|

市場調查報告書

商品編碼

1849989

農業酵素:市場佔有率分析、產業趨勢、統計數據、成長預測(2025-2030)Agricultural Enzymes - Market Share Analysis, Industry Trends & Statistics, Growth Forecasts (2025 - 2030) |

||||||

※ 本網頁內容可能與最新版本有所差異。詳細情況請與我們聯繫。

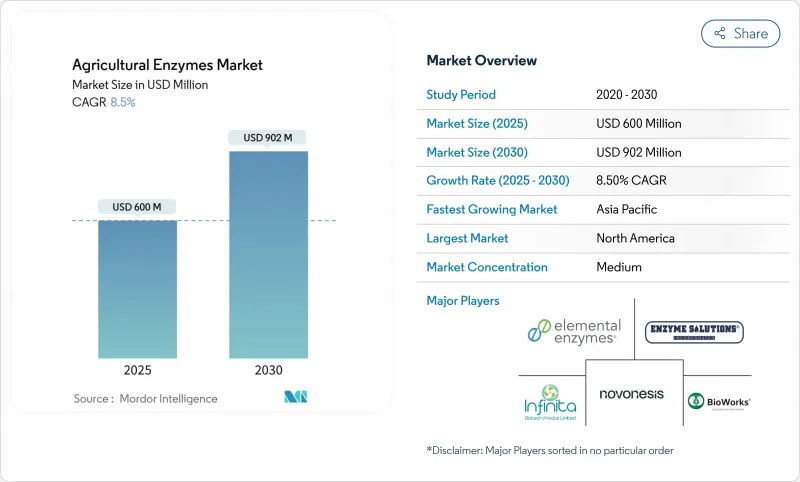

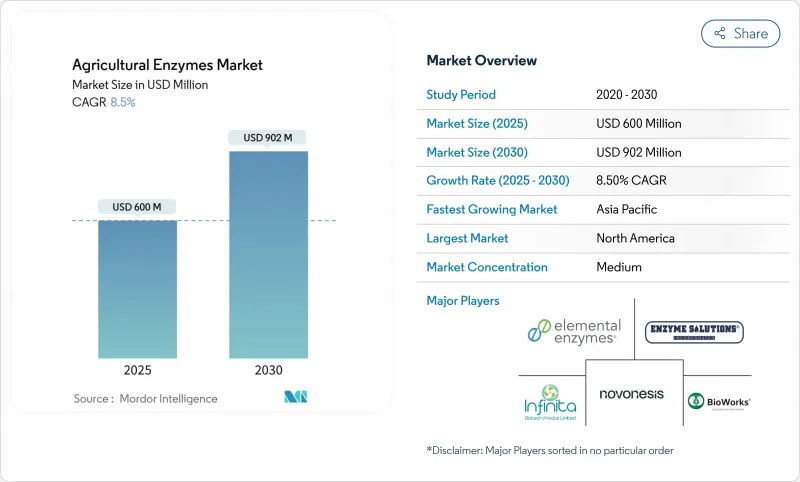

預計到 2025 年,農業酵素市場規模將達到 6 億美元,到 2030 年將達到 9.02 億美元,預測期內複合年成長率為 8.5%。

這一成長反映了對合成化學品監管的日益嚴格、消費者對無殘留食品需求的不斷成長,以及酶製劑和遞送技術的穩步進步。成熟市場的商業生產商正在用酵素生物製藥取代一些傳統投入品,而亞太地區的小農戶在專案補貼計畫的支持下,正逐步轉向使用產量生物製藥。精準發酵和人工智慧主導的蛋白質設計技術的同步發展正在縮短產品開發週期,而長期碳權計畫則為採用再生酶解決方案的農民提供了新的收入來源。隨著大型農化公司透過合作和收購加強其生物製劑產品組合,以及專業生物技術公司競相將下一代多酶混合物商業化,競爭日益激烈。

全球農業酵素市場趨勢與洞察

有機和無殘留食品的需求

隨著零售商收緊農藥殘留基準值,以及歐盟「從農場到餐桌」戰略要求到2030年將化學農藥的使用量減少50%,全球有機農產品的支出正在成長。農民在有機認證管道可獲得20%至30%的溢價,足以抵銷採用酵素製劑來促進無化學殘留養分轉換所帶來的轉型成本。添加酵素製劑的種植方案有助於縮小有機系統中的產量差距,其原理是透過提高磷氮肥的有效性、增強植物的防禦機制以及改善土壤微生物群的平衡。西班牙的商業果園主報告稱,2024年從磷肥改用顆粒狀磷酸酶-尿素酶混合物後,產量提高了9%,這充分證明了其經濟效益。類似的成果目前正在推動加拿大溫室蔬菜種植業的推廣,液態纖維素酶混合物透過改善作物輪作間的生質能分解,縮短了作物的生長週期。

生物投入物的引入迅速增加

巴西目前已在其超過60%的耕地上應用生物作物保護方案,比例遠超過歐盟和美國。作物對合成除草劑和殺菌劑的抗藥性日益增強,加速了人們尋找新的作用機制,使農業酵素成為生物防治微生物的協同增效劑。在馬托格羅索州,農民在2024/25年度種植玉米時,使用含有脂肪酶和甘露聚醣酶的種子處理劑,使玉米產量提高了4.6%。類似的成長動能在印度也十分明顯,該國政府提供的補貼可涵蓋高達30%的酵素製劑投入成本,從而推動了小農戶的採用,並促進了兩位數的市場成長。

零散的監管核准

生物製藥開發商仍面臨核准時間長短不一的問題,例如在歐盟,根據產品分類的不同,可能需要提交多份申請。雖然美國新推出的統一生物技術監管網站提高了國內的透明度,但全球協調統一仍遙遙無期。核准延誤會使平均商業化週期延長18至24個月,增加合規成本,並促使一些公司優先考慮少數但價值較高的市場。規模較小的創新企業面臨的困境尤其嚴重,因為它們通常需要與大型農化公司合作以獲得監管支持,這限制了它們自身的市場進入策略。

細分市場分析

磷酸酶能夠分解土壤中固定的磷,而土壤中固定的磷佔化肥施用量的80%之多。預計到2024年,磷酸酶將佔據農業酵素市場37%的佔有率。由於化肥價格波動,穀物和油籽作物對磷固定解決方案的需求仍然強勁。因此,預計到2030年,磷酸酶在農業酵素市場規模中將繼續保持其主導地位。纖維素酶在CelOCE及其相關創新技術的推動下,以13.8%的複合年成長率引領成長。這些酵素能夠分解作物殘茬,釋放醣類,從而為有益微生物提供養分並改善土壤結構。尿素酶、解離酶和蛋白酶構成了纖維素酶產品組合,越來越多的混合酶產品將多種酶的互補活性結合起來,以適應複雜的田間條件。

在高階園藝領域,多酵素混合物的應用趨勢尤其明顯。種植者希望透過單一處理實現精準的養分調動或增強作物的抗逆性。新興企業公司正在開發農場發酵套件,使種植者能夠釀造新鮮的富含纖維素酶的混合物,從而避免保存期限問題並降低成本。領導者正在整合磷酸酶和尿素酶的協同作用,以提高水稻田的氮肥利用效率並減少揮發,這反映出農業酵素市場解決方案的日益豐富。

到2024年,液態產品仍將佔據農業酵素市場46.2%的佔有率,這主要得益於其與現有噴灑設備的兼容性以及高效的葉面吸收。然而,物流成本和對低溫運輸的依賴正促使產品經理轉向耐溫性更強的技術。顆粒狀產品正以12.4%的複合年成長率快速發展,目前已採用「顆粒劑內生物反應器」結構,可將酵素的穩定性提高至24個月,並在接觸土壤後達到定時釋放。

粉劑配方經濟實惠,但需要專門的混合設備。水溶性混合顆粒模糊了這個界限,兼具液體的便利性和顆粒的耐用性。配方的多樣性將是企業脫穎而出的關鍵,尤其對於那些希望在亞太和非洲等熱帶地區實現成長、但這些地區低溫運輸缺口依然存在的公司而言更是如此。

區域分析

北美地區預計到2024年將佔農業酵素市場的約35%,這得益於其完善的分銷體系和生物投入品快速的法規核准流程。上個種植季,加拿大種植者種植了1,180萬公頃基改作物,為配套的酵素製劑計畫創造了有利環境。美國的生物促效劑市場同樣蓬勃發展,富含酵素的葉面噴布在杏仁和番茄種植者中越來越受歡迎。

亞太地區是成長最快的地區,預計到2030年將達到10%的複合年成長率。印度的生物農業產業預計到2023年將達到124億美元,政府補貼可涵蓋高達30%的酵素製劑成本,加速小農戶對酵素製劑的採用。低溫運輸缺口仍然是一個重大障礙,印度的酪農產業仍缺乏80%的所需產能,導致製造商專注於顆粒狀產品。中國的土地改革鼓勵發展更大規模的農場,從而改善了可大規模應用的酵素製劑技術的商業前景。

得益於「綠色新政」下嚴格的農藥減量目標,歐洲在生物防治領域中保持著穩固的地位。預計生物防治活性物質的種類將從2011年的120種增加到2022年的近220種,同期銷售額將翻倍,達到15.49億歐元。南美洲市場在巴西的推動下(巴西的生物製藥採用率高達60%)正經歷著成熟且不斷擴張的市場,尤其是在大豆和玉米的酵素強化種子處理方面。中東和非洲展現出新的潛力,但這取決於監管的清晰度和低溫運輸投資,其中南非和海灣國家作為早期採用者處於領先地位。

其他福利:

- Excel格式的市場預測(ME)表

- 3個月的分析師支持

目錄

第1章 引言

- 研究假設和市場定義

- 調查範圍

第2章調查方法

第3章執行摘要

第4章 市場情勢

- 市場概覽

- 市場促進因素

- 有機和無殘留食品的需求

- 生物投入物的快速採用

- 加強研發和產品創新

- 種子披衣衣微劑量遞送

- 再生農業碳權計劃

- 農場內酵素發酵裝置

- 市場限制

- 監管核准分散

- 土壤和氣候造成的性能差異

- 熱帶地區低溫運輸缺口

- 化學品的隱性短期投資報酬率

- 監管環境

- 技術展望

- 五力分析

- 供應商的議價能力

- 買方的議價能力

- 新進入者的威脅

- 替代品的威脅

- 競爭對手之間的競爭

第5章 市場規模與成長預測

- 依酶類型

- 磷酸酶

- 脫氫酶

- 尿素酶

- 蛋白酶

- 解離酶

- 纖維素酶

- 其他酵素類型

- 按劑型

- 液體

- 粉末

- 顆粒狀

- 透過使用

- 作物保護

- 生育能力提高

- 植物生長調節

- 透過應用模式

- 種子處理

- 葉面噴布

- 土壤處理

- 按作物類型

- 糧食

- 油籽和豆類

- 水果和蔬菜

- 草坪和觀賞植物

- 其他作物

- 按地區

- 北美洲

- 美國

- 加拿大

- 墨西哥

- 北美其他地區

- 歐洲

- 德國

- 英國

- 法國

- 義大利

- 西班牙

- 俄羅斯

- 其他歐洲地區

- 亞太地區

- 中國

- 日本

- 印度

- 澳洲

- 亞太其他地區

- 南美洲

- 巴西

- 阿根廷

- 其他南美洲

- 中東

- 沙烏地阿拉伯

- 阿拉伯聯合大公國

- 土耳其

- 其他中東地區

- 非洲

- 南非

- 肯亞

- 其他非洲地區

- 北美洲

第6章 競爭情勢

- 市場集中度

- 策略趨勢

- 市佔率分析

- 公司簡介

- Novonesis

- Elemental Enzymes

- Enzyme Solutions Inc.

- Bioworks Inc.

- Infinita Biotech Pvt. Ltd.

- Biocatalysts Ltd

- Enzyme Development Corporation

第7章 市場機會與未來展望

The Agricultural Enzymes Market size is estimated at USD 600 million in 2025, and is anticipated to reach USD 902 million by 2030, at a CAGR of 8.5% during the forecast period.

This growth reflects the tightening of regulations on synthetic chemicals, a greater consumer appetite for residue-free food, and steady advances in enzyme formulation and delivery technologies. Commercial growers in mature markets are replacing a share of conventional inputs with enzyme-based biologicals, while smallholders in Asia-Pacific are moving toward yield-boosting biologicals supported by targeted subsidy programs. Parallel advances in precision fermentation and AI-driven protein design are reducing product-development cycles, while long-term carbon-credit programs are generating new revenue streams for farmers who deploy regenerative enzyme solutions. Competitive intensity is rising as agrochemical majors strengthen biological portfolios through partnerships and acquisitions, and specialized biotechnology firms race to commercialize next-generation multi-enzyme cocktails.

Global Agricultural Enzymes Market Trends and Insights

Organic and Residue-free Food Demand

Global spending on organic produce is climbing as retailers tighten residue thresholds, and the EU Farm to Fork Strategy mandates a 50% cut in chemical pesticide use by 2030. Farmers gain 20-30% price premiums in certified organic channels, offsetting the transition costs of adopting enzymes that mobilize nutrients without chemical residues. Enzyme-embedded programs help close yield gaps in organic systems by enhancing phosphorus and nitrogen availability, fortifying plant defense pathways, and improving soil microbiome balance. Commercial orchard operators in Spain reported a 9% yield uplift after switching from phosphate fertilizers to a blended phosphatase-urease granule in 2024, demonstrating clear economic returns. Similar outcomes are now driving uptake in greenhouse vegetables across Canada, where liquid cellulase blends shorten crop cycles by improving biomass breakdown between rotations.

Biological Input Adoption Surge

Brazil now applies biological crop-protection solutions on more than 60% of cultivated land, significantly ahead of adoption rates in the EU and USA. Mounting resistance to synthetic herbicides and fungicides is accelerating the search for new modes of action, positioning agricultural enzymes as synergistic companions to biocontrol microbes. Row-crop growers in Mato Grosso logged a 4.6% corn-on-corn yield gain in the 2024/25 season after integrating a seed-treatment cocktail containing lipase and mannanase enzymes. Similar momentum is unfolding in India, where state-level subsidy programs cover up to 30% of enzyme input costs, catalyzing smallholder adoption and fueling double-digit market growth.

Fragmented Regulatory Approvals

Biological input developers still navigate divergent approval timelines, with the EU requiring multiple dossiers depending on product classification. The new US Unified Website for Biotechnology Regulation improves domestic transparency, yet global harmonization remains distant.Delays add 18-24 months to average commercialization cycles, inflating compliance costs and prompting some firms to prioritize fewer, high-value markets. Smaller innovators struggle most, often partnering with larger agrochemical companies for regulatory support, which can limit independent go-to-market strategies.

Other drivers and restraints analyzed in the detailed report include:

- Intensified Research and Development, and Product Innovation

- Seed-coating Micro-dose Delivery

- Cold-chain Gaps in Tropical Regions

For complete list of drivers and restraints, kindly check the Table Of Contents.

Segment Analysis

Phosphatases captured 37% of the agricultural enzymes market in 2024 by unlocking immobilized soil phosphorus that otherwise reaches 80% of applied fertilizer. As fertilizer prices remain volatile, demand for phosphorus-mobilizing solutions stays strong across cereals and oilseeds. The agricultural enzymes market size for phosphatases is, therefore, set to maintain a dominant revenue position through 2030. Cellulases, propelled by CelOCE and related innovations, top the growth chart at a 13.8% CAGR. These enzymes deconstruct crop residues, releasing sugars that fuel beneficial microbes and improve soil structure. Ureases, lyases, and proteases round out the portfolio, with cocktail products increasingly combining complementary activities to match complex field conditions.

The shift toward multi-enzyme blends is pronounced in high-value horticulture, where growers demand precise nutrient mobilization and stress-response enhancement in one pass. Start-ups are developing on-farm fermentation kits that allow growers to brew fresh cellulase-rich mixes, avoiding shelf-life concerns and reducing costs. Larger players integrate phosphatase-urease synergies to improve nitrogen use efficiency and mitigate volatilization in paddy fields, reflecting a broadening solution set within the agricultural enzymes market.

Liquid products retained 46.2% of the agricultural enzymes market size in 2024, primarily due to their compatibility with existing spraying equipment and efficient foliar absorption. Yet logistics costs and cold-chain dependency are steering product managers toward more temperature-tolerant technologies. Granular products, advancing at 12.4% CAGR, now embed "bioreactor-in-a-granule" architectures that stabilize enzymes for up to 24 months while enabling timed release after soil contact.

Powder formulations occupy a cost-efficient middle ground, but require dedicated mixing equipment. Hybrid water-dispersible granules blur these lines, providing liquid-like convenience with granular durability. Expect competitive differentiation to hinge on formulation versatility, particularly for companies pursuing growth in the Asia-Pacific and African tropics where cold-chain gaps persist.

The Agricultural Enzymes Market is Segmented by Enzyme Type (Phosphatases and More), by Formulation (Liquid and More), by Application (Crop Protection and More), by Mode of Application (Seed Treatment and More), by Crop Type (Cereals and Grains, Oil Seeds and Pulses, and More), and by Geography (North America, Europe, Asia-Pacific, South America, Middle East, and Africa). The Market Forecasts are Provided in Terms of Value (USD).

Geography Analysis

North America, holding about 35% of the agricultural enzymes market in 2024, benefits from robust distribution infrastructure and rapid regulatory clearance for biological inputs. Canadian growers planted 11.8 million hectare of genetically engineered crops last season, creating a receptive environment for complementary enzyme programs. The US biostimulant segment is equally vibrant, with enzyme-infused foliar sprays gaining traction among almond and tomato producers.

Asia-Pacific is the fastest-growing region, on track for a 10% CAGR through 2030. India's BioAgri segment reached USD 12.4 billion in 2023, and state subsidies now cover up to 30% of enzyme costs, accelerating adoption among smallholders. Cold-chain gaps remain a material hurdle; 80% of the required capacity is still absent across India's dairy sector, prompting manufacturers to emphasize granular products. China's land-transfer reforms encourage larger farm units, improving the business case for enzyme technologies that can be applied at scale.

Europe retains a strong foothold thanks to stringent pesticide-reduction goals under the Green Deal. Biocontrol active substances climbed from 120 in 2011 to almost 220 in 2022, doubling revenue to EUR 1.549 billion in that period. South America, led by Brazil's trail-blazing 60% biological adoption, remains a mature yet expanding arena, particularly for enzyme-enhanced seed treatments in soy and corn. The Middle East and Africa show emerging promise, though growth hinges on regulatory clarity and cold-chain investment, with South Africa and the Gulf states spearheading early adoption.

- Novonesis

- Elemental Enzymes

- Enzyme Solutions Inc.

- Bioworks Inc.

- Infinita Biotech Pvt. Ltd.

- Biocatalysts Ltd

- Enzyme Development Corporation

Additional Benefits:

- The market estimate (ME) sheet in Excel format

- 3 months of analyst support

TABLE OF CONTENTS

1 Introduction

- 1.1 Study Assumptions and Market Definition

- 1.2 Scope of the Study

2 Research Methodology

3 Executive Summary

4 Market Landscape

- 4.1 Market Overview

- 4.2 Market Drivers

- 4.2.1 Organic and Residue-free Food Demand

- 4.2.2 Biological Input Adoption Surge

- 4.2.3 Intensified Research and Development, and Product Innovation

- 4.2.4 Seed-coating Micro-dose Delivery

- 4.2.5 Regenerative-Ag Carbon-Credit Programs

- 4.2.6 On-farm Enzyme Fermentation Units

- 4.3 Market Restraints

- 4.3.1 Fragmented Regulatory Approvals

- 4.3.2 Soil and Climate based Performance Variability

- 4.3.3 Cold-chain Gaps in Tropical Regions

- 4.3.4 Invisible Short-term ROI vs Chemicals

- 4.4 Regulatory Landscape

- 4.5 Technological Outlook

- 4.6 Porters Five Forces

- 4.6.1 Bargaining Power of Suppliers

- 4.6.2 Bargaining Power of Buyers

- 4.6.3 Threat of New Entrants

- 4.6.4 Threat of Substitutes

- 4.6.5 Intensity of Competitive Rivalry

5 Market Size and Growth Forecasts

- 5.1 By Enzyme Type

- 5.1.1 Phosphatases

- 5.1.2 Dehydrogenases

- 5.1.3 Ureases

- 5.1.4 Proteases

- 5.1.5 Lyases

- 5.1.6 Cellulases

- 5.1.7 Other Enzyme Types

- 5.2 By Formulation

- 5.2.1 Liquid

- 5.2.2 Powder

- 5.2.3 Granular

- 5.3 By Application

- 5.3.1 Crop Protection

- 5.3.2 Fertility Enhancement

- 5.3.3 Plant Growth Regulation

- 5.4 By Mode of Application

- 5.4.1 Seed Treatment

- 5.4.2 Foliar Spray

- 5.4.3 Soil Treatment

- 5.5 By Crop Type

- 5.5.1 Cereals and Grains

- 5.5.2 Oilseeds and Pulses

- 5.5.3 Fruits and Vegetables

- 5.5.4 Turf and Ornamentals

- 5.5.5 Other Crops

- 5.6 By Geography

- 5.6.1 North America

- 5.6.1.1 United States

- 5.6.1.2 Canada

- 5.6.1.3 Mexico

- 5.6.1.4 Rest of North America

- 5.6.2 Europe

- 5.6.2.1 Germany

- 5.6.2.2 United Kingdom

- 5.6.2.3 France

- 5.6.2.4 Italy

- 5.6.2.5 Spain

- 5.6.2.6 Russia

- 5.6.2.7 Rest of Europe

- 5.6.3 Asia-Pacific

- 5.6.3.1 China

- 5.6.3.2 Japan

- 5.6.3.3 India

- 5.6.3.4 Australia

- 5.6.3.5 Rest of Asia-Pacific

- 5.6.4 South America

- 5.6.4.1 Brazil

- 5.6.4.2 Argentina

- 5.6.4.3 Rest of South America

- 5.6.5 Middle East

- 5.6.5.1 Saudi Arabia

- 5.6.5.2 United Arab Emirates

- 5.6.5.3 Turkey

- 5.6.5.4 Rest of Middle East

- 5.6.6 Africa

- 5.6.6.1 South Africa

- 5.6.6.2 Kenya

- 5.6.6.3 Rest of Africa

- 5.6.1 North America

6 Competitive Landscape

- 6.1 Market Concentration

- 6.2 Strategic Moves

- 6.3 Market Share Analysis

- 6.4 Company Profiles (includes Global level Overview, Market level overview, Core Segments, Financials as available, Strategic Information, Market Rank/Share, Products and Services, Recent Developments)

- 6.4.1 Novonesis

- 6.4.2 Elemental Enzymes

- 6.4.3 Enzyme Solutions Inc.

- 6.4.4 Bioworks Inc.

- 6.4.5 Infinita Biotech Pvt. Ltd.

- 6.4.6 Biocatalysts Ltd

- 6.4.7 Enzyme Development Corporation