|

市場調查報告書

商品編碼

1911425

工業緊固件:市場佔有率分析、產業趨勢與統計、成長預測(2026-2031)Industrial Fasteners - Market Share Analysis, Industry Trends & Statistics, Growth Forecasts (2026 - 2031) |

||||||

※ 本網頁內容可能與最新版本有所差異。詳細情況請與我們聯繫。

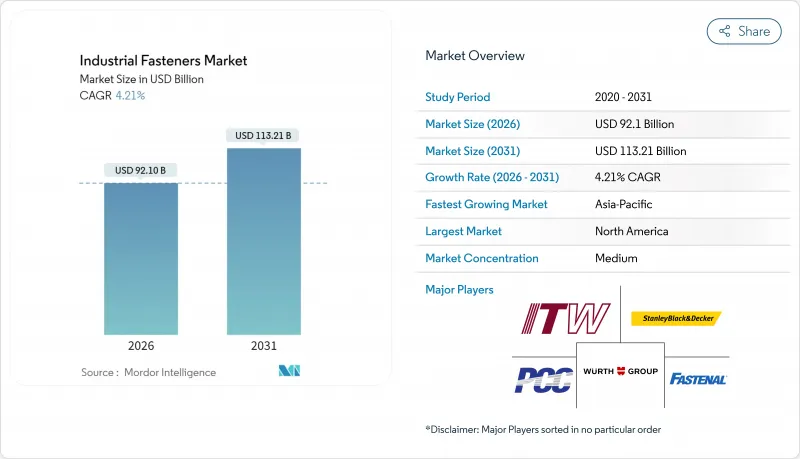

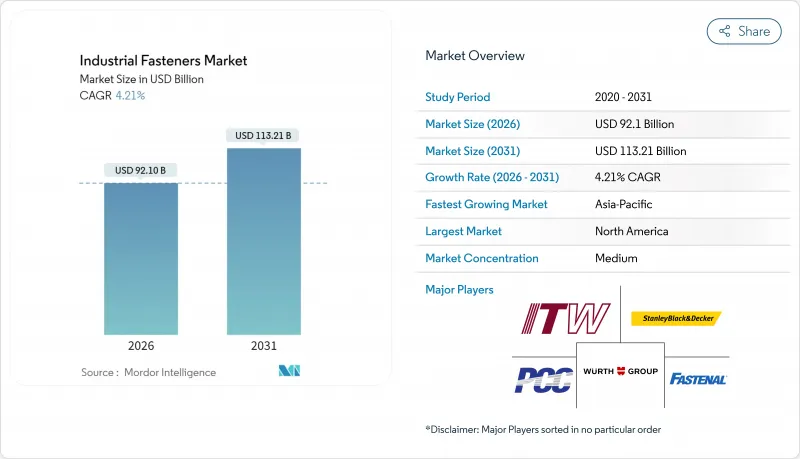

預計工業緊固件市場將從 2025 年的 883.8 億美元成長到 2026 年的 921 億美元,到 2031 年將達到 1,132.1 億美元,2026 年至 2031 年的複合年成長率為 4.21%。

製造自動化、重型機械升級以及精密組裝要求推動了市場需求,這些都要求複雜設備之間必須採用可靠、高強度的連接。工業4.0平台的普及加速了智慧感測器緊固件的應用,這些緊固件能夠收集扭矩和預緊力數據,幫助製造商減少停機時間並提高可追溯性。回流和本地化策略透過縮短前置作業時間和降低全球物流風險,正在增強工業緊固件市場。同時,亞洲和北美地區基礎設施升級和工業產能擴張投資的增加,也為結構件和特種產品的大宗訂單提供了穩定的支援。

全球工業緊固件市場趨勢與洞察

需要精密微型緊固件的工業自動化設備

如今,電子、醫療設備和半導體工廠需要重量僅為幾克的微型螺絲。這些螺絲必須提供可重複的夾緊力,且循環時間小於一秒鐘。 JR Automation 等整合商報告稱,其定位精度可達微米級,這推動了對客製化緊固件幾何形狀、扭矩小於 1 N·m 以及能夠減少快速負載循環下螺紋變形的先進塗層的需求。電動工具製造商正在積極回應,推出無線、感測器控制的扳手,這些扳手能夠記錄每一次擰緊事件,並將資料無線傳輸到 MES 控制面板。PanasonicAccuPulse 平台就展示了這項功能。製造商指出,這些產品能夠即時帶來品質和成本方面的效益,例如減少返工站和縮短節拍時間,從而鞏固高產量自動化生產線中工業緊固件市場的成長動能。隨著工廠數位化的不斷提高,製造商擴大指定使用內建 ID 晶片的緊固件,以實現可追溯性,並確保其能夠順利通過碗式送料器而不會發生堵塞。這一趨勢已經從電子產品轉向汽車電池模組和協作機器人關節,確保未來兩年持續成長。

製造業的復甦正在推動國內對工業緊固件的需求。

疫情期間的地緣政治不確定性和港口堵塞迫使美國和歐洲的原始設備製造商 (OEM) 重新評估的不僅是單價,還有總到岸成本。目前,美國消費的緊固件中約有三分之二是國內生產的,扭轉了十年前的境外外包趨勢。本地供應商受益於更緊密的工程合作、更少的庫存緩衝以及遵守公共基礎設施合約中規定的「購買美國貨」條款。從小型區域加工廠到跨國公司,對冷鐓生產線、熱處理爐和自動化分類單元的資本投資正在加速,從而提高了整個工業緊固件市場的運轉率。雖然人事費用仍然高於亞洲,但 OEM 認為運輸成本降低和產品過時風險減少是至關重要的優勢。預計這種回流趨勢將至少持續到 2028 年,並對市場規模產生正面影響,尤其是對於適合短期供應鏈的中高強度等級產品。

先進的連接技術取代了傳統的工業緊固件

大批量設備製造商正在嘗試將結構性黏著劑、雷射焊接和摩擦攪拌焊接應用於機殼和底盤等可接受永久性連接的領域。鉚釘或螺栓與黏合劑圓角相結合的混合設計可以減少零件數量並改善負載分佈,促使一些原始設備製造商 (OEM) 要求每個組裝使用更少的機械緊固件。鋁擠型製造商尤其積極地採用摩擦攪拌焊接技術來製造輕量化框架,從而在某些應用中減少螺栓的消費量。然而,泵浦、齒輪箱和製程閥組件等高維護環境仍需要可拆卸連接,這為工業緊固件市場維持了龐大的核心客戶群。未來三年,這項阻礙因素的實際影響將取決於可拆卸性和輕量化之間的平衡。

細分市場分析

2025年,金屬緊固件佔總收入的91.45%,其中抗張強度超過800兆帕的緊固件被廣泛應用於重型機械、工業機器人和沖壓生產線。 AISI 316等不鏽鋼牌號在食品加工和製藥高壓釜領域佔據了高階市場,因為在這些領域,耐腐蝕性是首要考慮因素。合金鋼和碳鋼螺栓作為結構框架、齒輪箱外殼和爐門的標準選擇,繼續支撐工業緊固件市場。鈦合金和鎳合金特殊產品被用於渦輪機殼體和石油化學反應器,但與海綿合金生產相關的供應限制不時導致交貨時間延長。這些趨勢為金屬產業在成熟市場持續穩定成長奠定了基礎,而新興國家的產能擴張則進一步推動了這一成長。

塑膠緊固件目前僅佔市場佔有率的8.55%,但其成長速度迅猛,預計2031年將以6.72%的複合年成長率成長。尼龍螺絲是PLC機櫃和LED驅動器外殼的標準配置,其優異的介電強度和化學惰性為其增添了價值。聚碳酸酯卡扣具有抗衝擊性和易於回收的特性,常用於AGV車隊中感測器模組的固定。智慧電錶組裝對輕量化機殼的需求激增,進一步推動了聚合物材料的普及應用。隨著潔淨室產業自動化程度的不斷提高,工程師開始使用PVDF和PEEK緊固件來消除粒狀物排放。因此,預計到2031年,塑膠工業緊固件市場規模將接近97億美元,凸顯了材料組合多元化的明顯趨勢。

預計到2025年,外螺紋產品(螺栓、螺絲和螺柱)將佔工業緊固件市場收入的44.30%。直徑大於M24的螺栓主要應用於起重機、壓力機和擠出機組件,而直徑小於M6的機螺絲則用於固定伺服馬達支架和線性致動器。國際標準化組織(ISO)的標準化工作正在推動這一細分市場的發展,簡化了跨國原始設備製造商(OEM)的庫存管理策略。此外,自動化料箱填充系統支援精實生產,也促進了互通性的發展,從而增強了工業緊固件市場大規模生產的成長。

航太級緊固件雖然出貨量佔比不高,但正以5.88%的複合年成長率成長。在工業用燃氣渦輪機和高精度工具機中,超合金螺栓能夠承受超過650°C的循環熱負荷。抗振結構(例如,帶有預緊螺母的柄部夾緊螺栓)為航太的技術向高循環壓力機滑台的轉移提供了寶貴的途徑。隨著國防合約的增加,擁有NADCAP認證的熱處理和測試設施的供應商能夠獲得更高的價格。預計到2031年,航太級工業緊固件市場規模將成長15.3億美元,反映出高性能連接件在關鍵任務型工業環境中的應用日益廣泛。

區域分析

預計到2025年,亞洲將佔全球收入的44.60%,年複合成長率達7.38%,主要得益於中國、印度和東南亞國協製造設施日益精進。政府對機器人應用的財政激勵措施,以及大型工業園區的建設,正推動大批量碳鋼和高階不銹鋼產品訂單的穩定成長。中國半導體製造設備的本土化生產帶動了對超潔淨、無顆粒緊固件的特殊需求,而印度的「印度製造」計畫則促進了需要大直徑螺栓的重型機械的本土化生產。這些計劃共同推動了主要供應商和區域供應商的整體工業緊固件市場發展。

由於國防採購的回歸、能源基礎設施現代化以及汽車和電子產品組裝的增加,北美仍然是關鍵市場。美國原始設備製造商 (OEM) 正在擴大國內緊固件採購,以減輕物流中斷和外匯波動的影響。墨西哥等新興地區正利用接近性美國買家的優勢,為輕型車輛平台和家用電子電器的最終組裝提供緊固件。加拿大由於資源開採設備需要用於礦用鏟車和油砂加工生產線的耐高溫緊固件,因此保持著成長動能。總體而言,穩定的計劃儲備支撐著該地區工業緊固件市場實現個位數的溫和成長。

在歐洲,德國的精密機械工業、義大利的工具機出口以及法國的航太供應鏈正在創造強勁的價值。優先考慮永續性的法規結構鼓勵材料可追溯性和閉合迴路回收,促使供應商採用QR碼識別和再生金屬含量。英國脫歐後的複雜情況導致部分供應鏈轉移到歐洲大陸樞紐,但英國離岸風力發電電場對鍍鋅結構螺栓的需求仍然強勁。在工業4.0加速普及的推動下,預計到2031年,該地區的工業緊固件市場將以3.74%的複合年成長率成長。

其他福利:

- Excel格式的市場預測(ME)表

- 3個月的分析師支持

目錄

第1章 引言

- 研究假設和市場定義

- 調查範圍

第2章調查方法

第3章執行摘要

第4章 市場情勢

- 市場概覽

- 市場促進因素

- 汽車電氣化將推動對電池相容型緊固件的需求。

- 抗震建築標準要求的高強度結構螺栓

- 大直徑耐腐蝕螺栓對於離岸風力發電設施至關重要。

- 航太緊固件供應鏈本地化

- 用於工業自動化設備的精密微型緊固件

- 新興經濟體的基礎設施獎勵策略

- 市場限制

- 在內飾模組中,黏合劑和膠帶可替代金屬緊固件。

- 鎳和鉬價格波動推高了不銹鋼成本。

- 中小型製造商的認證負擔(AS9100、IATF 16949)

- 鈦合金短缺限制了航太緊固件的生產能力。

- 價值/供應鏈分析

- 監理與技術展望

- 波特五力分析

- 供應商的議價能力

- 消費者議價能力

- 新進入者的威脅

- 替代品的威脅

- 競爭對手之間的競爭

第5章 市場規模及成長預測(價值,十億美元)

- 按原料

- 金屬

- 碳鋼

- 合金鋼

- 不銹鋼

- 非鐵金屬(鋁、鈦、銅)

- 塑膠

- 尼龍

- 聚碳酸酯

- 聚氯乙烯(PVC)及其他

- 金屬

- 依產品

- 外螺紋緊固件

- 螺栓

- 擰緊

- 釘子

- 內螺紋緊固件

- 堅果

- 插入

- 無螺紋緊固件

- 鉚釘

- 墊圈

- 別針和夾子

- 航太級緊固件

- 鈦合金拉鍊

- 超合金緊固件

- 外螺紋緊固件

- 透過使用

- 車

- 航太與國防

- 建築/施工

- 工業機械與機器人

- 家用電器和電子產品

- 管道和暖通空調產品

- 其他工業應用

- 按銷售管道

- OEM

- 售後市場/MRO

- 按地區

- 北美洲

- 美國

- 加拿大

- 墨西哥

- 歐洲

- 英國

- 德國

- 法國

- 義大利

- 其他歐洲地區

- 亞太地區

- 中國

- 日本

- 印度

- 韓國

- 亞太其他地區

- 中東

- 以色列

- 沙烏地阿拉伯

- 阿拉伯聯合大公國

- 土耳其

- 其他中東地區

- 非洲

- 南非

- 埃及

- 其他非洲地區

- 南美洲

- 巴西

- 阿根廷

- 南美洲其他地區

- 北美洲

第6章 競爭情勢

- 市場集中度

- 策略趨勢

- 市佔率分析

- 公司簡介

- Acument Global Technologies, Inc.

- Arconic Corporation

- LISI Group

- Nifco Inc.

- Hilti Corporation

- Stanley Black and Decker, Inc.

- MacLean-Fogg Company

- MISUMI Group Inc.

- Precision Castparts Corp.

- SFS Group

- Illinois Tool Works Inc.

- Fastenal Company

- Wurth Group

- Bossard Group

- PennEngineering

- Bulten AB

- KAMAX Holding GmbH

- Sundram Fasteners Ltd.

- Shanghai Prime Machinery Co. Ltd.

- TriMas Corporation

- Nitto Seiko Co., Ltd.

第7章 市場機會與未來展望

The industrial fasteners market is expected to grow from USD 88.38 billion in 2025 to USD 92.1 billion in 2026 and is forecast to reach USD 113.21 billion by 2031 at 4.21% CAGR over 2026-2031.

Demand is supported by manufacturing automation, heavy-machinery upgrades, and precision-assembly requirements that call for reliable, high-strength joints across complex equipment. Adoption of Industry 4.0 platforms is accelerating the use of smart, sensor-enabled fasteners that capture torque and preload data, helping manufacturers cut downtime and enhance traceability. Reshoring and localization strategies are reinforcing the industrial fasteners market by shortening lead times and reducing exposure to global logistics risks. Meanwhile, rising investment in infrastructure renewal and industrial capacity expansions in Asia and North America underpins a steady flow of large-volume orders for structural and specialty products.

Global Industrial Fasteners Market Trends and Insights

Industrial Automation Equipment Requiring Precision Micro-Fasteners

Electronics, medical-device, and semiconductor plants now specify micro-screws that weigh a fraction of a gram yet must deliver repeatable clamp loads at cycle times below one second. Integrators such as JR Automation report micron-level placement accuracy, and this drives demand for bespoke fastening geometries, torques under 1 N*m, and advanced coatings that mitigate galling under rapid load cycles. Power-tool suppliers are responding with cordless transducer-controlled wrenches that log every tightening event and transmit data wirelessly to MES dashboards, a capability showcased in Panasonic's AccuPulse platform. Manufacturers cite immediate quality-cost benefits, including fewer rework stations and shorter takt times, reinforcing the industrial fasteners market trajectory in high-volume automated lines. As more plants digitize, specifiers increasingly insist on fasteners that integrate ID chips for traceability and can be fed through bowl feeders without jamming. The trend has already migrated from electronics to automotive battery modules and collaborative-robot joints, ensuring sustained growth over the next two years

Manufacturing Reshoring Driving Domestic Industrial Fastener Demand

Geopolitical uncertainty and pandemic-era port congestion have prompted US and EU OEMs to reevaluate total landed costs rather than unit price alone. Roughly two-thirds of fasteners consumed in the United States are now produced domestically, a reversal of the offshoring trend observed a decade earlier. Local suppliers benefit from closer engineering collaboration, lower inventory buffers, and compliance with Buy-America clauses embedded in public-infrastructure awards. Capital investment in cold-heading lines, heat-treatment furnaces, and automated sorting cells is accelerating at both regional job shops and multinational firms, lifting utilization rates across the industrial fasteners market. While labor costs remain higher than in Asia, OEMs cite freight savings and reduced obsolescence risk as decisive advantages. The reshoring dynamic is expected to maintain a positive thrust on market volumes through at least 2028, especially for medium-to-high-strength grades that favor short supply chains.

Advanced Joining Technologies Substituting Traditional Industrial Fasteners

High-volume equipment producers are trialing structural adhesives, laser welding, and friction-stir welding for enclosures and chassis where permanent bonds are acceptable. Hybrid designs that combine a rivet or bolt with adhesive fillets reduce component counts and improve load distribution, compelling some OEMs to specify fewer mechanical fasteners per assembly. Aluminum extrusion manufacturers are particularly active in adopting friction-stir welding for lightweight frames, eroding bolt consumption in select applications. Nonetheless, maintenance-heavy environments such as pumps, gearboxes, and process-valve assemblies still require removable joints, preserving a large core base for the industrial fasteners market. The balance between removability and weight savings will define this restraint's real-world impact over the next three years.

Other drivers and restraints analyzed in the detailed report include:

- Heavy Machinery Modernization in Emerging Industrial Markets

- Industry 4.0 Implementation Requiring Smart Fastening Solutions

- Raw Material Cost Volatility Affecting Industrial Fastener Pricing

For complete list of drivers and restraints, kindly check the Table Of Contents.

Segment Analysis

Metal fasteners held 91.45% of 2025 revenue as heavy-duty machinery, industrial robots, and press lines demanded tensile strengths above 800 MPa. Stainless-steel grades such as AISI 316 captured a premium niche in food processing and pharmaceutical autoclaves where corrosion resistance is paramount. Alloy-steel and carbon-steel bolts remain the default choices for structural frames, gearbox casings, and furnace doors, underpinning the industrial fasteners market. Titanium and nickel-alloy specialty items serve turbine housings and petrochemical reactors, yet supply constraints tied to sponge production cause periodic lead-time extensions. These dynamics underpin a metal segment that, while mature, continues to accrue incremental gains from capacity expansions in emerging economies.

Plastic fasteners, though only 8.55% of volume, are scaling quickly on a 6.72% CAGR through 2031. Nylon screws are now routine in PLC cabinets and LED driver housings, where dielectric strength and chemical inertness add value. Polycarbonate clips secure sensor modules in AGV fleets because they resist impact and allow simplified recycling at end-of-life. Fast-growing demand for lightweight enclosures in smart-meter assemblies further propels polymer uptake. As automation spreads across clean-room industries, engineers are turning to PVDF and PEEK fasteners to eliminate particulate shedding. Consequently, the industrial fasteners market size for plastic variants is projected to approach USD 9.7 billion by 2031, highlighting a clear diversification trend across material portfolios.

Externally threaded products-bolts, screws, studs-delivered 44.30% of industrial fasteners market revenue in 2025. Bolts exceeding M24 diameter dominate crane, press, and extruder assemblies, while machine screws below M6 secure servo-motor mounts and linear actuators. The segment benefits from International Organization for Standardization (ISO) harmonization, which simplifies stocking strategies for multinational OEMs. Interchangeability also supports automatic bin-filling systems that underpin lean manufacturing, reinforcing high-volume growth in the industrial fasteners market.

Aerospace-grade fasteners, although a small slice of shipments, are advancing at 5.88% CAGR. In industrial gas turbines and high-precision machine tools, super-alloy bolts resist cyclical thermal loads exceeding 650 °C. Vibration-resistant configurations-such as shank-grip bolts with prevailing-torque nuts-bring transfer value from aerospace to high-cycle press slides. As defense contracts ramp, suppliers with NADCAP-certified heat-treatment and lab facilities enjoy premium pricing. The industrial fasteners market size for aerospace-grade variants is projected to add USD 1.53 billion by 2031, reflecting broader acceptance of high-performance joints in mission-critical industrial settings.

The Industrial Fasteners Market Report is Segmented by Raw Materials (Metal, Plastic), Products (Externally Threaded Fasteners, Internally Threaded Fasteners, Non-Threaded Fasteners, Aerospace Grade Fasteners), by Application (Automotive, Aerospace, Building and Construction, Industrial Machinery, Home Appliances, and More), and Geography. The Market Forecasts are Provided in Terms of Value (USD).

Geography Analysis

Asia generated 44.60% of global revenue in 2025 and is projected to expand at 7.38% CAGR on the back of manufacturing upgrades across China, India, and ASEAN nations. Fiscal incentives for robotics adoption, combined with large-scale industrial park developments, funnel steady orders into both high-volume carbon-steel and premium stainless-steel categories. China's localization of semiconductor equipment drives specialty demand for ultra-clean, particle-free fasteners, while India's Make-in-India policy pushes local production of heavy machinery that relies on large-diameter bolts. Collectively, these projects elevate the industrial fasteners market across tier-one and regional suppliers.

North America remains a critical node, supported by defense procurement, energy-infrastructure modernization, and reshoring of automotive and electronics assembly. US OEMs have ramped domestic fastener sourcing to mitigate logistics shocks and currency swings. Emerging hubs in Mexico supply fasteners for light-vehicle platforms and consumer-electronics final assembly, leveraging proximity to US buyers. Canada retains momentum through resource extraction equipment that demands extreme-temperature fasteners in mining shovels and oil-sands processing lines. Overall, stable project pipelines maintain mid-single-digit gains in the regional industrial fasteners market.

Europe contributes robust value through Germany's precision-machinery sector, Italy's machine-tool exports, and France's aerospace supply chain. Regulatory frameworks that prioritize sustainability encourage material traceability and closed-loop recycling, motivating suppliers to adopt QR-coded identification and reclaimed-metal content. Post-Brexit complexity has redirected some supply flows toward continental hubs, but UK offshore-wind installations sustain niche demand for galvanized structural bolts. With Industry 4.0 adoption accelerating, the region's industrial fasteners market is forecast to register a 3.74% CAGR through 2031.

- Acument Global Technologies, Inc.

- Arconic Corporation

- LISI Group

- Nifco Inc.

- Hilti Corporation

- Stanley Black and Decker, Inc.

- MacLean-Fogg Company

- MISUMI Group Inc.

- Precision Castparts Corp.

- SFS Group

- Illinois Tool Works Inc.

- Fastenal Company

- Wurth Group

- Bossard Group

- PennEngineering

- Bulten AB

- KAMAX Holding GmbH

- Sundram Fasteners Ltd.

- Shanghai Prime Machinery Co. Ltd.

- TriMas Corporation

- Nitto Seiko Co., Ltd.

Additional Benefits:

- The market estimate (ME) sheet in Excel format

- 3 months of analyst support

TABLE OF CONTENTS

1 INTRODUCTION

- 1.1 Study Assumptions and Market Definition

- 1.2 Scope of the Study

2 RESEARCH METHODOLOGY

3 EXECUTIVE SUMMARY

4 MARKET LANDSCAPE

- 4.1 Market Overview

- 4.2 Market Drivers

- 4.2.1 Automotive Electrification Boosting Demand for Battery-Ready Fasteners

- 4.2.2 Seismic-Resistant Building Codes Driving High-Strength Structural Bolts

- 4.2.3 Offshore Wind Installations Requiring Large-Diameter Corrosion-Resistant Bolts

- 4.2.4 Localization of Aerospace Fastener Supply Chains

- 4.2.5 Precision Micro-Fasteners for Industrial Automation Equipment

- 4.2.6 Infrastructure Stimulus Programs in Emerging Economies

- 4.3 Market Restraints

- 4.3.1 Adhesives and Tapes Substituting Metal Fasteners in Interior Modules

- 4.3.2 Volatile Nickel/Molybdenum Prices Inflating Stainless-Steel Costs

- 4.3.3 Certification Burden (AS9100, IATF 16949) for Small Manufacturers

- 4.3.4 Titanium Alloy Shortages Limiting Aerospace Fastener Capacity

- 4.4 Value / Supply-Chain Analysis

- 4.5 Regulatory and Technological Outlook

- 4.6 Porter's Five Forces Analysis

- 4.6.1 Bargaining Power of Suppliers

- 4.6.2 Bargaining Power of Consumers

- 4.6.3 Threat of New Entrants

- 4.6.4 Threat of Substitutes

- 4.6.5 Intensity of Competitive Rivalry

5 MARKET SIZE AND GROWTH FORECASTS (VALUE, USD BN)

- 5.1 By Raw Material

- 5.1.1 Metal

- 5.1.1.1 Carbon Steel

- 5.1.1.2 Alloy Steel

- 5.1.1.3 Stainless Steel

- 5.1.1.4 Non-Ferrous (Aluminum, Titanium, Copper)

- 5.1.2 Plastic

- 5.1.2.1 Nylon

- 5.1.2.2 Polycarbonate

- 5.1.2.3 PVC and Others

- 5.1.1 Metal

- 5.2 By Product

- 5.2.1 Externally Threaded Fasteners

- 5.2.1.1 Bolts

- 5.2.1.2 Screws

- 5.2.1.3 Studs

- 5.2.2 Internally Threaded Fasteners

- 5.2.2.1 Nuts

- 5.2.2.2 Inserts

- 5.2.3 Non-Threaded Fasteners

- 5.2.3.1 Rivets

- 5.2.3.2 Washers

- 5.2.3.3 Pins and Clips

- 5.2.4 Aerospace-Grade Fasteners

- 5.2.4.1 Titanium Fasteners

- 5.2.4.2 Super-Alloy Fasteners

- 5.2.1 Externally Threaded Fasteners

- 5.3 By Application

- 5.3.1 Automotive

- 5.3.2 Aerospace and Defense

- 5.3.3 Building and Construction

- 5.3.4 Industrial Machinery and Robotics

- 5.3.5 Home Appliances and Electronics

- 5.3.6 Plumbing and HVAC Products

- 5.3.7 Other Industrial Applications

- 5.4 By Sales Channel

- 5.4.1 OEM

- 5.4.2 Aftermarket / MRO

- 5.5 By Geography

- 5.5.1 North America

- 5.5.1.1 United States

- 5.5.1.2 Canada

- 5.5.1.3 Mexico

- 5.5.2 Europe

- 5.5.2.1 United Kingdom

- 5.5.2.2 Germany

- 5.5.2.3 France

- 5.5.2.4 Italy

- 5.5.2.5 Rest of Europe

- 5.5.3 Asia-Pacific

- 5.5.3.1 China

- 5.5.3.2 Japan

- 5.5.3.3 India

- 5.5.3.4 South Korea

- 5.5.3.5 Rest of Asia-Pacific

- 5.5.4 Middle East

- 5.5.4.1 Israel

- 5.5.4.2 Saudi Arabia

- 5.5.4.3 United Arab Emirates

- 5.5.4.4 Turkey

- 5.5.4.5 Rest of Middle East

- 5.5.5 Africa

- 5.5.5.1 South Africa

- 5.5.5.2 Egypt

- 5.5.5.3 Rest of Africa

- 5.5.6 South America

- 5.5.6.1 Brazil

- 5.5.6.2 Argentina

- 5.5.6.3 Rest of South America

- 5.5.1 North America

6 COMPETITIVE LANDSCAPE

- 6.1 Market Concentration

- 6.2 Strategic Moves

- 6.3 Market Share Analysis

- 6.4 Company Profiles (includes Global Level Overview, Market Level Overview, Core Segments, Financials as available, Strategic Information, Market Rank/Share, Products and Services, Recent Developments)

- 6.4.1 Acument Global Technologies, Inc.

- 6.4.2 Arconic Corporation

- 6.4.3 LISI Group

- 6.4.4 Nifco Inc.

- 6.4.5 Hilti Corporation

- 6.4.6 Stanley Black and Decker, Inc.

- 6.4.7 MacLean-Fogg Company

- 6.4.8 MISUMI Group Inc.

- 6.4.9 Precision Castparts Corp.

- 6.4.10 SFS Group

- 6.4.11 Illinois Tool Works Inc.

- 6.4.12 Fastenal Company

- 6.4.13 Wurth Group

- 6.4.14 Bossard Group

- 6.4.15 PennEngineering

- 6.4.16 Bulten AB

- 6.4.17 KAMAX Holding GmbH

- 6.4.18 Sundram Fasteners Ltd.

- 6.4.19 Shanghai Prime Machinery Co. Ltd.

- 6.4.20 TriMas Corporation

- 6.4.21 Nitto Seiko Co., Ltd.

7 MARKET OPPORTUNITIES AND FUTURE OUTLOOK

- 7.1 White-Space and Unmet-Need Assessment