|

市場調查報告書

商品編碼

1910467

雷射:市場佔有率分析、行業趨勢和統計數據、成長預測(2026-2031)Lasers - Market Share Analysis, Industry Trends & Statistics, Growth Forecasts (2026 - 2031) |

||||||

※ 本網頁內容可能與最新版本有所差異。詳細情況請與我們聯繫。

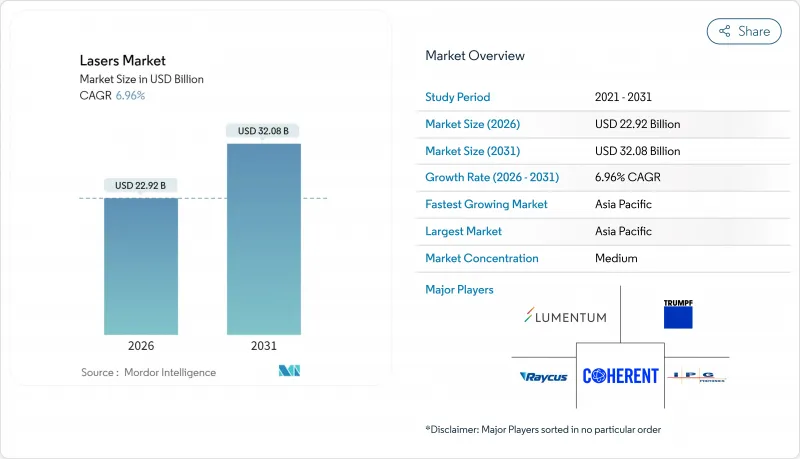

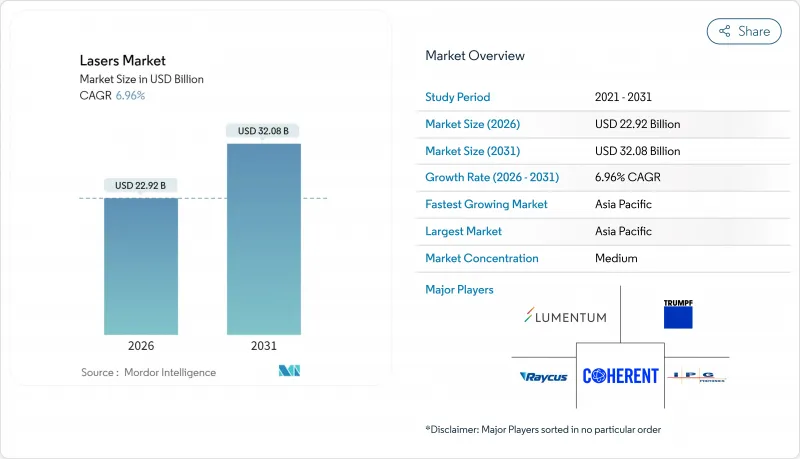

預計雷射市場將從 2025 年的 214.3 億美元成長到 2026 年的 229.2 億美元,預計到 2031 年將達到 320.8 億美元,2026 年至 2031 年的複合年成長率為 6.96%。

這一成長反映了雷射技術在精密微加工、積層製造、自動駕駛和下一代顯示器生產等領域的日益普及。用於加工10奈米以下半導體微結構的超快脈衝光源和用於切割厚金屬板的千瓦級光纖系統,如今已成為大批量生產工廠的主流設備。政府資助的光電叢集正在加速亞太地區的生態系統發展,而用於積層製造的雷射則正在減少航太零件的材料浪費並縮短生產週期。儘管鎵、鍺和磷化銦基板的供應鏈風險仍然是一大阻力,但溫度控管和光束合成架構的創新不斷提高可實現功率輸出的上限。

全球雷射市場趨勢與洞察

半導體後端封裝領域對高精度微加工的需求激增

扇出型晶圓級封裝和玻璃通孔製程要求使用飛秒準分子雷射器,其特徵尺寸小於10微米,脈衝間能量偏差小於1%,從而確保在300毫米晶圓上形成均勻的通孔。以雷射成型的微凸塊取代焊線可將互連電阻降低40%,為3D晶片堆疊鋪路。光束整形模組的同步和原位監測可提高產量比率並減少大批量晶圓廠的廢品率。亞太地區的晶圓代工廠持續採購承包雷射工作站,顯著推動了對超快光源供應商的需求。隨著封裝生產線節拍時間的縮短,對更高重複頻率的需求預計將會增加,從而推高高階超快雷射的平均售價。

雷射積層製造技術在航太高溫合金零件的應用日益廣泛

目前,領先的航太製造商正在對粉末層熔融光纖雷射進行認證,用於加工鈦鋁合金和鎳基高溫合金,材料利用率超過95%,遠超切割製程。動態光束整形技術可將成型週期縮短40%,能耗降低60%,同時維持對飛機設備至關重要的微觀結構完整性。修訂後的AS9100標準明確提及雷射列印零件,簡化了認證流程。美國和歐洲的引擎計畫擴大採用「列印優先」的外形設計,這些外形無法透過機械加工經濟地實現。這種轉變正在推動雷射技術的需求,同時,寬體機隊更新和計劃於2020年代末投入使用的超音速推進計劃也推動了這項需求的成長。

高品質砷化鎵/磷化銦外延晶片持續短缺

鎵和鍺出口限制的收緊加劇了化合物半導體基板的短缺,而這些基板對於高功率雷射二極體至關重要。不同批次基板導熱係數的差異迫使雷射製造商延長重新認證週期,導致出貨延遲和庫存積壓增加。儘管北美和歐洲的新興企業正在規劃建造新的晶體生長工廠,但設備前置作業時間和製程技術取得意味著實際的大規模生產不太可能在2027年或之後開始。高昂的基板價格正以兩位數的速度推高元件成本,尤其是對於工作在高結溫下的雷射雷達和通訊雷射而言。製造商正在嘗試使用矽基中間基板來補充現有的外延晶圓供應,但性能損失仍然十分顯著。

細分市場分析

光纖雷射器憑藉其卓越的光束品質、全光纖結構和極低的維護成本,預計到2025年將佔據全球雷射市場41.40%的佔有率。然而,由於定向能量武器和核融合實驗需要兆瓦級的光鏈路,固體雷射平台預計將在2031年之前以9.18%的複合年成長率實現最快成長。受國防資金投入趨勢的影響,預計2031年,全球固體雷射元件市場規模將超過56.2億美元。將板狀增益介質連接到鎧裝光纖傳輸線的混合配置有助於克服單根光纖的功率限制,同時保持亮度。二氧化碳光源在厚板切割領域仍佔有一席之地,而二極體雷射則在泵浦陣列和直寫應用中不斷擴展。準分子雷射和紫外線雷射對於100奈米以下的半導體微影術至關重要,即使在代工廠資本支出週期性波動的情況下,也能維持穩定的需求。

對分散式增益架構的持續研究有望在不引起熱致模式不穩定性的情況下實現功率擴展。雖然自由電子雷射和量子級聯技術目前仍佔據小眾光譜區域,但緊湊型加速器架構的突破最終可能使中紅外線波段惠及大眾。基於IEC 60825-1的安全標準規定了機殼設計,並影響高度自動化工廠的總安裝成本。隨著應用邊界的日益模糊,能夠將光纖的可靠性與固體雷射器的優勢相結合的供應商有望佔據主導地位。

至2025年,材料加工領域將佔全球雷射市場的30.10%,涵蓋汽車、航太和一般工業領域的切割、焊接、鑽孔和積層製造流程。然而,感測器(尤其是LiDAR和光譜模組)的普及預計將在未來十年內縮小這一差距,複合年成長率將達到8.58%。重工業訂單仍有週期性波動,但現有工廠的維修項目支撐著基準需求。同時,受門診手術興起的推動,醫療和美容雷射市場正經歷穩定成長。門診手術的特點是微創和恢復快。

光刻技術的支出依賴大型代工廠先進製程節點的量產,每台極紫外線(EUV)掃描儀都整合了多個高重複頻率準分子光源。下一代顯示器依靠超快速修復技術來維持產量比率,預計將提高面板的利潤率。軍方採購用於反無人機系統的高能系統正在推動需求波動,同時,公共部門也正在增加對基礎光學研究的投入。邊緣和雲端資料中心的激增正在推動光連接模組需求,從而促進通訊雷射的出貨量成長,並增強全球雷射市場的應用多樣性。

區域分析

預計到2025年,亞太地區將佔全球雷射市場46.40%的佔有率,並在2031年之前以8.17%的複合年成長率成長。這主要得益於高密度半導體晶圓廠、快速成長的顯示器生產線以及政府支持的光電園區。中國在先進光刻節點準分子雷射和超快雷射的採購方面主導,而日本正在升級對光束品質要求更高的精密加工應用。韓國的OLED和microLED生產線保持著高運轉率,支撐了持續的雷射維護合約。印度的生產掛鉤激勵措施鼓勵工具機製造商實現雷射切割和焊接能力的本地化,從而擴大了潛在需求。台灣和新加坡分別以其化合物叢集和精密工程產業叢集貢獻了細分市場需求。

北美保持第二的位置,這得益於航太生產和兆瓦級定向能系統國防合約的快速成長。在美國,美國製造計畫(Manufacturing USA)下屬的光電中心正在扶持整合光電和量子級聯設計領域的Start-Ups。加拿大材料科學實驗室正與當地加工中心合作,展示雷射覆層和硬化工藝。墨西哥的電動車走廊正在推進電池托盤光纖雷射焊接的大規模生產。儘管美墨加協定(USMCA)的協調有望改善跨境供應鏈,但出口管制限制了高功率設備向某些地區的出口。環境監測法規也刺激了國內對中紅外線氣體檢測模組的需求。

在歐洲,德國機械巨頭和法國國防整合商在推進高能量研究雷射方面發揮重要作用。英國正致力於利用雷射消熔進行航太複合材料加工,以最大限度地減少分層缺陷;一家義大利超級跑車製造商則採用多千瓦級碟片雷射高效焊接鋁製底盤。歐盟範圍內的法規,包括機械指令和IEC 60825-1標準,都對出口系統的安全性提出了要求。像DioHELIOS這樣的合作項目,透過匯集二極體雷射專業知識並推動經濟高效規模化生產的聯盟,展現了歐洲對核融合能源實行技術的承諾。不斷擴展的綠色氫能舉措也推動了全部區域對雷射切割和管道焊接技術的興趣。

其他福利:

- Excel格式的市場預測(ME)表

- 3個月的分析師支持

目錄

第1章 引言

- 研究假設和市場定義

- 調查範圍

第2章調查方法

第3章執行摘要

第4章 市場情勢

- 市場概覽

- 市場促進因素

- 半導體後端封裝領域對高精度微加工的需求激增

- 雷射積層製造技術在航太高溫合金零件製造的應用日益廣泛

- 自動駕駛系統中雷射雷達雷射的應用日益廣泛

- 超快雷射在下一代OLED和MicroLED顯示器修復的應用拓展

- 政府資助的光電叢集推動區域製造業生態系發展

- 用於鈑金切割的千瓦級光纖雷射的性價比迅速提高

- 市場限制

- 高品質砷化鎵/磷化銦外延晶片持續供不應求

- 出口管制制度限制向某些國家出口高功率雷射。

- 30kW以上功率的溫度控管挑戰限制了切割厚度藍圖

- 分散的安全標準增加了原始設備製造商的認證成本。

- 價值鏈分析

- 技術展望

- 監管環境

- 波特五力分析

- 供應商的議價能力

- 買方的議價能力

- 新進入者的威脅

- 替代品的威脅

- 競爭程度

第5章 市場規模與成長預測

- 依雷射類型

- 光纖雷射

- 二極體雷射

- 二氧化碳雷射

- 固體雷射

- 準分子雷射與紫外線雷射器

- 其他類型(量子級聯、自由電子)

- 透過使用

- 材料加工(切割、焊接、鑽孔)

- 通訊和光連接模組

- 醫療美容領域

- 光刻和半導體計量

- 軍事/國防

- 顯示器(有機發光二極體、微型發光二極體、投影式)

- 感測器(LiDAR、光譜儀)

- 印刷和標記

- 透過輸出

- 低功率(小於1千瓦)

- 中功率(1-3千瓦)

- 高功率(3kW 或以上)

- 按操作模式

- 連續波(CW)

- 脈衝(奈秒、皮秒、飛秒)

- 按最終用戶行業分類

- 電子和半導體

- 車

- 工業機械

- 衛生保健

- 航太/國防

- 研究和學術機構

- 按地區

- 北美洲

- 美國

- 加拿大

- 墨西哥

- 南美洲

- 巴西

- 阿根廷

- 其他南美洲

- 歐洲

- 德國

- 英國

- 法國

- 義大利

- 其他歐洲地區

- 亞太地區

- 中國

- 日本

- 韓國

- 印度

- 亞太其他地區

- 中東

- 沙烏地阿拉伯

- 阿拉伯聯合大公國

- 其他中東地區

- 非洲

- 南非

- 其他非洲地區

- 北美洲

第6章 競爭情勢

- 市場集中度

- 策略趨勢

- 市佔率分析

- 公司簡介

- Coherent Corp.

- IPG Photonics Corporation

- TRUMPF SE+Co. KG

- nLIGHT, Inc.

- Lumentum Holdings Inc.

- Jenoptik AG

- Novanta, Inc.

- Lumibird SA

- Wuhan Raycus Fiber Laser Technologies Co. Ltd

- Hans Laser Technology Industry Group Co., Ltd.

- Maxphotonics Co., Ltd.

- Keyence Corporation

- EKSPLA UAB

- MKS Instruments, Inc.(Spectra-Physics)

- Panasonic Corporation

- EdgeWave GmbH

- Civan Lasers Ltd.

- Synrad Laser Division

- Amonics Ltd.

- TOPTICA Photonics AG

第7章 市場機會與未來展望

The lasers market is expected to grow from USD 21.43 billion in 2025 to USD 22.92 billion in 2026 and is forecast to reach USD 32.08 billion by 2031 at 6.96% CAGR over 2026-2031.

This expansion reflects rising deployment across precision micromachining, additive manufacturing, autonomous mobility, and next-generation display production. Ultrafast pulse sources that machine sub-10 nm semiconductor features and kW-class fiber systems that cut thicker metal sheets are now mainstream in high-volume factories. Government-funded photonics clusters accelerate ecosystem development in Asia-Pacific, while additive manufacturing lasers lower material waste in aerospace components and shorten production cycles. Supply chain risks around gallium, germanium, and indium phosphide substrates remain a headwind, yet innovations in thermal management and beam-combining architectures continue to raise attainable power ceilings.

Global Lasers Market Trends and Insights

Surging Demand for High-Precision Micromachining in Semiconductor Back-End Packaging

Fan-Out Wafer Level Packaging and Through-Glass Via processes specify femtosecond and excimer sources that deliver sub-10 µm features with under-1% pulse-to-pulse energy deviation, ensuring uniform via formation across full 300 mm wafers. Replacing wire bonding with laser-formed micro-bumps reduces interconnect resistance by 40% and opens the path to three-dimensional chip stacks. Beam-shaping modules synchronized with in-situ monitoring raise yield and lower scrap rates in high-volume fabs. Asia-Pacific foundries continue to procure turnkey laser stations, creating a substantial pull on ultrafast source suppliers. As packaging line takt times tighten, demand for even higher repetition rates is expected to lift average selling prices in the premium ultrafast tier.

Growing Adoption of Additive Manufacturing Lasers for Aerospace Super-Alloy Parts

Aerospace primes now qualify powder-bed-fusion fiber lasers that process titanium aluminide and nickel super-alloys at material utilization rates above 95%, sharply outperforming subtractive machining. Dynamic beam shaping shortens build cycles by 40% and lowers energy consumption by 60%, while maintaining microstructure integrity critical for flight hardware. AS9100 revisions explicitly reference laser-printed parts, simplifying certification workflows. U.S. and European engine programs increasingly design for "print-first" geometries that cannot be machined economically. The shift ties laser demand to wide-body fleet renewal and hypersonic propulsion projects scheduled for late-decade entry into service.

Persistent Shortages of High-Grade Gallium Arsenide/Indium Phosphide Epi-Wafers

Export curbs on gallium and germanium intensify the scarcity of compound semiconductor substrates vital for high-power laser diodes. Variability in thermal conductivity across lots forces laser makers into lengthy re-qualification cycles, delaying shipments and elevating inventory buffers. Start-ups in North America and Europe plan new crystal-growth fabs, but tooling lead times and process know-how push meaningful volumes past 2027. Premium substrate pricing inflates the bill of materials by double digits, particularly for LiDAR and telecom lasers operating at elevated junction temperatures. Manufacturers are experimenting with silicon-based interposers to stretch the existing epi-wafer supply, yet performance penalties remain non-trivial.

Other drivers and restraints analyzed in the detailed report include:

- Rising Installation of LiDAR Lasers in Autonomous Mobility Stacks

- Expanding Use of Ultrafast Lasers for Next-Gen OLED and Micro-LED Display Repair

- Export-Control Regimes Limiting High-Power Laser Shipments to Certain Countries

For complete list of drivers and restraints, kindly check the Table Of Contents.

Segment Analysis

Fiber lasers held 41.40% of the global lasers market in 2025 thanks to robust beam quality, all-fiber architectures, and minimal service needs. Solid-state platforms, however, register the swiftest 9.18% CAGR to 2031 as directed-energy weapons and fusion experiments demand multi-megawatt optical chains. The global lasers market size for solid-state devices is projected to cross USD 5.62 billion by 2031, reflecting defense funding pipelines. Hybrid configurations that splice slab gain media into armored fiber delivery lines help transcend single-fiber power ceilings while preserving brightness. CO2 sources persist in thick-section cutting, whereas diode lasers expand in pump arrays and direct-write applications. Excimer and UV variants remain indispensable in sub-100 nm semiconductor lithography, anchoring steady demand despite cyclical foundry capex.

Ongoing research into distributed-gain architectures promises power scaling without thermally induced mode instabilities. Free-electron and quantum cascade technologies still occupy niche spectroscopy realms, but breakthroughs in compact accelerator structures could eventually democratize mid-infrared access. Safety compliance under IEC 60825-1 shapes enclosure designs, influencing total landed cost in high-automation factories. Vendors that fuse fiber reliability with solid-state punch position themselves to capture outsized share as application boundaries blur.

Materials processing retained a 30.10% share of the global lasers market in 2025, spanning cutting, welding, drilling, and additive build processes across automotive, aerospace, and general industry. Yet sensor deployments, notably LiDAR and spectroscopy modules, post an 8.58% CAGR, poised to narrow the gap by decade-end. Heavy-industry orders remain cyclical, but retrofit programs in brownfield plants sustain baseline volume. In parallel, medical and aesthetic lasers harvest incremental growth from outpatient procedures that favor low invasiveness and quick recovery.

Lithography expenditures hinge on advanced-node ramps at the top foundries, with each EUV scanner embedding multiple high-repetition excimer sources. Next-generation displays rely on ultrafast repair to maintain yield, unlocking higher panel profit margins. Military procurement of high-energy systems for counter-UAS duties injects lumpiness but also elevates public-sector funding for fundamental optics research. As edge and cloud data centers mushroom, optical interconnect demand boosts telecom laser volumes, reinforcing the application mix diversity within the global lasers market.

The Lasers Market Report is Segmented by Laser Type (Fiber Lasers, Diode Lasers, and More), Application (Materials Processing, and More), Power Output (Low-Power, Medium-Power, High-Power), Mode of Operation (Continuous-Wave, Pulsed), End-User Industry (Electronics and Semiconductor, and More), and Geography (North America, South America, Europe, Asia-Pacific, and More). The Market Forecasts are Provided in Terms of Value (USD).

Geography Analysis

Asia-Pacific controlled 46.40% of the global lasers market in 2025 and is projected to compound at 8.17% CAGR to 2031, propelled by dense semiconductor fabs, burgeoning display lines, and state-backed photonics parks. China leads excimer and ultrafast procurement for advanced lithography nodes, while Japan refines precision machining applications that demand superior beam quality. South Korea's OLED and micro-LED lines maintain high utilization, feeding sustained laser service contracts. India's Production-Linked Incentive schemes entice machine-tool makers to localize laser cutting and welding capacities, widening addressable demand. Taiwan and Singapore contribute niche volumes from compound semiconductor and precision engineering clusters, respectively.

North America ranks second, buoyed by aerospace build rates and defense contracts for megawatt-class directed-energy systems. U.S. photonics hubs under the Manufacturing USA umbrella foster start-up formation in integrated photonics and quantum cascade designs. Canada's materials-science institutes partner with local machine shops to trial laser cladding and hardening, while Mexico's electric-vehicle corridor scales fiber-laser welding for battery trays. Cross-border supply chains benefit from USMCA harmonization, though export controls constrain outbound shipments of high-power units to certain destinations. Environmental-monitoring mandates also spur domestic demand for mid-infrared gas-sensing modules.

Europe holds notable share through Germany's machinery giants and France's defense integrators that champion high-energy research lasers. The United Kingdom pursues aerospace composites processing with laser ablation to minimize delamination defects, and Italy's super-car makers adopt multi-kW disk lasers to weld aluminum chassis efficiently. EU-wide regulations, including the Machinery Directive and IEC 60825-1 alignment, shape safety features embedded in export-grade systems. Collaborative programs like DioHELIOS illustrate Europe's focus on fusion-energy enablers, with consortiums pooling diode-laser expertise to drive cost-effective scaling. Growing green-hydrogen initiatives further elevate interest in laser-based plate cutting and pipe welding across the region.

- Coherent Corp.

- IPG Photonics Corporation

- TRUMPF SE + Co. KG

- nLIGHT, Inc.

- Lumentum Holdings Inc.

- Jenoptik AG

- Novanta, Inc.

- Lumibird SA

- Wuhan Raycus Fiber Laser Technologies Co. Ltd

- Hans Laser Technology Industry Group Co., Ltd.

- Maxphotonics Co., Ltd.

- Keyence Corporation

- EKSPLA UAB

- MKS Instruments, Inc. (Spectra-Physics)

- Panasonic Corporation

- EdgeWave GmbH

- Civan Lasers Ltd.

- Synrad Laser Division

- Amonics Ltd.

- TOPTICA Photonics AG

Additional Benefits:

- The market estimate (ME) sheet in Excel format

- 3 months of analyst support

TABLE OF CONTENTS

1 INTRODUCTION

- 1.1 Study Assumptions and Market Definition

- 1.2 Scope of the Study

2 RESEARCH METHODOLOGY

3 EXECUTIVE SUMMARY

4 MARKET LANDSCAPE

- 4.1 Market Overview

- 4.2 Market Drivers

- 4.2.1 Surging demand for high-precision micromachining in semiconductor back-end packaging

- 4.2.2 Growing adoption of additive manufacturing lasers for aerospace super-alloy parts

- 4.2.3 Rising installation of LiDAR lasers in autonomous mobility stacks

- 4.2.4 Expanding use of ultrafast lasers for next-gen OLED and micro-LED display repair

- 4.2.5 Government-funded photonics clusters driving regional manufacturing ecosystems

- 4.2.6 Rapid price/performance improvements in kW-class fiber lasers for sheet-metal cutting

- 4.3 Market Restraints

- 4.3.1 Persistent shortages of high-grade gallium arsenide/indium phosphide epi-wafers

- 4.3.2 Export-control regimes limiting high-power laser shipments to certain countries

- 4.3.3 Thermal-management challenges above 30 kW limiting cutting-thickness roadmap

- 4.3.4 Fragmented safety standards increasing certification costs for OEMs

- 4.4 Value Chain Analysis

- 4.5 Technological Outlook

- 4.6 Regulatory Landscape

- 4.7 Porter's Five Forces Analysis

- 4.7.1 Bargaining Power of Suppliers

- 4.7.2 Bargaining Power of Buyers

- 4.7.3 Threat of New Entrants

- 4.7.4 Threat of Substitutes

- 4.7.5 Degree of Competition

5 MARKET SIZE AND GROWTH FORECASTS (VALUE)

- 5.1 By Laser Type

- 5.1.1 Fiber Lasers

- 5.1.2 Diode Lasers

- 5.1.3 CO2 Lasers

- 5.1.4 Solid-State Lasers

- 5.1.5 Excimer and Ultraviolet Lasers

- 5.1.6 Other Types (Quantum Cascade, Free-Electron)

- 5.2 By Application

- 5.2.1 Materials Processing (Cutting, Welding, Drilling)

- 5.2.2 Communications and Optical Interconnects

- 5.2.3 Medical and Aesthetic

- 5.2.4 Lithography and Semiconductor Metrology

- 5.2.5 Military and Defense

- 5.2.6 Displays (OLED, Micro-LED, Projection)

- 5.2.7 Sensors (LiDAR, Spectroscopy)

- 5.2.8 Printing and Marking

- 5.3 By Power Output

- 5.3.1 Low-Power (Less than 1 kW)

- 5.3.2 Medium-Power (1-3 kW)

- 5.3.3 High-Power (More than 3 kW)

- 5.4 By Mode of Operation

- 5.4.1 Continuous-Wave (CW)

- 5.4.2 Pulsed (ns, ps, fs)

- 5.5 By End-User Industry

- 5.5.1 Electronics and Semiconductor

- 5.5.2 Automotive

- 5.5.3 Industrial Machinery

- 5.5.4 Healthcare

- 5.5.5 Aerospace and Defense

- 5.5.6 Research and Academia

- 5.6 By Geography

- 5.6.1 North America

- 5.6.1.1 United States

- 5.6.1.2 Canada

- 5.6.1.3 Mexico

- 5.6.2 South America

- 5.6.2.1 Brazil

- 5.6.2.2 Argentina

- 5.6.2.3 Rest of South America

- 5.6.3 Europe

- 5.6.3.1 Germany

- 5.6.3.2 United Kingdom

- 5.6.3.3 France

- 5.6.3.4 Italy

- 5.6.3.5 Rest of Europe

- 5.6.4 Asia-Pacific

- 5.6.4.1 China

- 5.6.4.2 Japan

- 5.6.4.3 South Korea

- 5.6.4.4 India

- 5.6.4.5 Rest of Asia-Pacific

- 5.6.5 Middle East

- 5.6.5.1 Saudi Arabia

- 5.6.5.2 United Arab Emirates

- 5.6.5.3 Rest of Middle East

- 5.6.6 Africa

- 5.6.6.1 South Africa

- 5.6.6.2 Rest of Africa

- 5.6.1 North America

6 COMPETITIVE LANDSCAPE

- 6.1 Market Concentration

- 6.2 Strategic Moves

- 6.3 Market Share Analysis

- 6.4 Company Profiles (includes Global-level Overview, Market-level Overview, Core Segments, Financials as available, Strategic Information, Market Rank/Share, Products and Services, Recent Developments)

- 6.4.1 Coherent Corp.

- 6.4.2 IPG Photonics Corporation

- 6.4.3 TRUMPF SE + Co. KG

- 6.4.4 nLIGHT, Inc.

- 6.4.5 Lumentum Holdings Inc.

- 6.4.6 Jenoptik AG

- 6.4.7 Novanta, Inc.

- 6.4.8 Lumibird SA

- 6.4.9 Wuhan Raycus Fiber Laser Technologies Co. Ltd

- 6.4.10 Hans Laser Technology Industry Group Co., Ltd.

- 6.4.11 Maxphotonics Co., Ltd.

- 6.4.12 Keyence Corporation

- 6.4.13 EKSPLA UAB

- 6.4.14 MKS Instruments, Inc. (Spectra-Physics)

- 6.4.15 Panasonic Corporation

- 6.4.16 EdgeWave GmbH

- 6.4.17 Civan Lasers Ltd.

- 6.4.18 Synrad Laser Division

- 6.4.19 Amonics Ltd.

- 6.4.20 TOPTICA Photonics AG

7 MARKET OPPORTUNITIES AND FUTURE OUTLOOK

- 7.1 White-space and Unmet-need Assessment