|

市場調查報告書

商品編碼

1852155

工廠自動化和工業控制:市場佔有率分析、行業趨勢、統計數據和成長預測(2025-2030 年)Factory Automation And Industrial Controls - Market Share Analysis, Industry Trends & Statistics, Growth Forecasts (2025 - 2030) |

||||||

※ 本網頁內容可能與最新版本有所差異。詳細情況請與我們聯繫。

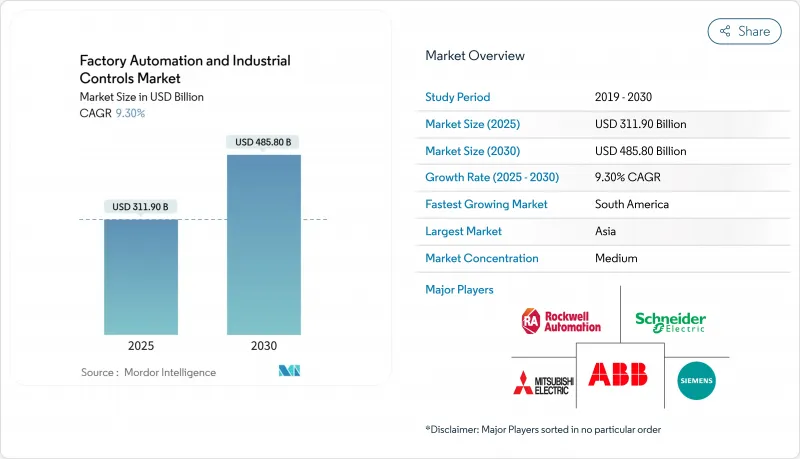

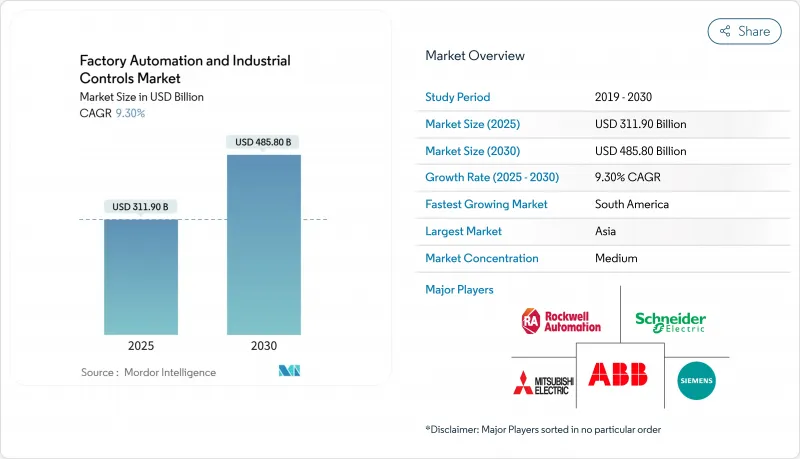

預計到 2025 年,工廠自動化和工業控制市場規模將達到 3,119 億美元,到 2030 年將擴大到 4,858 億美元。

隨著製造商面臨人才短缺、嚴格的能源效率法規以及縮短供應鏈的需求,其發展動能日益強勁。不斷上漲的人事費用促使企業部署智慧機器人和視覺檢測單元,而北美和歐盟的能源導向指令則鼓勵對高效驅動器和智慧電錶進行投資。數位孿生、邊緣分析和雲端連接控制器構成了下一代工廠的核心,為服務提供者創造了新的收入來源,這些服務提供者可以將基於狀態的維護疊加到現有硬體之上。同時,關稅主導的半導體採購改革正在加速區域製造基地的建設,進一步提升了工廠自動化和工業控制市場的發展軌跡。將操作技術專長與安全軟體生態系統結合的平台供應商持續獲得定價權,這得益於政府資金的支持,例如530億美元的《晶片和工業安全法案》(CHIPS Act),該法案為國內工廠的資本支出提供資金支持。

全球工廠自動化與工業控制市場趨勢及洞察

加速採用工業4.0

全球約80%的生產商計劃在2025年前實施工業4.0解決方案,但僅有10%實現了端到端的數位化。英國的「智慧製造」(Made Smarter)資助計畫和中國33個製造創新中心網路等國家級計畫提供資金和技術指導,推動工廠自動化和工業控制市場向高階分析和自主最佳化方向發展。新加坡的「智慧產業準備指數」(Smart Industry Readiness Index)同樣幫助中型企業衡量自身進展,確保自動化移動機器人和雲端調度工具能帶來可衡量的成本節約。人工智慧、物聯網感測器和巨量資料引擎的融合能夠提供即時洞察,從而減少廢料、平衡能源負荷並縮短維護週期。供應商透過在這些資料流周圍建立網路安全和遠端支援層來脫穎而出,將常規的控制器銷售轉化為多年的服務年金。

能源效率要求和成本壓力

各國政府已在能源效率專案上投資超過1兆美元,如今期望工業界為全球減碳目標做出重大貢獻。工廠正積極響應,部署變速驅動裝置、智慧壓縮機和人工智慧驅動的調度平台,將生產轉移到非尖峰時段的可再生能源。聯合國歐洲經濟委員會正在推廣工業能效的最佳實踐,並強調數位化控制與脫碳之間的連結。在工廠自動化和工業控制市場,供應商正將碳排放儀錶板預先整合到可程式邏輯控制器(PLC)中,使合規成為附加價值服務。隨著公用事業公司提高分時電價,智慧照明和熱回收系統等投資回收期短的計劃在企業的資本支出清單中佔據了重要地位。

自動化計劃初始投資較高

全面的自動化專案通常會超出傳統的預算週期,尤其對於中小企業而言更是如此。到2024年,該產業的併購倍數可能達到EBITDA的18倍,這將推高供應商的定價預期,並拉高損益平衡點。 10%的基本進口關稅,加上對中國製造的半導體徵收的50%關稅,推高了零件成本,並使資本項目的投資回報率計算變得更加複雜。儘管《晶片法案》(CHIPS Act)下的公共補貼可以幫助支付部分費用,但管理者仍需要應對培訓成本和整合風險,這些風險可能會在系統切換期間中斷生產。

細分市場分析

到2024年,工業控制系統將佔據工廠自動化和工業控制市場58%的佔有率,凸顯其作為連續製造和離散製造營運支柱的重要地位。分散式控制系統、SCADA系統和現代PLC正在整合人工智慧驅動的診斷功能,以預防停機事件的發生,並與企業資源計畫(ERP)系統同步,實現準時制生產。半導體製造和電池組裝行業對工業控制系統的需求日益成長,這些行業依賴微秒的循環執行來實現零缺陷的生產效率。同時,受智慧相機和協作機器人技術的進步推動,預計到2030年,現場設備所佔的工廠自動化和工業控制市場規模將以9.8%的複合年成長率成長,這些技術將自學習演算法整合到更靠近生產線的位置。

機器視覺平台正從簡單的存在檢測發展到複雜輪廓的3D測量,從而實現在線校正而非後續返工。曾經被隔離的工業機器人如今已與人類共用工作空間,並由安全操作韌體和接近感測器引導。這些功能降低了整合門檻,並為產品週期短的產業開闢了新的機會。感測器製造商正致力於開發更高解析度、更低功耗的設計,將振動、聲學和熱訊號即時反饋給控制層,從而增強預測性維護模型,延長設備壽命並減少計劃外停機。

到2024年,硬體將佔工廠自動化和工業控制市場規模的62.5%,因為企業需要對老舊的控制器和伺服驅動器進行現代化改造,以適應更快的生產週期和更嚴格的精度要求。同時,服務收入正以每年11.2%的速度成長,這反映出經營團隊傾向於採用基於結果的契約,以降低技術部署的風險。多年期合約通常將安裝、整合和分析支援打包到一個基於獎勵的定價框架中,使供應商的激勵機制與工廠的績效掛鉤。

預測性維護訂閱服務匯總振動和溫度趨勢,並將車隊與匿名化的同類資料集進行基準測試,以便在災難性故障發生之前識別異常情況。系統整合商正在透過協定轉換器和邊緣閘道器實現獲利,這些轉換器和閘道器將傳統的 Modbus 設備連接到運行在安全 OPC UA 鏈路上的雲端儀表板。隨著智慧感測器安裝數量的成長,培訓和變更管理活動也同步增加,這標誌著工廠自動化和工業控制市場從一次性通訊協定交易轉向年金式服務模式的轉變。

工廠和工業自動化市場按產品(工業控制系統、現場設備)、組件(硬體、其他)、控制系統結構(專有/廠商特定、其他)、最終用戶產業(汽車、化學和石化、公共產業、其他)以及地區進行細分。市場預測以美元計價。

區域分析

到2024年,亞洲將佔據全球39.4%的收入佔有率,這主要得益於其密集的製造業生態系統、技術純熟勞工儲備以及積極的數位化政策框架。中國的「2025願景」正在資助一條結合人工智慧調度和5G運動控制的示範生產線;與此同時,日本的大型企業集團正在部署自主物料搬運和精密焊接機器人,以緩解長期存在的勞動力短缺問題。韓國的晶片製造基地和印度智慧電錶的推廣應用將進一步推動硬體需求,鞏固亞洲在工廠自動化和工業控制市場的核心地位。

隨著供應鏈主權問題日益受到聯邦政府重視,北美製造商正加快投資步伐。 《晶片與整合產品法案》(CHIPS Act)撥款530億美元,將刺激本地感測器和控制器生產,進而帶動對安全邊緣運算設備的需求。將於2025年4月實施的普遍關稅將加強近岸外包,並促進先前依賴海外零件採購的中小型工廠自動化。

歐洲高度重視永續性和網路韌性。根據“復甦與韌性基金”,歐洲政府撥款1500億歐元(約1630億美元)用於數位轉型,旨在實現工業基礎現代化。然而,由於實施過程中存在差距,許多公司不得不求助於私人整合商以滿足報告期限的要求。能源法規和供應鏈可追溯性的合規壓力對食品、化學和消費品工廠的影響尤其顯著。

儘管南美洲的物聯網裝置容量較小,但預計到2030年將以10.1%的複合年成長率成長。巴西的「巴西新產業」計畫已撥款3,000億雷亞爾(約610億美元)用於研發獎勵、設備補貼和稅收減免,使自動化升級在經濟上更具吸引力。阿根廷的「數位化工廠藍圖」鼓勵在農業機械和食品加工領域開展物聯網試點項目,儘管該地區面臨技能短缺的問題。隨著跨境技術轉移的擴展,區域系統整合商正與全球原始設備製造商合作,提供適合該地區小批量生產和電源品質不穩定的承包生產線。

隨著政策制定者尋求擺脫資源密集型產業,中東和非洲也加入了工廠自動化和工業控制市場。待開發區工業園區將從一開始就採用預測性維護平台,從而能夠跨越傳統架構,專注於數據主導營運,並專注於滿足出口市場合規要求。

其他福利:

- Excel格式的市場預測(ME)表

- 3個月的分析師支持

目錄

第1章 引言

- 研究假設和市場定義

- 調查範圍

第2章調查方法

第3章執行摘要

第4章 市場情勢

- 市場概覽

- 市場促進因素

- 加速採用工業4.0

- 能源效率要求和成本壓力

- 製造業勞動力短缺問題日益嚴重

- 政府對數位化工廠的獎勵策略

- 低程式碼/無程式碼自動化平台

- 利用人工智慧升級預測性品管

- 市場限制

- 對自動化計劃的前期投資

- OT網路中的網路安全漏洞

- 互通性標準碎片化

- 控制器半導體供應的波動

- 價值/供應鏈分析

- 監管環境

- 技術展望

- 波特的五力模型

- 供應商的議價能力

- 買方的議價能力

- 新進入者的威脅

- 替代品的威脅

- 競爭對手之間的競爭

第5章 市場規模與成長預測

- 依產品

- 工業控制系統

- 分散式控制系統(DCS)

- 可程式邏輯控制器(PLC)

- 監控與數據採集(SCADA)

- 產品生命週期管理(PLM)

- 人機介面(HMI)

- 製造執行系統(MES)

- 企業資源規劃(ERP)

- 其他工業控制系統

- 現場設備

- 機器視覺系統

- 工業機器人

- 感測器和發射器

- 馬達和驅動器

- 其他現場設備

- 工業控制系統

- 按組件

- 硬體

- 軟體

- 服務

- 按最終用戶行業分類

- 車

- 化工/石油化工

- 公用事業

- 製藥

- 食品和飲料

- 石油和天然氣

- 電子和半導體

- 航太與國防

- 其他行業

- 按控制系統結構

- 專有/廠商特定

- 開放/互通

- 混合架構

- 按地區

- 北美洲

- 美國

- 加拿大

- 墨西哥

- 南美洲

- 巴西

- 阿根廷

- 其他南美洲

- 歐洲

- 英國

- 德國

- 法國

- 義大利

- 俄羅斯

- 其他歐洲地區

- 亞太地區

- 中國

- 印度

- 日本

- 韓國

- 澳洲、紐西蘭

- 亞太其他地區

- 中東

- 阿拉伯聯合大公國

- 沙烏地阿拉伯

- 土耳其

- 其他中東地區

- 非洲

- 南非

- 奈及利亞

- 埃及

- 其他非洲地區

- 北美洲

第6章 競爭情勢

- 市場集中度

- 策略趨勢

- 市佔率分析

- 公司簡介

- ABB Ltd

- Siemens AG

- Rockwell Automation Inc.

- Schneider Electric SE

- Mitsubishi Electric Corp.

- Honeywell International Inc.

- Emerson Electric Co.

- Omron Corp.

- Yokogawa Electric Corp.

- GE Vernova

- Texas Instruments Inc.

- Bosch Rexroth AG

- Fanuc Corp.

- Keyence Corp.

- Advantech Co. Ltd.

- Beckhoff Automation GmbH

- Delta Electronics Inc.

- Lenze SE

- WAGO Kontakttechnik GmbH

- Hollysys Automation Technologies

第7章 市場機會與未來展望

The factory automation and industrial controls market size reached USD 311.90 billion in 2025 and is forecast to advance to USD 485.80 billion by 2030, translating into a 9.30% CAGR.

Momentum builds as manufacturers confront talent shortages, stringent energy-efficiency rules, and the imperative to shorten supply chains. Rising labor costs encourage companies to install intelligent robotics and vision-enabled inspection cells, while energy-oriented directives in North America and the EU reward investments in high-efficiency drives and smart metering. Digital twins, edge analytics, and cloud-connected controllers form the core of next-generation factories, creating new revenue pools for service providers that overlay condition-based maintenance atop existing hardware stacks. Meanwhile, tariff-driven redesigns of semiconductor sourcing are accelerating regional production footprints, further lifting the factory automation and industrial controls market trajectory. Platform vendors that blend operational-technology expertise with secure software ecosystems continue to gain pricing power, supported by government funding such as the USD 53 billion CHIPS Act that underwrites capital outlays for domestic fabs.

Global Factory Automation And Industrial Controls Market Trends and Insights

Industry 4.0 Adoption Acceleration

Roughly 80% of global producers intend to embed Industry 4.0 solutions by 2025, yet only 10% have achieved end-to-end digitization. National programs-such as the UK's Made Smarter grants and China's network of 33 Manufacturing Innovation Centers-offer capital and technical guidance, pushing the factory automation and industrial controls market toward advanced analytics and autonomous optimisation. Singapore's Smart Industry Readiness Index likewise helps mid-sized firms benchmark progress, ensuring that automated mobile robots and cloud scheduling tools deliver measurable cost relief. Convergence of AI, IoT sensors, and big-data engines yields real-time insights that cut scrap, tune energy loads, and shorten maintenance interventions. Vendors differentiate by wrapping cybersecurity and remote-support layers around these data flows, turning routine controller sales into multi-year service annuities.

Energy-Efficiency Mandates & Cost Pressure

Governments invested more than USD 1 trillion in efficiency programs and now expect industry to shoulder a sizeable share of the global CO2-reduction target. Factories respond by installing variable-speed drives, smart compressors, and AI-enabled scheduling platforms that shift production to off-peak renewable availability. The United Nations Economic Commission for Europe promotes industrial energy-efficiency best practices, underscoring the link between digital controls and decarbonisation. In the factory automation and industrial controls market, vendors now pre-package carbon dashboards with programmable logic controllers, turning compliance into a value-added service. As utilities raise time-of-use tariffs, fast-payback projects such as intelligent lighting and heat-recovery systems climb the corporate capital list.

High Upfront CAPEX of Automation Projects

Comprehensive automation programs often exceed traditional budgeting cycles, especially for small and mid-sized enterprises. Sector M&A multiples reached 18 times EBITDA in 2024, raising vendor pricing expectations and extending break-even horizons. Universal baseline import tariffs of 10%, plus a 50% duty on Chinese semiconductors, elevate component costs and complicate ROI math for capital programmes. While public grants under the CHIPS Act defray some expenses, managers still contend with training outlays and integration risks that may disrupt production during cut-overs.

Other drivers and restraints analyzed in the detailed report include:

- Rising Labor Shortages in Manufacturing

- Low-Code / No-Code Automation Platforms

- Cyber-Security Vulnerabilities in OT Networks

For complete list of drivers and restraints, kindly check the Table Of Contents.

Segment Analysis

Industrial control systems secured 58% of the factory automation and industrial controls market in 2024, underscoring their role as the operational backbone for continuous and discrete manufacturing. Distributed control systems, SCADA, and modern PLCs integrate AI-powered diagnostics that pre-empt downtime events and synchronise with enterprise resource planning for just-in-time sequencing. Demand intensifies in semiconductor fabrication and battery cell assembly, areas that rely on microsecond-level loop execution to achieve defect-free throughput. At the same time, the factory automation and industrial controls market size attributed to field devices is on track to expand at 9.8% CAGR to 2030, propelled by advances in smart cameras and collaborative robotics that embed self-learning algorithms close to the production line.

Machine-vision platforms move beyond simple presence checks toward 3D measurement of complex contours, enabling in-line correction rather than post-process rework. Industrial robots, once fenced, now share workspace with humans, guided by safe-motion firmware and proximity sensors. These capabilities lower integration barriers and open fresh opportunities in industries with shorter product cycles. Sensor manufacturers push higher-resolution, lower-power designs that feed real-time vibration, acoustic, and thermal signatures back to the control layer, reinforcing predictive-maintenance models that stretch asset life and limit unplanned outages.

Hardware generated 62.5% of the factory automation and industrial controls market size in 2024 as companies refreshed aging controllers and servo drives to handle faster cycle times and tighter tolerances. Nevertheless, service revenues are climbing 11.2% per year, reflecting management's preference for outcome-based contracts that de-risk technology adoption. Multi-year agreements often bundle installation, integration, and analytics support into usage-based pricing frameworks that align vendor incentives with plant performance.

Predictive-maintenance subscriptions aggregate vibration and temperature trends, benchmarking equipment fleets against anonymised peer datasets to spotlight outliers well before catastrophic failure. System-integration houses monetise protocol converters and edge gateways that join legacy Modbus devices to cloud dashboards running on secure OPC UA links. As the installed base of intelligent sensors swells, training and change-management engagements rise in parallel, completing the shift from one-time capital transactions to annuity-style service flows within the factory automation and industrial controls market.

The Factory and Industrial Automation Market Segmented Into Product (By Industrial Control Systems, Field Devices), Component (hardware and More), Control System Architecture (Proprietary / Vendor-Specific and More), End-User Industry (Automotive, Chemical and Petrochemical, Utility and More), and by Geography. The Market Forecasts are Provided in Terms of Value (USD).

Geography Analysis

Asia captured 39.4% of 2024 revenue thanks to dense manufacturing ecosystems, skilled labour pools, and assertive digital-policy frameworks. China's 2025-era initiatives finance demonstration lines that combine AI scheduling with 5G-enabled motion control, while Japanese conglomerates deploy autonomous haulage and precision welding robots to offset chronic labour gaps. South Korea's chip fabrication complexes and India's smart-meter roll-outs further extend hardware demand, reinforcing Asia's central role in the factory automation and industrial controls market.

North American manufacturers accelerate investments as supply-chain sovereignty climbs the federal agenda. The CHIPS Act's USD 53 billion allotment stimulates local sensor and controller production, creating knock-on demand for secure edge-computing appliances. Universal tariffs introduced in April 2025 reinforce near-shoring, encouraging automation in small and mid-tier plants that previously relied on offshore component sourcing.

Europe focuses on sustainability and cyber-resilience. While the EUR 150 billion allocation for digital transition under the Recovery and Resilience Facility (USD 163 billion) aims to modernise industrial bases, execution gaps prompt many firms to leverage private-sector integrators to meet reporting deadlines eca. Compliance pressures with energy codes and supply-chain traceability hold particular sway in food, chemicals, and consumer goods plants.

South America, though starting from a smaller installed base, is projected to expand at a 10.1% CAGR through 2030. Brazil's "New Industry Brazil" program earmarks R$ 300 billion (USD 61 billion) for R&D incentives, equipment credits, and tax benefits, making automation upgrades financially attractive. Argentina's digital-factory roadmap encourages IoT pilots in agricultural machinery and food processing despite skills shortages. As cross-border technology transfer grows, regional system integrators partner with global OEMs to deliver turnkey lines suited to smaller batch volumes and variable-quality power supplies common in the region.

The Middle East and Africa join the factory automation and industrial controls market as policy makers diversify away from resource-heavy sectors. Green-field industrial zones embed predictive-maintenance platforms from inception, allowing them to leapfrog legacy architectures and focus on data-driven operations keyed to export-market compliance.

- ABB Ltd

- Siemens AG

- Rockwell Automation Inc.

- Schneider Electric SE

- Mitsubishi Electric Corp.

- Honeywell International Inc.

- Emerson Electric Co.

- Omron Corp.

- Yokogawa Electric Corp.

- GE Vernova

- Texas Instruments Inc.

- Bosch Rexroth AG

- Fanuc Corp.

- Keyence Corp.

- Advantech Co. Ltd.

- Beckhoff Automation GmbH

- Delta Electronics Inc.

- Lenze SE

- WAGO Kontakttechnik GmbH

- Hollysys Automation Technologies

Additional Benefits:

- The market estimate (ME) sheet in Excel format

- 3 months of analyst support

TABLE OF CONTENTS

1 INTRODUCTION

- 1.1 Study Assumptions and Market Definition

- 1.2 Scope of the Study

2 RESEARCH METHODOLOGY

3 EXECUTIVE SUMMARY

4 MARKET LANDSCAPE

- 4.1 Market Overview

- 4.2 Market Drivers

- 4.2.1 Industry 4.0 adoption acceleration

- 4.2.2 Energy-efficiency mandates & cost pressure

- 4.2.3 Rising labor shortages in manufacturing

- 4.2.4 Government stimulus for digital factories

- 4.2.5 Low-code / no-code automation platforms

- 4.2.6 AI-driven predictive quality control upgrades

- 4.3 Market Restraints

- 4.3.1 High upfront CAPEX of automation projects

- 4.3.2 Cyber-security vulnerabilities in OT networks

- 4.3.3 Fragmented interoperability standards

- 4.3.4 Semiconductor supply volatility for controllers

- 4.4 Value / Supply-Chain Analysis

- 4.5 Regulatory Landscape

- 4.6 Technological Outlook

- 4.7 Porters Five Forces

- 4.7.1 Bargaining Power of Suppliers

- 4.7.2 Bargaining Power of Buyers

- 4.7.3 Threat of New Entrants

- 4.7.4 Threat of Substitutes

- 4.7.5 Intensity of Competitive Rivalry

5 MARKET SIZE & GROWTH FORECASTS (VALUE)

- 5.1 By Product

- 5.1.1 Industrial Control Systems

- 5.1.1.1 Distributed Control System (DCS)

- 5.1.1.2 Programmable Logic Controller (PLC)

- 5.1.1.3 Supervisory Control & Data Acquisition (SCADA)

- 5.1.1.4 Product Lifecycle Management (PLM)

- 5.1.1.5 Human-Machine Interface (HMI)

- 5.1.1.6 Manufacturing Execution System (MES)

- 5.1.1.7 Enterprise Resource Planning (ERP)

- 5.1.1.8 Other Industrial Control Systems

- 5.1.2 Field Devices

- 5.1.2.1 Machine Vision Systems

- 5.1.2.2 Industrial Robotics

- 5.1.2.3 Sensors and Transmitters

- 5.1.2.4 Motors and Drives

- 5.1.2.5 Other Field Devices

- 5.1.1 Industrial Control Systems

- 5.2 By Component

- 5.2.1 Hardware

- 5.2.2 Software

- 5.2.3 Services

- 5.3 By End-User Industry

- 5.3.1 Automotive

- 5.3.2 Chemical and Petrochemical

- 5.3.3 Utility

- 5.3.4 Pharmaceutical

- 5.3.5 Food and Beverage

- 5.3.6 Oil and Gas

- 5.3.7 Electronics and Semiconductor

- 5.3.8 Aerospace and Defense

- 5.3.9 Other Industries

- 5.4 By Control System Architecture

- 5.4.1 Proprietary / Vendor-Specific

- 5.4.2 Open / Interoperable

- 5.4.3 Hybrid Architecture

- 5.5 By Geography

- 5.5.1 North America

- 5.5.1.1 United States

- 5.5.1.2 Canada

- 5.5.1.3 Mexico

- 5.5.2 South America

- 5.5.2.1 Brazil

- 5.5.2.2 Argentina

- 5.5.2.3 Rest of South America

- 5.5.3 Europe

- 5.5.3.1 United Kingdom

- 5.5.3.2 Germany

- 5.5.3.3 France

- 5.5.3.4 Italy

- 5.5.3.5 Russia

- 5.5.3.6 Rest of Europe

- 5.5.4 APAC

- 5.5.4.1 China

- 5.5.4.2 India

- 5.5.4.3 Japan

- 5.5.4.4 South Korea

- 5.5.4.5 Australia and New Zealand

- 5.5.4.6 Rest of APAC

- 5.5.5 Middle East

- 5.5.5.1 UAE

- 5.5.5.2 Saudi Arabia

- 5.5.5.3 Turkey

- 5.5.5.4 Rest of Middle East

- 5.5.6 Africa

- 5.5.6.1 South Africa

- 5.5.6.2 Nigeria

- 5.5.6.3 Egypt

- 5.5.6.4 Rest of Africa

- 5.5.1 North America

6 COMPETITIVE LANDSCAPE

- 6.1 Market Concentration

- 6.2 Strategic Moves

- 6.3 Market Share Analysis

- 6.4 Company Profiles (includes Recent Developments)

- 6.4.1 ABB Ltd

- 6.4.2 Siemens AG

- 6.4.3 Rockwell Automation Inc.

- 6.4.4 Schneider Electric SE

- 6.4.5 Mitsubishi Electric Corp.

- 6.4.6 Honeywell International Inc.

- 6.4.7 Emerson Electric Co.

- 6.4.8 Omron Corp.

- 6.4.9 Yokogawa Electric Corp.

- 6.4.10 GE Vernova

- 6.4.11 Texas Instruments Inc.

- 6.4.12 Bosch Rexroth AG

- 6.4.13 Fanuc Corp.

- 6.4.14 Keyence Corp.

- 6.4.15 Advantech Co. Ltd.

- 6.4.16 Beckhoff Automation GmbH

- 6.4.17 Delta Electronics Inc.

- 6.4.18 Lenze SE

- 6.4.19 WAGO Kontakttechnik GmbH

- 6.4.20 Hollysys Automation Technologies

7 MARKET OPPORTUNITIES AND FUTURE OUTLOOK

- 7.1 White-space and Unmet-Need Assessment