|

市場調查報告書

商品編碼

1907207

食品加工機械:市場佔有率分析、產業趨勢與統計、成長預測(2026-2031)Food Processing Machinery - Market Share Analysis, Industry Trends & Statistics, Growth Forecasts (2026 - 2031) |

||||||

※ 本網頁內容可能與最新版本有所差異。詳細情況請與我們聯繫。

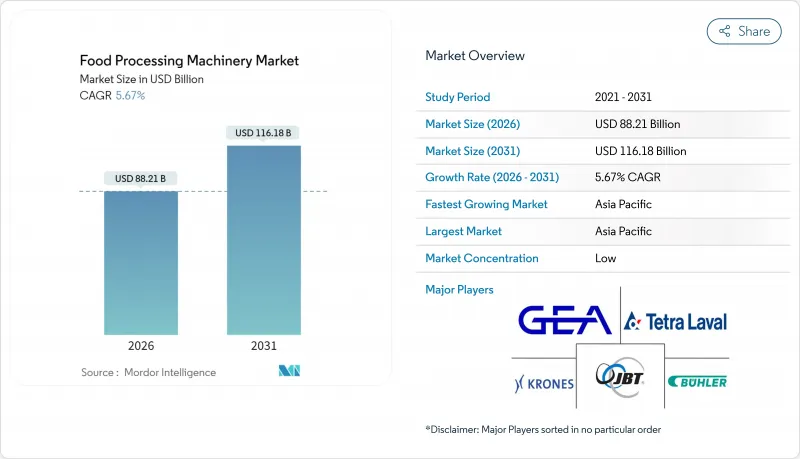

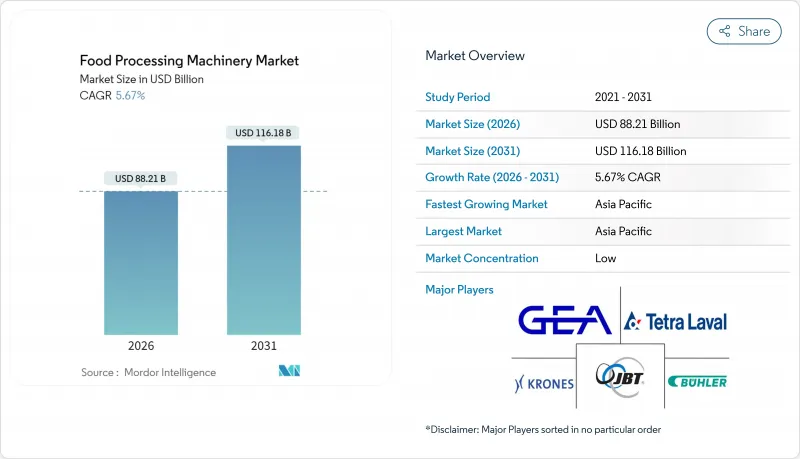

預計到 2026 年,食品加工機械市場價值將達到 882.1 億美元,從 2025 年的 834.8 億美元成長到 2031 年的 1,161.8 億美元。

預計2026年至2031年年複合成長率(CAGR)為5.67%。

工廠車間的持續現代化、日益嚴格的衛生法規以及包裝食品消費量的成長,共同支撐著這一成長趨勢。加工機械仍然是收入的最大來源,因為製造商將初級加工設備視為提高生產效率和確保產品品質穩定的最可靠途徑。亞太地區的工業擴張,加上不斷壯大的中產階級的購買力,正在推動該地區對符合不斷變化的食品安全法規的先進系統的需求。自動化仍然是關鍵,目前半自動化生產線佔據主導地位,但隨著企業追求預測性維護、資源效率和即時品質監控,智慧和人工智慧設備正以最快的速度應用。分散的供應鏈使得競爭保持適度,技術創新者憑藉專業化的互聯解決方案不斷擴大市場佔有率。

全球食品加工機械市場趨勢與洞察

對加工食品和簡便食品食品的需求不斷成長

消費者生活方式正朝著以便利為導向的消費模式轉變,推動了加工和包裝產業的持續資本投資。美國調理食品市場規模已達633億美元,並以9.1%的複合年成長率成長,這催生了對能夠適應不同產品配方和包裝形式的靈活生產線的上游需求。對於提供模組化系統的製造商而言,這一趨勢尤其有利,因為這些系統無需進行大規模重新配置即可實現快速產品切換。虛擬廚房營運商正擴大採用緊湊型、無廢氣排放的設備解決方案,以最大限度地利用空間並支援多種烹飪模式。例如,Altsham的Vector H系列多功能烤箱就支援七種虛擬主廚餐廳的營運。以配送為中心的經營模式與先進加工技術的結合,正在為面向都市區共享廚房運營的設備供應商創造一個新的市場細分領域。

工廠車間快速實現自動化和物聯網整合

製造智慧平台正在將食品加工從被動維護模式轉變為預測性營運模式,從而最佳化設備運轉率和產品品質。羅克韋爾自動化公司的 FactoryTalk Analytics 平台能夠即時監控制程參數,將計劃外停機時間減少高達 30%,同時提高整體設備效率 (OEE)。這種技術變革在高產量加工環境中尤其顯著,因為即使是微小的效率提升也能轉化為可觀的成本節約。智慧加工設備正日益融合邊緣運算功能,透過實現本地決策而無需依賴雲端連接,從而解決時間敏感型操作中的延遲問題。人工智慧在食品加工機械中的應用,例如 Chef Robotics 的人工智慧驅動的分切系統,該系統將產品一致性和產量比率提高了 30% 以上,這表明機器學習演算法可以最佳化份量控制並減少食物浪費。

先進衛生管理設備需要高額的資本投資和營運成本。

先進加工設備的投資障礙造成了市場分化,大型製造商與尋求經濟高效的自動化解決方案的中小型企業之間存在著明顯的市場隔閡。高度衛生的設計要求,例如採用316L不銹鋼材質和特殊的表面處理流程,顯著增加了設備的成本,遠高於標準工業機械。 GEA的入門級熱成型機正是針對那些尋求先進包裝功能但又不想投入高階系統所需資金的中小型企業而設計的。營運成本進一步加劇了初始投資的挑戰,因為專用清潔劑、驗證程序和維護通訊協定都需要持續的資金投入。這種成本結構對新興市場製造商的影響尤其顯著,他們必須在自動化帶來的優勢和資金限制之間取得平衡,這為提供靈活資金籌措和租賃模式的設備供應商創造了機會。

細分市場分析

在食品加工機械市場,加工設備預計到2025年將佔總收入的53.92%,反映出製造商專注於核心價值創造。熱加工、非熱加工和擠壓技術將成為產能擴張的基礎,預計複合年成長率將達到5.04%。布勒的SmartLine系列產品(包括在印度生產的DirectBake智慧烤箱)提供高階燃燒控制和配方管理,並根據當地價格分佈進行客製化。包裝器材是收入排名第二的市場,它正透過整合控制系統加強與上游工程的聯繫,這些控制系統可以同步灌裝速度、封口溫度和標籤供應。 CIP清洗裝置、廢棄物處理單元和HVAC系統等公用設施都連接到一個全廠儀錶板,用於分析水、能源和化學品消費量。這種連接表明食品加工機械市場正在從單機性能轉向全線最佳化。

直銷品牌和注重快速換線的「幽靈廚房」的興起,推動了對靈活的小批量熱處理系統的需求。同時,大型工廠正在安裝高容量蒸發器、超高溫瞬時滅菌(UHT)設備和無菌填充機,以支援出口管道。模組化熱交換器、泵浦和閥組供應商幫助加工商分階段進行投資,即使在現金流波動的情況下也能維持實施計畫。隨著網路安全PLC和工業乙太網標準的興起,設備間的互通性不再是錦上添花,而是保持競爭力的必要條件。

食品加工機械市場按機器類型(加工機械等)、自動化程度(手動、半自動、全自動、智慧和人工智慧賦能)、應用領域(烘焙和糖果甜點等)以及地區(北美、歐洲、亞太、南美、中東和非洲)進行細分。預測數據以以金額為準。

區域分析

預計到2025年,亞太地區將佔全球營收的38.21%,年複合成長率達5.33%,凸顯其在全球產能擴張中的關鍵角色。食品出口的快速成長、都市區消費的不斷成長以及政府為推動國內加工現代化而提供的激勵措施,都為該地區的成長提供了支撐。印尼嘉吉公司和印度龍沙公司等大型跨國公司正在擴大本地生產規模,以滿足國內市場和周邊出口走廊的需求。該地區的採購部門越來越重視能夠提供快速交貨、在地採購採購備件和及時售後服務的機械供應商。這一趨勢正在推動對模組化系統、自動化檢測技術以及根據該地區獨特的農作物和畜牧生產特徵量身定做的連續加工生產線的需求。

北美地區正致力於最佳化現有基礎設施,而非新建設。加工商正投資於數位化維修、預測維修系統和能源效率提升。鋼鐵和鋁關稅導致設備製造成本飆升25%,迫使買家轉向區域性原始設備製造商 (OEM) 和在美國設有組裝基地的全球性公司。市場正迅速採用機器人執行分裝、包裝和清潔等任務。這項轉變的主要促進因素是勞動力短缺、嚴格的衛生標準以及管理不同產品 SKU 生產差異的挑戰。

拉丁美洲、中東和非洲正在齊心協力發展食品加工基礎設施。這些舉措旨在加強糧食安全,減少收穫後損失,並重振農村農業產業價值鏈。創新技術包括移動式水果加工單元、貨櫃式乳製品生產線、太陽能脫水機和低壓家禽漂燙機。這些技術對於低溫運輸匱乏、電力供應不穩定的地區尤其重要。儘管政府支持的現代化改造津貼公私合營正在幫助中小加工企業升級設備,但外匯波動和進口依賴等挑戰仍然延緩了機械設備的訂購。然而,這些地區的總體目標很明確:填補關鍵產能缺口,提高本地附加價值,並使供應與不斷成長的國內需求相匹配。

其他福利:

- Excel格式的市場預測(ME)表

- 3個月的分析師支持

目錄

第1章 引言

- 研究假設和市場定義

- 調查範圍

第2章調查方法

第3章執行摘要

第4章 市場情勢

- 市場概覽

- 市場促進因素

- 對加工食品和簡便食品食品的需求不斷成長

- 工廠車間自動化和物聯網整合的快速進展

- 全球更嚴格的食品安全和衛生法規

- 擴大亞太地區的食品製造能力

- 向靈活的小批量生產線轉型,以服務D2C和幽靈廚房

- 美國和歐盟的近岸外包獎勵措施和關稅制度

- 市場限制

- 先進衛生管理設備需要高額的資本投資和營運成本。

- 能源和技術純熟勞工成本上漲

- 由於半導體和感測器短缺導致交貨延遲

- 互聯處理設備的網路安全風險

- 監管環境

- 技術展望

- 波特五力模型

- 新進入者的威脅

- 買方/消費者的議價能力

- 供應商的議價能力

- 替代品的威脅

- 競爭對手之間的競爭

第5章 市場規模與成長預測

- 按機器類型

- 加工機械

- 初級加工

- 熱處理

- 未經熱處理

- 擠出成型系統

- 包裝器材

- 初級包裝

- 二級包裝

- 生產線末端包裝

- 真空包裝/氣調包裝/無菌包裝系統

- 公用設施及輔助系統

- 加工機械

- 按自動化級別

- 手動的

- 半自動

- 全自動

- 智慧與人工智慧賦能

- 透過使用

- 烘焙和糖果甜點

- 肉類、魚貝類和肉品

- 乳製品及乳製品替代品

- 飲料

- 水果、蔬菜和堅果

- 調理食品及食材自煮包

- 其他

- 按地區

- 北美洲

- 美國

- 加拿大

- 墨西哥

- 北美其他地區

- 歐洲

- 德國

- 英國

- 義大利

- 法國

- 西班牙

- 荷蘭

- 波蘭

- 比利時

- 瑞典

- 其他歐洲地區

- 亞太地區

- 中國

- 印度

- 日本

- 澳洲

- 印尼

- 韓國

- 泰國

- 新加坡

- 亞太其他地區

- 南美洲

- 巴西

- 阿根廷

- 哥倫比亞

- 智利

- 秘魯

- 南美洲其他地區

- 中東和非洲

- 南非

- 沙烏地阿拉伯

- 阿拉伯聯合大公國

- 奈及利亞

- 埃及

- 摩洛哥

- 土耳其

- 其他中東和非洲地區

- 北美洲

第6章 競爭情勢

- 市場集中度

- 策略趨勢

- 市佔率分析

- 公司簡介

- Buhler AG

- GEA Group AG

- Tetra Laval(Tetra Pak)

- John Bean Technologies(JBT)

- Krones AG

- Marel hf.

- Alfa Laval AB

- SPX FLOW Inc.

- Tomra Systems ASA

- Satake Corp.

- Anko Food Machine Co.

- Hosokawa Micron Corp.

- Atlas Pacific Engineering

- Provisur Technologies

- Syntegon Technology

- Marelec Food Tech

- Key Technology

- Heat and Control

- Middleby Corp.

- Urschel Laboratories

第7章 市場機會與未來展望

Food processing machinery market size in 2026 is estimated at USD 88.21 billion, growing from 2025 value of USD 83.48 billion with 2031 projections showing USD 116.18 billion, growing at 5.67% CAGR over 2026-2031.

Steady modernization of plant floors, stricter hygiene regulations, and rising consumption of packaged foods underpin this growth trajectory. Processing machinery continues to command the largest revenue share because manufacturers view primary transformation equipment as the surest route to throughput gains and consistent product quality. Asia-Pacific's industrial build-out, coupled with expanding middle-class purchasing power, accelerates regional demand for advanced systems that comply with evolving food-safety mandates. Automation remains pivotal; semi-automatic lines dominate current installations, yet smart and AI-enabled equipment records the fastest uptake as firms pursue predictive maintenance, resource efficiency, and real-time quality monitoring. Competitive intensity stays moderate in a fragmented supplier base, enabling technology disruptors to win share with specialized, connected solutions.

Global Food Processing Machinery Market Trends and Insights

Rising Demand for Processed and Convenience Foods

Consumer lifestyle shifts toward convenience-oriented consumption patterns drive sustained equipment investment across processing and packaging segments. The U.S. ready meals market reached USD 63.3 billion with a 9.1% CAGR growth, creating upstream demand for flexible processing lines capable of handling diverse product formulations and packaging formats. This trend particularly benefits manufacturers offering modular systems that accommodate rapid product changeovers without extensive reconfiguration. Ghost kitchen operators increasingly specify compact, ventless equipment solutions that maximize space utilization while enabling multi-concept food preparation, as demonstrated by Alto-Shaam's Vector H Series Multi-Cook Oven powering Virtual Chef Hall's seven-concept operations. The convergence of delivery-focused business models with advanced processing technology creates new market segments for equipment suppliers targeting urban commissary operations.

Rapid Automation and IoT Integration in Plant Floors

Manufacturing intelligence platforms transform food processing from reactive maintenance toward predictive operational models that optimize equipment utilization and product quality. Rockwell Automation's FactoryTalk Analytics platform enables real-time monitoring of processing parameters, reducing unplanned downtime by up to 30% while improving overall equipment effectiveness. This technological shift particularly impacts high-volume processing environments where marginal efficiency gains translate to significant cost savings. Smart processing equipment increasingly incorporates edge computing capabilities that enable local decision-making without relying on cloud connectivity, addressing latency concerns in time-sensitive operations. The integration of artificial intelligence in food processing machinery, exemplified by Chef Robotics' AI-enabled depositing systems achieving greater than 30% improvement in consistency and yield, demonstrates how machine learning algorithms optimize portion control and reduce food waste.

High Capex and Opex of Advanced Hygienic Machinery

Investment barriers for sophisticated processing equipment create market segmentation between large-scale manufacturers and smaller operators seeking cost-effective automation solutions. Advanced hygienic design requirements, including 316L stainless steel construction and specialized surface finishes, significantly increase equipment costs compared to standard industrial machinery. GEA's introduction of entry-level thermoforming machines specifically targets small and medium-sized companies seeking advanced packaging capabilities without the capital commitment of high-end systems. Operating expenses compound initial investment challenges, as specialized cleaning chemicals, validation procedures, and maintenance protocols require ongoing financial commitments. This cost structure particularly impacts emerging market manufacturers who must balance automation benefits against capital constraints, creating opportunities for equipment suppliers offering flexible financing and leasing models.

Other drivers and restraints analyzed in the detailed report include:

- Stricter Global Food-Safety and Hygiene Regulations

- Expanding Food Manufacturing Capacity Across APAC

- Escalating Energy and Skilled-Labor Costs

For complete list of drivers and restraints, kindly check the Table Of Contents.

Segment Analysis

Processing equipment captured 53.92% of 2025 revenue within the food processing machinery market, reflecting manufacturers' focus on core value generation. Thermal, non-thermal, and extrusion technologies form the backbone of capacity expansions and recorded a 5.04% CAGR outlook. Buhler's SmartLine release, including the DirectBake Smart oven produced in India, tailors high-end combustion and recipe controls to local price points. Packaging machinery ranks second in revenue yet increasingly integrates with upstream processes through unified controls that synchronize fill rates, sealing temperatures, and label feeds. Utilities such as CIP skids, waste-handling units, and HVAC systems tie into overarching plant-wide dashboards that analyze water, energy, and chemical consumption. This linkage illustrates how the food processing machinery market is moving from machine-level performance to holistic line optimization.

Demand for flexible, small-batch thermal systems rises alongside D2C brands and ghost kitchens that prioritize rapid changeovers. At the other end of the scale, mega-plants order high-throughput evaporators, UHT units, and aseptic fillers to serve export channels. Suppliers that modularize heat exchangers, pumps, and valve manifolds allow processors to phase investments over multiple budget cycles, keeping adoption on track even when cash flows fluctuate. As cyber-secure PLCs and industrial Ethernet become standard, equipment interoperability becomes a competitive requirement rather than a luxury.

The Food Processing Machinery Market is Segmented by Machinery Type (Processing Machinery and More), Automation Level (Manual, Semi-Automatic, Fully Automatic, Smart and AI-Enabled), Application (Bakery and Confectionery, and More), and Geography (North America, Europe, Asia-Pacific, South America, Middle East, and Africa). Forecasts are Provided in Value Terms (USD).

Geography Analysis

In 2025, the Asia-Pacific region is projected to contribute 38.21% to global revenue and is set to grow at a CAGR of 5.33%. This underscores the region's pivotal role in global capacity expansion. Factors such as surging food exports, urban consumption, and government incentives for modernizing domestic processing bolster the region's growth. Multinational giants, including Cargill in Indonesia and Lonza in India, are broadening their localized manufacturing to cater to both domestic markets and nearby export corridors. Procurement teams in the region are increasingly favoring machinery suppliers who offer shorter lead times, local spare parts, and swift after-sales service. This trend fuels demand for modular systems, automated inspection technologies, and continuous processing lines, all tailored to the region's unique crop and livestock profiles.

North America is focusing on optimizing its existing infrastructure instead of pursuing greenfield expansions. Processors are channeling investments into digital retrofits, predictive maintenance systems, and energy-efficient upgrades. Rising tariffs on steel and aluminium, leading to a 25% spike in equipment fabrication costs-are nudging buyers to turn to regional OEMs or global firms with U.S.-based assembly units. The market is witnessing a robust adoption of robotics for tasks like portioning, packaging, and sanitation. This shift is largely driven by labor shortages, stringent hygiene standards, and the challenge of managing production variability across diverse product SKUs.

In South America, the Middle East, and Africa, there's a concerted push to establish foundational food processing infrastructure. This initiative aims to bolster food security, curtail post-harvest losses, and invigorate rural agro-industrial value chains. Innovations like mobile fruit processing units, containerized dairy lines, solar-powered dehydrators, and low-pressure poultry scalders are being deployed. These technologies are especially beneficial in areas with limited cold-chain access and inconsistent grid connectivity. While government-backed modernization grants and public-private partnerships are aiding small and mid-sized processors in upgrading their equipment, challenges like foreign exchange volatility and a reliance on imports are causing delays in machinery orders. Nevertheless, the overarching goal in these regions remains clear: to bridge critical capacity gaps, enhance local value addition, and align supply with the growing domestic demand.

- Buhler AG

- GEA Group AG

- Tetra Laval (Tetra Pak)

- John Bean Technologies (JBT)

- Krones AG

- Marel hf.

- Alfa Laval AB

- SPX FLOW Inc.

- Tomra Systems ASA

- Satake Corp.

- Anko Food Machine Co.

- Hosokawa Micron Corp.

- Atlas Pacific Engineering

- Provisur Technologies

- Syntegon Technology

- Marelec Food Tech

- Key Technology

- Heat and Control

- Middleby Corp.

- Urschel Laboratories

Additional Benefits:

- The market estimate (ME) sheet in Excel format

- 3 months of analyst support

TABLE OF CONTENTS

1 Introduction

- 1.1 Study Assumptions and Market Definition

- 1.2 Scope of the Study

2 Research Methodology

3 Executive Summary

4 Market Landscape

- 4.1 Market Overview

- 4.2 Market Drivers

- 4.2.1 Rising demand for processed and convenience foods

- 4.2.2 Rapid automation and IoT integration in plant floors

- 4.2.3 Stricter global food-safety and hygiene regulations

- 4.2.4 Expanding food manufacturing capacity across APAC

- 4.2.5 Shift toward flexible small-batch lines for D2C and ghost kitchens

- 4.2.6 Near-shoring incentives & tariff regimes in U.S./EU

- 4.3 Market Restraints

- 4.3.1 High capex and opex of advanced hygienic machinery

- 4.3.2 Escalating energy and skilled-labor costs

- 4.3.3 Semiconductor & sensor shortages delaying deliveries

- 4.3.4 Cyber-security risks in connected processing equipment

- 4.4 Regulatory Landscape

- 4.5 Technological Outlook

- 4.6 Porter's Five Forces

- 4.6.1 Threat of New Entrants

- 4.6.2 Bargaining Power of Buyers/Consumers

- 4.6.3 Bargaining Power of Suppliers

- 4.6.4 Threat of Substitute Products

- 4.6.5 Intensity of Competitive Rivalry

5 Market Size & Growth Forecasts (Value)

- 5.1 By Machinery Type

- 5.1.1 Processing Machinery

- 5.1.1.1 Primary Processing

- 5.1.1.2 Thermal Processing

- 5.1.1.3 Non-Thermal Processing

- 5.1.1.4 Extrusion and Forming Systems

- 5.1.2 Packaging Machinery

- 5.1.2.1 Primary Packaging

- 5.1.2.2 Secondary Packaging

- 5.1.2.3 End-of-Line packaging

- 5.1.2.4 Vacuum / MAP / Aseptic Systems

- 5.1.3 Utilities and Ancillary Systems

- 5.1.1 Processing Machinery

- 5.2 By Automation Level

- 5.2.1 Manual

- 5.2.2 Semi-Automatic

- 5.2.3 Fully Automatic

- 5.2.4 Smart and AI-Enabled

- 5.3 By Application

- 5.3.1 Bakery and Confectionery

- 5.3.2 Meat/Seafood and Meat-Alternative

- 5.3.3 Dairy and Dairy-Alternative

- 5.3.4 Beverages

- 5.3.5 Fruits, Vegetables & Nuts

- 5.3.6 Ready Meals and Meal Kits

- 5.3.7 Others

- 5.4 By Geography

- 5.4.1 North America

- 5.4.1.1 United States

- 5.4.1.2 Canada

- 5.4.1.3 Mexico

- 5.4.1.4 Rest of North America

- 5.4.2 Europe

- 5.4.2.1 Germany

- 5.4.2.2 United Kingdom

- 5.4.2.3 Italy

- 5.4.2.4 France

- 5.4.2.5 Spain

- 5.4.2.6 Netherlands

- 5.4.2.7 Poland

- 5.4.2.8 Belgium

- 5.4.2.9 Sweden

- 5.4.2.10 Rest of Europe

- 5.4.3 Asia-Pacific

- 5.4.3.1 China

- 5.4.3.2 India

- 5.4.3.3 Japan

- 5.4.3.4 Australia

- 5.4.3.5 Indonesia

- 5.4.3.6 South Korea

- 5.4.3.7 Thailand

- 5.4.3.8 Singapore

- 5.4.3.9 Rest of Asia-Pacific

- 5.4.4 South America

- 5.4.4.1 Brazil

- 5.4.4.2 Argentina

- 5.4.4.3 Colombia

- 5.4.4.4 Chile

- 5.4.4.5 Peru

- 5.4.4.6 Rest of South America

- 5.4.5 Middle East and Africa

- 5.4.5.1 South Africa

- 5.4.5.2 Saudi Arabia

- 5.4.5.3 United Arab Emirates

- 5.4.5.4 Nigeria

- 5.4.5.5 Egypt

- 5.4.5.6 Morocco

- 5.4.5.7 Turkey

- 5.4.5.8 Rest of Middle East and Africa

- 5.4.1 North America

6 Competitive Landscape

- 6.1 Market Concentration

- 6.2 Strategic Moves

- 6.3 Market Share Analysis

- 6.4 Company Profiles (includes Global level Overview, Market level overview, Core Segments, Financials as available, Strategic Information, Market Rank/Share for key companies, Products & Services, and Recent Developments)

- 6.4.1 Buhler AG

- 6.4.2 GEA Group AG

- 6.4.3 Tetra Laval (Tetra Pak)

- 6.4.4 John Bean Technologies (JBT)

- 6.4.5 Krones AG

- 6.4.6 Marel hf.

- 6.4.7 Alfa Laval AB

- 6.4.8 SPX FLOW Inc.

- 6.4.9 Tomra Systems ASA

- 6.4.10 Satake Corp.

- 6.4.11 Anko Food Machine Co.

- 6.4.12 Hosokawa Micron Corp.

- 6.4.13 Atlas Pacific Engineering

- 6.4.14 Provisur Technologies

- 6.4.15 Syntegon Technology

- 6.4.16 Marelec Food Tech

- 6.4.17 Key Technology

- 6.4.18 Heat and Control

- 6.4.19 Middleby Corp.

- 6.4.20 Urschel Laboratories