|

市場調查報告書

商品編碼

1851411

包裝自動化:市場佔有率分析、行業趨勢、統計數據和成長預測(2025-2030 年)Packaging Automation - Market Share Analysis, Industry Trends & Statistics, Growth Forecasts (2025 - 2030) |

||||||

※ 本網頁內容可能與最新版本有所差異。詳細情況請與我們聯繫。

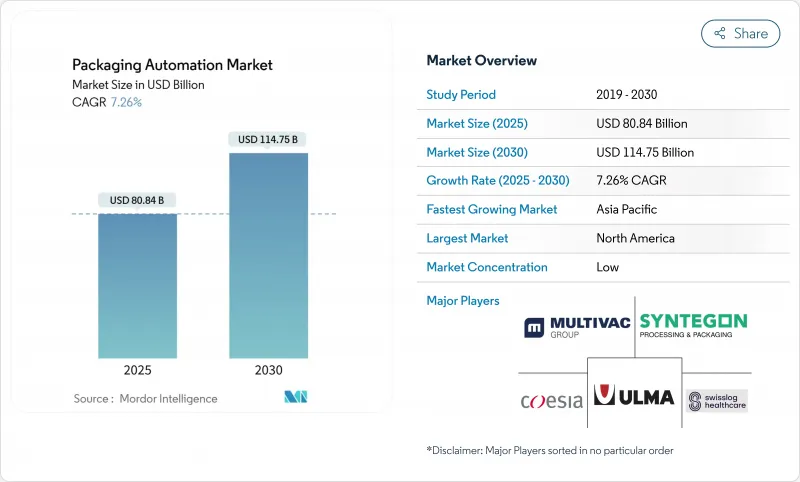

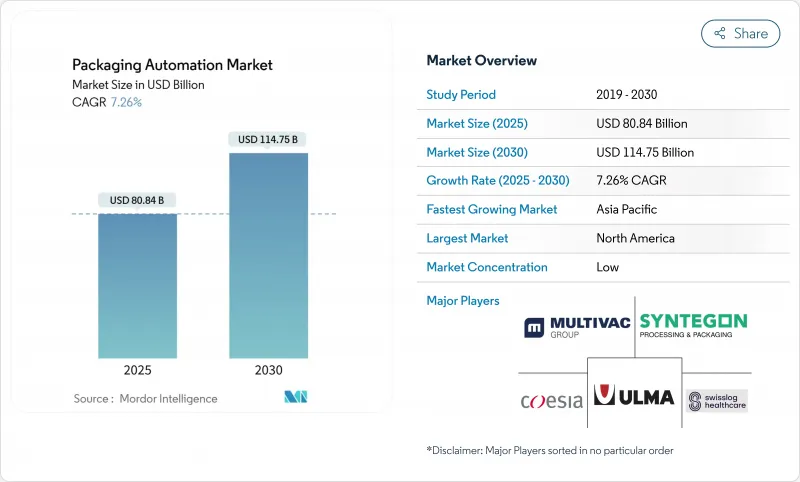

預計到 2025 年,包裝自動化市場規模將達到 808.4 億美元,到 2030 年將達到 1,147.5 億美元,複合年成長率為 7.26%。

對智慧製造系統的持續投資正在縮小勞動力缺口,提高生產線精度,並滿足監管要求。電子商務和嚴格的藥品序列化推動了產量成長,促使生產線在吞吐量和可追溯性之間取得平衡,從而推動了該行業的蓬勃發展。北美保持領先地位,但亞太地區正以最快的速度擴張,這主要得益於中國數十億美元的機器人技術投資。儘管銷售仍以硬體為主,但以服務為中心的績效付費模式正在加速發展,因為用戶更傾向於獲得運作保證而非所有權。瓦楞紙箱、折疊紙盒和物料輸送供應商之間的整合正在擴大客戶群體,並為自動化供應商創造新的規模。

全球包裝自動化市場趨勢與洞察

食品飲料、製藥和電子商務產業自動化應用日益普及

2024年,包裝器材出貨量將會成長,這主要得益於製藥生產線對彈性、小批量生產模式的需求,以及高產量食品生產的需求。製藥公司將在2025年投入1,600億美元用於工廠升級,以實現個人化藥品包裝。電商履約中心將採用可生產數千種不同規格包裝盒的最佳化包裝系統,在提高勞動生產力的同時,將紙板用量減少一半。隨著一個產業成熟解決方案的推廣應用以及包裝自動化市場滲透率的提高,跨產業技術轉移將加速。這些因素共同推動了對自適應機器人和整合視覺系統的需求,這些系統能夠在不同SKU類別之間快速切換,且停機時間極短。

電子商務需要高速二次包裝

一套尺寸合適的包裝箱系統與移動機器人結合,在短短幾個月內就將物流站點的生產力提高了97%,凸顯了二次包裝已成為提升效率的關鍵槓桿。可變尺寸自動化目前佔包裝自動化市場41.42%的佔有率,反映出快速處理混合訂單的需求。亞太地區的線上零售額正在蓬勃發展,預計到2024年,該地區的資本支出將達到180億美元。加之歐美地區的全通路模式,對生產線速度、軟體編配和符合人體工學的碼垛方式的持續需求,正在推動整個包裝自動化市場的不斷升級。

高昂的資本成本和網路安全風險

全規模包裝單元需要大量的前期投資,這對許多中小企業來說難以承受。同時,日益增強的互聯互通也使操作技術面臨網路威脅,而製造業佔工業事故總數的四分之一以上。企業必須同時投資自動化硬體和多層安全防護,這會加劇預算緊張並減緩技術普及。 「機器人即服務」(Robots-as-a-Service,簡稱ROaaS)模式透過將支出轉移到營運支出(OPEX)並在訂閱模式下提供託管網路安全服務來解決這兩個難題。這種方法可以減輕對資產負債表的影響,但要在整個包裝自動化市場推廣,仍需加強市場教育。

細分市場分析

至2024年,紙箱包裝將佔包裝自動化市場佔有率的32.12%,凸顯其在產品分銷過程中保護產品的重要角色。紙箱包裝領域的成長穩定,這得益於永續性發展概念推動了更薄的紙板和更精準的黏合劑應用。儘管碼垛業務的收入佔有率較小,但其複合年成長率仍高達12.31%。發那科(FANUC)的新型CRX-25iA協作機器人可處理30公斤的負載,並配備易於使用的示教器,同時還能縮小單元佔地面積。協作機器人能夠縮短試運行,改善工人的工作效率,使其成為自動化應用普及的領先指標。

在上游領域,隨著靈活的無菌包裝形式能夠滿足個人化治療的需求,製藥業的灌裝機投資正在增加。貼標生產線正在增加序列化模組,以滿足藥品和飲料的監管追溯要求。輕質薄膜技術的進步推動了包裝和封蓋製程的發展,而捆紮技術正在試驗中,旨在減少80%的塑膠用量。製袋生產線在耐磨材料領域也取得了進展,採用耐用的Hardox鋼材以延長使用壽命。這些產品之間的相互作用預示著市場正朝著端到端單元的方向發展,將多種任務整合到可靈活適應的包裝自動化解決方案中。

到2024年,食品製造商將佔據包裝自動化市場28.53%的佔有率,這主要得益於其龐大的SKU數量和嚴格的衛生標準。受注射療法興起的推動,醫藥包裝預計將從目前的小基準成長至11.98%的複合年成長率。 Syntegon的Pharmatag 2025生產線可在嚴格的無菌條件下填充液體,並能快速改變包裝規格以適應小批量生產。亞太地區的飲料生產線正在採用高速罐裝和套標技術,以滿足不斷成長的中階需求。

個人護理品牌正專注於採用自動化多行揀貨的高階自訂套裝。化學製造商則使用費斯托(Festo)經防爆認證的致動器進行密封灌裝,以減少產品暴露於腐蝕性介質的風險。隨著藥品序列化技術應用於消費品領域以打擊仿冒品產品,技術跨界融合的趨勢正在加速,從而拓寬了包裝自動化市場的應用範圍。

區域分析

2024年,北美將憑藉其先進的製造基礎設施和FDA序列化要求,佔據包裝自動化市場34.14%的佔有率。製藥公司將在2025年投入1,600億美元用於設施升級,持續推動對無塵室相容型機器人的需求。 ABB在密西根州投資2,000萬美元進行擴建,凸顯了該公司對區域客戶的承諾。電子商務履約中心的激增也將推動對適應性強的二級包裝的需求。

亞太地區是成長最快的地區,預計到2030年複合年成長率將達到10.64%。中國計劃在2024年投資66億美元用於工業機器人,這反映了其機器人密度翻倍的政策。 2025年上海國際包裝展(ProPak 2025)將吸引超過2,500家參展展示智慧包裝解決方案,凸顯該地區從人工生產線向數位化工廠的轉型。像易斯頓自動化這樣的本土供應商憑藉價格極具競爭力的機械臂正在不斷擴大市場佔有率,推動本地包裝自動化市場的發展。

在歐洲,永續性法規和工業4.0補貼正在推動包裝自動化技術的應用。瑞典一家工廠透過自動化捆紮減少了80%的塑膠包裝,實現了循環經濟目標。一家德國先進機械製造商增設了人工智慧模組,以保持出口競爭力。同時,中東和非洲正在試驗自動化乳製品生產線,以增強食品安全;而巴西一家南美工廠正在安裝堆垛機,以滿足該地區日益成長的飲料需求。這些多元化的措施正在拓展全球包裝自動化市場。

其他福利:

- Excel格式的市場預測(ME)表

- 3個月的分析師支持

目錄

第1章 引言

- 研究假設和市場定義

- 調查範圍

第2章調查方法

第3章執行摘要

第4章 市場情勢

- 市場概覽

- 市場促進因素

- 食品飲料、製藥和電子商務產業的自動化程度正在不斷提高。

- 電子商務推動了對二次包裝的高速需求。

- 勞動力短缺加速了機器人技術的應用

- 利用人工智慧預測性維護(在監控下)減少停機時間

- 中小企業的模組化協作機器人單元(鮮為人知)

- 以永續發展主導的材料減量自動化(悄悄進行)

- 市場限制

- 高昂的資本成本和網路安全風險

- 熟練操作人員短缺

- 供應商對專有控制軟體的鎖定(鮮為人知)

- 缺乏針對低調應用的認證開放原始碼機器視覺庫

- 供應鏈分析

- 監管環境

- 技術展望

- 波特五力分析

- 供應商的議價能力

- 買方的議價能力

- 新進入者的威脅

- 替代品的威脅

- 競爭對手之間的競爭

第5章 市場規模與成長預測

- 依產品類型

- 填充

- 標籤

- 包裝箱

- 裝袋

- 托盤堆疊

- 帽子

- 包裝

- 其他產品類型

- 最終用戶

- 食物

- 飲料

- 製藥

- 個人護理和盥洗用品

- 工業/化工

- 其他最終用戶

- 按自動化級別

- 全自動生產線

- 半自動生產線

- 協作/混合系統

- 透過解決方案

- 硬體(機器人、輸送機、感測器)

- 軟體(SCADA、MES、分析)

- 服務(安裝、維護、改裝)

- 包裝階段

- 初級包裝自動化

- 二級包裝自動化

- 三級/生產線末端自動化

- 按地區

- 北美洲

- 美國

- 加拿大

- 墨西哥

- 歐洲

- 德國

- 英國

- 法國

- 義大利

- 西班牙

- 俄羅斯

- 其他歐洲地區

- 亞太地區

- 中國

- 印度

- 日本

- 韓國

- 澳洲和紐西蘭

- 亞太其他地區

- 中東和非洲

- 中東

- 阿拉伯聯合大公國

- 沙烏地阿拉伯

- 土耳其

- 其他中東地區

- 非洲

- 南非

- 奈及利亞

- 埃及

- 其他非洲地區

- 南美洲

- 巴西

- 阿根廷

- 其他南美洲

- 北美洲

第6章 競爭情勢

- 市場集中度

- 策略趨勢

- 市佔率分析

- 公司簡介

- Multivac Group

- Coesia SpA

- ULMA Packaging

- Syntegon Technology

- Swisslog Healthcare

- Rockwell Automation Inc.

- Sealed Air Corporation

- Mitsubishi Electric Corporation

- Automated Packaging Systems LLC

- ABB Ltd.

- Fanuc Corp.

- KUKA AG

- Schneider Electric SE

- Siemens AG

- Tetra Pak International SA

- ProMach Inc.

- Barry-Wehmiller Companies Inc.

- Sidel Group

- Ishida Co. Ltd.

- Yaskawa Motoman Robotics

第7章 市場機會與未來展望

The packaging automation market size is valued at USD 80.84 billion in 2025 and is forecast to reach USD 114.75 billion by 2030, registering a 7.26% CAGR.

Continued investment in intelligent manufacturing systems is narrowing labor gaps, lifting line precision, and meeting rising regulatory expectations. The sector benefits from e-commerce volume growth that overlaps with stringent pharmaceutical serialization, forcing lines to balance throughput with traceability. North America retains leadership, yet Asia-Pacific delivers the fastest expansion, supported by China's multi-billion-dollar robotics outlays. Hardware still dominates revenue, but service-centric, outcome-based models accelerate as users seek guaranteed uptime rather than ownership. Consolidation across corrugated, folding carton, and material handling suppliers is enlarging customer footprints and creating fresh scale for automation providers.

Global Packaging Automation Market Trends and Insights

Rising Adoption of Automation Across F&B, Pharma and E-commerce Sectors

Packaging machinery shipments climbed in 2024, propelled by pharmaceutical lines that demand flexible, small-batch formats beside high-volume food operations. Pharmaceutical manufacturers are committing USD 160 billion to site upgrades in 2025 to enable personalized medicine packaging. E-commerce fulfillment centers adopt right-sizing systems generating thousands of box variations, halving corrugate use while boosting labor productivity. Cross-industry technology transfer quickens as solutions proven in one sector migrate to another, accelerating packaging automation market penetration. The combined momentum amplifies demand for adaptive robotics and integrated vision that can shift between SKU classes with limited downtime.

E-commerce-Induced Demand for High-Speed Secondary Packaging

Right-sized box systems coupled with mobile robots lifted a distribution site's productivity by 97% within months, underscoring how secondary packaging has become the pivotal efficiency lever. Variable-dimension automation now comprises 41.42% of the packaging automation market, reflecting the need to process mixed orders at speed. Asia-Pacific's surging online retail sales are projected to escalate regional equipment outlays to USD 18 billion in 2024. Coupled with omnichannel models in Europe and North America, the shift places sustained pressure on line speeds, software orchestration, and ergonomic palletizing, stimulating continuous upgrades across the packaging automation market.

High Capital Cost and Cybersecurity Risks

Full-scale packaging cells require significant upfront cash that many SMEs find prohibitive. Simultaneously, rising connectivity exposes operational technology to cyber threats, with manufacturing representing over one quarter of industrial incidents. Firms must invest in both automation hardware and layered security, stretching budgets and slowing adoption. Robots-as-a-Service models address this dual hurdle by shifting spending to OPEX and providing managed cybersecurity within the subscription. The approach lessens balance-sheet impact, yet market education is still needed before it scales across the packaging automation market.

Other drivers and restraints analyzed in the detailed report include:

- Labor Shortages Accelerating Robotics Deployment

- AI-Driven Predictive Maintenance Lowering Downtime

- Skilled-Operator Scarcity

For complete list of drivers and restraints, kindly check the Table Of Contents.

Segment Analysis

Case packaging accounted for 32.12% of packaging automation market share in 2024, underscoring its essential role in safeguarding goods during distribution. Growth within the case segment remains steady as sustainability pushes thinner corrugate and precision glue application. Palletizing, though smaller in revenue, is expanding at 12.31% CAGR. FANUC's new CRX-25iA cobot, able to handle 30 kg loads, compresses cell footprints while offering easy teach pendants. Collaborative robots shorten commissioning and improve worker ergonomics, making the segment a leading indicator of wider automation uptake.

Upstream, filling machines win pharmaceutical investment as flexible aseptic formats accommodate personalized therapies. Labeling lines add serialization modules that satisfy regulatory traceability in medicine and beverages. Wrapping and capping rise on the back of lightweight film advances, with banding technology reducing plastic by 80% in pilot deployments. Bagging lines gain footing in abrasive material sectors where ruggedized Hardox steel prolongs service life. The interplay among these products signals a move toward end-to-end cells that fuse multiple tasks into an adaptive packaging automation market solution.

Food manufacturers held 28.53% of the packaging automation market in 2024, benefiting from high-volume SKUs and rigid hygiene standards. Despite its smaller baseline, pharmaceutical packaging is poised for 11.98% CAGR as injectable therapies rise. Syntegon's Pharmatag 2025 line fills liquids under strict sterility while switching formats quickly to handle short runs. Beverage lines in Asia-Pacific install high-speed canning and sleeving to satisfy rising middle-class demand.

Personal-care brands focus on luxurious, custom packs enabled by automated multi-line order picking. Chemical producers adopt enclosed filling and sealing to limit exposure to aggressive media, leveraging Festo's EX-certified actuators. Technology crossover accelerates as pharma serialization migrates into consumer goods to combat counterfeits, broadening application scope for the packaging automation market.

The Packaging Automation Market Report is Segmented by Product Type (Filling, Labeling, Case Packaging, and More), End-User (Food, Beverage, Pharmaceuticals, and More), Automation Level (Fully-Automated Lines, Semi-Automated Lines, Collaborative/Hybrid Systems), Solution (Hardware, and More), Packaging Stage (Primary, Secondary, Tertiary/End-of-Line), and Geography. The Market Forecasts are Provided in Terms of Value (USD).

Geography Analysis

North America contributed 34.14% to the packaging automation market in 2024, leveraging sophisticated manufacturing infrastructure and FDA serialization mandates. Drug makers will spend USD 160 billion on facility upgrades during 2025, sustaining demand for clean-room ready robots. ABB's USD 20 million expansion in Michigan underscores vendor commitment to regional customers. E-commerce fulfillment hubs proliferate, amplifying calls for adaptive secondary packaging.

Asia-Pacific is the fastest region at 10.64% CAGR through 2030. China spent USD 6.6 billion on industrial robots in 2024, reflecting policy ambitions to double robot density. Shanghai's ProPak 2025 will gather more than 2,500 exhibitors in smart packaging solutions, highlighting the region's shift from manual lines to digital factories. Domestic suppliers such as Estun Automation are winning share with competitively priced robotic arms, expanding the packaging automation market locally.

Europe drives adoption through sustainability regulation and Industry 4.0 grants. A Swedish facility cut plastic wrap by 80% via automated banding, satisfying circular-economy goals. Germany's advanced machine builders add AI modules to retain export competitiveness. Elsewhere, Middle East and Africa pilot automated dairy lines to bolster food security, while South American plants in Brazil install palletizers to serve growing regional beverage demand. These diverse initiatives collectively extend the global packaging automation market footprint.

- Multivac Group

- Coesia S.p.A.

- ULMA Packaging

- Syntegon Technology

- Swisslog Healthcare

- Rockwell Automation Inc.

- Sealed Air Corporation

- Mitsubishi Electric Corporation

- Automated Packaging Systems LLC

- ABB Ltd.

- Fanuc Corp.

- KUKA AG

- Schneider Electric SE

- Siemens AG

- Tetra Pak International SA

- ProMach Inc.

- Barry-Wehmiller Companies Inc.

- Sidel Group

- Ishida Co. Ltd.

- Yaskawa Motoman Robotics

Additional Benefits:

- The market estimate (ME) sheet in Excel format

- 3 months of analyst support

TABLE OF CONTENTS

1 INTRODUCTION

- 1.1 Study Assumptions and Market Definition

- 1.2 Scope of the Study

2 RESEARCH METHODOLOGY

3 EXECUTIVE SUMMARY

4 MARKET LANDSCAPE

- 4.1 Market Overview

- 4.2 Market Drivers

- 4.2.1 Rising adoption of automation across FandB, pharma and e-commerce sectors

- 4.2.2 E-commerce-induced demand for high-speed secondary packaging

- 4.2.3 Labor shortages accelerating robotics deployment

- 4.2.4 AI-driven predictive maintenance lowering downtime (under-radar)

- 4.2.5 Modular cobot cells for SMEs (under-radar)

- 4.2.6 Sustainability-led material-reduction automation (under-radar)

- 4.3 Market Restraints

- 4.3.1 High capital cost and cybersecurity risks

- 4.3.2 Skilled-operator scarcity

- 4.3.3 Vendor lock-in to proprietary control software (under-radar)

- 4.3.4 Lack of certified open-source machine-vision libraries for hygienic zones (under-radar)

- 4.4 Supply-Chain Analysis

- 4.5 Regulatory Landscape

- 4.6 Technological Outlook

- 4.7 Porter's Five Forces Analysis

- 4.7.1 Bargaining Power of Suppliers

- 4.7.2 Bargaining Power of Buyers

- 4.7.3 Threat of New Entrants

- 4.7.4 Threat of Substitutes

- 4.7.5 Intensity of Competitive Rivalry

5 MARKET SIZE AND GROWTH FORECASTS {VALUE)

- 5.1 By Product Type

- 5.1.1 Filling

- 5.1.2 Labeling

- 5.1.3 Case Packaging

- 5.1.4 Bagging

- 5.1.5 Palletizing

- 5.1.6 Capping

- 5.1.7 Wrapping

- 5.1.8 Other Product Types

- 5.2 By End-user

- 5.2.1 Food

- 5.2.2 Beverage

- 5.2.3 Pharmaceuticals

- 5.2.4 Personal Care and Toiletries

- 5.2.5 Industrial and Chemicals

- 5.2.6 Other End-users

- 5.3 By Automation Level

- 5.3.1 Fully-Automated Lines

- 5.3.2 Semi-Automated Lines

- 5.3.3 Collaborative/Hybrid Systems

- 5.4 By Solution

- 5.4.1 Hardware (Robots, Conveyors, Sensors)

- 5.4.2 Software (SCADA, MES, Analytics)

- 5.4.3 Services (Installation, Maintenance, Retrofits)

- 5.5 By Packaging Stage

- 5.5.1 Primary Packaging Automation

- 5.5.2 Secondary Packaging Automation

- 5.5.3 Tertiary / End-of-Line Automation

- 5.6 By Geography

- 5.6.1 North America

- 5.6.1.1 United States

- 5.6.1.2 Canada

- 5.6.1.3 Mexico

- 5.6.2 Europe

- 5.6.2.1 Germany

- 5.6.2.2 United Kingdom

- 5.6.2.3 France

- 5.6.2.4 Italy

- 5.6.2.5 Spain

- 5.6.2.6 Russia

- 5.6.2.7 Rest of Europe

- 5.6.3 Asia-Pacific

- 5.6.3.1 China

- 5.6.3.2 India

- 5.6.3.3 Japan

- 5.6.3.4 South Korea

- 5.6.3.5 Australia and New Zealand

- 5.6.3.6 Rest of Asia-Pacific

- 5.6.4 Middle East and Africa

- 5.6.4.1 Middle East

- 5.6.4.1.1 United Arab Emirates

- 5.6.4.1.2 Saudi Arabia

- 5.6.4.1.3 Turkey

- 5.6.4.1.4 Rest of Middle East

- 5.6.4.2 Africa

- 5.6.4.2.1 South Africa

- 5.6.4.2.2 Nigeria

- 5.6.4.2.3 Egypt

- 5.6.4.2.4 Rest of Africa

- 5.6.5 South America

- 5.6.5.1 Brazil

- 5.6.5.2 Argentina

- 5.6.5.3 Rest of South America

- 5.6.1 North America

6 COMPETITIVE LANDSCAPE

- 6.1 Market Concentration

- 6.2 Strategic Moves

- 6.3 Market Share Analysis

- 6.4 Company Profiles {(includes Global level Overview, Market level overview, Core Segments, Financials as available, Strategic Information, Market Rank/Share for key companies, Products and Services, and Recent Developments)}

- 6.4.1 Multivac Group

- 6.4.2 Coesia S.p.A.

- 6.4.3 ULMA Packaging

- 6.4.4 Syntegon Technology

- 6.4.5 Swisslog Healthcare

- 6.4.6 Rockwell Automation Inc.

- 6.4.7 Sealed Air Corporation

- 6.4.8 Mitsubishi Electric Corporation

- 6.4.9 Automated Packaging Systems LLC

- 6.4.10 ABB Ltd.

- 6.4.11 Fanuc Corp.

- 6.4.12 KUKA AG

- 6.4.13 Schneider Electric SE

- 6.4.14 Siemens AG

- 6.4.15 Tetra Pak International SA

- 6.4.16 ProMach Inc.

- 6.4.17 Barry-Wehmiller Companies Inc.

- 6.4.18 Sidel Group

- 6.4.19 Ishida Co. Ltd.

- 6.4.20 Yaskawa Motoman Robotics

7 MARKET OPPORTUNITIES AND FUTURE OUTLOOK

- 7.1 White-space and Unmet-Need Assessment