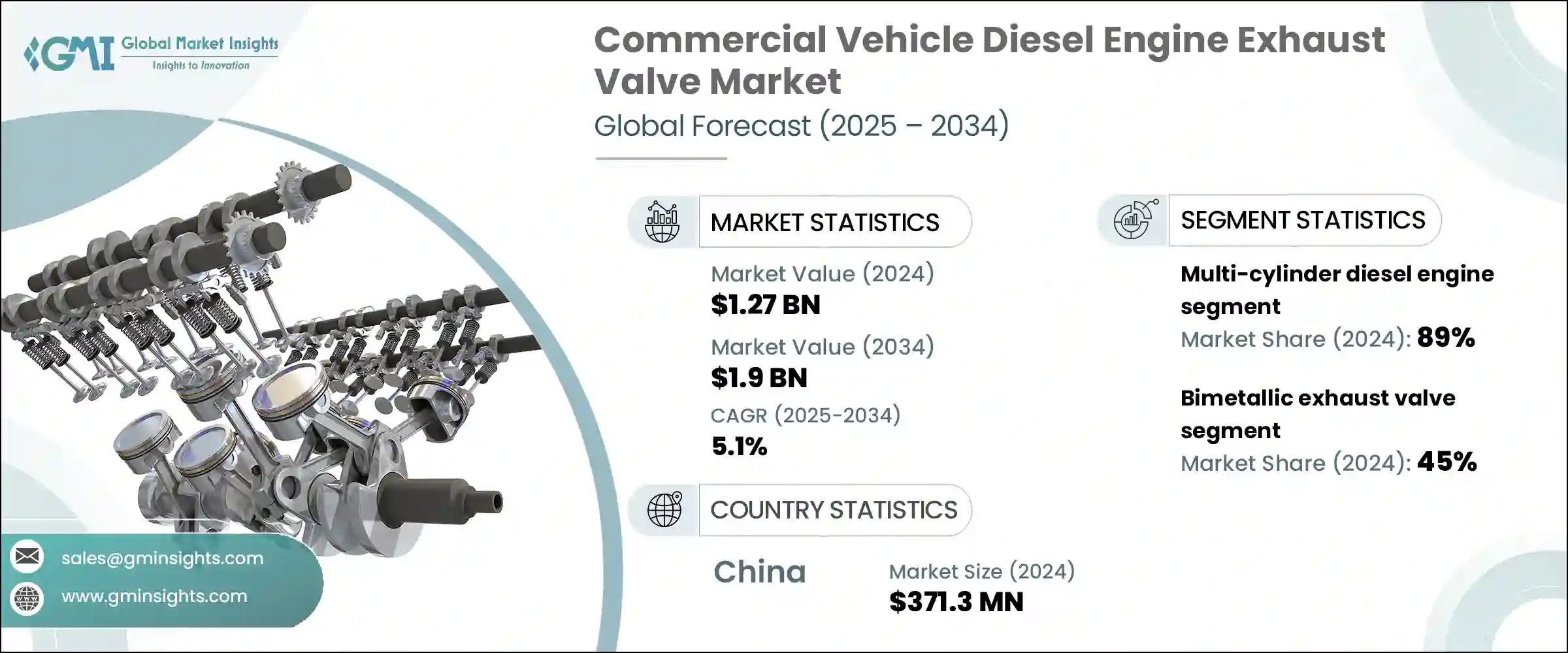

2024 年全球商用車柴油引擎排氣門市場價值為 12.7 億美元,預計到 2034 年將以 5.1% 的複合年成長率成長,達到 19 億美元。商用車製造業的穩定成長和柴油引擎使用壽命的延長是推動該市場成長的兩個最重要因素。柴油卡車和巴士仍然是貨運和建築作業的基石,排氣門對於保持高效的引擎性能和排放合規性至關重要。由於這些車輛承受著巨大的運行負荷,堅固的排氣門系統對於確保長期耐用性、減少引擎磨損和遵守監管標準至關重要。隨著排放法規的日益嚴格以及正常運行時間變得比以往任何時候都更加重要,原始設備製造商 (OEM) 和車隊營運商正在轉向技術先進的耐熱閥門解決方案,以滿足不斷變化的需求。

全球商用車產量的快速成長是推動該市場擴張的關鍵因素之一。從送貨卡車到建築設備,北美、亞洲和歐洲部分地區的原始設備製造商 (OEM) 都在增加產量,以滿足不斷成長的物流需求。這些車輛依賴能夠承受長距離高工作溫度、壓力循環和機械應力的排氣閥。製造商目前正致力於開發高耐用性的排氣閥組件,採用先進的材料和設計技術,以最大限度地降低故障率並提高整體系統效率。可靠的排氣閥性能與柴油引擎的健康狀況直接相關,進而影響停機時間、油耗和排放。

| 市場範圍 | |

|---|---|

| 起始年份 | 2024 |

| 預測年份 | 2025-2034 |

| 起始值 | 12.7億美元 |

| 預測值 | 19億美元 |

| 複合年成長率 | 5.1% |

2024年,多缸柴油引擎市場佔了89%的市場佔有率,預計2025年至2034年的複合年成長率為5.2%。多缸引擎在該領域佔據主導地位,因為它們在中型和重型商用車中應用廣泛,而這些車輛對耐用性、持續的動力輸出和引擎平衡至關重要。這些引擎的設計旨在應對長時間運行和多變的地形條件,其性能在很大程度上取決於精確的排氣門回饋機制。適當的氣門控制有助於維持燃燒效率,改善排放狀況,並降低機械故障風險。這些成果對於開發下一代卡車的原始設備製造商(OEM)和管理數千輛車輛性能的車隊營運商都至關重要。

雙金屬排氣閥市場在2024年佔據45%的市場佔有率,預計在2025-2034年期間的複合年成長率為6.7%。這些閥門採用兩種不同的金屬——通常為耐熱合金製造閥頭,耐腐蝕鋼製造閥桿——以平衡成本效益和耐用性。它們特別適用於商用柴油引擎,因為它們能夠承受高溫和腐蝕性化學物質的侵蝕,且不會影響結構強度。雙金屬閥門具有卓越的抗氧化性能和導熱性,並在高強度工作條件下支援更長的引擎循環。對於注重營運效率和最大程度減少計畫外維護的車隊來說,這些閥門兼具性能和使用壽命。

2024年,中國商用車柴油引擎排氣門市場規模達3.713億美元,佔57%。中國在該地區的主導地位源於其龐大的商用車隊規模、嚴格的柴油引擎排放標準執行以及數位技術在動力總成系統中的日益融合。領先的中國主機廠正在將感測器驅動的排氣門嵌入柴油機平台,以促進預測性維護、減少排放並在高產量營運中保持合規性。這些技術還能實現更精準的診斷,並支持更清潔的燃燒過程。商用運輸基礎設施的持續發展和監管執法進一步擴大了該市場的需求。

全球商用車柴油引擎排氣閥市場的主要參與者包括日立、大陸集團、電裝株式會社、伊頓公司、克諾爾煞車股份有限公司、馬勒集團和中國重汽引擎氣門。這些公司正在採取各種方法來鞏固其市場地位並適應不斷變化的行業需求。為了擴大市場佔有率,該領域的領先公司正在大力投資研發,使用先進的合金和塗層技術設計高效能排氣閥。他們還與主要原始設備製造商簽訂了長期供應契約,以確保在全球市場上保持穩定的銷售。一個關鍵的策略重點包括在關鍵需求區域附近建立在地化生產設施,以實現更快的交付和更高的成本效益。此外,參與者正在透過數位和感測器整合閥門系統增強產品組合,以滿足日益成長的預測性維護和排放監測需求。

目錄

第1章:方法論

- 市場範圍和定義

- 研究設計

- 研究方法

- 資料收集方法

- 資料探勘來源

- 全球的

- 地區/國家

- 基礎估算與計算

- 基準年計算

- 市場評估的主要趨勢

- 初步研究和驗證

- 主要來源

- 預測模型

- 研究假設和局限性

第2章:執行摘要

第3章:行業洞察

- 產業生態系統分析

- 供應商格局

- 利潤率分析

- 成本結構

- 每個階段的增值

- 影響價值鏈的因素

- 中斷

- 產業衝擊力

- 成長動力

- 商用車產量上升

- 柴油車壽命延長

- 閥門材料的技術進步

- 貨運及物流業的擴張

- 產業陷阱與挑戰

- 轉向電動和替代燃料汽車

- 先進閥門材料成本高

- 市場機會

- 老舊車隊售後市場的擴張

- 非公路用車需求激增

- 成長動力

- 成長潛力分析

- 監管格局

- 北美洲

- 歐洲

- 亞太地區

- 拉丁美洲

- 中東和非洲

- 波特的分析

- PESTEL分析

- 技術和創新格局

- 當前的技術趨勢

- 新興技術

- 成本細分分析

- 軟體開發和授權成本

- 部署和整合成本

- 維護和支援成本

- 網路安全與合規成本

- 培訓和變更管理成本

- 專利分析

- 永續性和環境方面

- 永續實踐

- 減少廢棄物的策略

- 生產中的能源效率

- 環保舉措

- 碳足跡考量

- 用例

- 最佳情況

第4章:競爭格局

- 介紹

- 公司市佔率分析

- 北美洲

- 歐洲

- 亞太地區

- 拉丁美洲

- MEA

- 主要市場參與者的競爭分析

- 競爭定位矩陣

- 戰略展望矩陣

- 關鍵進展

- 併購

- 夥伴關係與合作

- 新產品發布

- 擴張計劃和資金

第5章:市場估計與預測:按引擎,2021 - 2034 年

- 主要趨勢

- 單缸柴油機

- 多缸柴油引擎

第6章:市場估計與預測:Valve,2021 - 2034

- 主要趨勢

- 單金屬排氣閥

- 雙金屬排氣閥

- 空心桿閥

- 充鈉閥

第7章:市場估計與預測:按材料類型,2021 - 2034 年

- 主要趨勢

- 鋼

- 鈦

- 鎳基合金

- 其他高溫合金

第8章:市場估計與預測:依銷售管道,2021 - 2034 年

- 主要趨勢

- OEM

- 售後市場

第9章:市場估計與預測:依最終用途,2021 - 2034 年

- 主要趨勢

- 運輸與物流

- 建築和採礦

- 農業

- 大眾運輸

- 緊急救援和公用事業服務

- 軍事與國防

- 其他

第10章:市場估計與預測:按地區,2021 - 2034 年

- 主要趨勢

- 北美洲

- 美國

- 加拿大

- 歐洲

- 德國

- 英國

- 法國

- 義大利

- 西班牙

- 北歐人

- 俄羅斯

- 亞太地區

- 中國

- 印度

- 日本

- 澳洲

- 韓國

- 東南亞

- 拉丁美洲

- 巴西

- 墨西哥

- 阿根廷

- MEA

- 南非

- 沙烏地阿拉伯

- 阿拉伯聯合大公國

第 11 章:公司簡介

- Anhui Yuxi Industrial

- AVR Valves

- Continental AG

- Delphi Automotive AG

- Denso Corporation

- Eaton Corporation

- Federal-Mogul Holding Corp

- FTE Automotive

- FUJI OOZX

- Hitachi

- Knorr-Bremse

- Mahle Group

- MS Motorservice International

- Nanjing Shengpai Auto Parts

- Riken Corporation

- Shijiazhuang Advanced Valve

- Sinotruck Engine Valve

- Tenneco

- TRW Automotive

- Wuxi Volex Auto Parts

The Global Commercial Vehicle Diesel Engine Exhaust Valve Market was valued at USD 1.27 billion in 2024 and is estimated to grow at a CAGR of 5.1% to reach USD 1.9 billion by 2034. The steady rise in commercial vehicle manufacturing and extended diesel engine lifespans are two of the most significant factors driving this market's growth. Diesel-powered trucks and buses remain the cornerstone of freight and construction operations, and exhaust valves are critical for maintaining efficient engine performance and emissions compliance. As these vehicles endure intense operational loads, robust exhaust valve systems are essential to ensure long-term durability, reduce engine wear, and uphold regulatory standards. With emission regulations tightening and uptime becoming more critical than ever, OEMs and fleet operators are turning to technologically advanced, heat-resistant valve solutions to meet evolving demands.

One of the key forces behind this market's expansion is the rapid increase in production of commercial vehicles globally. From delivery trucks to construction equipment, OEMs across North America, Asia, and parts of Europe are ramping up output to keep pace with rising logistics demand. These vehicles rely on exhaust valves that can withstand intense operating temperatures, pressure cycles, and mechanical stress over long distances. Manufacturers are now focused on developing high-durability valve components using advanced materials and design techniques that minimize failure rates and boost overall system efficiency. Dependable exhaust valve performance is directly tied to diesel engine health, which in turn affects downtime, fuel consumption, and emission output.

| Market Scope | |

|---|---|

| Start Year | 2024 |

| Forecast Year | 2025-2034 |

| Start Value | $1.27 Billion |

| Forecast Value | $1.9 Billion |

| CAGR | 5.1% |

In 2024, the multi-cylinder diesel engines segment accounted for 89% share and is forecast to grow at a CAGR of 5.2% from 2025 through 2034. Multi-cylinder engines dominate this space due to their prominent use in medium and heavy commercial vehicles, where durability, consistent power delivery, and engine balance are essential. These engines are built to manage extended operating hours and variable terrain conditions, and their performance heavily depends on precise exhaust valve feedback mechanisms. Proper valve control helps maintain combustion efficiency, improve emissions profiles, and reduce the risk of mechanical failure. These outcomes are vital for both OEMs developing next-gen trucks and fleet operators managing performance across thousands of vehicles.

The bimetallic exhaust valves segment held a 45% share in 2024 and is projected to register a CAGR of 6.7% during 2025-2034. These valves use two different metals-typically a heat-resistant alloy for the valve head and corrosion-resistant steel for the stem-to balance cost-efficiency and durability. They are especially suitable for commercial diesel engines due to their ability to endure both high temperatures and aggressive chemical exposure without compromising structural strength. Bimetallic valves offer superior resistance to oxidation, enable better thermal conductivity, and support prolonged engine cycles in the face of intensive work conditions. For fleets that prioritize operational efficiency and minimal unplanned maintenance, these valves deliver both performance and longevity.

China Commercial Vehicle Diesel Engine Exhaust Valve Market generated USD 371.3 million in 2024, representing a 57% share. China's dominance in the regional landscape stems from its massive commercial fleet, the enforcement of strict diesel emission standards, and the increased integration of digital technologies within powertrains. Leading Chinese OEMs are embedding sensor-enabled exhaust valves into diesel platforms to facilitate predictive maintenance, reduce emissions, and maintain compliance across high-volume operations. These technologies also enable better diagnostics and support cleaner combustion processes. The ongoing development of commercial transport infrastructure and regulatory enforcement further amplifies demand in this market.

Key players in the Global Commercial Vehicle Diesel Engine Exhaust Valve Market include Hitachi, Continental, Denso Corporation, Eaton Corporation, Knorr-Bremse AG, Mahle Group, and Sinotruck Engine Valve. These companies are adopting diverse approaches to strengthen their market position and adapt to evolving industry needs. To expand their market footprint, leading companies in this sector are investing heavily in R&D to engineer high-efficiency exhaust valves using advanced alloys and coating technologies. They are also forming long-term supply contracts with major OEMs to ensure consistent volume sales across global markets. A key strategic focus includes localizing production facilities near key demand zones, which allows for faster delivery and cost efficiency. Additionally, players are enhancing product portfolios with digital and sensor-integrated valve systems to meet the rising demand for predictive maintenance and emission monitoring.

Table of Contents

Chapter 1 Methodology

- 1.1 Market scope and definition

- 1.2 Research design

- 1.2.1 Research approach

- 1.2.2 Data collection methods

- 1.3 Data mining sources

- 1.3.1 Global

- 1.3.2 Regional/Country

- 1.4 Base estimates and calculations

- 1.4.1 Base year calculation

- 1.4.2 Key trends for market estimation

- 1.5 Primary research and validation

- 1.5.1 Primary sources

- 1.6 Forecast model

- 1.7 Research assumptions and limitations

Chapter 2 Executive Summary

- 2.1 Industry 3600 synopsis, 2021 – 2034

- 2.2 Key market trends

- 2.2.1 Regional

- 2.2.2 Engine

- 2.2.3 Valve

- 2.2.4 Material Type

- 2.2.5 Sales Channel

- 2.2.6 End Use

- 2.3 TAM Analysis, 2025-2034

- 2.4 CXO perspectives: Strategic imperatives

- 2.4.1 Executive decision points

- 2.4.2 Critical success factors

- 2.5 Future outlook and strategic recommendations

Chapter 3 Industry Insights

- 3.1 Industry ecosystem analysis

- 3.1.1 Supplier landscape

- 3.1.2 Profit margin analysis

- 3.1.3 Cost structure

- 3.1.4 Value addition at each stage

- 3.1.5 Factor affecting the value chain

- 3.1.6 Disruptions

- 3.2 Industry impact forces

- 3.2.1 Growth drivers

- 3.2.1.1 Rising commercial vehicle production

- 3.2.1.2 Growing diesel vehicle lifespan

- 3.2.1.3 Technological advancements in valve materials

- 3.2.1.4 Expansion of freight & logistics industry

- 3.2.2 Industry pitfalls and challenges

- 3.2.2.1 Shift toward electric and alternative fuel vehicles

- 3.2.2.2 High cost of advanced valve materials

- 3.2.3 Market opportunities

- 3.2.3.1 Aftermarket expansion in aging vehicle fleets

- 3.2.3.2 Surge in off-highway vehicle demand

- 3.2.1 Growth drivers

- 3.3 Growth potential analysis

- 3.4 Regulatory landscape

- 3.4.1 North America

- 3.4.2 Europe

- 3.4.3 Asia Pacific

- 3.4.4 Latin America

- 3.4.5 Middle East & Africa

- 3.5 Porter's analysis

- 3.6 PESTEL analysis

- 3.7 Technology and Innovation landscape

- 3.7.1 Current technological trends

- 3.7.2 Emerging technologies

- 3.8 Cost breakdown analysis

- 3.8.1 Software development & licensing cost

- 3.8.2 Deployment & integration cost

- 3.8.3 Maintenance & support cost

- 3.8.4 Cybersecurity & compliance cost

- 3.8.5 Training & change management cost

- 3.9 Patent analysis

- 3.10 Sustainability and environmental aspects

- 3.10.1 Sustainable practices

- 3.10.2 Waste reduction strategies

- 3.10.3 Energy efficiency in production

- 3.10.4 Eco-friendly Initiatives

- 3.10.5 Carbon footprint considerations

- 3.11 Use cases

- 3.12 Best-case scenario

Chapter 4 Competitive Landscape, 2024

- 4.1 Introduction

- 4.2 Company market share analysis

- 4.2.1 North America

- 4.2.2 Europe

- 4.2.3 Asia Pacific

- 4.2.4 LATAM

- 4.2.5 MEA

- 4.3 Competitive analysis of major market players

- 4.4 Competitive positioning matrix

- 4.5 Strategic outlook matrix

- 4.6 Key developments

- 4.6.1 Mergers & acquisitions

- 4.6.2 Partnerships & collaborations

- 4.6.3 New Product Launches

- 4.6.4 Expansion Plans and funding

Chapter 5 Market Estimates & Forecast, By Engine, 2021 - 2034 ($Mn, Units)

- 5.1 Key trends

- 5.2 Single cylinder diesel engine

- 5.3 Multi-cylinder diesel engine

Chapter 6 Market Estimates & Forecast, By Valve, 2021 - 2034 ($Mn, Units)

- 6.1 Key trends

- 6.2 Mono-metallic exhaust valve

- 6.3 Bimetallic exhaust valve

- 6.4 Hollow stem valve

- 6.5 Sodium-filled valve

Chapter 7 Market Estimates & Forecast, By Material Type, 2021 - 2034 ($Mn, Units)

- 7.1 Key trends

- 7.2 Steel

- 7.3 Titanium

- 7.4 Nickel-based alloys

- 7.5 Other high-temperature alloys

Chapter 8 Market Estimates & Forecast, By Sales Channel, 2021 - 2034 ($Mn, Units)

- 8.1 Key trends

- 8.2 OEM

- 8.3 Aftermarket

Chapter 9 Market Estimates & Forecast, By End Use, 2021 - 2034 ($Mn, Units)

- 9.1 Key trends

- 9.2 Transportation & logistics

- 9.3 Construction & mining

- 9.4 Agriculture

- 9.5 Public transportation

- 9.6 Emergency & utility services

- 9.7 Military & defense

- 9.8 Others

Chapter 10 Market Estimates & Forecast, By Region, 2021 - 2034 ($Mn, Units)

- 10.1 Key trends

- 10.2 North America

- 10.2.1 U.S.

- 10.2.2 Canada

- 10.3 Europe

- 10.3.1 Germany

- 10.3.2 UK

- 10.3.3 France

- 10.3.4 Italy

- 10.3.5 Spain

- 10.3.6 Nordics

- 10.3.7 Russia

- 10.4 Asia Pacific

- 10.4.1 China

- 10.4.2 India

- 10.4.3 Japan

- 10.4.4 Australia

- 10.4.5 South Korea

- 10.4.6 Southeast Asia

- 10.5 Latin America

- 10.5.1 Brazil

- 10.5.2 Mexico

- 10.5.3 Argentina

- 10.6 MEA

- 10.6.1 South Africa

- 10.6.2 Saudi Arabia

- 10.6.3 UAE

Chapter 11 Company Profiles

- 11.1 Anhui Yuxi Industrial

- 11.2 AVR Valves

- 11.3 Continental AG

- 11.4 Delphi Automotive AG

- 11.5 Denso Corporation

- 11.6 Eaton Corporation

- 11.7 Federal-Mogul Holding Corp

- 11.8 FTE Automotive

- 11.9 FUJI OOZX

- 11.10 Hitachi

- 11.11 Knorr-Bremse

- 11.12 Mahle Group

- 11.13 MS Motorservice International

- 11.14 Nanjing Shengpai Auto Parts

- 11.15 Riken Corporation

- 11.16 Shijiazhuang Advanced Valve

- 11.17 Sinotruck Engine Valve

- 11.18 Tenneco

- 11.19 TRW Automotive

- 11.20 Wuxi Volex Auto Parts