|

市場調查報告書

商品編碼

1842478

汽車引擎封裝:市場佔有率分析、行業趨勢、統計數據和成長預測(2025-2030 年)Automotive Engine Encapsulation - Market Share Analysis, Industry Trends & Statistics, Growth Forecasts (2025 - 2030) |

||||||

※ 本網頁內容可能與最新版本有所差異。詳細情況請與我們聯繫。

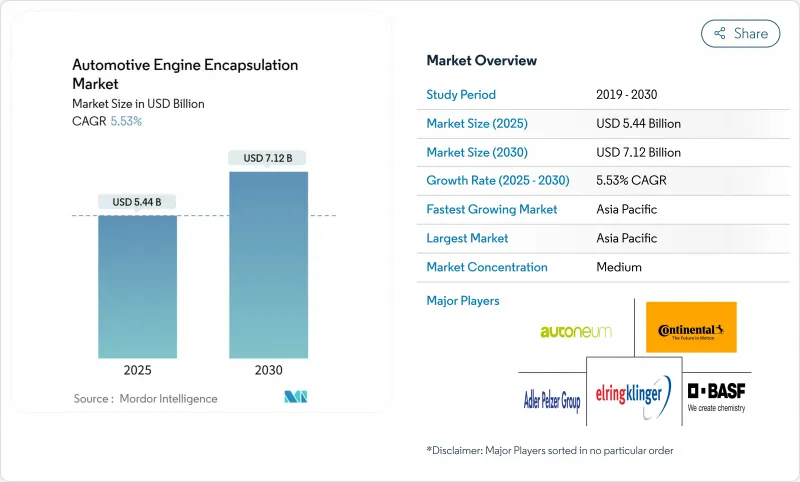

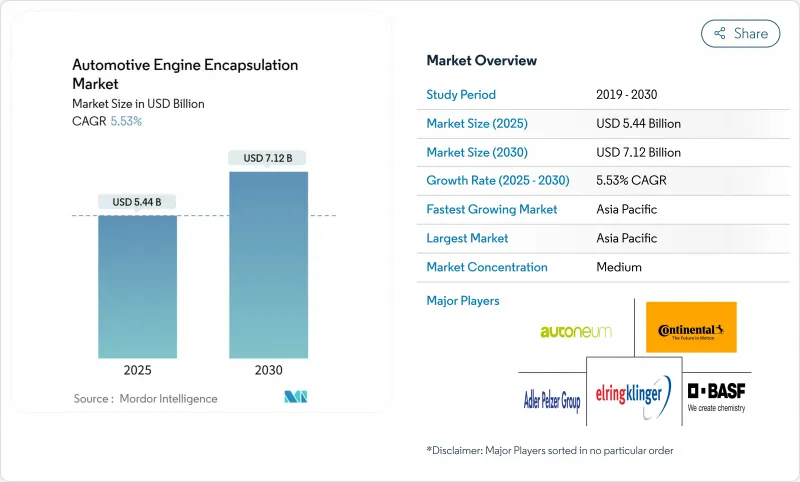

預計汽車引擎封裝市場規模到 2025 年將達到 54.4 億美元,到 2030 年將達到 71.2 億美元,複合年成長率高達 5.53%。

隨著歐7法規收緊冷啟動二氧化碳排放限值、高階品牌追求圖書館般安靜的座艙環境以及混合動力傳動系統對先進引擎蓋下熱控制的需求不斷成長,需求將加速成長。汽車製造商正在採用千兆乙太網路和數位雙胞胎設計環路,將結構、熱和聲學功能整合在一起,以減少零件數量並提高熱效率。材料策略正轉向可回收熱塑性塑膠以滿足循環經濟的要求,而碳纖維成本的下降也為中等產量車型提供了輕量化的選擇。隨著汽車引擎封裝市場從內燃機向電動轉型,供應商正在與電池熱專家合作,以彌合內燃機和電動車需求之間的差距。

全球汽車引擎封裝市場趨勢與洞察

歐7標準後冷啟動二氧化碳排放目標更加嚴格

歐盟7標準將於2026年11月在新車型上生效,屆時車輛續航里程將延長至20萬公里,對冷啟動排放的審查也將比以往任何時候都更加嚴格。汽車製造商現在需要能夠加快預熱速度並在-7°C至35°C環境溫度範圍內降低引擎噪音的封裝材料。這項要求推動了混合材料堆疊的發展,該堆疊將碳纖維結構與相變層相結合,以確保排放合規性,同時又不犧牲聲學性能。

奢侈品牌轉向安靜、圖書館般的 ICE 車廂

豪華品牌的目標是將怠速狀態下的車內噪音水平控制在40分貝以下,以體現電動車的靜謐性。多層氣凝膠封裝技術在維持隔熱性能的同時,實現了超過0.9的降噪係數。目前,該專案已從引擎延伸至變速箱通道,將整個動力傳動系統視為單一聲音來源,從而打造一體化解決方案。

純電動車動力傳動系統快速混合稀釋了內燃機車隊

預計到 2024 年,BEV 在歐洲新車註冊中的滲透率將達到 15.40%,到 2030 年將超過 50%。供應商將不得不將 ICE 項目下降的利潤重新投資到 EV熱感產品中,否則將面臨利潤率下降的情況。

細分分析

引擎封裝將在2024年引領汽車引擎封裝材料市場,佔51.71%的市場。這些模組直接安裝在動力裝置上,具有出色的隔振性能,可快速預熱並實現線邊安裝。車身安裝設計正以7.56%的複合年成長率加速成長,在大型車身底部應用的應用日益廣泛。

車身安裝式封裝將隔音屏障與結構構件整合,在密封引擎室的同時提高剛性。這種設計與 Gigacast 底盤完美契合,無需使用多個支架和緊固件。供應商必須研發出能夠承受晶粒熱循環且不發生分層的材料。因此,預計到 2030 年,車身安裝式汽車引擎封裝解決方案的市場規模將穩定成長。

2024年,汽油引擎將佔汽車引擎封裝材料市場規模的65.91%。汽油引擎封裝注重快速預熱和怠速時抑制噪音。

由於混合動力汽車和增程式車型將電池冷卻與燃燒隔熱相結合,電動動力傳動系統發展勢頭最為強勁,複合年成長率高達 7.87%。供應商正在設計雙用途屏障,以保護電池免受引擎熱峰值的影響,同時抑制逆變器的轟鳴聲。柴油引擎仍然適用於扭力驅動的用途,但由於複雜的後處理,柴油引擎面臨成本方面的挑戰。

區域分析

至2024年,亞太地區將以48.55%的市佔率引領汽車引擎封裝材料市場,複合年成長率達8.52%。中國佔據主導地位的原因在於其龐大的汽車產量以及政策主導的混合動力汽車,即使中國製定了以電動車為中心的發展藍圖,這也將延長內燃機汽車對封裝材料的需求。在印度,與生產相關的激勵措施鼓勵供應商在本地生產封裝,將成本競爭力與關稅優勢相結合。

歐洲則位居第二,因為歐盟7標準推動了先進的冷啟動排放解決方案,而混合動力汽車的普及則延長了內燃機汽車的適用性。碳纖維數位雙胞胎工具將首先在這裡成熟,然後推廣到全球,從而增強該地區的思想領袖。北美將因使用大型動力傳動系統的SUV和皮卡的銷售而實現強勁成長,這些車型需要堅固的隔熱隔音屏障。

中東、非洲和南美洲仍是新興市場。這些地區依賴進口和CKD組裝生產NVH套件,但隨著本地產能的增加,越來越多的供應商正在待開發區工廠。總體而言,汽車引擎封裝市場正在經歷區域整合,亞太地區在產能方面處於領先地位,而歐洲則引領全球規格趨勢。

其他福利:

- Excel 格式的市場預測 (ME) 表

- 3個月的分析師支持

目錄

第1章 引言

- 研究假設和市場定義

- 調查範圍

第2章調查方法

第3章執行摘要

第4章 市場狀況

- 市場概況

- 市場促進因素

- 歐7標準後冷啟動二氧化碳排放目標更加嚴格

- 轉向高階品牌ICE艙“圖書館安靜”

- 插電式混合動力汽車 (PHEV) 的電池預處理需求

- 輕量化碳纖維成本曲線彎曲。

- 擴大機身支架,配備 Gigacasting

- OEM 的數位雙胞胎最佳化了引擎蓋熱圖

- 市場限制

- 純電動車動力傳動系統快速混合稀釋了內燃機車隊

- 聚合物泡沫石化產品價格的波動;

- 多層NVH複合材料的可回收性有限

- 內燃機小型化引發引擎室封裝競爭

- 價值/供應鏈分析

- 監管狀況

- 技術展望

- 五力分析

- 新進入者的威脅

- 買家/消費者的議價能力

- 供應商的議價能力

- 替代品的威脅

- 競爭對手之間的競爭強度

第5章市場規模及成長預測(單位:美元)

- 依產品類型

- 引擎配備型

- 車身支架

- 按燃料類型

- 汽油

- 柴油引擎

- 電

- 按材質

- 碳纖維

- 聚氨酯

- 聚丙烯

- 聚醯胺

- 玻璃絨

- 按車輛類型

- 搭乘用車

- 輕型商用車

- 中大型商用車

- 按銷售管道

- 配備 OEM 的車輛

- 售後市場

- 按地區

- 北美洲

- 美國

- 加拿大

- 北美其他地區

- 南美洲

- 巴西

- 阿根廷

- 南美洲其他地區

- 歐洲

- 德國

- 英國

- 法國

- 義大利

- 西班牙

- 其他歐洲國家

- 亞太地區

- 中國

- 日本

- 印度

- 韓國

- 澳洲

- 紐西蘭

- 其他亞太地區

- 中東和非洲

- 沙烏地阿拉伯

- 阿拉伯聯合大公國

- 埃及

- 土耳其

- 南非

- 其他中東和非洲地區

- 北美洲

第6章 競爭態勢

- 市場集中度

- 策略舉措

- 市佔率分析

- 公司簡介

- Autoneum Holding AG

- Continental AG

- ElringKlinger AG

- BASF SE

- 3M Company

- Rochling Group

- Adler Pelzer Group

- Trocellen Automotive

- Woco Group

- SA Automotive

- Charlotte Baur Formschaumtechnik GmbH

- Sumitomo Riko Co. Ltd

- Sika Automotive

- Pritex Ltd

- UGN Inc.

- Langfang Sound(China)

第7章 市場機會與未來展望

The automotive engine encapsulation size market is valued at USD 5.44 billion in 2025 and is projected to reach USD 7.12 billion by 2030, reflecting a robust 5.53% CAGR.

Demand accelerates as Euro 7 regulations tighten cold-start CO2 limits, premium brands chase library-quiet cabins, and hybrid powertrains require sophisticated under-hood thermal control. Automakers adopt gigacasting and digital-twin design loops that merge structural, thermal, and acoustic functions, cutting component counts while boosting thermal efficiency. Material strategies pivot toward recyclable thermoplastics to meet circular-economy mandates, and carbon-fiber cost declines open lightweight options for mid-volume models. Suppliers form alliances with battery-thermal specialists to bridge ICE and EV requirements as the automotive engine encapsulation market navigates the combustion-to-electric transition.

Global Automotive Engine Encapsulation Market Trends and Insights

Stricter Post-Euro 7 Cold-Start CO2 Targets

Euro 7 takes effect for new vehicle types in November 2026 and extends compliance to 200,000 km, putting cold-start emissions under unprecedented scrutiny. Automakers now need encapsulation that accelerates warm-up times and dampens engine noise across ambient ranges from -7°C to 35°C. The requirement pushes hybrid material stacks that blend carbon-fiber structures with phase-change layers, securing emission compliance without sacrificing acoustics.

Premium-Brand Shift to Library-Quiet ICE Cabins

Luxury marques target idle cabin noise below 40 dB, mirroring silent EV experiences. Multi-layer encapsulation with aerogel barriers achieves noise reduction coefficients above 0.9 while sustaining thermal insulation. Programs now extend beyond engines to transmission tunnels, treating the full powertrain as one acoustic source for a unified solution.

Rapid BEV Power-Train Mix Diluting ICE Volume

BEV penetration in new car registration across Europe hit 15.40% in 2024 and is forecast to be above 50% by 2030, shrinking demand for ICE-specific encapsulation. Suppliers must reinvest profits from declining ICE programs into EV-thermal products or face margin erosion.

Other drivers and restraints analyzed in the detailed report include:

- Battery Pre-Conditioning Needs in PHEVs

- Lightweight Carbon-Fiber Cost Curve Inflection

- Petro-Chemical Price Volatility for Polymer Foams

For complete list of drivers and restraints, kindly check the Table Of Contents.

Segment Analysis

Engine-mounted encapsulations led the automotive engine encapsulation market with a 51.71% share in 2024. These modules excel at vibration isolation because they sit directly on the power unit, enabling rapid warm-up and line-side installation. Body-mounted designs are accelerating at 7.56% CAGR and increasingly cast into large underbody sections, supporting platform consolidation and lowering assembly time.

Body-mounted encapsulation integrates acoustic barriers with structural members, improving stiffness while sealing the engine bay. This format dovetails with gigacast underbodies that eliminate multiple brackets and fasteners. Suppliers must formulate materials that tolerate die-casting thermal cycles without delamination. Consequently, the automotive engine encapsulation market size for body-mounted solutions is projected to expand steadily through 2030.

Gasoline engines accounted for 65.91% automotive engine encapsulation market size in 2024, supported by their prevalence in global passenger fleets. Encapsulation for gasoline units emphasizes rapid warm-up and idle noise suppression.

Electric powertrains exhibit the briskest 7.87% CAGR because hybrids and range-extended models blend battery cooling with combustion insulation. Suppliers engineer dual-purpose barriers that protect cells from engine heat spikes while muting inverter whine. Diesel remains for torque-intensive use cases but faces cost headwinds due to after-treatment complexity.

The Automotive Engine Encapsulation Market Report is Segmented by Product Type (Engine-Mounted and Body-Mounted), Fuel Type (Gasoline, Diesel, and More), Material Type (Carbon Fiber, Polyurethane, and More), Vehicle Type (Passenger Cars, Light Commercial Vehicles, and More), Sales Channel (OEM-Fitted and Aftermarket), and Geography (North America, South America, and More). The Market Forecasts are Provided in Terms of Value (USD).

Geography Analysis

Asia-Pacific led the automotive engine encapsulation market with 48.55% share in 2024 and is advancing at 8.52% CAGR. China's dominance derives from vast vehicle output and policy-driven hybrid growth that prolongs ICE encapsulation demand even in an EV-centric roadmap. India's production-linked incentives lure suppliers to localize encapsulation, combining cost competitiveness with duty advantages.

Europe ranks second as Euro 7 catalyzes advanced solutions for cold-start emissions, plus widespread hybrid adoption that prolongs ICE relevance. Carbon-fiber and digital-twin tools mature here first, then migrate globally, reinforcing the region's thought leadership. North America grows steadily on the back of SUV and pickup sales that use larger powertrains, which need robust thermal-acoustic barriers.

The Middle East and Africa, and South America remain emerging pockets. They rely on imported NVH kits or CKD assembly, yet rising local output attracts suppliers establishing greenfield plants. Altogether, the automotive engine encapsulation market continues regional consolidation around APAC capacity while Europe drives specification trends embraced worldwide.

- Autoneum Holding AG

- Continental AG

- ElringKlinger AG

- BASF SE

- 3M Company

- Rochling Group

- Adler Pelzer Group

- Trocellen Automotive

- Woco Group

- SA Automotive

- Charlotte Baur Formschaumtechnik GmbH

- Sumitomo Riko Co. Ltd

- Sika Automotive

- Pritex Ltd

- UGN Inc.

- Langfang Sound (China)

Additional Benefits:

- The market estimate (ME) sheet in Excel format

- 3 months of analyst support

TABLE OF CONTENTS

1 Introduction

- 1.1 Study Assumptions & Market Definition

- 1.2 Scope of the Study

2 Research Methodology

3 Executive Summary

4 Market Landscape

- 4.1 Market Overview

- 4.2 Market Drivers

- 4.2.1 Stricter post-Euro 7 cold-start CO2 targets

- 4.2.2 Premium-brand shift to "library-quiet" ICE cabins

- 4.2.3 Battery pre-conditioning needs in PHEVs

- 4.2.4 Lightweight carbon-fiber cost curve inflection

- 4.2.5 Gigacasting enabling larger body-mounted encapsulations

- 4.2.6 OEM digital twins optimising under-hood thermal maps

- 4.3 Market Restraints

- 4.3.1 Rapid BEV power-train mix diluting ICE volumes

- 4.3.2 Petro-chemical price volatility for polymer foams

- 4.3.3 Limited recyclability of multi-layer NVH composites

- 4.3.4 Engine-bay packaging conflicts in downsized ICEs

- 4.4 Value / Supply-Chain Analysis

- 4.5 Regulatory Landscape

- 4.6 Technological Outlook

- 4.7 Porter's Five Forces

- 4.7.1 Threat of New Entrants

- 4.7.2 Bargaining Power of Buyers / Consumers

- 4.7.3 Bargaining Power of Suppliers

- 4.7.4 Threat of Substitute Products

- 4.7.5 Intensity of Competitive Rivalry

5 Market Size & Growth Forecasts (Value in USD)

- 5.1 By Product Type

- 5.1.1 Engine-Mounted

- 5.1.2 Body-Mounted

- 5.2 By Fuel Type

- 5.2.1 Gasoline

- 5.2.2 Diesel

- 5.2.3 Electric

- 5.3 By Material Type

- 5.3.1 Carbon Fiber

- 5.3.2 Polyurethane

- 5.3.3 Polypropylene

- 5.3.4 Polyamide

- 5.3.5 Glasswool

- 5.4 By Vehicle Type

- 5.4.1 Passenger Cars

- 5.4.2 Light Commercial Vehicles

- 5.4.3 Medium and Heavy Commercial Vehicles

- 5.5 By Sales Channel

- 5.5.1 OEM-Fitted

- 5.5.2 Aftermarket

- 5.6 Geography

- 5.6.1 North America

- 5.6.1.1 United States

- 5.6.1.2 Canada

- 5.6.1.3 Rest of North America

- 5.6.2 South America

- 5.6.2.1 Brazil

- 5.6.2.2 Argentina

- 5.6.2.3 Rest of South America

- 5.6.3 Europe

- 5.6.3.1 Germany

- 5.6.3.2 United Kingdom

- 5.6.3.3 France

- 5.6.3.4 Italy

- 5.6.3.5 Spain

- 5.6.3.6 Rest of Europe

- 5.6.4 Asia-Pacific

- 5.6.4.1 China

- 5.6.4.2 Japan

- 5.6.4.3 India

- 5.6.4.4 South Korea

- 5.6.4.5 Australia

- 5.6.4.6 New Zealand

- 5.6.4.7 Rest of Asia-Pacific

- 5.6.5 Middle East and Africa

- 5.6.5.1 Saudi Arabia

- 5.6.5.2 United Arab Emirates

- 5.6.5.3 Egypt

- 5.6.5.4 Turkey

- 5.6.5.5 South Africa

- 5.6.5.6 Rest of Middle East and Africa

- 5.6.1 North America

6 Competitive Landscape

- 6.1 Market Concentration

- 6.2 Strategic Moves

- 6.3 Market Share Analysis

- 6.4 Company Profiles (Includes Global Level Overview, Market Level Overview, Core Segments, Financials as Available, Strategic Information, Market Rank/Share for Key Companies, Products and Services, SWOT Analysis, and Recent Developments)

- 6.4.1 Autoneum Holding AG

- 6.4.2 Continental AG

- 6.4.3 ElringKlinger AG

- 6.4.4 BASF SE

- 6.4.5 3M Company

- 6.4.6 Rochling Group

- 6.4.7 Adler Pelzer Group

- 6.4.8 Trocellen Automotive

- 6.4.9 Woco Group

- 6.4.10 SA Automotive

- 6.4.11 Charlotte Baur Formschaumtechnik GmbH

- 6.4.12 Sumitomo Riko Co. Ltd

- 6.4.13 Sika Automotive

- 6.4.14 Pritex Ltd

- 6.4.15 UGN Inc.

- 6.4.16 Langfang Sound (China)

7 Market Opportunities & Future Outlook

- 7.1 White-space & Unmet-Need Assessment