|

市場調查報告書

商品編碼

1740859

汽車氣門座圈市場機會、成長動力、產業趨勢分析及 2025 - 2034 年預測Automotive Valve Seat Insert Market Opportunity, Growth Drivers, Industry Trend Analysis, and Forecast 2025 - 2034 |

||||||

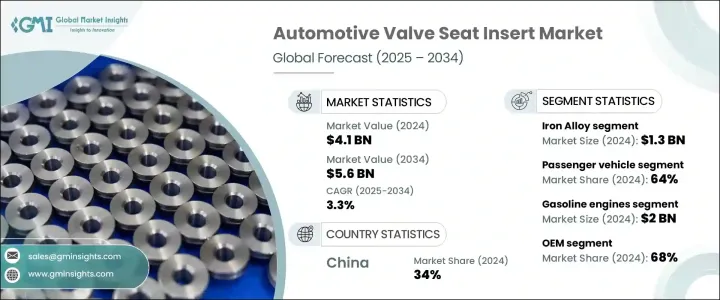

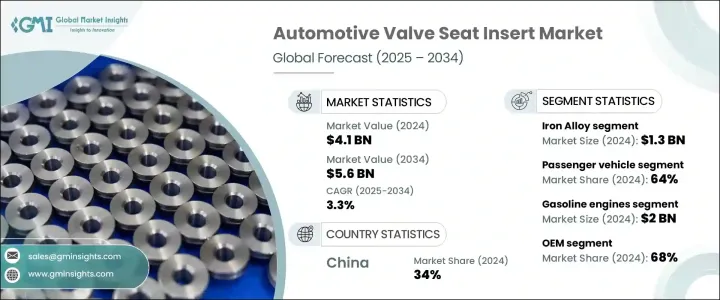

2024年,全球汽車氣門座圈市值為41億美元,預計2034年將以3.3%的複合年成長率成長,達到56億美元。這一穩定成長主要得益於重型卡車、農業機械和工程車輛產量和部署的不斷增加。這些車輛在嚴苛的工況下行駛,行駛里程長,這給引擎部件帶來了巨大的壓力。為了應對這些挑戰,引擎部件必須耐用可靠。氣門座圈在維持適當的引擎壓縮力以及防止熱腐蝕或機械磨損造成的引擎損壞方面發揮關鍵作用。它們能夠承受高溫和高壓,是高性能引擎的重要組成部分。

隨著人們對燃油經濟性和長壽命引擎的需求不斷成長,對堅固耐用的氣門座圈的需求也不斷成長,尤其是在混合動力系統和小型渦輪增壓引擎中。除了延長使用壽命外,這些座圈對於降低維護成本和延長引擎壽命也至關重要。製造商擴大轉向採用能夠提高耐熱性和機械耐久性的材料和技術。此外,遵守不斷演變的排放法規的壓力也越來越大,這促使座圈設計和材料成分不斷創新。粉末冶金和特殊耐熱合金等先進技術正被採用,以確保在極端條件下獲得更佳性能。

| 市場範圍 | |

|---|---|

| 起始年份 | 2024 |

| 預測年份 | 2025-2034 |

| 起始值 | 41億美元 |

| 預測值 | 56億美元 |

| 複合年成長率 | 3.3% |

依材料,市場細分為鐵合金、鋼、鎳基合金、鈷基合金等。 2024年,鐵合金市場以13億美元的收入領先市場。鐵合金因其價格實惠、強度和耐磨性均衡而成為首選。這些材料與常用引擎缸蓋的熱膨脹特性高度相容,使其成為大規模生產的可靠選擇。它們能夠承受高溫和機械負荷且成本低廉,這對於追求成本效益而不犧牲品質的製造商尤其重要。易於加工、鍛造和熱處理的特性也支援大批量生產流程,並降低了操作複雜性。

就車輛類型而言,市場分為乘用車、商用車和摩托車。乘用車佔了最大的市場佔有率,2024 年貢獻了 64%。乘用車的產量巨大,這促成了其主導地位,因為每台引擎都需要多個氣門座圈。全球汽車需求的不斷成長極大地增加了對這些部件的需求,使乘用車領域成為市場收入的核心驅動力。

按引擎類型分類,市場包括汽油引擎、柴油引擎、燃氣引擎(CNG、LPG、天然氣)、混合動力引擎等。汽油引擎細分市場在2024年創造了20億美元的收入,成為市場主導類別。汽油引擎通常以更高的轉速運轉,導致氣門活動更頻繁。這種更高的運動會導致更大的磨損和摩擦,因此需要能夠承受熱應力的耐用嵌件。此外,小型渦輪增壓汽油引擎的使用日益增多,也增加了對能夠耐受高壓燃燒環境的嵌件的需求。

從銷售管道來看,市場分為OEM)和售後市場兩部分。 2024 年,原廠(OEM ) 佔據了 68% 的市佔率。原廠 (OEM) 在新引擎的初始生產階段就整合了氣門座圈,從而提供無縫且經濟高效的解決方案。原廠組裝車輛的高產量確保了OEM)座圈的持續需求,尤其是在乘用車和輕型商用車領域。售後市場雖然規模較小,但卻是現有車輛在使用壽命期間取得替換零件和服務的重要管道。

從區域來看,亞太地區引領市場,光是中國就佔據該地區34%的市場佔有率,預計2024年將達到34%。亞太市場受惠於汽車產量的大幅成長,主要製造中心的產量持續成長。隨著引擎產量擴大以滿足消費者需求,這種擴張直接刺激了對氣門座圈的需求。

塑造競爭格局的主要參與者包括伊頓、輝門(天納克)、吉凱恩汽車、古德森工具及用品公司、哈金森、卡維亞國際、三菱綜合材料、馬勒、日本活塞環和TPR。這些公司積極投資創新,以提升產品性能,通常透過合作和合資的方式。他們也正在應對來自利基材料專家和探索先進引擎部件的新進入者日益激烈的競爭。他們越來越關注開發適用於混合動力和高效引擎的下一代氣門座圈,以滿足新的環保標準和性能預期。

目錄

第1章:方法論與範圍

第2章:執行摘要

第3章:行業洞察

- 產業生態系統分析

- 供應商格局

- 原物料供應商

- 零件供應商

- 製造商

- 技術提供者

- 最終用途

- 供應商格局

- 川普政府關稅的影響

- 對貿易的影響

- 貿易量中斷

- 報復措施

- 對產業的影響

- 供給側影響(原料)

- 主要材料價格波動

- 供應鏈重組

- 生產成本影響

- 需求面影響(售價)

- 價格傳導至終端市場

- 市佔率動態

- 消費者反應模式

- 供給側影響(原料)

- 策略產業反應

- 供應鏈重組

- 定價和產品策略

- 對貿易的影響

- 利潤率分析

- 技術與創新格局

- 專利分析

- 重要新聞和舉措

- 監管格局

- 成本細分分析

- 價格趨勢

- 地區

- 引擎型號

- 永續性和環境影響

- 環保材料

- 氣門座圈製造的碳足跡

- 回收實踐

- ESG合規性

- 衝擊力

- 成長動力

- 引擎技術的進步

- 嚴格的排放法規

- 汽車產量上升

- 向替代燃料過渡

- 產業陷阱與挑戰

- 來自電動車的競爭

- 原物料價格波動

- 成長動力

- 成長潛力分析

- 波特的分析

- PESTEL分析

第4章:競爭格局

- 介紹

- 公司市佔率分析

- 競爭定位矩陣

- 戰略展望矩陣

第5章:市場估計與預測:依資料,2021 - 2034 年

- 主要趨勢

- 鐵合金

- 鋼

- 鎳基合金

- 鈷基合金

- 其他

第6章:市場估計與預測:依車型,2021 - 2034 年

- 主要趨勢

- 搭乘用車

- 掀背車

- 轎車

- 越野車

- 商用車

- 輕型商用車(LCV)

- 中型商用車(MCV)

- 重型商用車(HCV)

- 摩托車

第7章:市場估計與預測:按引擎,2021 - 2034 年

- 主要趨勢

- 汽油引擎

- 柴油引擎

- 燃氣引擎(天然氣、CNG、LPG)

- 油電混合引擎

- 其他

第8章:市場估計與預測:依銷售管道,2021 - 2034 年

- 主要趨勢

- OEM

- 售後市場

第9章:市場估計與預測:按地區,2021 - 2034 年

- 主要趨勢

- 北美洲

- 美國

- 加拿大

- 歐洲

- 英國

- 德國

- 法國

- 義大利

- 西班牙

- 俄羅斯

- 北歐人

- 亞太地區

- 中國

- 印度

- 日本

- 澳洲

- 韓國

- 東南亞

- 拉丁美洲

- 巴西

- 墨西哥

- 阿根廷

- MEA

- 阿拉伯聯合大公國

- 南非

- 沙烏地阿拉伯

第10章:公司簡介

- AVL List

- BorgWarner

- DENSO

- Dura-Bond Bearing Company

- Eaton

- ElringKlinger

- Forvia SE (Faurecia)

- GKN Automotive

- Goodson Tools & Supplies

- Hutchinson

- Kavya International

- MAHLE

- Microfinish Group

- Mitsubishi Materials

- Nippon Piston Ring

- Perfect Alloy Components

- Rane Engine Valve

- Tenneco

- TPR

- XLP Engineers

The Global Automotive Valve Seat Insert Market was valued at USD 4.1 billion in 2024 and is estimated to grow at a CAGR of 3.3% to reach USD 5.6 billion by 2034. This steady growth is driven largely by the increasing production and deployment of heavy-duty trucks, agricultural machinery, and construction vehicles. These vehicles operate in demanding conditions and cover extensive distances, which puts significant pressure on engine components. To meet these challenges, the engine parts must be durable and reliable. Valve seat inserts play a key role in maintaining proper engine compression and preventing engine damage caused by thermal erosion or mechanical wear. Their ability to withstand intense heat and pressure makes them an essential component for high-performance engines.

The expanding need for fuel-efficient and long-lasting engines continues to push the demand for robust valve seat inserts, particularly in hybrid powertrains and downsized turbo engines. In addition to supporting longevity, these inserts are integral in reducing maintenance costs and enhancing the life cycle of the engine. Manufacturers are increasingly turning to materials and technologies that improve heat resistance and mechanical endurance. There is also growing pressure to comply with evolving emission regulations, leading to innovation in insert design and material composition. Advancements such as powder metallurgy and specialized heat-resistant alloys are being adopted to ensure better performance under extreme conditions.

| Market Scope | |

|---|---|

| Start Year | 2024 |

| Forecast Year | 2025-2034 |

| Start Value | $4.1 Billion |

| Forecast Value | $5.6 Billion |

| CAGR | 3.3% |

Based on material, the market is segmented into iron alloys, steel, nickel-based alloys, cobalt-based alloys, and others. In 2024, the iron alloy segment led the market with USD 1.3 billion in revenue. Iron alloys have become the preferred choice due to their affordability and a balanced mix of strength and wear resistance. These materials are highly compatible with the thermal expansion properties of commonly used engine heads, making them a reliable option for mass production. Their ability to handle high temperatures and mechanical loads without excessive cost is especially valuable to manufacturers aiming for cost-efficiency without sacrificing quality. The ease of machining, forging, and heat treatment also supports high-volume manufacturing processes and reduces operational complexity.

In terms of vehicle type, the market is divided into passenger vehicles, commercial vehicles, and motorcycles. Passenger vehicles accounted for the largest market share, contributing 64% in 2024. The sheer volume of passenger vehicle production contributes to this dominance, as each engine requires multiple valve seat inserts. The growing global demand for cars significantly amplifies the need for these components, making the passenger vehicle segment a core driver of market revenue.

By engine type, the market includes gasoline engines, diesel engines, gas engines (CNG, LPG, natural gas), hybrid engines, and others. The gasoline engine segment generated USD 2 billion in revenue in 2024, making it the dominant category. Gasoline engines typically operate at higher revolutions per minute, resulting in more frequent valve activity. This increased motion contributes to greater wear and friction, requiring durable inserts that can withstand thermal stress. Additionally, the growing use of small, turbocharged gasoline engines adds to the demand for inserts capable of tolerating high-pressure combustion environments.

Looking at the sales channel, the market is split between OEM and aftermarket segments. In 2024, the OEM segment captured 68% of the market share. OEMs integrate valve seat inserts during the initial production of new engines, offering a seamless and cost-effective solution. The high output of factory-fitted vehicles ensures consistent demand for OEM inserts, particularly in passenger and light commercial vehicles. The aftermarket, while smaller, serves as a vital channel for replacement parts and services over the lifespan of vehicles already on the road.

Regionally, the Asia-Pacific area led the market, with China alone holding a 34% share within the region in 2024. The APAC market benefits from high automotive production volumes, which continue to grow in key manufacturing hubs. This expansion directly boosts the need for valve seat inserts as engine production scales up to meet consumer demand.

Major players shaping the competitive landscape include Eaton, Federal-Mogul (Tenneco), GKN Automotive, Goodson Tools & Supplies, Hutchinson, Kavya International, Mitsubishi Materials, MAHLE, Nippon Piston Ring, and TPR. These companies are actively investing in innovation to enhance product performance, often through collaborations and joint ventures. They are also navigating rising competition from niche material specialists and new entrants exploring advanced engine components. The focus is increasingly on developing next-generation valve seat inserts tailored for hybrid and high-efficiency engines that align with new environmental standards and performance expectations.

Table of Contents

Chapter 1 Methodology & Scope

- 1.1 Research design

- 1.1.1 Research approach

- 1.1.2 Data collection methods

- 1.2 Base estimates & calculations

- 1.2.1 Base year calculation

- 1.2.2 Key trends for market estimation

- 1.3 Forecast model

- 1.4 Primary research and validation

- 1.4.1 Primary sources

- 1.4.2 Data mining sources

- 1.5 Market scope & definition

Chapter 2 Executive Summary

- 2.1 Industry synopsis, 2021 - 2034

Chapter 3 Industry Insights

- 3.1 Industry ecosystem analysis

- 3.1.1 Supplier landscape

- 3.1.1.1 Raw material suppliers

- 3.1.1.2 Component suppliers

- 3.1.1.3 Manufacturers

- 3.1.1.4 Technology providers

- 3.1.1.5 End use

- 3.1.1 Supplier landscape

- 3.2 Impact of trump administration tariffs

- 3.2.1 Impact on trade

- 3.2.1.1 Trade volume disruptions

- 3.2.1.2 Retaliatory measures

- 3.2.2 Impact on industry

- 3.2.2.1 Supply-side impact (raw materials)

- 3.2.2.1.1 Price volatility in key materials

- 3.2.2.1.2 Supply chain restructuring

- 3.2.2.1.3 Production cost implications

- 3.2.2.2 Demand-side impact (selling price)

- 3.2.2.2.1 Price transmission to end markets

- 3.2.2.2.2 Market share dynamics

- 3.2.2.2.3 Consumer response patterns

- 3.2.2.1 Supply-side impact (raw materials)

- 3.2.3 Strategic industry responses

- 3.2.3.1 Supply chain reconfiguration

- 3.2.3.2 Pricing and product strategies

- 3.2.1 Impact on trade

- 3.3 Profit margin analysis

- 3.4 Technology & innovation landscape

- 3.5 Patent analysis

- 3.6 Key news & initiatives

- 3.7 Regulatory landscape

- 3.8 Cost breakdown analysis

- 3.9 Price trend

- 3.9.1 Region

- 3.9.2 Mode of engine

- 3.10 Sustainability & environmental impact

- 3.10.1 Eco-friendly materials

- 3.10.2 Carbon footprint of valve seat inserts manufacturing

- 3.10.3 Recycling practices

- 3.10.4 ESG compliance

- 3.11 Impact forces

- 3.11.1 Growth drivers

- 3.11.1.1 Advancement in engine technology

- 3.11.1.2 Strict emission regulations

- 3.11.1.3 Rising vehicle production

- 3.11.1.4 Transition to alternative fuels

- 3.11.2 Industry pitfalls & challenges

- 3.11.2.1 Competition from electric vehicles

- 3.11.2.2 Volatility in raw material prices

- 3.11.1 Growth drivers

- 3.12 Growth potential analysis

- 3.13 Porter's analysis

- 3.14 PESTEL analysis

Chapter 4 Competitive Landscape, 2024

- 4.1 Introduction

- 4.2 Company market share analysis

- 4.3 Competitive positioning matrix

- 4.4 Strategic outlook matrix

Chapter 5 Market Estimates & Forecast, By Material, 2021 - 2034 ($Bn, Units)

- 5.1 Key trends

- 5.2 Iron alloys

- 5.3 Steel

- 5.4 Nickel-based alloys

- 5.5 Cobalt-based alloys

- 5.6 Other

Chapter 6 Market Estimates & Forecast, By Vehicle, 2021 - 2034 ($Bn, Units)

- 6.1 Key trends

- 6.2 Passenger Vehicles

- 6.2.1 Hatchback

- 6.2.2 Sedan

- 6.2.3 SUV

- 6.3 Commercial Vehicles

- 6.3.1 Light commercial vehicles (LCV)

- 6.3.2 Medium commercial vehicles (MCV)

- 6.3.3 Heavy commercial vehicles (HCV)

- 6.4 Motorcycle

Chapter 7 Market Estimates & Forecast, By Engine, 2021 - 2034 ($Bn, Units)

- 7.1 Key trends

- 7.2 Gasoline engines

- 7.3 Diesel engines

- 7.4 Gas engines (Natural Gas, CNG, LPG)

- 7.5 Hybrid engines

- 7.6 Others

Chapter 8 Market Estimates & Forecast, By Sales Channel, 2021 - 2034 ($Bn, Units)

- 8.1 Key trends

- 8.2 OEM

- 8.3 Aftermarket

Chapter 9 Market Estimates & Forecast, By Region, 2021 - 2034 ($Bn, Units)

- 9.1 Key trends

- 9.2 North America

- 9.2.1 U.S.

- 9.2.2 Canada

- 9.3 Europe

- 9.3.1 UK

- 9.3.2 Germany

- 9.3.3 France

- 9.3.4 Italy

- 9.3.5 Spain

- 9.3.6 Russia

- 9.3.7 Nordics

- 9.4 Asia Pacific

- 9.4.1 China

- 9.4.2 India

- 9.4.3 Japan

- 9.4.4 Australia

- 9.4.5 South Korea

- 9.4.6 Southeast Asia

- 9.5 Latin America

- 9.5.1 Brazil

- 9.5.2 Mexico

- 9.5.3 Argentina

- 9.6 MEA

- 9.6.1 UAE

- 9.6.2 South Africa

- 9.6.3 Saudi Arabia

Chapter 10 Company Profiles

- 10.1 AVL List

- 10.2 BorgWarner

- 10.3 DENSO

- 10.4 Dura-Bond Bearing Company

- 10.5 Eaton

- 10.6 ElringKlinger

- 10.7 Forvia SE (Faurecia)

- 10.8 GKN Automotive

- 10.9 Goodson Tools & Supplies

- 10.10 Hutchinson

- 10.11 Kavya International

- 10.12 MAHLE

- 10.13 Microfinish Group

- 10.14 Mitsubishi Materials

- 10.15 Nippon Piston Ring

- 10.16 Perfect Alloy Components

- 10.17 Rane Engine Valve

- 10.18 Tenneco

- 10.19 TPR

- 10.20 XLP Engineers