|

市場調查報告書

商品編碼

1906022

藥品包裝:市場佔有率分析、產業趨勢與統計、成長預測(2026-2031)Pharmaceutical Packaging - Market Share Analysis, Industry Trends & Statistics, Growth Forecasts (2026 - 2031) |

||||||

※ 本網頁內容可能與最新版本有所差異。詳細情況請與我們聯繫。

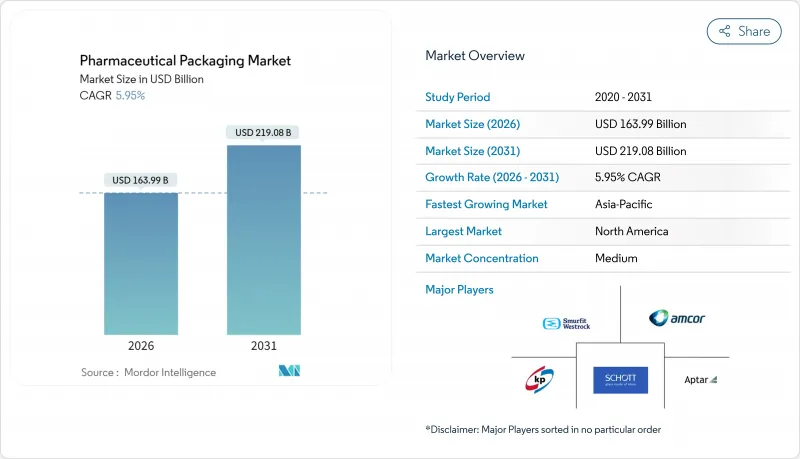

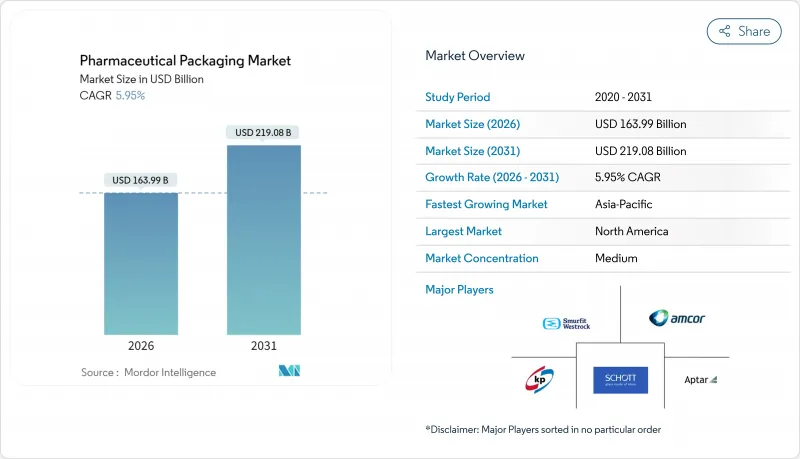

預計藥品包裝市場將從 2025 年的 1,547.8 億美元成長到 2026 年的 1,639.9 億美元,到 2031 年將達到 2,190.8 億美元,2026 年至 2031 年的複合年成長率為 5.95%。

未來五年,生物製藥需求的成長、全球可追溯性法規的加強以及永續性推進,預計將繼續推動對新型灌裝和包裝生產線、阻隔性材料以及循環設計領域的資本投資。隨著基因和細胞療法達到商業規模,對能夠容納小規模個人化治療藥物的軟性包裝產能的需求預計將會成長。由於《藥品分銷和安全法案》(DSCSA) 推動了藥品序列化,北美仍將保持其最大的區域貢獻;而亞太地區將呈現8.96%的高複合年成長率,這反映出該地區國內藥品產量的增加和醫療保健覆蓋範圍的擴大。材料策略正在改變:儘管塑膠仍佔據主導地位,但在歐盟和美國即將訂定的PFAS法規的背景下,生物基聚合物、無鋁泡殼和消費後回收薄膜正迅速從試點階段過渡到大規模生產。同時,聚乙烯、聚丙烯和PET價格的波動正在收緊利潤空間,促使大型加工商簽訂長期供應合約並進行垂直整合。

全球醫藥包裝市場趨勢及展望

人口老化和慢性病流行

隨著平均年齡的成長,長期照護需求也隨之增加,這支撐了對日曆式泡殼包裝、大寫字母標籤和單手開啟管瓶等產品的穩定需求,這些產品有助於提高行動不便患者的用藥依從性。德國2024年疫苗接種計畫的調整(肺炎鏈球菌疫苗接種量增加23%,B群腦膜炎雙球菌疫苗接種量增加52%)顯示老年人對預防性照護的接受度較高。包裝供應商正在積極回應,推出包含開啟記錄並將依從性資料傳輸給醫療團隊的智慧包裝。隨著支付方將報銷與實際治療效果掛鉤,智慧封口和支援NFC功能的紙盒預計將加速成長。

不斷擴大的生物製藥和注射產品線

預填充式注射器是新型生物製劑的核心,因為它們簡化了患者自行給藥流程,最大限度地降低了污染風險,並減少了填充和表面處理工程中的廢棄物。 BD 的 iDFill 注射器整合了 RFID 技術,可即時檢驗;Neopak XtraFlow 設計則可容納以前只能使用管瓶的高黏度製劑。修訂後的 GMP 附錄 1 正在加速市場對即用型玻璃管和聚合物容器的需求,這些產品無需清洗和冷卻過程,使 CDMO 能夠在不新建無塵室的情況下擴大產能。

石油衍生樹脂的價格波動

供應中斷和不可抗力事件導致PET價格在2024年6月上漲1.1%,進一步擠壓了加工業者本已微薄的利潤空間。醫藥契約製造材料規格限制了快速更換等級,迫使許多加工商要么自行承擔成本飆升,要么重新談判長期合約。瓦楞紙箱生產商也面臨纖維成本上漲的困境,預計2025年1月起每噸將上漲70美元。

細分市場分析

2025年,塑膠在醫藥包裝市場仍佔45.05%的佔有率,主要得益於高密度聚乙烯(HDPE)瓶、聚丙烯(PP)瓶蓋和聚對苯二甲酸乙二醇酯(PET)泡殼,這些產品在成本和阻隔性實現了良好的平衡。然而,隨著品牌所有者追求循環經濟目標,該領域的成長速度正在放緩。在塑膠產業內部,由於具有優異抗破損性能的環烯烴基材料的出現,用於PP注射器的醫藥包裝市場正在穩步擴張。玻璃仍然是光敏性和濕敏性生物製藥包裝的必備材料。儘管重量較大且易碎,但優質硼矽酸管瓶在細胞毒性填充劑市場中佔據主導地位。金屬在氣霧劑和植入式醫療設備則扮演獨特的角色。

人們對生物基樹脂、再生PET阻隔性膜和紙質藥瓶(例如,阿勒格尼健康網路的TallyTube試點計畫)的興趣日益濃厚。儘管開發商在產品上市前會仔細考慮保存期限保證、萃取物成分和生產線轉換成本,但早期採用者往往能夠從將永續性評估納入供應商審核的醫院中贏得採購競標。

區域分析

到2025年,北美將佔據全球藥品包裝市場35.01%的佔有率,這主要得益於生物製藥領域的巨額投資以及《藥品供應鏈安全法案》(DSCSA)先進的序列化要求。預計到2025年,光是美國製造商就將投資1,600億美元用於新建灌裝和原料藥生產工廠,這將推動可滅菌聚合物、即用型玻璃容器和高容量低溫運輸運輸容器的需求。該地區還在試點應用人工智慧視覺系統,以生產線速度掃描小於100微米的顆粒,有助於降低召回風險並增強品牌可靠性。

歐洲正努力在雄心勃勃的永續性法規與能源成本壓力之間尋求平衡。隨著即將實施的《包裝和包裝廢棄物法規》(該法規要求在2030年回收所有形式的包裝),人們對單一材料泡殼包裝和紙質藥瓶的興趣日益濃厚。儘管德國2024年的藥品產量下降了1.5%,但開發平臺仍豐富,其中包括需要超低溫包裝的mRNA和基因療法。將於2026年生效的PFAS法規將要求對材料進行重新認證,這將為無氟阻隔膜供應商帶來先發優勢。

亞太地區將達到最高成長率,到2031年複合年成長率將達到8.73%。這一成長主要得益於中國和印度合約研發生產機構(CDMO)的擴張以及公共醫療保險覆蓋範圍的擴大。當地監管機構正努力使無菌標準與人用藥品註冊技術要求國際協調會議(ICH)和人用藥品註冊技術要求國際協調理事會(PIC/S)的標準接軌,並推動包裝廠實施ISO 5級阻隔性能和全線序列化。然而,該地區也面臨地緣政治的挑戰。中國修訂後的反間諜法使追蹤系統技術的轉移變得更加複雜,跨國公司正在將其採購來源多元化,轉向東協市場。以精密模塑技術著稱的日本加工商正在贏得COP注射器的出口訂單,因為全球品牌正在減少對單一國家的依賴。

其他福利:

- Excel格式的市場預測(ME)表

- 3個月的分析師支持

目錄

第1章 引言

- 研究假設和市場定義

- 調查範圍

第2章調查方法

第3章執行摘要

第4章 市場情勢

- 市場概覽

- 市場促進因素

- 人口老化和慢性病流行

- 不斷拓展的生物製藥和注射產品線

- 永續性材料替代

- 強制性數位可追溯性(例如,DSCSA、歐盟FMD)

- 人工智慧驅動的自適應填充和收尾線

- 增加居家/分散式檢測,需郵寄包裹

- 市場限制

- 石油衍生樹脂的價格波動

- 資本密集的無菌和驗證要求

- 歐盟和美國對 PFAS/氟聚合物的監管問題

- 產業供應鏈分析

- 監管環境

- 技術展望

- 波特五力分析

- 供應商的議價能力

- 買方的議價能力

- 新進入者的威脅

- 替代品的威脅

- 競爭程度

第5章 市場規模與成長預測

- 材料

- 塑膠

- HDPE

- 低密度聚乙烯和線性低密度聚乙烯

- PET

- 其他塑膠製品

- 玻璃

- I型硼硼矽酸玻璃

- II 型處理鈉石灰

- III型鈉石灰

- 金屬

- 紙和紙板

- 生物聚合物和其他材料

- 塑膠

- 按包裝級別

- 初級包裝

- 瓶子

- 預填充式注射器

- 管瓶和安瓿

- 泡殼包裝

- 二級包裝

- 紙箱和紙套

- 標籤和插頁

- 三級包裝

- 紙板運輸容器

- 托盤和防護系統

- 初級包裝

- 依產品類型

- 瓶子

- 預填充式注射器

- 管瓶和安瓿

- 泡殼包裝

- 瓶蓋和封口

- 管狀和袋狀

- 其他產品類型

- 按地區

- 北美洲

- 美國

- 加拿大

- 墨西哥

- 歐洲

- 德國

- 英國

- 法國

- 義大利

- 西班牙

- 俄羅斯

- 其他歐洲地區

- 亞太地區

- 中國

- 印度

- 日本

- 韓國

- 亞太其他地區

- 中東和非洲

- 中東

- 阿拉伯聯合大公國

- 沙烏地阿拉伯

- 土耳其

- 其他中東地區

- 非洲

- 南非

- 奈及利亞

- 埃及

- 其他非洲地區

- 中東

- 南美洲

- 巴西

- 阿根廷

- 南美洲其他地區

- 北美洲

第6章 競爭情勢

- 市場集中度

- 策略趨勢

- 市佔率分析

- 公司簡介

- Amcor plc

- Gerresheimer AG

- Schott AG

- West Pharmaceutical Services Inc.

- AptarGroup Inc.

- Smurfit WestRock

- Becton, Dickinson & Company

- Catalent Inc.

- CCL Industries Inc.

- Klockner Pentaplast Group

- Nipro Corporation

- Vetter Pharma International GmbH

- McKesson Corporation

- FlexiTuff International Ltd.

- WL Gore & Associates Inc.

- Stevanato Group

- Corning Incorporated

- Owen-Illinois Inc.

- SGD Pharma

第7章 市場機會與未來展望

The pharmaceutical packaging market is expected to grow from USD 154.78 billion in 2025 to USD 163.99 billion in 2026 and is forecast to reach USD 219.08 billion by 2031 at 5.95% CAGR over 2026-2031.

Over the next five years, the increasing demand for biologics, stricter global traceability regulations, and widespread sustainability targets will continue to drive capital investment in new fill-finish lines, high-barrier materials, and circular-ready designs. Demand for flexible pack volumes that match smaller, personalized therapy batches is expected to expand as gene and cell therapies reach commercial scale. North America remains the largest regional contributor, supported by DSCSA-driven serialization, while the Asia-Pacific's sizable 8.96% CAGR reflects rising domestic drug production and broadening health coverage.Material strategies are in flux: plastics still dominate, yet bio-based polymers, aluminum-free blisters, and post-consumer-recycled films are quickly transitioning from pilot to production as EU and US PFAS curbs near enforcement. Meanwhile, price swings in polyethylene, polypropylene, and PET keep margins tight, encouraging longer supplier contracts and vertical integration by larger converters.

Global Pharmaceutical Packaging Market Trends and Insights

Aging population and chronic disease prevalence

Rising median ages drive up long-term therapy volumes, underpinning consistent demand for calendar blisters, large-print labels, and one-hand-open vials that aid adherence among patients with reduced dexterity. Germany's 2024 vaccination shifts, with pneumococcal doses up 23% and meningococcal B up 52%, illustrate broader preventive care uptake among seniors. Packaging suppliers respond with connected packs that log opening events and forward adherence data to care teams. Growth in smart closures and NFC-enabled cartons is expected to intensify as payers link reimbursement to real-world outcomes.

Biologics and injectable pipeline expansion

Prefilled syringes sit at the core of new biologic launches because they simplify self-administration, minimize contamination risks, and reduce waste during the fill-finish process. BD's iDFill syringe embeds RFID for instant verification, while its Neopak XtraFlow design handles viscous formulations that were once vial-only. GMP Annex 1 revisions are accelerating demand for ready-to-use glass tubing and polymer containers that bypass washing and depyrogenation steps, helping CDMOs scale capacity without the need to construct new cleanrooms.

Petro-derivative resin price volatility

Supply disruptions and force majeure events led to a 1.1% increase in PET prices in June 2024, further tightening already narrow converter margins. Pharmaceutical contract material specs restrict rapid grade switches, forcing many converters to absorb cost spikes or renegotiate long contracts. Corrugated shippers also face higher fibre costs, with a USD 70 per-ton increase announced for January 2025.

Other drivers and restraints analyzed in the detailed report include:

- Sustainability-driven material substitution

- Digital traceability mandates (DSCSA, EU-FMD)

- Capital-intensive sterility and validation requirements

For complete list of drivers and restraints, kindly check the Table Of Contents.

Segment Analysis

Plastics retained 45.05% of the pharmaceutical packaging market share in 2025, primarily driven by HDPE bottles, PP closures, and PET blisters that strike a balance between cost and barrier needs. Yet the segment's growth moderates as brand owners court circularity objectives. Within the plastics industry, the pharmaceutical packaging market size for PP-based syringes is rising steadily, thanks to break-resistant cyclic olefin options. Glass remains indispensable for light- and moisture-sensitive biologics; Type I borosilicate vials dominate cytotoxic fills, despite their higher weight and shatter risk. Metals play a niche role in aerosol and implantable devices.

Momentum is gathering around bio-attributed resins, recycled PET mid-barrier webs, and paper-based pill bottles, such as Allegheny Health Network's Tully Tube pilot. Developers weigh shelf-life assurance, extractables profiles, and line changeover costs before a wide release, yet early adopters often win procurement tenders from hospitals, incorporating sustainability scoring into vendor audits.

The Pharmaceutical Packaging Market Report is Segmented by Material (Plastics, Glass, Metal, and More), Packaging Level (Primary Packaging, Secondary Packaging, and More), Product Type (Bottles, Prefilled Syringes, Vials and Ampoules, Blister Packs, Caps and Closures, and More), and Geography (North America, South America, Europe, Asia Pacific, and Middle East and Africa). The Market Forecasts are Provided in Terms of Value (USD).

Geography Analysis

North America accounted for 35.01% of the pharmaceutical packaging market share in 2025, driven by significant investments in biologics and advanced DSCSA serialization mandates. U.S. manufacturers alone are investing USD 160 billion in new fill-finish and API plants through 2025, a trend that drives demand for sterilizable polymers, ready-to-use glass, and high-capacity cold-chain shippers. The region also pilots AI vision systems that scan for sub-100 µm particulates at line speed, lowering recall risk and strengthening brand trust.

Europe balances ambitious sustainability regulations with energy cost pressures. The forthcoming Packaging and Packaging Waste Regulation requires every format to be recyclable by 2030, escalating interest in monomaterial blisters and paper-based pill bottles. Germany's pharmaceutical output slipped 1.5% in 2024, yet its R&D pipelines remain rich in mRNA and gene therapies that require ultra-low-temperature packaging. PFAS restrictions, effective in 2026, force material requalification, offering an early-mover advantage to suppliers with fluorine-free barrier films.

The Asia-Pacific region grows at the fastest rate of 8.73% CAGR through 2031, driven by the expanding CDMO footprints of China and India, as well as the widening of public health coverage. Local regulators align sterility rules with ICH and PIC/S guides, pushing packaging plants to adopt ISO 5 barriers and full-line serialization. Yet the region faces geopolitical headwinds; China's updated Anti-Espionage Law complicates technology transfer for track-and-trace systems, prompting multinationals to diversify sourcing across ASEAN markets. Japanese converters, renowned for their precision molding, secure export orders for COP syringes as global brands hedge against dependence on a single country.

- Amcor plc

- Gerresheimer AG

- Schott AG

- West Pharmaceutical Services Inc.

- AptarGroup Inc.

- Smurfit WestRock

- Becton, Dickinson & Company

- Catalent Inc.

- CCL Industries Inc.

- Klockner Pentaplast Group

- Nipro Corporation

- Vetter Pharma International GmbH

- McKesson Corporation

- FlexiTuff International Ltd.

- W. L. Gore & Associates Inc.

- Stevanato Group

- Corning Incorporated

- Owen-Illinois Inc.

- SGD Pharma

Additional Benefits:

- The market estimate (ME) sheet in Excel format

- 3 months of analyst support

TABLE OF CONTENTS

1 INTRODUCTION

- 1.1 Study Assumptions and Market Definition

- 1.2 Scope of the Study

2 RESEARCH METHODOLOGY

3 EXECUTIVE SUMMARY

4 MARKET LANDSCAPE

- 4.1 Market Overview

- 4.2 Market Drivers

- 4.2.1 Ageing population and chronic disease prevalence

- 4.2.2 Biologics and injectable pipeline expansion

- 4.2.3 Sustainability-driven material substitution

- 4.2.4 Digital traceability mandates (e.g., DSCSA, EU-FMD)

- 4.2.5 AI-enabled adaptive fill-finish lines

- 4.2.6 Rise of at-home/decentralised trials needing mail-ready packs

- 4.3 Market Restraints

- 4.3.1 Petro-derivative resin price volatility

- 4.3.2 Capital-intensive sterility and validation requirements

- 4.3.3 Looming PFAS/fluoropolymer restrictions in EU and US

- 4.4 Industry Supply Chain Analysis

- 4.5 Regulatory Landscape

- 4.6 Technological Outlook

- 4.7 Porter's Five Forces Analysis

- 4.7.1 Bargaining Power of Suppliers

- 4.7.2 Bargaining Power of Buyers

- 4.7.3 Threat of New Entrants

- 4.7.4 Threat of Substitutes

- 4.7.5 Degree of Competition

5 MARKET SIZE AND GROWTH FORECASTS (VALUE)

- 5.1 By Material

- 5.1.1 Plastics

- 5.1.1.1 HDPE

- 5.1.1.2 LDPE and LLDPE

- 5.1.1.3 PET

- 5.1.1.4 Other Plastics

- 5.1.2 Glass

- 5.1.2.1 Type I Borosilicate

- 5.1.2.2 Type II Treated Soda-lime

- 5.1.2.3 Type III Soda-lime

- 5.1.3 Metal

- 5.1.4 Paper and Paperboard

- 5.1.5 Biopolymers and Other Materials

- 5.1.1 Plastics

- 5.2 By Packaging Level

- 5.2.1 Primary Packaging

- 5.2.1.1 Bottles

- 5.2.1.2 Prefilled Syringes

- 5.2.1.3 Vials and Ampoules

- 5.2.1.4 Blister Packs

- 5.2.2 Secondary Packaging

- 5.2.2.1 Cartons and Sleeves

- 5.2.2.2 Labels and Inserts

- 5.2.3 Tertiary Packaging

- 5.2.3.1 Corrugated Shippers

- 5.2.3.2 Pallets and Protective Systems

- 5.2.1 Primary Packaging

- 5.3 By Product Type

- 5.3.1 Bottles

- 5.3.2 Prefilled Syringes

- 5.3.3 Vials and Ampoules

- 5.3.4 Blister Packs

- 5.3.5 Caps and Closures

- 5.3.6 Tubes and Pouches

- 5.3.7 Other Product Types

- 5.4 By Geography

- 5.4.1 North America

- 5.4.1.1 United States

- 5.4.1.2 Canada

- 5.4.1.3 Mexico

- 5.4.2 Europe

- 5.4.2.1 Germany

- 5.4.2.2 United Kingdom

- 5.4.2.3 France

- 5.4.2.4 Italy

- 5.4.2.5 Spain

- 5.4.2.6 Russia

- 5.4.2.7 Rest of Europe

- 5.4.3 Asia-Pacific

- 5.4.3.1 China

- 5.4.3.2 India

- 5.4.3.3 Japan

- 5.4.3.4 South Korea

- 5.4.3.5 Rest of Asia-Pacific

- 5.4.4 Middle East and Africa

- 5.4.4.1 Middle East

- 5.4.4.1.1 United Arab Emirates

- 5.4.4.1.2 Saudi Arabia

- 5.4.4.1.3 Turkey

- 5.4.4.1.4 Rest of Middle East

- 5.4.4.2 Africa

- 5.4.4.2.1 South Africa

- 5.4.4.2.2 Nigeria

- 5.4.4.2.3 Egypt

- 5.4.4.2.4 Rest of Africa

- 5.4.4.1 Middle East

- 5.4.5 South America

- 5.4.5.1 Brazil

- 5.4.5.2 Argentina

- 5.4.5.3 Rest of South America

- 5.4.1 North America

6 COMPETITIVE LANDSCAPE

- 6.1 Market Concentration

- 6.2 Strategic Moves

- 6.3 Market Share Analysis

- 6.4 Company Profiles (includes Global level Overview, Market level overview, Core Segments, Financials as available, Strategic Information, Market Rank/Share for key companies, Products and Services, and Recent Developments)

- 6.4.1 Amcor plc

- 6.4.2 Gerresheimer AG

- 6.4.3 Schott AG

- 6.4.4 West Pharmaceutical Services Inc.

- 6.4.5 AptarGroup Inc.

- 6.4.6 Smurfit WestRock

- 6.4.7 Becton, Dickinson & Company

- 6.4.8 Catalent Inc.

- 6.4.9 CCL Industries Inc.

- 6.4.10 Klockner Pentaplast Group

- 6.4.11 Nipro Corporation

- 6.4.12 Vetter Pharma International GmbH

- 6.4.13 McKesson Corporation

- 6.4.14 FlexiTuff International Ltd.

- 6.4.15 W. L. Gore & Associates Inc.

- 6.4.16 Stevanato Group

- 6.4.17 Corning Incorporated

- 6.4.18 Owen-Illinois Inc.

- 6.4.19 SGD Pharma

7 MARKET OPPORTUNITIES AND FUTURE OUTLOOK

- 7.1 White-space and Unmet-need Assessment