|

市場調查報告書

商品編碼

1773376

自動膠帶應用系統市場機會、成長動力、產業趨勢分析及 2025 - 2034 年預測Automated Tape Application Systems Market Opportunity, Growth Drivers, Industry Trend Analysis, and Forecast 2025 - 2034 |

||||||

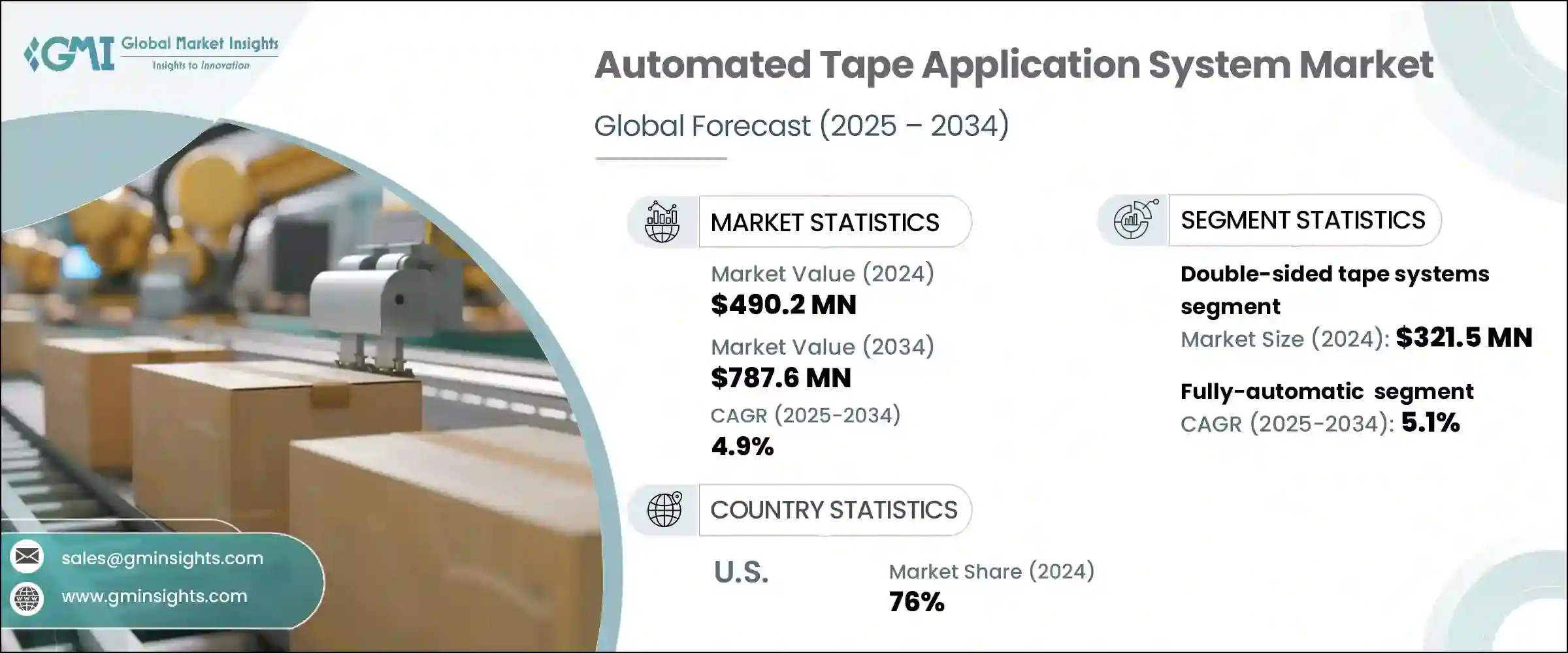

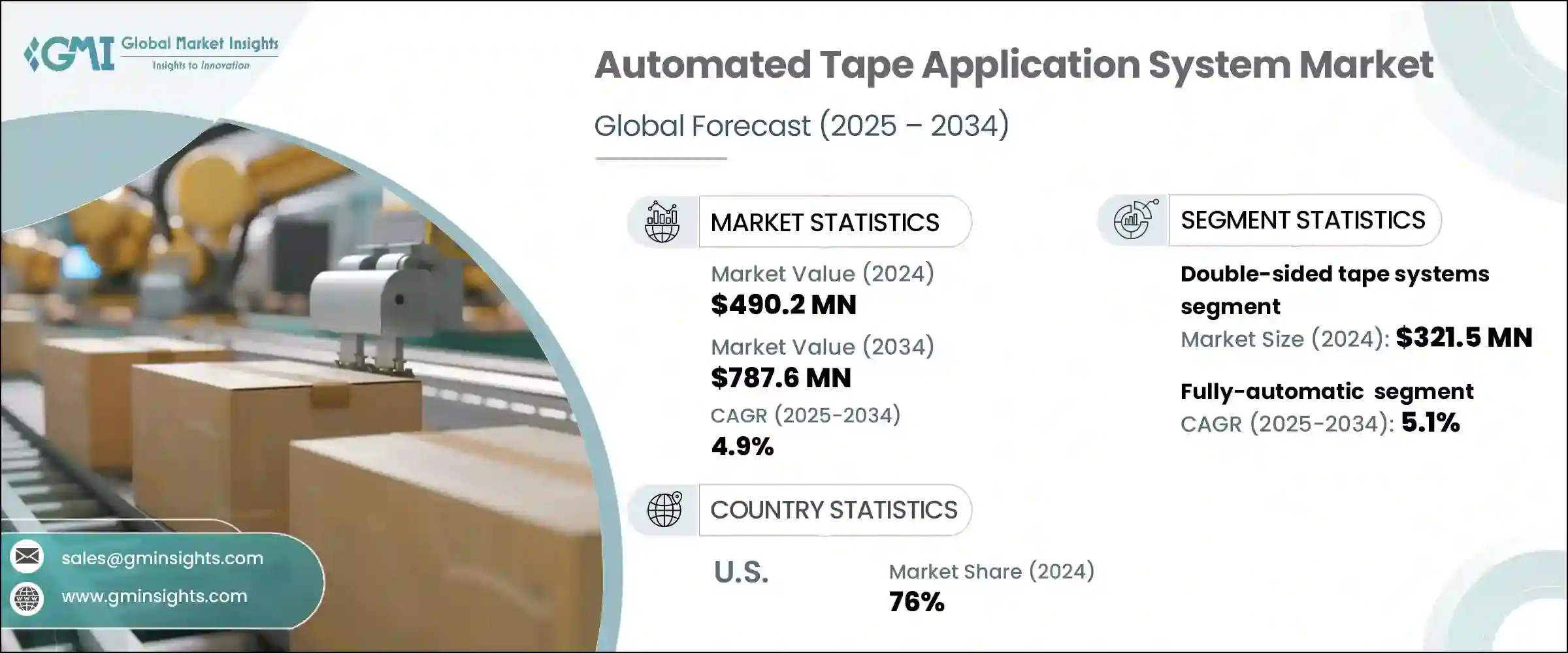

2024年,全球自動膠帶應用系統市場規模達4.902億美元,預計2034年將以4.9%的複合年成長率成長,達到7.876億美元。該市場的成長主要得益於電子商務產業快速成長所推動的包裝流程自動化程度的提升。隨著對更快、更有效率包裝解決方案的需求日益成長,企業擴大轉向自動化系統。自動膠帶應用系統在簡化包裝流程方面發揮著至關重要的作用,它能夠提供可靠、一致的黏合效果,同時最大限度地減少對人工的需求。此外,這些系統還有助於減少膠帶浪費和能源消耗,從而節省成本,提高生產力和永續性。

全自動配送中心的日益普及,尤其是在大型電商平台中,大大推動了全球自動膠帶應用系統的普及。這些中心利用尖端機器人技術、人工智慧和機器視覺技術,旨在最佳化包裝和物流的各個環節。隨著電商公司尋求更快、更有效率的訂單履行,對自動化的需求也隨之激增,這使得自動膠帶應用系統對於簡化包裝操作至關重要。為了應對這項需求激增,膠帶應用系統製造商正在大力投資,開發更先進、更快速、更可靠的解決方案。這些投資不僅提高了系統性能,還降低了營運成本和能耗。

| 市場範圍 | |

|---|---|

| 起始年份 | 2024 |

| 預測年份 | 2025-2034 |

| 起始值 | 4.902億美元 |

| 預測值 | 7.876億美元 |

| 複合年成長率 | 4.9% |

2024年,雙面膠帶系統細分市場產值達3.215億美元,預計2025-2034年複合年成長率為5.3%。由於航太、建築和消費電子等行業對高性能黏合和潔淨表面的需求,該細分市場引領市場。雙面膠帶系統在需要直接、持久黏合的組裝應用中具有優勢,可消除可見的膠帶痕跡。這些系統隨著技術進步而不斷發展,包括能夠使用客製化膠帶送料系統和自動化品質檢測,從而提高了靈活性和可靠性。

全自動膠帶應用系統市場在2024年佔據59%的市場佔有率,預計在2025年至2034年期間的複合年成長率為5.1%。全自動系統尤其受汽車、電子和包裝等需要高吞吐量、高精度和低干預的行業的青睞。這些系統利用整合機器人技術、機器視覺和基於人工智慧的控制技術,在確保品質穩定的同時最大限度地減少停機時間。工業4.0技術(包括即時監控和預測性維護)的日益普及,透過提高生產力和減少營運效率低下,進一步推動了這一趨勢。

2024年,美國自動膠帶應用系統市場佔76%的市場佔有率,產值達9,820萬美元。這一成長主要得益於製造業、汽車業、包裝業和電子商務等各行各業對自動化解決方案的廣泛採用。隨著對更有效率、更快速、更可靠的膠帶應用設備的需求不斷成長,自動化系統市場持續擴張,尤其是在大量包裝和組裝作業領域。

自動膠帶應用系統市場的主要參與者包括 Ambica Pharma Machines、APR Solutions、Cyklop、Daap Machinery、東莞科琪自動化設備、Global Packaging Automation、Intec Automation、Kylin Machines、Robo Tape、Robus India、Rocket Industrial、Smart Tec Automation、Straub Design Company Automation。自動膠帶應用系統市場的公司正專注於各種策略以鞏固其市場地位。這些策略包括大力投資研發,以提高產品的精度、效率和多功能性。公司也在探索合作夥伴關係和協作,以擴大其產品組合併拓展新的客戶群。自動化和智慧技術(例如機器人、人工智慧和機器視覺)的整合是許多參與者提高系統可靠性和性能策略的核心。

目錄

第1章:方法論與範圍

第2章:執行摘要

第3章:行業洞察

- 產業生態系統分析

- 供應商概況

- 利潤率

- 每個階段的增值

- 影響價值鏈的因素

- 產業衝擊力

- 成長動力

- 電子商務和包裝自動化的興起

- 製造業和工業自動化的成長

- 產業陷阱與挑戰

- 初始投資成本高

- 整合複雜性

- 機會

- 成長動力

- 成長潛力分析

- 未來市場趨勢

- 技術和創新格局

- 當前的技術趨勢

- 新興技術

- 價格趨勢

- 按地區

- 按產品

- 監管格局

- 標準和合規要求

- 區域監理框架

- 認證標準

- 波特的分析

- PESTEL分析

第4章:競爭格局

- 介紹

- Company market share analysis

- By region

- 公司矩陣分析

- 主要市場參與者的競爭分析

- 競爭定位矩陣

- 關鍵進展

- 併購

- 夥伴關係與合作

- 新產品發布

- 擴張計劃

第5章:市場估計與預測:按類型,2021 - 2034 年

- 主要趨勢

- 單面膠帶系統

- 雙面膠帶系統

第6章:市場估計與預測:依自動化水平,2021 - 2034 年

- 主要趨勢

- 全自動

- 半自動

第7章:市場估計與預測:依包裝類型,2021 - 2034 年

- 主要趨勢

- 紙箱

- 瓦楞紙箱

- 外送袋

- 其他

第8章:市場估計與預測:按產量,2021 - 2034 年

- 主要趨勢

- 高達 1000 箱/小時

- 1000箱/小時至5000箱/小時

- 每小時5000箱以上

第9章:市場估計與預測:依最終用途產業,2021 - 2034 年

- 主要趨勢

- 電子商務及配送中心

- 零售和消費品

- 食品和飲料

- 製藥和醫療

- 物流與倉儲

- 其他(電子、電器等)

第 10 章:市場估計與預測:按配銷通路,2021 年至 2034 年

- 主要趨勢

- 直接的

- 間接

第 11 章:市場估計與預測:按地區,2021 年至 2034 年

- 主要趨勢

- 北美洲

- 美國

- 加拿大

- 歐洲

- 德國

- 英國

- 法國

- 西班牙

- 義大利

- 荷蘭

- 亞太地區

- 中國

- 日本

- 印度

- 澳洲

- 韓國

- 拉丁美洲

- 巴西

- 墨西哥

- 阿根廷

- 中東和非洲

- 南非

- 沙烏地阿拉伯

- 阿拉伯聯合大公國

第12章:公司簡介

- Ambica Pharma Machines

- APR Solutions

- Cyklop

- Daap Machinery

- Dongguan KEQI automation equipment

- Global Packaging Automation

- Intec Automation

- Kylin Machines

- Robo Tape

- Robus India

- Rocket Industrial

- Smart Tec Automation

- Straub Design Company

- Vulkan Technic

- Wayne Automation

The Global Automated Tape Application Systems Market was valued at USD 490.2 million in 2024 and is estimated to grow at a CAGR of 4.9% to reach USD 787.6 million by 2034. This market is expanding primarily due to the rise in automation in packing processes, driven by the rapid growth of the e-commerce industry. As the demand for faster, more efficient packaging solutions intensifies, businesses are increasingly turning to automated systems. Automated tape application systems play a crucial role in streamlining packaging by providing reliable, consistent adhesion while minimizing the need for manual labor. Additionally, these systems contribute to cost savings in terms of reduced tape waste and energy consumption, enhancing both productivity and sustainability.

The growing presence of fully automated fulfillment centers, particularly among major e-commerce players, is significantly boosting the global adoption of automated tape application systems. These centers, which leverage cutting-edge robotics, artificial intelligence, and machine vision, are designed to optimize every aspect of packaging and logistics. As e-commerce companies seek faster and more efficient order fulfillment, the demand for automation has skyrocketed, making automated tape application systems crucial for streamlining packing operations. In response to this surge, manufacturers of tape application systems are making significant investments in developing more advanced, faster, and more reliable solutions. These investments are not only improving system performance but also reducing operational costs and energy consumption.

| Market Scope | |

|---|---|

| Start Year | 2024 |

| Forecast Year | 2025-2034 |

| Start Value | $490.2 Million |

| Forecast Value | $787.6 Million |

| CAGR | 4.9% |

In 2024, the double-sided tape systems segment generated USD 321.5 million and is expected to grow at a CAGR of 5.3% during 2025-2034. This segment leads the market due to the demand from industries such as aerospace, construction, and consumer electronics, which require high-performance adhesion and clean finishes. Double-sided tape systems offer an advantage in assembly applications where direct, durable bonds are needed, eliminating visible tape lines. These systems continue to evolve with technological improvements, including the ability to utilize custom tape feed systems and automated quality inspections, increasing both flexibility and reliability.

The fully automatic tape application systems segment held 59% share in 2024 and is projected to grow at a CAGR of 5.1% between 2025 and 2034. Fully automated systems are particularly preferred in industries that require high throughput, precision, and minimal intervention, such as automotive, electronics, and packaging. These systems leverage integrated robotics, machine vision, and AI-based controls to ensure consistent quality while minimizing downtime. The growing adoption of Industry 4.0 technologies, including real-time monitoring and predictive maintenance, is further fueling this trend by improving productivity and reducing operational inefficiencies.

United States Automated Tape Application Systems Market held a 76% share in 2024, generating USD 98.2 million. This growth is largely driven by the widespread adoption of automated solutions across various sectors, including manufacturing, automotive, packaging, and e-commerce. As demand for more efficient, faster, and reliable tape application equipment increases, the market for automated systems continues to expand, particularly in high-volume packaging and assembly operations.

Key players in the Automated Tape Application Systems Market include Ambica Pharma Machines, APR Solutions, Cyklop, Daap Machinery, Dongguan KEQI Automation Equipment, Global Packaging Automation, Intec Automation, Kylin Machines, Robo Tape, Robus India, Rocket Industrial, Smart Tec Automation, Straub Design Company, Vulkan Technic, and Wayne Automation. Companies in the automated tape application systems market are focusing on various strategies to strengthen their market position. These include investing heavily in research and development to enhance the precision, efficiency, and versatility of their products. Companies are also exploring partnerships and collaborations to expand their product portfolios and reach new customer segments. Automation and integration of smart technologies, such as robotics, AI, and machine vision, are central to many players' strategies to improve the reliability and performance of their systems.

Table of Contents

Chapter 1 Methodology & Scope

- 1.1 Market scope and definition

- 1.2 Research design

- 1.2.1 Research approach

- 1.2.2 Data collection methods

- 1.3 Data mining sources

- 1.3.1 Global

- 1.3.2 Regional/Country

- 1.4 Base estimates and calculations

- 1.4.1 Base year calculation

- 1.4.2 Key trends for market estimation

- 1.5 Primary research and validation

- 1.5.1 Primary sources

- 1.6 Forecast model

- 1.7 Research assumptions and limitations

Chapter 2 Executive Summary

- 2.1 Industry 360° synopsis

- 2.2 Key market trends

- 2.2.1 Regional

- 2.2.2 Type

- 2.2.3 Automation Level

- 2.2.4 Packaging Type

- 2.2.5 Output Capacity

- 2.2.6 End Use Industry

- 2.2.7 Distribution Channel

- 2.3 CXO perspectives: Strategic imperatives

- 2.3.1 Key decision points for industry executives

- 2.3.2 Critical success factors for market players

- 2.4 Future Outlook and Strategic Recommendations

Chapter 3 Industry Insights

- 3.1 Industry ecosystem analysis

- 3.1.1 Supplier Landscape

- 3.1.2 Profit Margin

- 3.1.3 Value addition at each stage

- 3.1.4 Factor affecting the value chain

- 3.2 Industry impact forces

- 3.2.1 Growth drivers

- 3.2.1.1 Rise in E-commerce and Packaging Automation

- 3.2.1.2 Growth in Manufacturing and Industrial Automation

- 3.2.2 Industry pitfalls & challenges

- 3.2.2.1 High Initial Investment Costs

- 3.2.2.2 Integration Complexity

- 3.2.3 Opportunities

- 3.2.1 Growth drivers

- 3.3 Growth potential analysis

- 3.4 Future market trends

- 3.5 Technology and Innovation landscape

- 3.5.1 Current technological trends

- 3.5.2 Emerging technologies

- 3.6 Price trends

- 3.6.1 By region

- 3.6.2 By product

- 3.7 Regulatory landscape

- 3.7.1 standards and compliance requirements

- 3.7.2 Regional regulatory frameworks

- 3.7.3 Certification standards

- 3.8 Porter's analysis

- 3.9 PESTEL analysis

Chapter 4 Competitive Landscape, 2024

- 4.1 Introduction

- 4.1.1 Company market share analysis

- 4.1.2 By region

- 4.1.2.1 North America

- 4.1.2.2 Europe

- 4.1.2.3 Asia Pacific

- 4.1.2.4 Latin America

- 4.1.2.5 MEA

- 4.2 Company matrix analysis

- 4.3 Competitive analysis of major market players

- 4.4 Competitive positioning matrix

- 4.5 Key developments

- 4.5.1 Mergers & acquisitions

- 4.5.2 Partnerships & collaborations

- 4.5.3 New Product Launches

- 4.5.4 Expansion Plans

Chapter 5 Market Estimates & Forecast, By Type, 2021 - 2034 ($Million, Thousand Units)

- 5.1 Key trends

- 5.2 Single-sided tape systems

- 5.3 Double-sided tape systems

Chapter 6 Market Estimates & Forecast, By Automation Level, 2021 - 2034 ($Million, Thousand Units)

- 6.1 Key trends

- 6.2 Fully automatic

- 6.3 Semi-automatic

Chapter 7 Market Estimates & Forecast, By Packaging Type, 2021 - 2034 ($Million, Thousand Units)

- 7.1 Key trends

- 7.2 Cardboard boxes

- 7.3 Corrugated boxes

- 7.4 Delivery bags

- 7.5 Others

Chapter 8 Market Estimates & Forecast, By Output Capacity, 2021 - 2034 ($Million, Thousand Units)

- 8.1 Key trends

- 8.2 Up to 1000 cartons/hour

- 8.3 1000 cartons/hour to 5,000 cartons/hour

- 8.4 above 5,000 cartons/hour

Chapter 9 Market Estimates & Forecast, By End Use Industry, 2021 - 2034 ($Million, Thousand Units)

- 9.1 Key trends

- 9.2 E-commerce & fulfillment centers

- 9.3 Retail & consumer goods

- 9.4 Food & beverage

- 9.5 Pharmaceutical & medical

- 9.6 Logistics & warehousing

- 9.7 Others( electronics & appliances, etc.)

Chapter 10 Market Estimates & Forecast, By Distribution Channel, 2021 - 2034 ($Million, Thousand Units)

- 10.1 Key trends

- 10.2 Direct

- 10.3 Indirect

Chapter 11 Market Estimates & Forecast, By Region, 2021 - 2034 ($Million, Thousand Units)

- 11.1 Key trends

- 11.2 North America

- 11.2.1 U.S.

- 11.2.2 Canada

- 11.3 Europe

- 11.3.1 Germany

- 11.3.2 UK

- 11.3.3 France

- 11.3.4 Spain

- 11.3.5 Italy

- 11.3.6 Netherlands

- 11.4 Asia Pacific

- 11.4.1 China

- 11.4.2 Japan

- 11.4.3 India

- 11.4.4 Australia

- 11.4.5 South Korea

- 11.5 Latin America

- 11.5.1 Brazil

- 11.5.2 Mexico

- 11.5.3 Argentina

- 11.6 Middle East and Africa

- 11.6.1 South Africa

- 11.6.2 Saudi Arabia

- 11.6.3 UAE

Chapter 12 Company Profiles

- 12.1 Ambica Pharma Machines

- 12.2 APR Solutions

- 12.3 Cyklop

- 12.4 Daap Machinery

- 12.5 Dongguan KEQI automation equipment

- 12.6 Global Packaging Automation

- 12.7 Intec Automation

- 12.8 Kylin Machines

- 12.9 Robo Tape

- 12.10 Robus India

- 12.11 Rocket Industrial

- 12.12 Smart Tec Automation

- 12.13 Straub Design Company

- 12.14 Vulkan Technic

- 12.15 Wayne Automation