|

市場調查報告書

商品編碼

1755269

化工電鍋爐市場機會、成長動力、產業趨勢分析及2025-2034年預測Chemical Industrial Electric Boiler Market Opportunity, Growth Drivers, Industry Trend Analysis, and Forecast 2025 - 2034 |

||||||

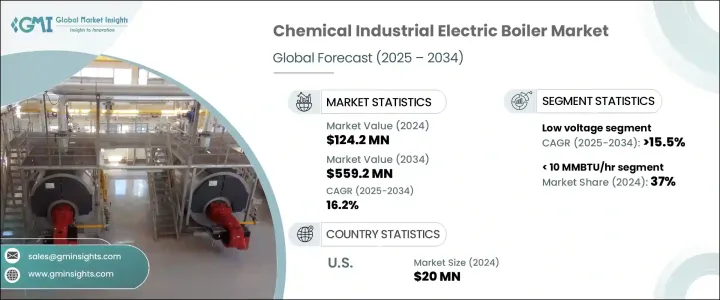

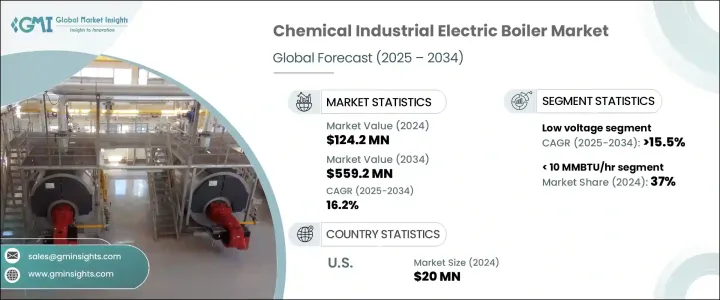

2024年,全球工電鍋爐市場規模達1.242億美元,預計2034年將以16.2%的複合年成長率成長,達到5.592億美元。這得歸功於全球向清潔能源轉型,以及政府推出的節能供熱系統支援計畫。隨著化工廠擴大採用永續生產方式,電鍋爐已成為可靠、精準供熱的關鍵解決方案。

電鍋爐系統(整合基於物聯網的控制和自動化技術)的技術進步持續推動其應用。這些創新透過即時監控和預測性維護,有助於減少停機時間,同時提高能源效率。如今,電鍋爐可以客製化以適應各種加熱能力,同時最大程度地減少對現有工廠基礎設施的干擾。其能夠精確地保持恆定的溫度,使其成為需要嚴格控制熱工條件的化學生產過程的理想選擇。隨著製造商應對化學設施的空間限制,緊湊型鍋爐設計也日益受到青睞。這些節省空間的配置可以無縫整合到舊系統中,並透過替換老舊鍋爐單元的現代化改造計劃進一步支持其發展。這一發展趨勢鞏固了業界向更清潔、更智慧的加熱技術的轉型。

| 市場範圍 | |

|---|---|

| 起始年份 | 2024 |

| 預測年份 | 2025-2034 |

| 起始值 | 1.242億美元 |

| 預測值 | 5.592億美元 |

| 複合年成長率 | 16.2% |

預計到2034年,化學工業低壓電鍋爐的複合年成長率將達到15.5%,這得益於日益成長的監管壓力,即減少對化石燃料的依賴,以及優惠的稅收優惠和財政支持。這類鍋爐因其維護成本低、設計節省空間而日益受到青睞,是佔地面積有限的工業環境的理想選擇。它們能夠為傳統燃料系統提供可靠、高效的替代方案,這對於尋求降低營運成本和提高永續性的產業極具吸引力。

預計到2034年,10-50百萬英熱單位/小時的細分市場複合年成長率將達到15%,因為這些設備在產量和效率之間實現了完美平衡。此尺寸範圍適用於中型化學企業,在這些企業中,精確控制和空間效率對於日常營運至關重要。

預計到2034年,北美化工電鍋爐市場將以20.5%的複合年成長率成長。製造業活動的不斷成長、技術進步以及私營企業與國家級機構為實現工業基礎設施現代化而建立的戰略合作夥伴關係,共同推動著該市場的成長。這些合作關係有助於推廣更清潔、更有效率的電鍋爐,從而實現環境和營運目標。

為化工電鍋爐行業的發展和成長做出貢獻的關鍵參與者包括博世工業鍋爐公司 (Bosch Industriekessel)、賽蒙 (Thermona)、PARAT Halvorsen AS、阿法拉伐 (ALFA LAVAL)、Precision Boilers、Cleaver-Brooks、Chromalox、Thermodyne 蒙賽、Ther熱愛(Thermon)、巴布科克·萬森 (Babcock Wanson)、Klopper-Therm、LACAZE ENERGIES、羅斯鍋爐公司 (Ross Boilers)、Acme Engineering Products、Cerney、費羅利 (FERROLI)、Danstoker A/S 和 Chromalox。化工電鍋爐市場的產業領導者正在大力投資研發,以提高其鍋爐系統的能源效率、控制精度和適應性。許多公司正在推出可與現有基礎設施整合的緊湊型型號,從而加快安裝速度並降低改造成本。一些公司在其產品中優先考慮物聯網和自動化功能,以滿足預測性維護和即時監控的需求。此外,與地區政府和工業客戶的策略合作旨在擴大影響力並獲得激勵支持的基礎設施項目。

目錄

第1章:方法論與範圍

第2章:執行摘要

第3章:行業洞察

- 產業生態系統分析

- 川普政府關稅分析

- 對貿易的影響

- 貿易量中斷

- 報復措施

- 對產業的影響

- 供應方影響(原料)

- 主要材料價格波動

- 供應鏈重組

- 生產成本影響

- 需求面影響(售價)

- 價格傳導至終端市場

- 市佔率動態

- 消費者反應模式

- 供應方影響(原料)

- 受影響的主要公司

- 策略產業反應

- 供應鏈重組

- 定價和產品策略

- 政策參與

- 展望與未來考慮

- 對貿易的影響

- 監管格局

- 產業衝擊力

- 成長動力

- 產業陷阱與挑戰

- 成長潛力分析

- 波特的分析

- PESTEL分析

第4章:競爭格局

- 介紹

- 公司市佔率分析

- 戰略儀表板

- 策略舉措

- 競爭基準測試

- 創新與永續發展格局

第5章:市場規模及預測:依電壓等級,2021 - 2034

- 主要趨勢

- 低電壓

- 中壓

第6章:市場規模及預測:依產能,2021 - 2034 年

- 主要趨勢

- < 10 百萬英熱單位/小時

- 10 - 50 百萬英熱單位/小時

- 50 - 100 百萬英熱單位/小時

- 100 - 250 百萬英熱單位/小時

- > 250 百萬英熱單位/小時

第7章:市場規模及預測:依產品,2021 - 2034

- 主要趨勢

- 熱水

- 蒸氣

第8章:市場規模及預測:依銷售管道,2021 - 2034 年

- 主要趨勢

- 線上

- 經銷商

- 零售

第9章:市場規模及預測:按地區,2021 - 2034

- 主要趨勢

- 北美洲

- 美國

- 加拿大

- 墨西哥

- 歐洲

- 法國

- 英國

- 波蘭

- 義大利

- 西班牙

- 德國

- 俄羅斯

- 奧地利

- 瑞典

- 亞太地區

- 中國

- 印度

- 日本

- 韓國

- 澳洲

- 印尼

- 菲律賓

- 中東和非洲

- 沙烏地阿拉伯

- 伊朗

- 阿拉伯聯合大公國

- 埃及

- 奈及利亞

- 肯亞

- 摩洛哥

- 南非

- 拉丁美洲

- 巴西

- 阿根廷

- 哥倫比亞

- 智利

第10章:公司簡介

- ALFA LAVAL

- Acme Engineering Products

- ACV

- Babcock Wanson

- Bosch Industriekessel

- Cerney

- Chromalox

- Cleaver-Brooks

- Danstoker A/S

- Ecotherm Austria

- FERROLI

- Klopper-Therm

- LACAZE ENERGIES

- PARAT Halvorsen AS

- Precision Boilers

- Reimers Electra Steam

- Ross Boilers

- Thermodyne Boilers

- Thermon

- Thermona

- Vapor Power

The Global Chemical Industrial Electric Boiler Market was valued at USD 124.2 million in 2024 and is estimated to grow at a CAGR of 16.2% to reach USD 559.2 million by 2034, fueled by the global shift toward clean energy and the introduction of supportive government programs aimed at promoting energy-efficient heating systems. As chemical plants increasingly adopt sustainable practices, electric boilers have emerged as a critical solution for reliable and precise heating.

Technological progress in electric boiler systems-integrated with IoT-based controls and automation-continues to drive adoption. These innovations help reduce operational downtimes through real-time monitoring and predictive maintenance, while also enhancing energy efficiency. Electric boilers can now be tailored to fit a wide range of heating capacities with minimal disruption to existing plant infrastructure. Their precision in maintaining consistent temperatures makes them ideal for chemical manufacturing processes that require tightly regulated thermal conditions. Compact boiler designs are also gaining momentum as manufacturers respond to spatial constraints in chemical facilities. These space-saving configurations allow seamless integration into older systems, further supported by modernization initiatives to replace outdated boiler units. This evolution reinforces the industry's transition toward cleaner, smarter heating technologies.

| Market Scope | |

|---|---|

| Start Year | 2024 |

| Forecast Year | 2025-2034 |

| Start Value | $124.2 Million |

| Forecast Value | $559.2 Million |

| CAGR | 16.2% |

Low-voltage electric boilers in the chemical industry are projected to grow at a CAGR of 15.5% through 2034, driven by increasing regulatory pressure to reduce fossil fuel dependence, along with favorable tax incentives and financial support. These boilers are gaining traction due to their low-maintenance requirements and space-efficient design, making them ideal for industrial environments where floor space is limited. Their ability to provide a reliable, efficient alternative to traditional fuel-based systems appeal to industries looking to reduce operational costs and improve sustainability.

The 10-50 MMBTU/hr segment is expected to see a CAGR of 15% through 2034, as these units offer a perfect balance between output and efficiency. This size range is suited to medium-sized chemical operations where precise control and space efficiency are crucial for day-to-day functioning.

North America Chemical Industrial Electric Boiler Market is anticipated to grow at a 20.5% CAGR by 2034. A combination of increasing manufacturing activity, technological advancements, and strategic partnerships between private companies and state-level organizations to modernize industrial infrastructure is driving the growth of this market. These partnerships facilitate the adoption of cleaner, more efficient electric boilers to meet environmental and operational goals.

Key players contributing to the development and growth of the chemical industrial electric boiler industry include Bosch Industriekessel, Thermona, PARAT Halvorsen AS, ALFA LAVAL, Precision Boilers, Cleaver-Brooks, Chromalox, Thermodyne Boilers, Ecotherm Austria, Reimers Electra Steam, Thermon, Babcock Wanson, Klopper-Therm, LACAZE ENERGIES, Ross Boilers, Acme Engineering Products, Cerney, FERROLI, Danstoker A/S, and Chromalox. Industry leaders in the chemical industrial electric boiler market are investing significantly in R&D to enhance the energy efficiency, control precision, and adaptability of their boiler systems. Many are introducing compact models that integrate with existing infrastructure, enabling faster installations and reducing retrofitting costs. Several companies prioritize IoT and automation capabilities in their product offerings to meet the demand for predictive maintenance and real-time monitoring. Additionally, strategic collaborations with regional governments and industrial clients pursue to expand reach and gain access to incentive-backed infrastructure projects.

Table of Contents

Chapter 1 Methodology & Scope

- 1.1 Research design

- 1.2 Market estimates & forecast parameters

- 1.3 Forecast calculation

- 1.4 Data sources

- 1.4.1 Primary

- 1.4.2 Secondary

- 1.4.2.1 Paid

- 1.4.2.2 Public

- 1.5 Market definitions

Chapter 2 Executive Summary

- 2.1 Industry synopsis, 2021 - 2034

Chapter 3 Industry Insights

- 3.1 Industry ecosystem analysis

- 3.2 Trump administration tariffs analysis

- 3.2.1 Impact on trade

- 3.2.1.1 Trade volume disruptions

- 3.2.1.2 Retaliatory measures

- 3.2.2 Impact on the industry

- 3.2.2.1 Supply-side impact (raw materials)

- 3.2.2.1.1 Price volatility in key materials

- 3.2.2.1.2 Supply chain restructuring

- 3.2.2.1.3 Production cost implications

- 3.2.2.2 Demand-side impact (selling price)

- 3.2.2.2.1 Price transmission to end markets

- 3.2.2.2.2 Market share dynamics

- 3.2.2.2.3 Consumer response patterns

- 3.2.2.1 Supply-side impact (raw materials)

- 3.2.3 Key companies impacted

- 3.2.4 Strategic industry responses

- 3.2.4.1 Supply chain reconfiguration

- 3.2.4.2 Pricing and product strategies

- 3.2.4.3 Policy engagement

- 3.2.5 Outlook and future considerations

- 3.2.1 Impact on trade

- 3.3 Regulatory landscape

- 3.4 Industry impact forces

- 3.4.1 Growth drivers

- 3.4.2 Industry pitfalls & challenges

- 3.5 Growth potential analysis

- 3.6 Porter's analysis

- 3.6.1 Bargaining power of suppliers

- 3.6.2 Bargaining power of buyers

- 3.6.3 Threat of new entrants

- 3.6.4 Threat of substitutes

- 3.7 PESTEL analysis

Chapter 4 Competitive Landscape, 2025

- 4.1 Introduction

- 4.2 Company market share analysis, 2024

- 4.3 Strategic dashboard

- 4.4 Strategic initiatives

- 4.5 Competitive benchmarking

- 4.6 Innovation & sustainability landscape

Chapter 5 Market Size and Forecast, By Voltage Rating, 2021 - 2034 (USD Million & Units)

- 5.1 Key trends

- 5.2 Low voltage

- 5.3 Medium voltage

Chapter 6 Market Size and Forecast, By Capacity, 2021 - 2034 (USD Million & Units)

- 6.1 Key trends

- 6.2 < 10 MMBTU/hr

- 6.3 10 - 50 MMBTU/hr

- 6.4 50 - 100 MMBTU/hr

- 6.5 100 - 250 MMBTU/hr

- 6.6 > 250 MMBTU/hr

Chapter 7 Market Size and Forecast, By Product, 2021 - 2034 (USD Million & Units)

- 7.1 Key trends

- 7.2 Hot water

- 7.3 Steam

Chapter 8 Market Size and Forecast, By Sales Channel, 2021 - 2034 (USD Million & Units)

- 8.1 Key trends

- 8.2 Online

- 8.3 Dealer

- 8.4 Retail

Chapter 9 Market Size and Forecast, By Region, 2021 - 2034 (USD Million & Units)

- 9.1 Key trends

- 9.2 North America

- 9.2.1 U.S.

- 9.2.2 Canada

- 9.2.3 Mexico

- 9.3 Europe

- 9.3.1 France

- 9.3.2 UK

- 9.3.3 Poland

- 9.3.4 Italy

- 9.3.5 Spain

- 9.3.6 Germany

- 9.3.7 Russia

- 9.3.8 Austria

- 9.3.9 Sweden

- 9.4 Asia Pacific

- 9.4.1 China

- 9.4.2 India

- 9.4.3 Japan

- 9.4.4 South Korea

- 9.4.5 Australia

- 9.4.6 Indonesia

- 9.4.7 Philippines

- 9.5 Middle East & Africa

- 9.5.1 Saudi Arabia

- 9.5.2 Iran

- 9.5.3 UAE

- 9.5.4 Egypt

- 9.5.5 Nigeria

- 9.5.6 Kenya

- 9.5.7 Morocco

- 9.5.8 South Africa

- 9.6 Latin America

- 9.6.1 Brazil

- 9.6.2 Argentina

- 9.6.3 Colombia

- 9.6.4 Chile

Chapter 10 Company Profiles

- 10.1 ALFA LAVAL

- 10.2 Acme Engineering Products

- 10.3 ACV

- 10.4 Babcock Wanson

- 10.5 Bosch Industriekessel

- 10.6 Cerney

- 10.7 Chromalox

- 10.8 Cleaver-Brooks

- 10.9 Danstoker A/S

- 10.10 Ecotherm Austria

- 10.11 FERROLI

- 10.12 Klopper-Therm

- 10.13 LACAZE ENERGIES

- 10.14 PARAT Halvorsen AS

- 10.15 Precision Boilers

- 10.16 Reimers Electra Steam

- 10.17 Ross Boilers

- 10.18 Thermodyne Boilers

- 10.19 Thermon

- 10.20 Thermona

- 10.21 Vapor Power