|

市場調查報告書

商品編碼

1844731

功能添加劑:市場佔有率分析、行業趨勢、統計數據和成長預測(2025-2030 年)Performance Additives - Market Share Analysis, Industry Trends & Statistics, Growth Forecasts (2025 - 2030) |

||||||

※ 本網頁內容可能與最新版本有所差異。詳細情況請與我們聯繫。

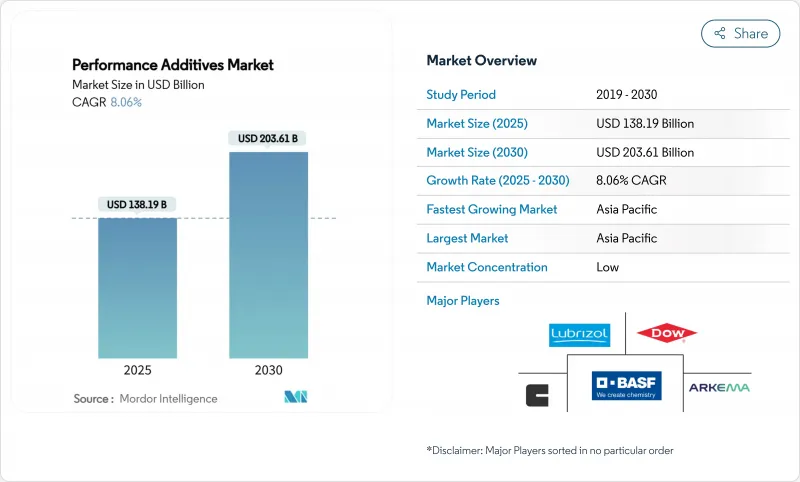

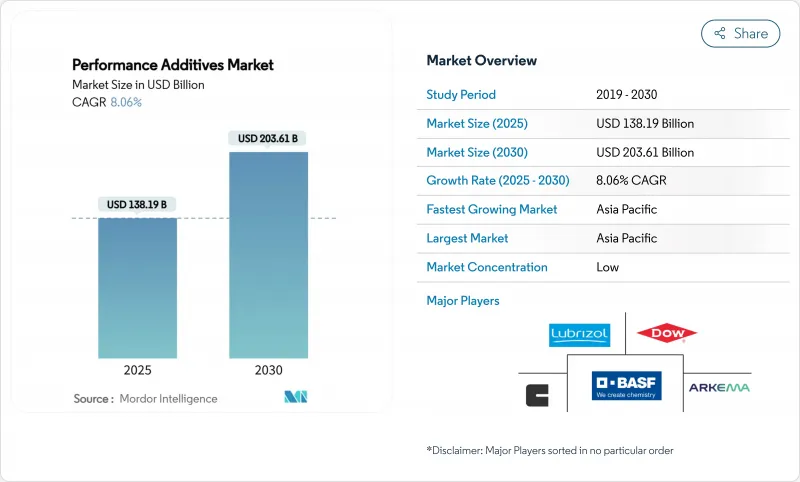

功能添加劑市場規模預計在 2025 年為 1,381.9 億美元,預計到 2030 年將達到 2,036.1 億美元,預測期內(2025-2030 年)的複合年成長率為 8.06%。

市場對用於提升塑膠、潤滑劑和塗料的耐久性、永續性和加工效率的特種化學品的需求強勁,推動著高性能添加劑市場呈現擴張態勢。成長的利多因素包括:汽車電氣化進程加快、全球向水性低VOC塗料的轉變,以及支持添加劑驅動的化學回收解決方案的循環經濟政策的加強。儘管原油衍生原料的不確定性導致短期成本壓力,但亞太地區的快速工業化仍在支撐產量和價值的成長,生產商也正在利用該地區的基礎設施項目。對阻燃性、紫外線穩定性和增強阻隔性能的需求不斷成長,進一步鞏固了高性能添加劑市場作為現代材料解決方案關鍵要素的地位。

全球功能添加劑市場趨勢與洞察

終端使用領域以塑膠取代傳統材料

在汽車、建築和消費品製造業中,對輕質、耐腐蝕且易於成型的塑膠的需求逐漸取代金屬、木材和玻璃。每種替代材料都需要熱穩定劑、紫外線吸收劑和阻燃劑,以在日益嚴苛的環境中保持性能。BASF用於高壓電動車零件的阻燃材料Ultramid聚鄰苯二甲醯胺展現了其先進的添加劑特性,使塑膠能夠承受-40°C至150°C的溫度波動,同時滿足嚴格的介電常數閾值。隨著塑膠逐漸滲透到引擎蓋下部件、車身外板和模組化建築部件中,對多功能添加劑包的產量需求也將相應增加,從而為功能性添加劑市場奠定長期成長的基礎。

新興經濟體塑膠需求快速成長

都市化、可支配收入的增加以及基礎設施項目的激增,正在推動亞太和非洲部分地區的塑膠消費。大型公路、鐵路和住房計劃需要地聚合物、管道和隔熱材料,而這些材料又依賴抗氧化劑、加工助劑和抗衝改質劑。在印度,隨著國內水泥產量以每年6-8%的速度成長,特種化學品製造商正在擴大產能,以滿足對建築添加劑的激增需求。東南亞的消費包裝產業也呈現類似的勢頭,刺激了高性能分散劑和增滑劑的進口。這些動態將鞏固新興地區在2030年之前作為高性能添加劑市場主要銷售驅動力的地位。

對一次性塑膠和有害物質的嚴格監管

監管部門禁止在食品接觸和包裝材料中使用某些添加劑,這促使配方師採取成本更高的配方調整和生態標籤。加州將於2027年禁止在食品包裝中使用四種傳統塑膠添加劑,這為其他司法管轄區樹立了榜樣。歐盟2025年食品接觸法規更新規定了嚴格的過渡限制,要求進行全面的產品組合審核。科萊恩等公司已於2023年12月完成從穩定劑中逐步淘汰PFAS的工作。雖然這些措施加強了環保合規性,但也會導致短期成本增加和資格認證延遲,從而削弱功能性添加劑市場的成長點。

細分分析

到2024年,塑膠添加劑將佔據功能性添加劑市場的43.15%,佔功能性添加劑市場總收益的大部分。到2030年,塑膠添加劑的複合年成長率將達到9.72%,這主要得益於電子產品更嚴格的可燃性法規以及電動車對抗紫外線、輕量化零件的需求。隨著加工商尋求在不犧牲強度的情況下減輕重量,先進的分散劑、抗氧化劑和無鹵阻燃劑的價格也隨之上漲。

在輪胎和輸送機製造領域,橡膠添加劑的產量保持穩定;而隨著出行方式轉向青睞輕質聚合物複合材料的電動車平台,塑膠添加劑的成長則有所滯後。由於水性塗料的轉型,油漆和塗料添加劑的需求有所成長,尤其是在除生物劑和流變控制劑組合中。

功能添加劑報告按添加劑類別(塑膠添加劑、橡膠添加劑、油漆和塗料添加劑、燃料添加劑等)、形式(固體/粉末、液體、母粒/顆粒、微膠囊)、最終用戶行業(包裝、汽車和運輸、建築和施工等)和地區(亞太地區、北美、歐洲、南美、中東和非洲)細分。

區域分析

預計到 2024 年,亞太地區將在功能添加劑市場佔據 47.12% 的主導佔有率,到 2030 年收益的複合年成長率將達到 8.84%。鐵路、公路和數位基礎設施的大量公共投資正在推動對建築級分散劑、高效塑化劑和防護被覆劑的需求。

受嚴格的燃油經濟性標準和對在地採購特種化學品日益成長的偏好推動,北美市場呈現緩慢但持續的成長態勢。汽車製造商和航太企業正利用與添加劑供應商的密切合作,以達到生命週期碳排放目標,並維持先進分散劑和潤滑調節劑的優質利潤率。

歐洲正面臨動盪的宏觀環境:能源成本壓力將在2024年抑制化學品生產,但氣候變遷和循環經濟的政策主導將促進新的添加劑需求。企業正在加速開發不含PFAS的阻燃劑和低遷移穩定劑,以符合歐盟化學品永續性策略。

中東和非洲雖然在高性能添加劑市場中仍佔較小佔有率,但其基礎設施被覆劑、管道樹脂和潤滑油基料添加劑的需求成長高於平均水準。碳氫化合物原料的供應推動了波灣合作理事會國家後後向整合添加劑生產線的擴張,而撒哈拉以南非洲地區都市化進程的加速則推動了對耐候塗料和包裝的需求。

其他福利:

- Excel 格式的市場預測 (ME) 表

- 3個月的分析師支持

目錄

第1章 引言

- 研究假設和市場定義

- 調查範圍

第2章調查方法

第3章執行摘要

第4章 市場狀況

- 市場概況

- 市場促進因素

- 終端使用領域以塑膠取代傳統材料

- 新興經濟體塑膠需求快速成長

- 全球範圍內更嚴格的燃油經濟性和排放法規推動了高性能潤滑油和燃料添加劑的發展

- 向水性和低VOC塗料的轉變將推動特種添加劑的採用

- 基於添加劑的化學回收和循環聚合物計劃將引領潮流

- 市場限制

- 對一次性塑膠和有害物質的嚴格監管

- 原油衍生原料價格波動

- 微塑膠立法針對包裝中的功能性添加劑

- 價值鏈分析

- 五力分析

- 供應商的議價能力

- 買方的議價能力

- 新進入者的威脅

- 替代品的威脅

- 競爭程度

第5章市場規模及成長預測

- 按添加劑類別

- 塑膠添加劑

- 潤滑劑

- 加工助劑(氟樹脂類)

- 流動改進劑

- 滑爽添加劑

- 抗靜電添加劑

- 顏料潤濕劑

- 填料分散劑

- 防霧添加劑

- 塑化劑

- 穩定劑

- 阻燃劑

- 抗衝擊改質劑

- 橡膠添加劑

- 加速器

- 抗分解劑

- 發泡和黏合劑

- 塗料添加劑

- 除生物劑

- 分散劑和潤濕劑

- 消泡劑和脫泡劑

- 流變改性劑

- 表面改質劑

- 穩定劑

- 流動和流平添加劑

- 其他塗料添加劑

- 燃料添加劑

- 存款控制

- 十六烷改良劑

- 潤滑性促進劑

- 抗氧化劑

- 防鏽劑

- 燃料染料

- 低溫操作改善劑

- 抗爆劑

- 其他燃料添加劑

- 油墨添加劑

- 流變改性劑

- 滑爽/摩擦劑

- 消泡劑

- 分散劑

- 抗氧化劑

- 螯合劑

- 其他油墨添加劑

- 皮革添加物

- 整理加工劑

- 脂肪液體

- 新灘

- 其他皮革添加劑

- 潤滑油添加劑

- 分散劑和乳化劑

- 黏度指數增進劑

- 清潔劑

- 腐蝕抑制劑

- 抗氧化劑

- 極壓添加劑

- 摩擦改進劑

- 其他潤滑油添加劑

- 黏合劑和密封劑添加劑

- 抗氧化劑

- 光穩定劑

- 增黏劑

- 其他添加物

- 塑膠添加劑

- 按形狀

- 固體/粉末

- 液體

- 母粒/顆粒

- 微膠囊化

- 按最終用戶產業

- 包裝

- 汽車和運輸

- 建築/施工

- 電氣和電子

- 工業機械

- 消費品

- 能源和電力(包括石油和天然氣)

- 其他最終用戶產業

- 按地區

- 亞太地區

- 中國

- 日本

- 印度

- 韓國

- 東南亞國協

- 其他亞太地區

- 北美洲

- 美國

- 加拿大

- 墨西哥

- 歐洲

- 德國

- 英國

- 法國

- 義大利

- 西班牙

- 俄羅斯

- 北歐國家

- 其他歐洲國家

- 南美洲

- 巴西

- 阿根廷

- 其他南美

- 中東和非洲

- 沙烏地阿拉伯

- 南非

- 其他中東和非洲地區

- 亞太地區

第6章 競爭態勢

- 市場集中度

- 策略舉措

- 市佔率(%)/排名分析

- 公司簡介

- Afton Chemical

- Akzo Nobel NV

- Albemarle Corporation

- Arkema

- Ashland

- Baerlocher GmbH

- BASF

- Chevron Oronite Company LLC

- Clariant

- Dow

- Eastman Chemical Company

- Evonik Industries AG

- Exxon Mobil Corporation

- Honeywell International Inc.

- Huntsman International LLC

- Lanxess

- Mitsui & Co.(Asia Pacific)Pte. Ltd.

- Performance Additives

- Songwon

- The Lubrizol Corporation

- Univar Solutions LLC

- WR Grace & Co

第7章 市場機會與未來展望

The Performance Additives Market size is estimated at USD 138.19 billion in 2025, and is expected to reach USD 203.61 billion by 2030, at a CAGR of 8.06% during the forecast period (2025-2030).

Strong demand for specialty chemicals that boost durability, sustainability, and processing efficiency across plastics, lubricants, and coatings keeps the performance additives market on an expansion track. Growth tailwinds include accelerating automotive electrification, the global pivot toward waterborne low-VOC coatings, and intensified circular-economy policies that elevate additive-enabled chemical recycling solutions. Producers are also capitalizing on infrastructure programs in Asia-Pacific, where rapid industrialization supports both volume and value growth despite short-term cost pressure from volatile crude-derived feedstocks. Heightened requirements for flammability resistance, UV stability, and enhanced barrier properties further anchor the performance additives market as an essential enabler of modern materials solutions.

Global Performance Additives Market Trends and Insights

Replacement of Conventional Materials by Plastics Across End-Use Sectors

Demand for light, corrosion-resistant, and easily formable plastics displaces metals, wood, and glass across automotive, construction, and consumer-goods manufacturing. Each substitution requires thermal stabilizers, UV absorbers, and flame retardants that preserve performance under harsher operating envelopes. BASF's flame-retardant Ultramid polyphthalamide for high-voltage electric-vehicle components illustrates how advanced additives permit plastics to withstand temperature swings from -40 °C to 150 °C while meeting stringent dielectric thresholds. As plastics penetrate under-the-hood parts, exterior body panels, and modular building components, volume requirements for multi-functional additive packages climb in tandem, anchoring a long-run growth vector for the performance additives market.

Rapid Plastics Demand Growth in Emerging Economies

Urbanization, rising disposable incomes, and pervasive infrastructure programs are accelerating plastics consumption in Asia-Pacific and parts of Africa. Large-scale highway, rail, and housing projects demand geosynthetics, pipes, and insulation that rely on antioxidants, processing aids, and impact modifiers. In India, specialty-chemical producers are adding capacity to meet surging demand for construction additives that align with national cement output growing 6 to 8% annually. Similar momentum in Southeast Asia's consumer-packaging sector is stimulating imports of high-performance dispersants and slip agents. These dynamics solidify emerging regions as the principal volume engine of the performance additives market through 2030.

Stringent Restrictions on Single-Use Plastics and Hazardous Substances

Regulatory bans on selected additives in food contact and packaging push formulators toward costlier reformulations and eco-labels. California's 2027 prohibition on four legacy plastic additives in food packaging establishes a template for other jurisdictions. The European Union's 2025 update to food-contact regulations imposes tighter migration limits that force comprehensive portfolio audits. Companies like Clariant completed a phased elimination of PFAS from stabilizer ranges by December 2023. While these moves enhance environmental compliance, they introduce short-term cost spikes and qualification delays that shave growth points from the performance additives market.

Other drivers and restraints analyzed in the detailed report include:

- Tightening Global Fuel-Economy and Emissions Norms

- Shift Toward Water-Borne and Low-VOC Coatings

- Volatile Crude-Derived Feedstock Prices

For complete list of drivers and restraints, kindly check the Table Of Contents.

Segment Analysis

Plastic additives commanded 43.15% of the performance additives market share in 2024, contributing the lion's share of revenue to the overall performance additives market. Their 9.72% CAGR through 2030 is propelled by dual imperatives: tighter flammability rules in electronics and the need for UV-stable lightweight parts in electric vehicles. Cutting-edge dispersants, antioxidants, and halogen-free flame retardants capture premium pricing as processors target weight savings without compromising strength.

Rubber additives uphold steady volumes in tire and conveyor-belt manufacturing, but growth lags plastics as mobility shifts to EV platforms that favor lightweight polymer composites. Paints and coatings additives enjoy a lift from waterborne migration, especially for biocide and rheology-control packages.

The Performance Additives Report is Segmented by Additive Category (Plastic Additives, Rubber Additives, Paints and Coatings Additives, Fuel Additives, and More), Form (Solid/Powder, Liquid, Masterbatch/Pellet, and Micro-Encapsulated), End-User Industry (Packaging, Automotive and Transportation, Building and Construction, and More), and Geography (Asia-Pacific, North America, Europe, South America, and Middle-East and Africa).

Geography Analysis

Asia-Pacific retained a commanding 47.12% share of the performance additives market in 2024 and is forecast to lift revenues at an 8.84% CAGR to 2030. High public spending on rail, highways, and digital infrastructure multiplies demand for construction-grade dispersants, superplasticizers, and protective coatings.

North America exhibits moderate yet durable expansion underpinned by stringent fuel-economy standards and a growing preference for locally sourced specialty chemicals. Auto OEMs and aerospace primes leverage close collaboration with additive suppliers to meet lifecycle-carbon targets, sustaining premium margins for advanced dispersants and lubricity modifiers.

Europe navigates mixed macro conditions: energy-cost pressures curtailed chemical output in 2024, but policy leadership on climate and circularity nurtures new additive demand. Companies fast-track PFAS-free flame retardants and low-migration stabilizers to comply with the EU Chemicals Strategy for Sustainability.

Middle East and Africa, while still representing a smaller slice of the performance additives market size, register above-average growth in additives for infrastructure coatings, pipe resins, and lubricant basestocks. Hydrocarbon feedstock availability positions Gulf Cooperation Council members to expand backward-integrated additive lines, while sub-Saharan Africa's urbanization lifts demand for weather-resistant paints and packaging.

- Afton Chemical

- Akzo Nobel N.V.

- Albemarle Corporation

- Arkema

- Ashland

- Baerlocher GmbH

- BASF

- Chevron Oronite Company LLC

- Clariant

- Dow

- Eastman Chemical Company

- Evonik Industries AG

- Exxon Mobil Corporation

- Honeywell International Inc.

- Huntsman International LLC

- Lanxess

- Mitsui & Co. (Asia Pacific) Pte. Ltd.

- Performance Additives

- Songwon

- The Lubrizol Corporation

- Univar Solutions LLC

- W. R. Grace & Co

Additional Benefits:

- The market estimate (ME) sheet in Excel format

- 3 months of analyst support

TABLE OF CONTENTS

1 Introduction

- 1.1 Study Assumptions and Market Definition

- 1.2 Scope of the Study

2 Research Methodology

3 Executive Summary

4 Market Landscape

- 4.1 Market Overview

- 4.2 Market Drivers

- 4.2.1 Replacement of Conventional Materials by Plastics Across End-Use Sectors

- 4.2.2 Rapid Plastics Demand Growth in Emerging Economies

- 4.2.3 Tightening Global Fuel-Economy and Emissions Norms Driving High-Performance Lubricant and Fuel Additives

- 4.2.4 Shift Toward Water-Borne and Low-VOC Coatings Boosts Specialty Additive Uptake

- 4.2.5 Additive-Enabled Chemical-Recycling and Circular-Polymer Initiatives Gain Traction

- 4.3 Market Restraints

- 4.3.1 Stringent Restrictions on Single-Use Plastics and Hazardous Substances

- 4.3.2 Volatile Crude-Derived Feedstock Prices

- 4.3.3 Pending Micro-Plastics Legislation Targeting Functional Additives in Packaging

- 4.4 Value Chain Analysis

- 4.5 Porter's Five Forces

- 4.5.1 Bargaining Power of Suppliers

- 4.5.2 Bargaining Power of Buyers

- 4.5.3 Threat of New Entrants

- 4.5.4 Threat of Substitutes

- 4.5.5 Degree of Competition

5 Market Size and Growth Forecasts (Value)

- 5.1 By Additive Category

- 5.1.1 Plastic Additives

- 5.1.1.1 Lubricants

- 5.1.1.2 Processing Aids (Fluoropolymer-based)

- 5.1.1.3 Flow Improvers

- 5.1.1.4 Slip Additives

- 5.1.1.5 Antistatic Additives

- 5.1.1.6 Pigment Wetting Agents

- 5.1.1.7 Filler Dispersants

- 5.1.1.8 Antifog Additives

- 5.1.1.9 Plasticizers

- 5.1.1.10 Stabilizers

- 5.1.1.11 Flame Retardants

- 5.1.1.12 Impact Modifiers

- 5.1.2 Rubber Additives

- 5.1.2.1 Accelerators

- 5.1.2.2 Antidegradants

- 5.1.2.3 Blowing and Adhesive Agents

- 5.1.3 Paints and Coatings Additives

- 5.1.3.1 Biocides

- 5.1.3.2 Dispersants and Wetting Agents

- 5.1.3.3 Defoamers and De-aerators

- 5.1.3.4 Rheology Modifiers

- 5.1.3.5 Surface Modifiers

- 5.1.3.6 Stabilizers

- 5.1.3.7 Flow and Leveling Additives

- 5.1.3.8 Other Paint and Coating Additives

- 5.1.4 Fuel Additives

- 5.1.4.1 Deposit Control

- 5.1.4.2 Cetane Improvers

- 5.1.4.3 Lubricity Improvers

- 5.1.4.4 Antioxidants

- 5.1.4.5 Anticorrosion

- 5.1.4.6 Fuel Dyes

- 5.1.4.7 Cold-Flow Improvers

- 5.1.4.8 Antiknock Agents

- 5.1.4.9 Other Fuel Additives

- 5.1.5 Ink Additives

- 5.1.5.1 Rheology Modifiers

- 5.1.5.2 Slip / Rub Agents

- 5.1.5.3 Defoamers

- 5.1.5.4 Dispersants

- 5.1.5.5 Antioxidants

- 5.1.5.6 Chelating Agents

- 5.1.5.7 Other Ink Additives

- 5.1.6 Leather Additives

- 5.1.6.1 Finishing Agents

- 5.1.6.2 Fat Liquors

- 5.1.6.3 Syntans

- 5.1.6.4 Other Leather Additives

- 5.1.7 Lubricant Additives

- 5.1.7.1 Dispersants and Emulsifiers

- 5.1.7.2 Viscosity-Index Improvers

- 5.1.7.3 Detergents

- 5.1.7.4 Corrosion Inhibitors

- 5.1.7.5 Oxidation Inhibitors

- 5.1.7.6 Extreme-Pressure Additives

- 5.1.7.7 Friction Modifiers

- 5.1.7.8 Other Lubricant Additives

- 5.1.8 Adhesives and Sealants Additives

- 5.1.8.1 Antioxidants

- 5.1.8.2 Light Stabilizers

- 5.1.8.3 Tackifiers

- 5.1.8.4 Other Additives

- 5.1.1 Plastic Additives

- 5.2 By Form

- 5.2.1 Solid / Powder

- 5.2.2 Liquid

- 5.2.3 Masterbatch / Pellet

- 5.2.4 Micro-encapsulated

- 5.3 By End-user Industry

- 5.3.1 Packaging

- 5.3.2 Automotive and Transportation

- 5.3.3 Building and Construction

- 5.3.4 Electrical and Electronics

- 5.3.5 Industrial Machinery

- 5.3.6 Consumer Goods

- 5.3.7 Energy and Power (incl. Oil and Gas)

- 5.3.8 Other End-user Industries

- 5.4 By Geography

- 5.4.1 Asia-Pacific

- 5.4.1.1 China

- 5.4.1.2 Japan

- 5.4.1.3 India

- 5.4.1.4 South Korea

- 5.4.1.5 ASEAN Countries

- 5.4.1.6 Rest of Asia-Pacific

- 5.4.2 North America

- 5.4.2.1 United States

- 5.4.2.2 Canada

- 5.4.2.3 Mexico

- 5.4.3 Europe

- 5.4.3.1 Germany

- 5.4.3.2 United Kingdom

- 5.4.3.3 France

- 5.4.3.4 Italy

- 5.4.3.5 Spain

- 5.4.3.6 Russia

- 5.4.3.7 NORDIC Countries

- 5.4.3.8 Rest of Europe

- 5.4.4 South America

- 5.4.4.1 Brazil

- 5.4.4.2 Argentina

- 5.4.4.3 Rest of South America

- 5.4.5 Middle-East and Africa

- 5.4.5.1 Saudi Arabia

- 5.4.5.2 South Africa

- 5.4.5.3 Rest of Middle-East and Africa

- 5.4.1 Asia-Pacific

6 Competitive Landscape

- 6.1 Market Concentration

- 6.2 Strategic Moves

- 6.3 Market Share (%)/Ranking Analysis

- 6.4 Company Profiles (includes Global level Overview, Market level overview, Core Segments, Financials as available, Strategic Information, Market Rank/Share, Products and Services, Recent Developments)

- 6.4.1 Afton Chemical

- 6.4.2 Akzo Nobel N.V.

- 6.4.3 Albemarle Corporation

- 6.4.4 Arkema

- 6.4.5 Ashland

- 6.4.6 Baerlocher GmbH

- 6.4.7 BASF

- 6.4.8 Chevron Oronite Company LLC

- 6.4.9 Clariant

- 6.4.10 Dow

- 6.4.11 Eastman Chemical Company

- 6.4.12 Evonik Industries AG

- 6.4.13 Exxon Mobil Corporation

- 6.4.14 Honeywell International Inc.

- 6.4.15 Huntsman International LLC

- 6.4.16 Lanxess

- 6.4.17 Mitsui & Co. (Asia Pacific) Pte. Ltd.

- 6.4.18 Performance Additives

- 6.4.19 Songwon

- 6.4.20 The Lubrizol Corporation

- 6.4.21 Univar Solutions LLC

- 6.4.22 W. R. Grace & Co

7 Market Opportunities and Future Outlook

- 7.1 White-space and Unmet-Need Assessment