|

市場調查報告書

商品編碼

1836725

纖維增強複合材料:市場佔有率分析、產業趨勢、統計數據和成長預測(2025-2030)Fiber Reinforced Composites - Market Share Analysis, Industry Trends & Statistics, Growth Forecasts (2025 - 2030) |

||||||

※ 本網頁內容可能與最新版本有所差異。詳細情況請與我們聯繫。

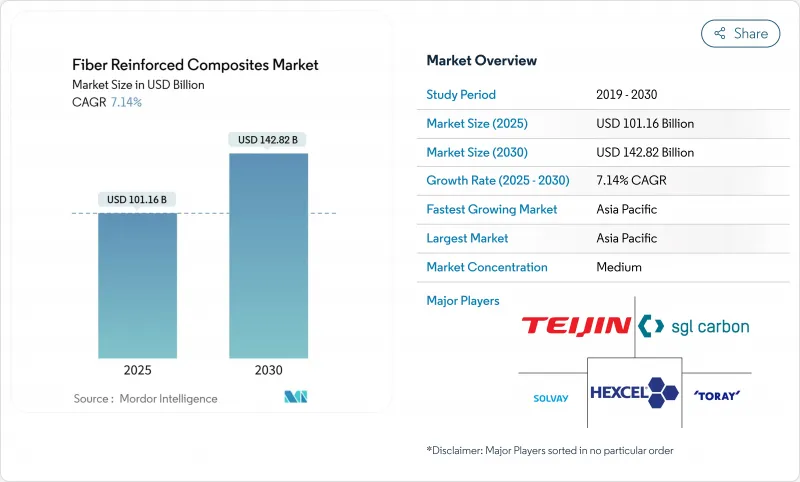

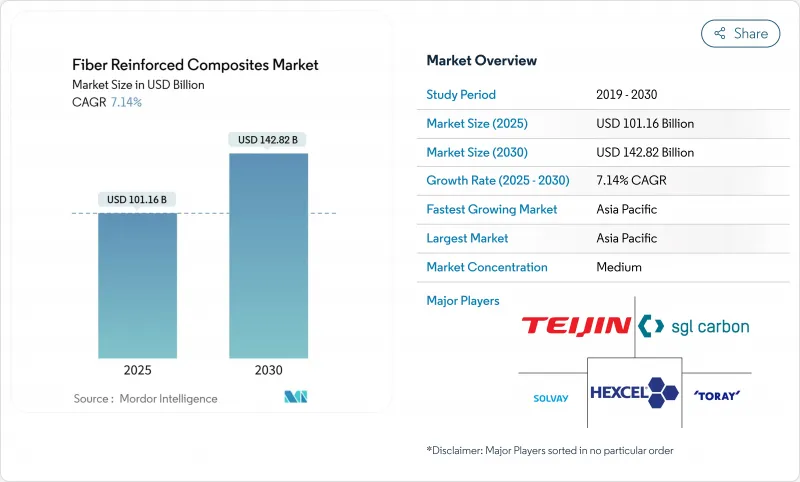

預計到 2025 年纖維增強複合材料市場規模將達到 1,011.6 億美元,到 2030 年將擴大到 1,428.1 億美元,複合年成長率為 7.14%。

航空項目,尤其是波音 787 和空中巴士 A350 等飛機平台,其超過 50% 的結構重量由複合材料構成,正在產生強勁的需求。汽車製造商尋求滿足企業平均燃油經濟性目標並延長電動車續航里程,正在加速採用輕質碳纖維層壓板;而風電行業對百米葉片的追求則進一步擴大了纖維增強複合材料市場。製程自動化增強了競爭力,自動化纖維鋪線則解決了勞動力短缺和一致性挑戰。按地區分類,受中國龐大製造能力的推動,亞太地區引領市場。然而,即使印度新興的航太生態系統不斷擴張,當地產能過剩的壓力依然存在。

全球纖維增強複合材料市場趨勢與洞察

航太複合材料的需求不斷成長

商業項目的目標是複合材料含量達到50%,以確保節省15-20%的燃油,而eVTOL設計將這一比例推得更高。由於寬體飛機的生產率,赫氏公司(Hexcel)的商用航太業務收入在2024年飆升了21.3%,但供應鏈的限制制約了近期的交付。美國太空總署(NASA)的HiCAM計畫旨在將熱固性和熱塑性機身的生產力提高一倍,這表明對結構的需求正在成長。用於液氫推進的全複合材料低溫儲槽的平行研發將為纖維增強複合材料市場引入一個新的細分市場。這些轉變相結合,使航太成為中期成長的催化劑。

風力發電機葉片長度增加

隨著葉片長度超過100米,碳纖維翼梁帽需要在不減輕重量的情況下保持剛性。美國大型自我調整轉子計劃清晰地展現了這一發展軌跡,其天然纖維和合成纖維的混合使用提高了生命週期的永續性。陶氏新型聚氨酯-碳纖維拉擠生產線實現了90%的線上固化,提高了大型層壓板的產量。預計2030年,全球產能將達到981吉瓦,但廢棄葉片的回收仍未解決,亟需循環經濟創新。

原料及加工成本高

曼徹斯特大學的木質素基前體預計將成本降低三到五倍。傳統的AFP系統成本在300萬至600萬美元之間,但模組化租賃模式的進入門檻較低。西格里碳素公司(SGL Carbon)纖維銷售額下降35.2%,顯示對商品價格波動的敏感度。再生碳纖維所需的能量要少得多,這使得它能夠在保持機械性能的同時釋放應力。

報告中分析的其他促進因素和限制因素

- 汽車輕量化

- 使用 FRP 鋼筋修復基礎設施

- 回收的困難

細分分析

2024 年,玻璃纖維以 61.87% 的佔有率佔據市場主導地位,這得益於建築、汽車和風力發電領域的成本效率和強大的供應鏈。碳纖維雖然所佔佔有率較小,但預計到 2030 年將以 8.04% 的複合年成長率成長,這主要得益於航太和高性能汽車行業不斷成長的需求。醯胺纖維以其抗衝擊性和熱穩定性而聞名,主要用於防護設備和航太零件。硼纖維雖然成本高,但用於專門的航太應用。透過結合合成纖維和天然纖維的混合複合材料,天然纖維的應用正在增加,在保持性能的同時提供環境效益。例如,竹子和劍麻纖維用於風力發電機葉片。

製造業的進步正在改變纖維生產的經濟性。 CARBOWAVE計劃引進了微波輔助碳纖維生產技術,預計將能耗降低高達70%,從而改變成本結構並減少環境影響。沙烏地阿拉伯正在建造首個工業規模的石墨烯增強碳纖維生產設施,目標是航太、汽車和建築應用,預計2030年收益將超過16億美元。玄武岩纖維正逐漸成為一種永續的替代品,與天然纖維複合材料相比,它具有更優異的機械性能和耐環境性。此外,玄武岩纖維相對於碳纖維的成本優勢使其非常適合需要在惡劣環境下保持耐用性的離岸風電應用。

到2024年,聚合物系統將佔總收益的70.45%,而金屬基質材料的複合年成長率預計將達到7.50%,這凸顯了纖維增強複合材料市場持續的重要性,尤其是在航太溫度控管應用領域。通用電氣公司開發的陶瓷基質複合材料可提高噴射引擎的工作溫度,使燃油效率提高高達20%。此外,碳-碳材料必須在2000°C下保持耐用,這對於暴露於高超音速再入和核融合反應器的零件至關重要。

聚碳酸酯、PEKK 和 PEEK 等快速循環熱塑性塑膠因其可回收性和一分鐘壓製成型能力而日益普及。科思創推出了針對家電產業的連續纖維聚碳酸酯面板。美國國家再生能源實驗室 (NREL) 也展示了一種生物基環氧樹脂,與石化基樹脂相比,該材料可減少 40% 的溫室氣體排放,同時保持生產成本效益。三菱化學還開發了一種陶瓷複合材料,可承受高達 1,500°C 的高溫,並符合日本宇宙航空研究開發機構 (JAXA) 的火箭規格,為國防和航太領域創造了新的商機。

區域分析

預計到2024年,亞太地區將佔總收入的41.05%,複合年成長率為8.38%。中國HRC公司正常熟投資3,380萬美元,擴大其熱固性和熱塑性樹脂的連續生產;印度Kineco Exel公司正在其果阿工廠向維斯塔斯供應拉擠碳纖維板;台灣上緯公司正在為海上計劃實現樹脂板的本地化供應,以深化其區域價值鏈。

北美正在利用其完善的航太基礎設施和燃油經濟性法規來維持需求。吉凱恩航空航太公司(GKN Aerospace)將其在墨西哥奇瓦瓦州的組裝能加倍,新增了200個工作崗位,以支持灣流和本田噴射機計畫。賽峰集團(Safran)擴大了在克雷塔羅的LEAP引擎產能,凸顯了墨西哥作為複合材料製造地的崛起。麻省理工學院的研究人員開發了奈米碳管“奈米縫合線”,可將層間剪切力提高62%,這意味著可以進一步減輕重量。

歐洲正在推動低碳材料回收和創新。 「清潔天空2號框架」計劃檢驗了氙氣閃光燈AFP加熱PEEK和PEKK機翼蒙皮的可行性,Strata和索爾維在阿拉伯聯合大公國艾因開設了中東和北非地區首家波音777X零件預浸料廠。預計到2024年,巴西複合材料銷售額將成長5.6%,達到5.6億美元,凸顯了南美洲的成長潛力。

其他福利:

- Excel 格式的市場預測 (ME) 表

- 3個月的分析師支持

目錄

第1章 引言

- 調查先決條件

- 調查範圍

第2章調查方法

第3章執行摘要

第4章 市場狀況

- 市場概況

- 市場促進因素

- 航太複合材料的需求不斷成長

- 風力發電機葉片尺寸不斷增大

- 汽車輕量化

- 使用 FRP 鋼筋進行基礎設施修復

- 快速積層法熱塑性UD膠帶生產線

- 碳捕獲衍生的丙烯腈原料

- 市場限制

- 原料及加工成本高

- 回收的困難

- 吸水和阻燃性差導致性能缺陷

- 價值鏈分析

- 五力分析

- 供應商的議價能力

- 買方的議價能力

- 新進入者的威脅

- 替代品的威脅

- 競爭程度

第5章 市場規模及成長預測(金額)

- 依纖維類型

- 碳纖維

- 玻璃纖維

- 醯胺纖維

- 硼纖維

- 其他纖維種類(玄武岩纖維、天然纖維等)

- 按基材

- 聚合物基複合材料

- 金屬基複合材料

- 陶瓷複合材料

- 碳-碳複合材料

- 混合複合材料

- 按製造程序

- 積層法(手/噴霧)

- 纏繞成型

- 拉擠成型

- 樹脂轉注成形

- 自動纖維鋪放和鋪帶

- 壓縮和射出成型

- 3D列印/積層製造

- 按最終用戶產業

- 航太/國防

- 車

- 風力發電

- 建築/施工

- 電氣和電子

- 體育用品

- 其他終端用戶產業(海洋、石油和天然氣等)

- 按地區(金額)

- 亞太地區

- 中國

- 日本

- 印度

- 韓國

- 東南亞國協

- 其他亞太地區

- 北美洲

- 美國

- 加拿大

- 墨西哥

- 歐洲

- 德國

- 英國

- 法國

- 義大利

- 其他歐洲國家

- 南美洲

- 巴西

- 阿根廷

- 其他南美

- 中東

- 沙烏地阿拉伯

- 南非

- 中東和非洲

- 亞太地區

第6章 競爭態勢

- 市場集中度

- 策略趨勢

- 市佔率(%)/排名分析

- 公司簡介

- Avient Corporation

- Covestro AG

- Hexcel Corporation

- Huntsman Corporation

- Mitsubishi Chemical Corporation

- Owens Corning

- Plasan

- SABIC

- SGL Carbon

- Solvay

- Teijin Limited

- Toray Industries Inc.

- TPI Composites

第7章 市場機會與未來展望

The fiber reinforced composites market reached USD 101.16 billion in 2025 and is projected to advance to USD 142.81 billion by 2030, registering a 7.14% CAGR.

Robust demand originates from aviation programmes that allocate more than 50% of structural weight to composites, notably the Boeing 787 and Airbus A350 platforms. Automakers pursuing Corporate Average Fuel Economy compliance and electric-vehicle range gains accelerate adoption of lightweight carbon laminates, while the wind sector's push toward 100-meter blades further enlarges the fiber reinforced composites market. Process automation deepens competitiveness, with automated fiber placement lines resolving labour shortages and consistency challenges. Regionally, Asia-Pacific leads on the back of China's large-scale manufacturing capacity, although local overcapacity pressures linger even as India's nascent aerospace ecosystem scales.

Global Fiber Reinforced Composites Market Trends and Insights

Growing Aerospace Composite Demand

Commercial programmes target 50% composite content to secure 15-20% fuel-burn reductions, and eVTOL designs push that ratio even higher. Hexcel's commercial aerospace revenue jumped 21.3% in 2024 on wide-body build rates, yet supply chain tightness tempers near-term deliveries. NASA's HiCAM effort aims to multiply output rates for thermoset and thermoplastic fuselages, signaling a structural demand uplift. Parallel R&D on fully composite cryogenic tanks for liquid-hydrogen propulsion opens new sub-segments for the fiber reinforced composites market. Together, these shifts cement aerospace as a medium-term growth catalyst.

Wind-Turbine Blade Length Upsizing

Blade lengths now exceed 100 meters, demanding carbon spar caps to retain stiffness without weight penalties. The U.S. Big Adaptive Rotor project underscores this trajectory, while hybrid natural-synthetic fibre blends improve lifecycle sustainability. New polyurethane-carbon pultrusion lines from Dow achieve 90% in-line cure, boosting throughput for oversized laminates. Global capacity is forecast to reach 981 GW by 2030, yet recycling end-of-life blades remains unresolved, inviting circular-economy innovation.

High Raw-Material & Processing Costs

Energy-intensive carbonisation drives elevated input costs, although lignin-based precursors from the University of Manchester suggest 3-5 X savings potential. Traditional AFP systems list at USD 3-6 million, but modular leasing models lower the entry barrier. SGL Carbon's 35.2% sales drop in fiber units shows sensitivity to volatile commodity pricing. Recycled carbon fibre, requiring far less energy, can relieve some pressure while preserving mechanical properties.

Other drivers and restraints analyzed in the detailed report include:

- Automotive Lightweighting Mandates

- Infrastructure Rehab with FRP Rebar

- Difficulties in Recycling

For complete list of drivers and restraints, kindly check the Table Of Contents.

Segment Analysis

In 2024, glass fibers dominated the market with a 61.87% share, driven by cost efficiencies and robust supply chains in the construction, automotive, and wind energy sectors. While holding a smaller share, carbon fibers are projected to grow at a CAGR of 8.04% through 2030, supported by increasing demand in the aerospace and high-performance automotive industries. Aramid fibers, known for their impact resistance and thermal stability, are primarily used in protective equipment and aerospace components. Despite their higher costs, Boron fibers are utilized in specialized aerospace applications. The adoption of natural fibers is increasing through hybrid composites that combine synthetic and natural fibers, offering environmental benefits while maintaining performance. For example, bamboo and sisal fibers are used in wind turbine blades.

Advancements in manufacturing are transforming fiber production economics. The CARBOWAVE project has introduced microwave-assisted carbon fiber production, reducing energy consumption by up to 70%, potentially altering cost structures and environmental impacts. Saudi Arabia has established the first industrial-scale facility for graphene-enriched carbon fiber production, targeting aerospace, automotive, and construction applications, with projected revenues exceeding USD 1.6 billion by 2030. Basalt fibers are emerging as a sustainable alternative, offering superior mechanical properties and environmental resistance compared to natural fiber composites. Additionally, their cost advantages over carbon fibers make them suitable for offshore wind applications requiring durability in harsh environments.

In 2024, polymer systems accounted for 70.45% of the revenue, while metal matrix options are projected to achieve a 7.50% CAGR, highlighting their sustained importance in the fiber-reinforced composites market, particularly for aerospace thermal-management applications. Ceramic matrix composites developed by GE enhance jet engine operating temperatures, improving fuel efficiency by up to 20%. Additionally, carbon-carbon materials are critical for components exposed to hypersonic re-entry and fusion reactors, where endurance at 2,000 °C is essential.

Rapid-cycle thermoplastics, such as polycarbonate, PEKK, and PEEK, are gaining traction due to their recyclability and capability for one-minute press molding. Covestro has introduced continuous-fiber polycarbonate panels targeting the consumer electronics sector. Furthermore, NREL has demonstrated a bio-based epoxy that reduces greenhouse gas emissions by 40% compared to petrochemical-based resins while maintaining production cost efficiency. Mitsubishi Chemical has also developed a ceramic composite capable of withstanding temperatures of 1,500 °C, meeting JAXA specifications for launch vehicles and creating new revenue opportunities in the defense and space sectors.

The Fiber Reinforced Composites Market Report Segments the Industry by Fiber Type (Carbon Fibers, Glass Fibers and More), Matrix (Polymer Matrix Composites, Metal Matrix Composites, and More), Manufacturing Process (Pultrusion, Filament Winding, and More), End-User Industry (Aerospace and Defense, Automotive, and More) and Geography (Asia-Pacific, North America, and More). The Market Forecasts are Provided in Terms of Value (USD).

Geography Analysis

Asia-Pacific generated 41.05% of 2024 sales and is set to post an 8.38% CAGR, ensuring that the fiber reinforced composites market remains anchored in the region. China's HRC invested USD 33.8 million in Changshu to expand serial thermoset and thermoplastic part output, while India's Kineco Exel now supplies pultruded carbon planks to Vestas from its Goa site. Taiwan's Swancor has localised resin plate supply for offshore projects, deepening the regional value chain.

North America leverages an entrenched aerospace base and fuel-economy regulation to maintain demand. GKN Aerospace doubled assembly capacity in Chihuahua, Mexico, adding 200 jobs to serve Gulfstream and HondaJet programmes. Safran expanded LEAP engine capacity in Queretaro, underscoring Mexico's rise as a composites manufacturing node. MIT researchers developed "nanostitching" with carbon nanotubes, lifting interlaminar shear by 62% and hinting at further light-weighting gains.

Europe champions recycling mandates and low-carbon material innovation. The Clean Sky 2 FRAMES project validated xenon flashlamp AFP heating for PEEK and PEKK wingskins, while Strata and Solvay opened the first MENA prepreg plant for Boeing 777X parts in Al Ain, UAE. Brazil's composites turnover rose 5.6% to USD 560 million in 2024, pointing to latent growth potential across South America.

- Avient Corporation

- Covestro AG

- Hexcel Corporation

- Huntsman Corporation

- Mitsubishi Chemical Corporation

- Owens Corning

- Plasan

- SABIC

- SGL Carbon

- Solvay

- Teijin Limited

- Toray Industries Inc.

- TPI Composites

Additional Benefits:

- The market estimate (ME) sheet in Excel format

- 3 months of analyst support

TABLE OF CONTENTS

1 Introduction

- 1.1 Study Assumptions

- 1.2 Scope of the Study

2 Research Methodology

3 Executive Summary

4 Market Landscape

- 4.1 Market Overview

- 4.2 Market Drivers

- 4.2.1 Growing aerospace composite demand

- 4.2.2 Wind-turbine blade length upsizing

- 4.2.3 Automotive lightweighting mandates

- 4.2.4 Infrastructure rehab with FRP rebar

- 4.2.5 Rapid-layup thermoplastic UD tape lines

- 4.2.6 Carbon-capture derived acrylonitrile feedstock

- 4.3 Market Restraints

- 4.3.1 High raw-material & processing costs

- 4.3.2 Difficulties in Recycling

- 4.3.3 Performance defects due to wate absorption and low fire resistance

- 4.4 Value Chain Analysis

- 4.5 Porter's Five Forces

- 4.5.1 Bargaining Power of Suppliers

- 4.5.2 Bargaining Power of Buyers

- 4.5.3 Threat of New Entrants

- 4.5.4 Threat of Substitutes

- 4.5.5 Degree of Competition

5 Market Size & Growth Forecasts (Value)

- 5.1 By Fiber Type

- 5.1.1 Carbon Fibers

- 5.1.2 Glass Fibers

- 5.1.3 Aramid Fibers

- 5.1.4 Boron Fibers

- 5.1.5 Other Fiber Types (Basalt Fibers, Natural Fibers, etc.)

- 5.2 By Matrix

- 5.2.1 Polymer Matrix Composites

- 5.2.2 Metal Matrix Composites

- 5.2.3 Ceramic Composites

- 5.2.4 Carbon-Carbon Composites

- 5.2.5 Hybrid Composites

- 5.3 By Manufacturing Process

- 5.3.1 Lay-Up (Hand/Spray)

- 5.3.2 Filament Winding

- 5.3.3 Pultrusion

- 5.3.4 Resin Transfer Molding

- 5.3.5 Automated Fiber Placement & Tape Laying

- 5.3.6 Compression & Injection Molding

- 5.3.7 3D Printing / Additive Manufacturing

- 5.4 By End-user Industry

- 5.4.1 Aerospace & Defense

- 5.4.2 Automotive

- 5.4.3 Wind Energy

- 5.4.4 Building & Construction

- 5.4.5 Electrical & Electronics

- 5.4.6 Sporting Goods

- 5.4.7 Other End-user Industries (Marine, Oil and Gas, etc.)

- 5.5 By Geography (Value)

- 5.5.1 Asia-Pacific

- 5.5.1.1 China

- 5.5.1.2 Japan

- 5.5.1.3 India

- 5.5.1.4 South Korea

- 5.5.1.5 ASEAN Countries

- 5.5.1.6 Rest of Asia-Pacific

- 5.5.2 North America

- 5.5.2.1 United States

- 5.5.2.2 Canada

- 5.5.2.3 Mexico

- 5.5.3 Europe

- 5.5.3.1 Germany

- 5.5.3.2 United Kingdom

- 5.5.3.3 France

- 5.5.3.4 Italy

- 5.5.3.5 Rest of Europe

- 5.5.4 South America

- 5.5.4.1 Brazil

- 5.5.4.2 Argentina

- 5.5.4.3 Rest of South America

- 5.5.5 Middle East

- 5.5.5.1 Saudi Arabia

- 5.5.5.2 South Africa

- 5.5.5.3 Middle-East and Africa

- 5.5.1 Asia-Pacific

6 Competitive Landscape

- 6.1 Market Concentration

- 6.2 Strategic Moves

- 6.3 Market Share(%)/Ranking Analysis

- 6.4 Company Profiles (includes Global level Overview, Market level overview, Core Segments, Financials as available, Strategic Information, Market Rank/Share for key companies, Products & Services, and Recent Developments)

- 6.4.1 Avient Corporation

- 6.4.2 Covestro AG

- 6.4.3 Hexcel Corporation

- 6.4.4 Huntsman Corporation

- 6.4.5 Mitsubishi Chemical Corporation

- 6.4.6 Owens Corning

- 6.4.7 Plasan

- 6.4.8 SABIC

- 6.4.9 SGL Carbon

- 6.4.10 Solvay

- 6.4.11 Teijin Limited

- 6.4.12 Toray Industries Inc.

- 6.4.13 TPI Composites

7 Market Opportunities & Future Outlook

- 7.1 White-space & Unmet-need Assessment

- 7.2 Growing Innovation on Bio-based Resin Systems