|

市場調查報告書

商品編碼

1906128

歐洲苛性鈉:市場佔有率分析、產業趨勢、統計數據和成長預測(2026-2031)Europe Caustic Soda - Market Share Analysis, Industry Trends & Statistics, Growth Forecasts (2026 - 2031) |

||||||

※ 本網頁內容可能與最新版本有所差異。詳細情況請與我們聯繫。

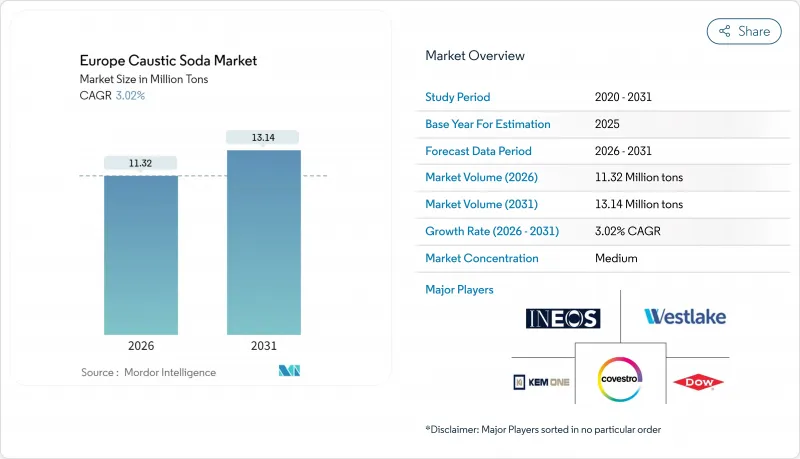

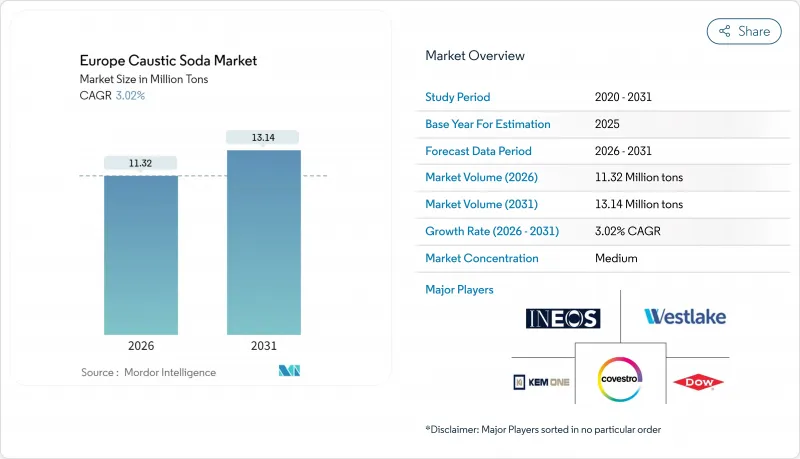

2025年歐洲苛性鈉市場價值為1,099萬噸,預計2031年將達到1,314萬噸,高於2026年的1,132萬噸。

預計在預測期(2026-2031 年)內,複合年成長率將達到 3.02%。

這種穩定擴張標誌著該行業已進入成熟階段,節能技術和監管利好因素超過了電力價格上漲等成長阻礙因素。歐盟《基本化學品法》將苛性鈉列為關鍵化學品,凸顯了其在保護該地區工業自主性方面的戰略作用。隨著現貨價格飆升至275歐元/兆瓦時的壓力測試水平,膜電極技術透過降低電力消耗保持了競爭優勢。下游一體化繼續有利於液態產品,而對污水處理、電池氧化鋁提純和纖維基包裝材料的持續投資則確保了需求即使在周期性低迷時期也能保持韌性。同時,來自亞洲低成本出口商的進口套利和能源成本的波動正在擠壓利潤空間,並加速老牌生產商的產品組合最佳化。

歐洲苛性鈉市場趨勢與分析

水處理應用需求不斷成長

歐盟新的都市廢水處理法規強制要求進行三級和四級處理,這導致用於控制pH值和去除磷的苛性鈉用量激增。西班牙和德國的污水處理廠升級改造正在擴大,各市政當局必須在2045年前實現能源中和目標,以確保即使設施向可再生能源過渡,也能維持基準的能源消費量。更嚴格的微量污染物去除標準進一步擴大了苛性鈉在高級氧化和沈澱過程中的應用。由於市政升級改造是數十億歐元的計劃,歐洲苛性鈉市場享有長期穩定的市場需求,不受更廣泛的工業放緩的影響。產業數據顯示,氯鹼製程每噸氯消耗約2600千瓦時電能,因此苛性鈉供應與能源效率投資直接相關。

電動車電池供應鏈對氧化鋁的需求不斷成長

圍繞歐洲超級工廠而建的電池氧化鋁精煉廠,其純度要求更高,苛性鈉消費量也高於傳統產品。德國的汽車產業是推動這項需求的主要力量,而法國和比利時的工廠則正競相取得當地原料。儘管Northvolt公司2024年的破產令市場情緒承壓,但汽車電氣化仍是結構性成長的引擎。該產業歷來佔全球苛性鈉消費量的21%,如今受惠於溢價,足以抵銷能源成本,從而鞏固了其長期需求基礎。

歐洲能源成本高企

由於電力成本佔氯鹼生產現金成本的一半以上,俄烏衝突導致的波動使得當電價接近275歐元/兆瓦時,區域產能運轉率驟降。BASF國內化學品產量下降了25%,決定安裝一座54兆瓦的綠色氫氣電解,預計每年可生產8,000噸氫氣,並減少7.2萬噸排放。在電網透過增加可再生能源而趨於穩定之前,生產商將被迫承擔更高的電價,導致利潤空間受壓,並出現部分停產的情況。

細分市場分析

截至2025年,膜電解將佔據歐洲苛性鈉市場77.48%的佔有率,體現了其卓越的能源效率和合規性。不斷上漲的電力成本正促使製造商加速從隔膜電解系統轉型為膜電解系統。預計到2031年,這項轉變將推動膜電解產能以3.14%的複合年成長率成長。新興的電滲析技術可望進一步降低單位電力消耗量,進而鞏固膜技術的長期優勢。隨著環境法規強制淘汰汞電解槽,歐洲膜苛性鈉市場預計將穩定擴張。同時,歐洲工程公司在沙烏地阿拉伯的計劃為區域技術供應商提供了全球出口機遇,從而形成創新與應用的良性循環。

隨著奧林等業者關閉無法滿足能源效率標準的舊生產線,傳統膜分離設備正在萎縮。儘管維修活動需要大量資金投入,但由於貸款機構擴大將信貸成本與排放績效掛鉤,使得膜分離升級的投資回報更加可量化,因此資金籌措依然暢通。汞電解槽曾經普遍使用,如今僅在一些獨立的整合設施中仍有應用,並且由於歐盟指令的規定,預計將在2027年之前完全淘汰。總體而言,生產流程格局為歐洲苛性鈉市場提供了逐步提高效率的機會,這在一定程度上抵消了電價上漲的不利影響。

其他福利:

- Excel格式的市場預測(ME)表

- 3個月的分析師支持

目錄

第1章 引言

- 研究假設和市場定義

- 調查範圍

第2章調查方法

第3章執行摘要

第4章 市場情勢

- 市場概覽

- 市場促進因素

- 水處理應用需求不斷成長

- 電動車電池供應鏈對氧化鋁的需求不斷成長

- 纖維基包裝的成長

- 擴大肥皂和清潔劑製造地

- 化學合成需求不斷成長

- 市場限制

- 歐洲能源成本高企

- 職業健康與安全以及 REACH 合規成本

- 進口套利擠壓歐盟利潤率

- 價值鏈分析

- 監管環境

- 技術展望

- 波特五力模型

- 供應商的議價能力

- 買方的議價能力

- 新進入者的威脅

- 替代品的威脅

- 競爭程度

- 貿易分析

- 價格趨勢

- 生產分析

第5章 市場規模和成長預測(價值和數量)

- 透過製造程序

- 膜細胞

- 膈肌細胞

- 其他製造流程(汞電池(舊式)、新興的電滲析和直接電合成)

- 按形式

- 固體的

- 液體

- 透過使用

- 紙漿和造紙

- 有機化學品

- 無機化學品

- 肥皂和清潔劑

- 氧化鋁

- 水處理

- 其他用途(食品和飼料加工等)

- 按地區

- 德國

- 英國

- 法國

- 義大利

- 西班牙

- 俄羅斯

- 其他歐洲地區

第6章 競爭情勢

- 市場集中度

- 策略趨勢

- 市佔率(%)/排名分析

- 公司簡介

- BASF

- Covestro

- Dow

- Ercros

- INEOS

- Kem One

- Nouryon

- Olin Corporation

- PCC SE

- Spolchemie

- Vynova Group

- Westlake Corporation

- WeylChem International GmbH

第7章 市場機會與未來展望

The Europe Caustic Soda Market was valued at 10.99 Million tons in 2025 and estimated to grow from 11.32 Million tons in 2026 to reach 13.14 Million tons by 2031, at a CAGR of 3.02% during the forecast period (2026-2031).

This steady expansion signals a mature phase in which energy-efficient technologies and regulatory tailwinds outweigh growth constraints such as elevated power prices. Caustic soda's classification as a critical chemical under the proposed EU Critical Chemicals Act underscores its strategic role in safeguarding regional industrial autonomy. Membrane cell technology dominates the competitive arena because it cuts electricity consumption at a time when spot prices have spiked to stress-test levels of EUR 275/MWh. Downstream integration continues to favor the liquid form, while sustained investments in wastewater treatment, battery-grade alumina refining and fiber-based packaging keep demand resilient across cyclical downturns. At the same time, import arbitrage from low-cost Asian exporters and volatile energy costs create margin pressure that accelerates portfolio rationalization among incumbent producers.

Europe Caustic Soda Market Trends and Insights

Increasing Demand from Water Treatment Application

New urban-wastewater rules require tertiary and quaternary treatment across the bloc, triggering a surge in caustic-soda dosing for pH control and phosphorus removal. Spain and Germany are scaling plant upgrades, and municipalities must comply with an energy-neutral target by 2045, guaranteeing baseline consumption even as facilities pivot to renewable power. Micropollutant removal standards further broaden caustic-soda usage in advanced oxidation and precipitation. Because municipal upgrades are multi-billion-euro projects, the European caustic soda market enjoys stable long-cycle demand insulated from broader industrial slowdowns. Industry data show chlor-alkali processes consume roughly 2,600 kWh per ton of chlorine, linking caustic-soda supply directly to energy-efficiency investments.

Rising Alumina Demand from EV-Battery Supply Chain

Battery-grade alumina refineries that cluster near European gigafactories require higher caustic-soda purity and volumes per output ton than legacy grades. German automotive hubs anchor this pull, while French and Belgian sites race to secure regional feedstock. Although Northvolt's 2024 bankruptcy dented sentiment, vehicle electrification remains a structural growth engine. The sector historically consumes 21% of global caustic soda and now benefits from premium pricing that offsets energy costs, strengthening the long-run demand case.

High Energy Costs in Europe

Electricity accounts for over half of chlor-alkali cash costs, so volatility tied to the Russia-Ukraine conflict slashed regional operating rates when prices neared EUR 275/MWh. BASF lost 25% domestic chemical output, prompting a 54 MW green-hydrogen electrolyzer that should yield 8,000 t of H2 annually and curb 72,000 t of emissions. Producers must absorb higher power tariffs until renewable additions stabilize the grid, translating into margin compression and selective shutdowns.

Other drivers and restraints analyzed in the detailed report include:

- Growth of Fiber-Based Packaging

- Expansion of Soap and Detergent Manufacturing Hubs

- Import Arbitrage Squeezing EU Margins

For complete list of drivers and restraints, kindly check the Table Of Contents.

Segment Analysis

The membrane cell route commands 77.48% of the European caustic soda market share in 2025, reflecting its superior energy profile and regulatory compliance advantages. Producers accelerated diaphragm-to-membrane conversions as electricity costs soared, a shift that lifted membrane capacity additions to 3.14% CAGR through 2031. Emerging electro-electrodialysis technologies promise further cuts in specific power consumption, reinforcing the long-term dominance of membranes. The European caustic soda market size for membrane-based output is forecast to widen steadily because legacy mercury cells face mandatory phase-outs under environmental statutes. In parallel, Saudi projects supplied by European engineering firms signal global export opportunities for the region's technology providers, sustaining a virtuous cycle of innovation and deployment.

Traditional diaphragm assets are shrinking as operators such as Olin shutter older lines that cannot meet energy-intensity benchmarks. Retrofit activity is capital-heavy, yet financing remains accessible because lenders increasingly link credit costs to emissions performance, giving membrane upgrades a quantifiable payback. Mercury cells, once common, linger only in isolated integrated complexes and will exit entirely before 2027 under EU directives. Overall, the production-process landscape positions the European caustic soda market for incremental efficiency gains that partly offset power-price headwinds.

The Caustic Soda Europe Market Report Segments the Industry by Production Process (Membrane Cell, Diaphragm Cell, Other Production Processes), Form (Solid, Liquid), Application (Pulp and Paper, Organic Chemical, Inorganic Chemical, Soap and Detergent, Alumina, Water Treatment, Other Applications), and Geography (Germany, United Kingdom, Italy, and More). The Market Forecasts are Provided in Terms of Value (USD) and Volume (tons).

List of Companies Covered in this Report:

- BASF

- Covestro

- Dow

- Ercros

- INEOS

- Kem One

- Nouryon

- Olin Corporation

- PCC SE

- Spolchemie

- Vynova Group

- Westlake Corporation

- WeylChem International GmbH

Additional Benefits:

- The market estimate (ME) sheet in Excel format

- 3 months of analyst support

TABLE OF CONTENTS

1 Introduction

- 1.1 Study Assumptions and Market Definition

- 1.2 Scope of the Study

2 Research Methodology

3 Executive Summary

4 Market Landscape

- 4.1 Market Overview

- 4.2 Market Drivers

- 4.2.1 Increasing Demand from Water Treatment Application

- 4.2.2 Rising Alumina Demand from EV-Battery Supply Chain

- 4.2.3 Growth of Fiber-Based Packaging

- 4.2.4 Expansion of Soap and Detergent Manufacturing Hubs

- 4.2.5 Growing Requirement for Chemical Synthesis

- 4.3 Market Restraints

- 4.3.1 High Energy Costs in Europe

- 4.3.2 Occupational-Safety and REACH Compliance Costs

- 4.3.3 Import Arbitrage squeezing European Union's margins

- 4.4 Value Chain Analysis

- 4.5 Regulatory Landscape

- 4.6 Technological Outlook

- 4.7 Porter's Five Forces

- 4.7.1 Bargaining Power of Suppliers

- 4.7.2 Bargaining Power of Buyers

- 4.7.3 Threat of New Entrants

- 4.7.4 Threat of Substitutes

- 4.7.5 Degree of Competition

- 4.8 Trade Analysis

- 4.9 Price Trends

- 4.10 Production Analysis

5 Market Size and Growth Forecasts (Value and Volume)

- 5.1 By Production Process

- 5.1.1 Membrane Cell

- 5.1.2 Diaphragm Cell

- 5.1.3 Other Production Processes (Mercury Cell (legacy), Emerging Electro-electrodialysis and Direct Electro-synthesis)

- 5.2 By Form

- 5.2.1 Solid

- 5.2.2 Liquid

- 5.3 By Application

- 5.3.1 Pulp and Paper

- 5.3.2 Organic Chemicals

- 5.3.3 Inorganic Chemicals

- 5.3.4 Soap and Detergents

- 5.3.5 Alumina

- 5.3.6 Water Treatment

- 5.3.7 Other Applications (Food and Feed Processing, etc.)

- 5.4 By Geography

- 5.4.1 Germany

- 5.4.2 United Kingdom

- 5.4.3 France

- 5.4.4 Italy

- 5.4.5 Spain

- 5.4.6 Russia

- 5.4.7 Rest of Europe

6 Competitive Landscape

- 6.1 Market Concentration

- 6.2 Strategic Moves

- 6.3 Market Share(%)/Ranking Analysis

- 6.4 Company Profiles (includes Global level Overview, Market level overview, Core Segments, Financials as available, Strategic Information, Market Rank/Share for key companies, Products and Services, and Recent Developments)

- 6.4.1 BASF

- 6.4.2 Covestro

- 6.4.3 Dow

- 6.4.4 Ercros

- 6.4.5 INEOS

- 6.4.6 Kem One

- 6.4.7 Nouryon

- 6.4.8 Olin Corporation

- 6.4.9 PCC SE

- 6.4.10 Spolchemie

- 6.4.11 Vynova Group

- 6.4.12 Westlake Corporation

- 6.4.13 WeylChem International GmbH

7 Market Opportunities and Future Outlook

- 7.1 White-space and Unmet-need Assessment