|

市場調查報告書

商品編碼

1850214

汽車煞車系統:市場佔有率分析、產業趨勢、統計數據和成長預測(2025-2030 年)Automotive Brake System - Market Share Analysis, Industry Trends & Statistics, Growth Forecasts (2025 - 2030) |

||||||

※ 本網頁內容可能與最新版本有所差異。詳細情況請與我們聯繫。

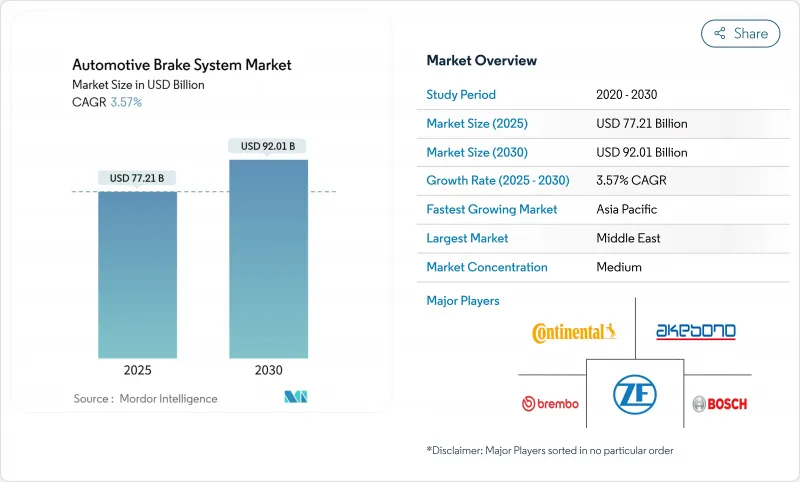

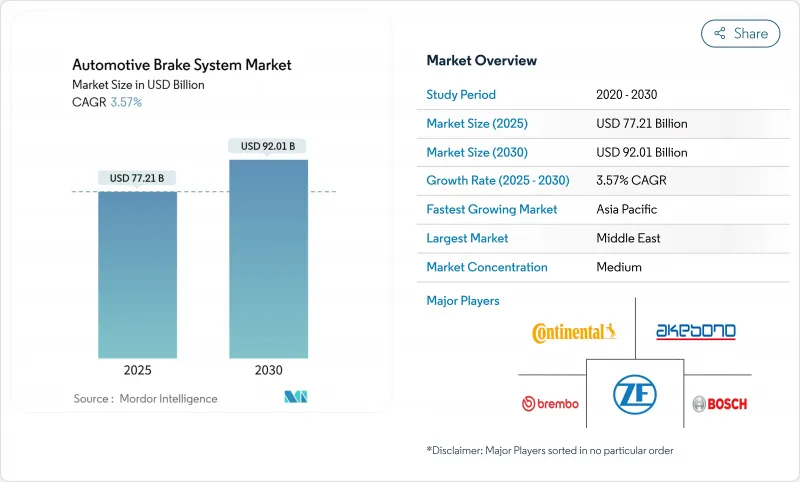

預計到 2025 年,汽車煞車系統市場規模將達到 772.1 億美元,到 2030 年將達到 920.1 億美元,年複合成長率為 3.57%。

市場成長反映了從純液壓系統向電子控制架構的穩定轉變,這種架構能夠協調軟體定義車輛中的防鎖死、穩定性控制和能量回收功能。亞太地區透過大規模電動車生產和電子煞車組件外包來支撐需求,而中東地區則在車輛現代化政策和基礎設施投資的共同作用下實現了最快速的成長。輕型商用車業者也透過預測性維護計畫來減少非計畫性停機時間,從而促進售後市場銷售。

全球汽車煞車系統市場趨勢與洞察

快速電氣化推動了再生煞車硬體的發展

由於電動車的佈局會將更大的煞車扭力施加在牽引馬達上,因此摩擦系統必須與軟體控制的能量回收系統無縫同步。由Tevva和ZF共同開發的這套能量回收套件,其能量回收量是標準空氣煞車的四倍,可將7.5噸卡車的續航里程延長至140英里。在梅賽德斯-奔馳的原型車中,煞車單元嵌入在電力驅動裝置外殼內,從而避免了易生鏽的硬體,並減少了顆粒物排放。愛信的協調能量回收系統進一步最佳化了液壓煞車和馬達煞車之間的平衡,確保車輛在各種負載條件下都能保持穩定性。

ADAS技術的日益普及推動了對線控刹車的需求。

2+級援助和計畫中的4級自動駕駛需要毫秒級的反應速度,而液壓連桿無法保證這一點。博世即將推出的液壓線控刹車平台取消了機械踏板路徑,同時保留了雙油路以實現冗餘。採埃孚的機電煞車技術已獲得近500萬輛汽車的預訂,該技術將整合式煞車控制與軟體定義的底盤模組相結合。半導體層也正在效仿:瑞薩電子的R-Car X5H晶片系統採用硬體隔離來保護安全關鍵的煞車區域。

稀土價格波動推高了電子煞車致動器的成本。

美國能源局已將釹、镨、鏑和鋱列為關鍵材料,這些材料的加工高度集中於中國,使得線控刹車致動器面臨價格波動的風險。儘管供應商正在努力實現磁性材料化學成分的多元化,並探索非磁性馬達的替代方案,但汽車煞車系統市場短期內仍將面臨成本壓力。

細分市場分析

到2024年,碟式煞車將佔汽車煞車系統銷量的63.10%,憑藉其熱穩定性,將成為乘用車和輕型卡車的首選。預計到2030年,電動駐煞車系統的汽車煞車系統市場規模將成長5.22%,這主要得益於節省空間和電子整合以完善高級駕駛輔助系統(ADAS)。 Brake India將於2024年率先與全球汽車製造商合作推出電動停車煞車,這標誌著新興市場將以成本最佳化的方式採用該技術。鼓式煞車將繼續用於對成本較為敏感的後軸,而能量回收模組將在純電動車中佔據更大的佔有率。

這款源自NASA的輕量化煞車碟盤,現已授權給Orbis Brakes公司使用,可將簧下品質降低42%,並透過扇形通風口提升散熱性能。這款創新鏈正助力汽車煞車系統市場在不犧牲現有產品銷售的前提下,採用新一代材料。

到2024年,防鎖死系統(ABS)將佔據45.10%的市場佔有率,成為安全系統的核心。然而,電子穩定控制系統(ESC)正以8.65%的複合年成長率成長,並且在許多地區已成為強制性配置,這使其能夠迅速縮小與ABS的差距。大陸集團計劃在2024年在印度生產超過100萬套電子煞車系統(EBD),展現出其可擴展的經濟效益。牽引力控制系統(TCS)和電子煞車力道分配系統(EBD)相輔相成,分別最佳化牽引力和負載平衡。

Brembo 的人工智慧控制器將於 2024 年底推出,它能在車輪鎖死前預測抓地力喪失,證實了軟體在曾經的硬體競爭中已成為決定性因素。因此,汽車煞車系統市場正持續從零件供應轉向演算法主導的性能提升。

到2024年,液壓驅動系統將佔總收入的66.25%,這主要得益於其穩固的供應鏈和服務基礎設施。然而,預計年複合成長率將達到9.50%的線控刹車解決方案,能夠滿足自動駕駛車輛對延遲的要求。博斯的液壓線控刹車混合動力系統無需機械踏板,同時保留了冗餘的液壓迴路,為謹慎的原始設備製造商(OEM)提供了一個可行且先進的解決方案。氣動系統已廣泛應用於重型卡車,而機械電纜系統則仍處於成本限制的細分市場。

採埃孚輕型商用車的訂單量證實了純電子機械煞車系統的商業性可行性。汽車煞車系統市場的兩條發展路徑——漸進式混合動力和革命性的線傳——允許在不影響現有生產佈局的情況下進行逐步投資。

區域分析

2024年,亞太地區將佔總銷售額的58.55%,這主要得益於中國電動車的推廣和印度電子組裝規模的擴大。光是大陸集團一家,2024年就在印度生產了超過100萬套電子煞車系統。諸如Brakes India-ADVICS等本地合資企業也提升了印度的本土技術能力。

歐洲正在推動市場對電動車的需求日益成熟且有利,這得益於粒狀物排放上限和電子穩定維修。歐盟7排放基準值(7毫克/公里)將於2025年中期生效,這將加速無銅材料和低阻力卡鉗的普及。北歐國家也將迎來強勁成長,年複合成長率將達到5%,因為電動車的普及推動了能源回收系統的發展。

到2030年,中東地區將以8.90%的複合年成長率引領區域成長,這主要得益於沙烏地阿拉伯的「2030願景」基礎設施規劃和阿拉伯聯合大公國的交通運輸多元化發展。非洲緊隨其後,年複合成長率將達到6.90%,這主要得益於南非和埃及不斷壯大的組裝中心。北美市場正以4.5%的速度成長,老舊的液壓系統正被現代技術取代。光是在馬科姆縣,到2024年,煞車相關產品的銷售額就可能達到1.003億美元。

其他福利:

- Excel格式的市場預測(ME)表

- 3個月的分析師支持

目錄

第1章 引言

- 研究假設和市場定義

- 調查範圍

第2章調查方法

第3章執行摘要

第4章 市場情勢

- 市場概覽

- 市場促進因素

- 快速電氣化推動再生煞車硬體的轉型

- ADAS技術的日益普及將推動對線控刹車架構的需求。

- 嚴格的美國FMVSS 126和UNECE R140法規推動了ABS/ESC的安裝

- 新冠疫情後電子商務激增,擴大了輕型商用車煞車售後市場。

- 加速全球純電動車生產需要低粉塵、無銅摩擦材料。

- 延長原廠保固期推動了長壽命陶瓷墊片配方的應用

- 市場限制

- 稀土元素價格波動推高電子煞車致動器成本

- 歐盟高等級鋼轉子供應鏈出現瓶頸

- 減少再生煞車磨損可降低售後墊片銷量

- 柴油商用車產量下降導致對氣動煞車的需求減少

- 價值鏈分析

- 監理展望

- 技術展望

- 波特五力模型

- 供應商的議價能力

- 買方的議價能力

- 新進入者的威脅

- 替代品的威脅

- 競爭的激烈程度

第5章 市場規模與成長預測

- 依產品類型

- 碟煞

- 鼓式煞車

- 電動駐煞車系統

- 再生煞車模組

- 透過技術

- 防鎖死煞車系統(ABS)

- 電子穩定控制系統(ESC)

- 牽引力控制系統(TCS)

- 電子煞車力道分配(EBD)

- 透過操作機制

- 油壓

- 氣壓

- 電磁式/線控刹車

- 機械式(電纜式)

- 按組件

- 煞車皮和煞車蹄

- 卡尺

- 轉子和滾筒

- 煞車增壓器和主缸

- 電控系統和致動器

- 按墊片材質

- 有機(不含石棉)

- 類金屬

- 金屬

- 陶瓷製品

- 按銷售管道

- 原始設備製造商 (OEM)

- 售後市場

- 按車輛類型

- 搭乘用車

- 輕型商用車

- 重型商用車輛和巴士

- 透過推廣

- 內燃機(ICE)車輛

- 混合動力電動車(HEV/PHEV)

- 電池電動車(BEV)

- 燃料電池電動車(FCEV)

- 按地區

- 北美洲

- 美國

- 加拿大

- 北美其他地區

- 南美洲

- 巴西

- 阿根廷

- 其他南美洲

- 歐洲

- 德國

- 英國

- 法國

- 義大利

- 西班牙

- 其他歐洲地區

- 亞太地區

- 中國

- 印度

- 日本

- 韓國

- 亞太其他地區

- 中東和非洲

- 沙烏地阿拉伯

- 阿拉伯聯合大公國

- 土耳其

- 南非

- 埃及

- 其他中東和非洲地區

- 北美洲

第6章 競爭情勢

- 市場集中度

- 策略性舉措(併購、合資、產品發布)

- 市佔率分析

- 公司簡介

- Continental AG

- Robert Bosch GmbH

- ZF Friedrichshafen AG

- Brembo SpA

- Akebono Brake Industry Co. Ltd

- Aisin Corporation

- ADVICS Co. Ltd

- Knorr-Bremse AG

- Hyundai Mobis Co. Ltd

- Mando Corporation

- Federal-Mogul Motorparts(Tenneco)

- Hitachi Astemo, Ltd.

- WABCO(ZF CVS)

- Meritor Inc.

- Nissin Kogyo Co. Ltd

- Bendix Commercial Vehicle Systems

- Aptiv PLC

- Haldex AB

- Hella Pagid GmbH

- Carlisle Brake & Friction

第7章 市場機會與未來展望

The automotive brake system market stood at USD 77.21 billion in 2025 and is forecast to reach USD 92.01 billion by 2030, advancing at a 3.57% CAGR.

The market's growth reflects a steady migration from purely hydraulic setups toward electronically governed architectures that coordinate anti-lock, stability, and regenerative functions in software-defined vehicles. Asia Pacific anchors demand through large-scale electric-vehicle (EV) production and outsourcing of electronic brake assemblies, while the Middle East records the quickest expansion as fleet-modernization policies intersect with infrastructure spending. Technology vendors concentrate on brake-by-wire and low-dust friction materials to comply with UNECE R140 and Euro 7 particulate limits, and light commercial vehicle (LCV) operators lift aftermarket volumes via predictive maintenance programs that cut unplanned downtime.

Global Automotive Brake System Market Trends and Insights

Rapid Electrification Driving Regenerative-Compatible Brake Hardware

Electric-vehicle layouts place more braking torque on traction motors, so friction systems must synchronize seamlessly with software-managed energy recovery. A regenerative kit co-developed by Tevva and ZF captures up to four times more energy than standard air brakes, extending a 7.5-ton truck's range to 140 miles. Mercedes-Benz prototypes embed the brake unit inside the e-drive housing, eliminating rust-prone hardware and reducing particulate emissions. Aisin's cooperative regenerative system further balances hydraulic and motor braking to maintain vehicle stability under all load states.

Heightened ADAS Penetration Raising Demand for Brake-by-Wire

Level-2+ assistance and planned Level-4 autonomy require millisecond actuation that hydraulic linkages cannot guarantee. Bosch's upcoming hydraulic brake-by-wire platform removes mechanical pedal paths yet retains dual fluid circuits for redundancy. ZF has already booked almost 5 million vehicles for its electro-mechanical brake technology that combines integrated brake control and software-defined chassis modules. The semiconductor layer follows suit: Renesas' R-Car X5H system-on-chip uses hardware isolation to protect safety-critical braking domains.

Volatility in Rare-Earth Prices Inflating Electronic Brake Actuator Costs

The U.S. Department of Energy lists neodymium, praseodymium, dysprosium, and terbium as critical materials with concentrated processing in China, exposing brake-by-wire actuators to price swings. Suppliers are diversifying magnet chemistries and seeking non-magnetic motor alternatives, yet near-term cost pressures persist across the automotive brake system market.

Other drivers and restraints analyzed in the detailed report include:

- Stricter FMVSS 126 & UNECE R140 Mandates Boosting ABS/ESC Installations

- Post-COVID E-commerce Surge Increasing LCV Brake Aftermarket

- Reduced Wear in Regenerative Braking Curtailing Aftermarket Pad Revenues

For complete list of drivers and restraints, kindly check the Table Of Contents.

Segment Analysis

Disc brakes accounted for 63.10% of 2024 revenue, their thermal stability keeping them the default choice in passenger cars and light trucks. The automotive brake system market size for electric parking brakes is projected to expand 5.22% by 2030, driven by space savings and electronic integration that complements ADAS. Brakes India introduced its first electric park brake with a global OEM in 2024, signaling cost-optimized uptake in emerging markets. Drum brakes continue on rear axles where cost is king, while regenerative modules carve a share in battery electric vehicles.

NASA-derived lightweight rotors, now licensed to Orbis Brakes, lower unsprung mass by 42% and improve cooling via wave-shaped vents, an innovation likely to debut in high-performance EVs where every kilogram matters. This cascade of innovations helps the automotive brake system market embrace next-generation materials without sacrificing legacy volumes.

Anti-lock systems held 45.10% market share in 2024, anchoring the safety stack. Electronic stability control, however, is growing at 8.65% CAGR and is already mandated in many regions, positioning it to narrow the gap swiftly. Continental produced more than 1 million electronic brake systems in India during 2024, illustrating scalable economics. TCS and EBD remain complementary, optimizing traction and load balance respectively.

Artificial-intelligence layers are now enhancing classical ABS; Brembo's AI-enabled controller launched in late 2024 anticipates grip losses before wheel lock, confirming that software will differentiate what once was a hardware race. As a result, the automotive brake system market continues to pivot from component supply toward algorithm-driven performance gains.

Hydraulic actuation generated 66.25% of 2024 revenue as its supply chain and service base remain entrenched. Yet brake-by-wire solutions, forecast at a 9.50% CAGR, address autonomous-vehicle latency standards. Bosch's hydraulic brake-by-wire hybrid keeps fluid pathways for redundancy while removing mechanical pedals, offering an evolutionary step for cautious OEMs. Pneumatic systems hold in heavy trucks, and mechanical cables survive in cost-constrained niches.

ZF's bookings for light vehicles confirm the commercial viability of pure electro-mechanical brakes. For the automotive brake system market, this dual track, evolutionary hybrids and revolutionary by-wire, permits staged investment without disrupting existing manufacturing footprints.

The Automotive Brake System Market Report is Segmented by Vehicle Type (Passenger Cars and More), Product Type (Disc Brakes and More), Technology (Anti-Lock Braking System (ABS) and More), Actuation Mechanism (Hydraulic and More), Component (Brake Pads & Shoes and More), Pad Material (Organic and More), Sales Channel, Propulsion, and Geography. The Market Forecasts are Provided in Terms of Value (USD) and Volume (Units).

Geography Analysis

Asia Pacific held 58.55% of 2024 revenue, fueled by China's EV rollout and India's electronics assembly scale. Continental alone produced more than 1 million electronic brake systems in India during 2024. Local joint ventures, such as Brakes India-ADVICS, reinforce indigenous technology capability.

Europe contributes mature yet lucrative demand stemming from mandated particulate caps and rapid ESC retrofits. Euro 7's 7 mg/km brake-dust threshold, effective mid-2025, accelerates copper-free material adoption and low-drag calipers. Nordic nations also post a robust 5% CAGR as EV penetration fosters regenerative-ready systems.

The Middle East leads regional growth at an 8.90% CAGR through 2030, powered by Vision 2030 infrastructure programs in Saudi Arabia and transport diversification in the UAE. Africa follows at 6.90% due to growing assembly hubs in South Africa and Egypt. North America advances at 4.5% as technology refresh cycles replace legacy hydraulic setups; Macomb County alone tallied USD 100.3 million in brake-specific sales in 2024

- Continental AG

- Robert Bosch GmbH

- ZF Friedrichshafen AG

- Brembo S.p.A

- Akebono Brake Industry Co. Ltd

- Aisin Corporation

- ADVICS Co. Ltd

- Knorr-Bremse AG

- Hyundai Mobis Co. Ltd

- Mando Corporation

- Federal-Mogul Motorparts (Tenneco)

- Hitachi Astemo, Ltd.

- WABCO (ZF CVS)

- Meritor Inc.

- Nissin Kogyo Co. Ltd

- Bendix Commercial Vehicle Systems

- Aptiv PLC

- Haldex AB

- Hella Pagid GmbH

- Carlisle Brake & Friction

Additional Benefits:

- The market estimate (ME) sheet in Excel format

- 3 months of analyst support

TABLE OF CONTENTS

1 Introduction

- 1.1 Study Assumptions & Market Definition

- 1.2 Scope of the Study

2 Research Methodology

3 Executive Summary

4 Market Landscape

- 4.1 Market Overview

- 4.2 Market Drivers

- 4.2.1 Rapid Electrification Driving Shift to Regenerative-Compatible Brake Hardware

- 4.2.2 Heightened ADAS Penetration Raising Demand for Brake-by-Wire Architectures

- 4.2.3 Stricter U.S. FMVSS 126 & UNECE R140 Mandates Boosting ABS/ESC Installations

- 4.2.4 Post-COVID E-commerce Surge Increasing LCV Brake Aftermarket

- 4.2.5 Accelerating Global BEV Production Necessitating Low-Dust, Copper-Free Friction Materials

- 4.2.6 OEM Warranty Extensions Driving Adoption of Long-Life Ceramic Pad Formulations

- 4.3 Market Restraints

- 4.3.1 Volatility in Rare-earth Prices Inflating Electronic Brake Actuator Costs

- 4.3.2 Supply-chain Bottlenecks for High-grade Steel Rotors in EU

- 4.3.3 Reduced Wear in Regenerative Braking Curtailing Aftermarket Pad Revenues

- 4.3.4 Declining Diesel CV Production Dampening Pneumatic Brake Demand

- 4.4 Value-Chain Analysis

- 4.5 Regulatory Outlook

- 4.6 Technological Outlook

- 4.7 Porter's Five Forces

- 4.7.1 Bargaining Power of Suppliers

- 4.7.2 Bargaining Power of Buyers

- 4.7.3 Threat of New Entrants

- 4.7.4 Threat of Substitutes

- 4.7.5 Intensity of Rivalry

5 Market Size & Growth Forecasts (Value (USD) and Volume (Units))

- 5.1 By Product Type

- 5.1.1 Disc Brakes

- 5.1.2 Drum Brakes

- 5.1.3 Electric Parking Brakes

- 5.1.4 Regenerative Braking Modules

- 5.2 By Technology

- 5.2.1 Anti-lock Braking System (ABS)

- 5.2.2 Electronic Stability Control (ESC)

- 5.2.3 Traction Control System (TCS)

- 5.2.4 Electronic Brake-force Distribution (EBD)

- 5.3 By Actuation Mechanism

- 5.3.1 Hydraulic

- 5.3.2 Pneumatic

- 5.3.3 Electromagnetic / Brake-by-Wire

- 5.3.4 Mechanical (Cable)

- 5.4 By Component

- 5.4.1 Brake Pads & Shoes

- 5.4.2 Calipers

- 5.4.3 Rotors & Drums

- 5.4.4 Brake Boosters & Master Cylinders

- 5.4.5 Electronic Control Units & Actuators

- 5.5 By Pad Material

- 5.5.1 Organic (Non-Asbestos)

- 5.5.2 Semi-Metallic

- 5.5.3 Metallic

- 5.5.4 Ceramic

- 5.6 By Sales Channel

- 5.6.1 Original Equipment Manufacturers (OEM)

- 5.6.2 Aftermarket

- 5.7 By Vehicle Type

- 5.7.1 Passenger Cars

- 5.7.2 Light Commercial Vehicles

- 5.7.3 Heavy Commercial Vehicles & Buses

- 5.8 By Propulsion

- 5.8.1 Internal Combustion Engine (ICE) Vehicles

- 5.8.2 Hybrid Electric Vehicles (HEV/PHEV)

- 5.8.3 Battery Electric Vehicles (BEV)

- 5.8.4 Fuel-Cell Electric Vehicles (FCEV)

- 5.9 By Geography

- 5.9.1 North America

- 5.9.1.1 United States

- 5.9.1.2 Canada

- 5.9.1.3 Rest of North America

- 5.9.2 South America

- 5.9.2.1 Brazil

- 5.9.2.2 Argentina

- 5.9.2.3 Rest of South America

- 5.9.3 Europe

- 5.9.3.1 Germany

- 5.9.3.2 United Kingdom

- 5.9.3.3 France

- 5.9.3.4 Italy

- 5.9.3.5 Spain

- 5.9.3.6 Rest of Europe

- 5.9.4 Asia Pacific

- 5.9.4.1 China

- 5.9.4.2 India

- 5.9.4.3 Japan

- 5.9.4.4 South Korea

- 5.9.4.5 Rest of Asia Pacific

- 5.9.5 Middle East and Africa

- 5.9.5.1 Saudi Arabia

- 5.9.5.2 United Arab Emirates

- 5.9.5.3 Turkey

- 5.9.5.4 South Africa

- 5.9.5.5 Egypt

- 5.9.5.6 Rest of Middle East and Africa

- 5.9.1 North America

6 Competitive Landscape

- 6.1 Market Concentration

- 6.2 Strategic Moves (M&A, JV, Product Launches)

- 6.3 Market Share Analysis

- 6.4 Company Profiles (includes Global level Overview, Market level overview, Core Segments, Financials as available, Strategic Information, Products & Services, and Recent Developments)

- 6.4.1 Continental AG

- 6.4.2 Robert Bosch GmbH

- 6.4.3 ZF Friedrichshafen AG

- 6.4.4 Brembo S.p.A

- 6.4.5 Akebono Brake Industry Co. Ltd

- 6.4.6 Aisin Corporation

- 6.4.7 ADVICS Co. Ltd

- 6.4.8 Knorr-Bremse AG

- 6.4.9 Hyundai Mobis Co. Ltd

- 6.4.10 Mando Corporation

- 6.4.11 Federal-Mogul Motorparts (Tenneco)

- 6.4.12 Hitachi Astemo, Ltd.

- 6.4.13 WABCO (ZF CVS)

- 6.4.14 Meritor Inc.

- 6.4.15 Nissin Kogyo Co. Ltd

- 6.4.16 Bendix Commercial Vehicle Systems

- 6.4.17 Aptiv PLC

- 6.4.18 Haldex AB

- 6.4.19 Hella Pagid GmbH

- 6.4.20 Carlisle Brake & Friction

7 Market Opportunities & Future Outlook

- 7.1 Integration of IoT & Predictive Maintenance Platforms

- 7.2 Next-Gen Solid-state Brake-by-Wire for Level-4 Autonomy

- 7.3 Copper-free Pad Mandates Creating Material Innovation Space

- 7.4 Lightweight Carbon-Ceramic Discs for High-Performance EVs