|

市場調查報告書

商品編碼

1835660

水性膠合劑:市場佔有率分析、產業趨勢、統計數據和成長預測(2025-2030 年)Water-borne Adhesives - Market Share Analysis, Industry Trends & Statistics, Growth Forecasts (2025 - 2030) |

||||||

※ 本網頁內容可能與最新版本有所差異。詳細情況請與我們聯繫。

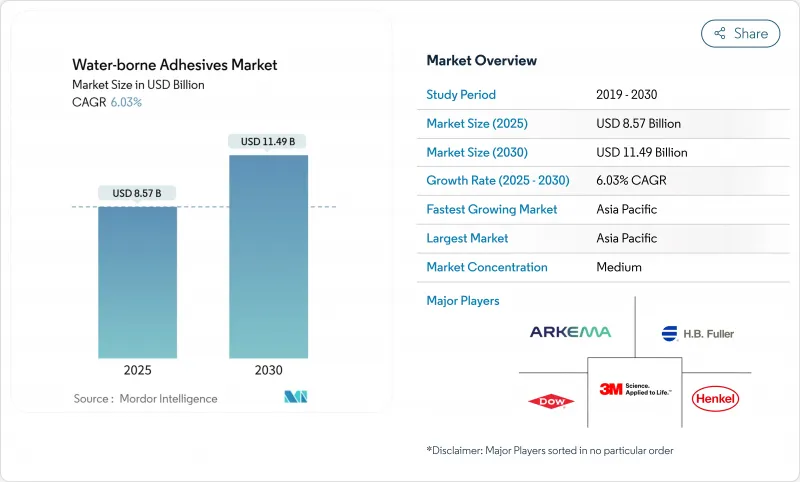

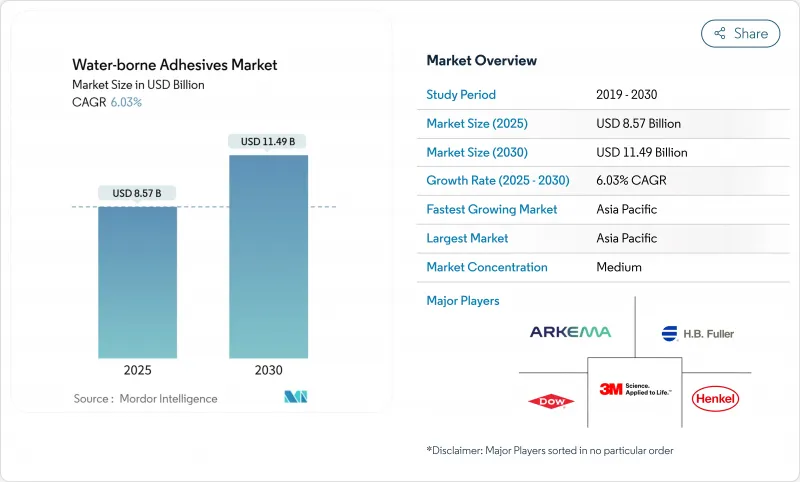

預計 2025 年水性黏合劑市場價值將達到 85.7 億美元,到 2030 年預計將達到 114.9 億美元,預測期內(2025-2030 年)的複合年成長率為 6.03%。

隨著製造商加速從溶劑型化學品向水性化學品的轉型,以應對日益嚴格的全球揮發性有機化合物 (VOC) 法規並滿足品牌商的永續性目標,水性黏合劑市場正在蓬勃發展。電子商務包裝、汽車輕量化和模組化建築的快速發展進一步推動了這一成長勢頭,這些領域都需要高性能、低排放的黏合劑系統。監管趨同,尤其是《歐洲揮發性有機化合物排放指令》和《永續產品生態設計》法規,實際上賦予了水性化學品經營許可,促使跨國公司重組其產品組合,同時也為新興市場提供了技術轉移機會。

全球水性膠合劑市場趨勢與洞察

電商主導北美瓦楞紙箱熱潮

線上零售額的爆炸性成長導致瓦楞紙托運商每美元使用的黏合劑比傳統零售商多七倍。品牌商正在收緊「自有貨櫃運輸」要求,促使加工商採用快速固化水性膠合劑,例如HB Fuller的Advantra系列,該系列膠合劑能夠承受多節點物流,同時符合路邊回收指南。自動化封箱生產線進一步推動了對清潔、低黏度配方的需求,這些配方與高速施用器相容。這些因素共同提振了水性膠合劑市場,因為加工商指定使用符合環保要求的化學品,以確保與全通路零售商達成交易。

歐洲VOC減量要求加速溶劑型塗料向水型塗料的轉變

由於歐盟《揮發性排放(VOC)溶劑排放指令》嚴格限制工業排放,水性系統已成為汽車內裝、地板材料和建築幕牆板的標準。在最近的歐洲塗料展上,一種生物基聚氨酯分散體得到了展示,其剪切強度相當於或優於溶劑基替代品。阿科瑪推出了一款用於低碳包裝的丙烯酸水性黏合劑,工業級銷量成長了5.1%。

熱阻差距限制了其在高溫應用領域的滲透

持續暴露在150°C以上的高溫下,對大多數水性網路構成挑戰。雖然3M的Fastbond 1000NF代表了其在提供經GREENGUARD認證、能夠承受週期性峰值的黏接方面取得的進步,但重型引擎、烤箱面板和引擎蓋內襯仍然主要採用溶劑型體系。彌補這一熱Delta需要新型有機矽混合晶格,目前該技術正處於研發的早期階段。

報告中分析的其他促進因素和限制因素

- 東協模組化建築推動PVA需求激增

- 輕量化汽車黏合促進了亞洲聚氨酯分散體的發展。

- 更高的初始成本和投資

細分分析

丙烯酸乳液憑藉其多功能性和低成本,預計銷售量,但由於其高剝離強度和柔韌性,以及在鋰離子電池組和殺菌袋層壓板中的重要特性,預計其複合年成長率將達到6.55%。

由於丙烯和丙烯酸原料價格波動,丙烯酸嵌段面臨利潤壓力,迫使供應商整合生物丙烯酸酯製程路線和產品線。氯丁二烯分散體和利基混合材料在金屬家具、鞋類和採礦帶等需要耐油性的應用領域仍然產量受限。整體而言,能夠平衡價格敏感型丙烯酸和高價值聚氨酯產品的改質材料生產商將實現多層次的成長。

受全通路零售向袋裝、小袋和郵寄袋轉變的推動,到2024年,軟質包裝將佔水性膠合劑市場規模的40%。然而,由於品牌商尋求結合PET、氧化鋁和生物基PLA薄膜的高阻隔設計,多層複合膠合劑是成長最快的細分市場,複合年成長率高達7.23%。水性雙組分系統目前的黏合強度超過65N/15mm,可與溶劑型聚氨酯領先相媲美,同時確保符合食品接觸要求。

膠帶、標籤和印刷品供應鏈正在採用基於分散體的壓敏膠,以實現快速自動化應用,且無需拉線。書籍裝訂和紙張加工應用正在採用新型醋酸乙烯酯-乙烯共聚物提供的低能耗熱固化循環。電子商務的蓬勃發展正在推動對即時黏性、防撕裂瓦楞紙箱黏合劑的需求成長。

水性膠合劑市場報告按樹脂類型(例如丙烯酸、聚醋酸乙烯酯乳液)、應用領域(例如軟包裝、膠帶和標籤)、終端用戶行業(例如建築施工、紙張和紙板)、基材(例如紙張和紙板、金屬)以及地區(例如亞太地區、北美)對行業進行了細分。市場預測以美元計算。

區域分析

到2024年,亞太地區的銷售額將領先全球40%,這得益於其無與倫比的製造業深度、強勁的建築產品線以及電動車生產的加速發展。中國二線城市將推動面板膠合劑的普及,而印度的基礎建設將支撐銷售成長。該地區6.89%的複合年成長率也受到日本和韓國法規收緊的推動,這些法規透過稅收減免和綠色採購清單鼓勵使用無溶劑膠粘劑。

北美則位居第二,受電商包裝和汽車輕量化的推動。美國持續要求降低消費品的揮發性有機化合物(VOC)限值,擴大了水性膠合劑市場;而加拿大的能源效率法規則刺激了住宅維修隔熱材料的採用。墨西哥的加工出口走廊擴大指定使用水性配方,以滿足原始設備製造商(OEM)的出口要求。

歐洲正透過嚴格的指令發揮重要的技術影響力。德國汽車內裝、法國軟質食品包裝和英國木質房屋產業都在推動歐洲大陸的需求。在歐盟凝聚基金的支持下,東歐加工商正在升級到分散生產線,溶劑佔有率的下降速度比最初預期的要快。

南美市場前景看好,巴西建設業復甦,相關企業對包裝的需求也推動了漢高在雲迪亞伊的新創新中心的建設,推動了需求的溫和成長。阿根廷市場需求保持穩定,儘管規模較小,但專注於軟性食品包裝。沙烏地阿拉伯的計劃和南非的零售物流開始指定使用水性塗料以滿足進口標準。

其他福利:

- Excel 格式的市場預測 (ME) 表

- 3個月的分析師支持

目錄

第1章 引言

- 研究假設和市場定義

- 調查範圍

第2章調查方法

第3章執行摘要

第4章 市場狀況

- 市場概況

- 市場促進因素

- 電商主導北美瓦楞紙箱熱潮

- 歐洲VOC減量指令加速溶劑向水的轉化

- 東協模組化建築推動PVA需求快速成長

- 亞洲輕量化汽車膠合劑市場受益於聚氨酯分散體

- 新興市場監管趨嚴

- 市場限制

- 熱阻差距限制了其在高溫應用領域的滲透

- 在高階應用的使用有限

- 初始成本和投資高

- 價值鏈分析

- 波特五力分析

- 供應商的議價能力

- 買方的議價能力

- 新進入者的威脅

- 替代品的威脅

- 競爭對手之間的競爭

第5章市場規模及成長預測

- 依樹脂類型

- 丙烯酸纖維

- 聚醋酸乙烯酯(PVA)乳液

- 乙烯醋酸乙烯酯(EVA)乳液

- 聚氨酯分散體和CR(氯丁橡膠)乳膠

- 其他樹脂類型

- 按用途

- 軟包裝

- 膠帶標籤

- 紙張加工與印刷藝術

- 層壓板和薄膜結構

- 地板和地毯

- 書籍裝訂和出版

- 不織布和衛生用品

- 其他

- 按最終用戶產業

- 建築/施工

- 紙、紙板和包裝

- 木工和細木工

- 運輸

- 衛生保健

- 電氣和電子

- 其他最終用戶產業

- 按基材

- 紙和紙板

- 塑膠薄膜

- 木材/複合材料

- 金屬

- 玻璃和陶瓷

- 其他

- 按地區

- 亞太地區

- 中國

- 印度

- 日本

- 韓國

- ASEAN

- 其他亞太地區

- 北美洲

- 美國

- 加拿大

- 墨西哥

- 歐洲

- 德國

- 法國

- 英國

- 義大利

- 其他歐洲國家

- 南美洲

- 巴西

- 阿根廷

- 其他南美

- 中東和非洲

- 沙烏地阿拉伯

- 南非

- 其他中東和非洲地區

- 亞太地區

第6章 競爭態勢

- 市場集中度

- 策略性舉措(併購、合資、業務擴張)

- 市佔率分析

- 公司簡介

- 3M

- Arkema

- Ashland

- Avery Dennison Corporation

- Benson Polymers Pvt Ltd.

- DIC CORPORATION

- Dow

- Dymax

- Evonik Industries AG

- HB Fuller Company

- Henkel AG & Co. KGaA

- Jowat SE

- MAPEI SpA

- Parker Hannifin Corp

- Pidilite Industries Ltd.

- PPG Industries, Inc.

- Sika AG

- Soudal Group

- Wacker Chemie AG

第7章 市場機會與未來展望

The Water-borne Adhesives Market size is estimated at USD 8.57 billion in 2025, and is expected to reach USD 11.49 billion by 2030, at a CAGR of 6.03% during the forecast period (2025-2030).

The water-borne adhesives market is growing as manufacturers accelerate the shift from solvent-based to water-based chemistries to comply with tightening global VOC rules and meet brand-owner sustainability targets. Growth momentum is reinforced by fast-expanding e-commerce packaging volumes, automotive lightweighting, and modular construction, each of which demands high-performance yet low-emission bonding systems. Regulatory convergence, especially Europe's VOC Solvents Emissions Directive and the Ecodesign for Sustainable Products Regulation, has made water-based chemistries a de facto license to operate, prompting multinationals to re-engineer portfolios while opening technology-transfer opportunities in emerging markets.

Global Water-borne Adhesives Market Trends and Insights

E-commerce-Led Boom in Corrugated Packaging in North America

Explosive online retail sales mean corrugated shippers now use seven times more adhesive per dollar transacted than traditional retail. Brand owners have tightened "ship-in-own-container" requirements, pushing converters to adopt fast-setting water-based grades such as H.B. Fuller's Advantra series that survive multi-node logistics while meeting curbside-recyclability guidelines. Automated case-sealing lines further amplify demand for clean-running, low-viscosity formulations compatible with high-speed applicators. These factors collectively lift the water-borne adhesives market as converters specify eco-compliant chemistries to secure contracts with omnichannel retailers.

VOC-Reduction Mandates Accelerating Solvent-to-Water Conversion in Europe

The EU VOC Solvents Emissions Directive caps industrial emissions so rigorously that water-borne systems have become standard in automotive trim, flooring and facade panels. Recent European Coatings Show demonstrations of bio-based PU dispersions highlighted equal or superior shear strength versus solvent counterparts, eroding legacy performance objections and consolidating the regulatory-driven shift. Early movers such as Arkema report a 5.1% volume lift in industrial grades after launching new acrylic water-borne binders tailored for low-carbon packaging.

Heat-Resistance Gap Limits Penetration into High-Temperature Applications

Continuous exposure beyond 150 °C challenges most water-borne networks. 3M's Fastbond 1000NF illustrates progress-delivering GREENGUARD-certified bonds that tolerate cyclical peaks-but heavy-duty engines, baking-oven panels and under-hood linings remain dominated by solvent systems. Bridging this thermal delta will require novel silicone-hybrid lattices now in early R&D pipelines; until then, market penetration into these niches stays capped.

Other drivers and restraints analyzed in the detailed report include:

- ASEAN Modular Construction Driving Fast-Setting PVA Demand

- Light-Weight Automotive Bonding Boosting PU Dispersions in Asia

- Higher Initial Cost and Investment

For complete list of drivers and restraints, kindly check the Table Of Contents.

Segment Analysis

Acrylic emulsions held 38% of water-borne adhesives market share in 2024 thanks to versatility and low cost. Polyvinyl acetate remains the workhorse for wood bonding, yet rising indoor-air standards are steering contractors toward formaldehyde-free acrylics. Polyurethane dispersions, although contributing a modest slice of 2024 volume, are advancing at a 6.55% CAGR because they pair high peel strength with flexibility-attributes critical in lithium-ion battery packs and retort-pouch laminates.

The acrylic bloc faces margin pressure from propylene and acrylic-acid feedstock swings, nudging suppliers to integrate bio-acrylate routes or by-product streams. Chloroprene dispersions and niche hybrids serve metal furniture, footwear and mining belts where oil-resistance is non-negotiable, but remain volume-constrained. Overall, formulators that balance price-sensitive acrylic offerings with high-value PU portfolios will capture multi-tier growth.

Flexible packaging generated 40% of water-borne adhesives market size in 2024, driven by pouch, sachet and mailer conversions for omnichannel retail. Yet multi-layer lamination is the fastest-advancing cell at 7.23% CAGR as brand owners seek high-barrier designs combining PET, aluminum oxide and bio-PLA films. Water-based two-component systems now enable more than 65 N/15 mm bond strength, matching solvent-polyurethane predecessors while ensuring food-contact compliance.

Tapes, labels and graphic arts supply chains adopt dispersion-based PSAs that meet automated application speeds without stringing. Book-binding and paper-converting segments respond to lower-energy hot-cure cycles offered by new vinyl-acetate-ethylene copolymers. As e-commerce accelerates, corrugated-case adhesives with immediate tack yet fiber-tear substrate failure gain prominence, expanding total addressable demand.

The Water-Borne Adhesives Market Report Segments the Industry by Resin Type (Acrylics, Polyvinyl Acetate Emulsion, and More), Application (Flexible Packaging, Tapes and Labels, and More), End-User Industry (Building and Construction, Paper, Board, and More), Substrate (Paper and Paperboard, Metals, and More), and Geography (Asia-Pacific, North America, and More). The Market Forecasts are Provided in Terms of Value (USD).

Geography Analysis

Asia-Pacific's 40% revenue leadership in 2024 reflects its unrivaled manufacturing depth, robust construction pipeline and accelerating electric-vehicle production. China's Tier-2 cities drive panel adhesive uptake, while India's infrastructure push anchors volume gains. The region's 6.89% CAGR also stems from regulatory tightening in Japan and South Korea, which incentivizes solvent-free chemistries through tax breaks and green-procurement lists.

North America ranks second, buoyed by e-commerce packaging and automotive lightweighting. The United States continues to mandate lower VOC limits in consumer products, expanding the water-borne adhesives market, whereas Canada's energy-efficiency codes spur adoption in residential retrofit insulation. Mexico's maquiladora corridors increasingly specify water-based formulations to service OEM export requirements.

Europe exerts outsized technology influence through stringent directives. Germany's auto interiors, France's flexible food packaging and the UK's timber-frame housing sectors collectively lift continental demand. Eastern European converters, supported by EU cohesion funds, upgrade to dispersion lines, eroding solvent share faster than originally forecast.

South America offers a mixed outlook: Brazil's construction recovery and agribusiness packaging needs push modest demand growth, aided by Henkel's new innovation hub in Jundiai. Argentina maintains smaller but specialized appetites in flexible food wraps. Middle East and Africa remain nascent yet promising; Saudi giga-projects and South African retail logistics are starting to specify water-based grades to meet imported-goods standards.

- 3M

- Arkema

- Ashland

- Avery Dennison Corporation

- Benson Polymers Pvt Ltd.

- DIC CORPORATION

- Dow

- Dymax

- Evonik Industries AG

- H.B. Fuller Company

- Henkel AG & Co. KGaA

- Jowat SE

- MAPEI S.p.A.

- Parker Hannifin Corp

- Pidilite Industries Ltd.

- PPG Industries, Inc.

- Sika AG

- Soudal Group

- Wacker Chemie AG

Additional Benefits:

- The market estimate (ME) sheet in Excel format

- 3 months of analyst support

TABLE OF CONTENTS

1 Introduction

- 1.1 Study Assumptions and Market Definition

- 1.2 Scope of the Study

2 Research Methodology

3 Executive Summary

4 Market Landscape

- 4.1 Market Overview

- 4.2 Market Drivers

- 4.2.1 E-commerce-Led Boom in Corrugated Packaging in North America

- 4.2.2 VOC-Reduction Mandates Accelerating Solvent-to-Water Conversion in Europe

- 4.2.3 ASEAN Modular Construction Driving Fast-Setting PVA Demand

- 4.2.4 Light-weight Automotive Bonding Boosting PU Dispersions in Asia

- 4.2.5 Regulatory Push in Emerging Markets

- 4.3 Market Restraints

- 4.3.1 Heat-Resistance Gap Limits Penetration into High-Temperature Applications

- 4.3.2 Limited Usage in High-end Applications

- 4.3.3 Higher Initial Cost and Investment

- 4.4 Value Chain Analysis

- 4.5 Porter's Five Forces Analysis

- 4.5.1 Bargaining Power of Suppliers

- 4.5.2 Bargaining Power of Buyers

- 4.5.3 Threat of New Entrants

- 4.5.4 Threat of Substitutes

- 4.5.5 Competitive Rivalry

5 Market Size and Growth Forecasts

- 5.1 By Resin Type

- 5.1.1 Acrylics

- 5.1.2 Polyvinyl Acetate (PVA) Emulsion

- 5.1.3 Ethylene Vinyl Acetate (EVA) Emulsion

- 5.1.4 Polyurethane Dispersions and CR (Chloroprene Rubber) Latex

- 5.1.5 Other Resin Types

- 5.2 By Application

- 5.2.1 Flexible Packaging

- 5.2.2 Tapes and Labels

- 5.2.3 Paper Converting and Graphic Arts

- 5.2.4 Laminating and Filmic Structures

- 5.2.5 Flooring and Carpeting

- 5.2.6 Bookbinding and Publishing

- 5.2.7 Non-woven and Hygiene Products

- 5.2.8 Others

- 5.3 By End-user Industry

- 5.3.1 Building and Construction

- 5.3.2 Paper, Board, and Packaging

- 5.3.3 Woodworking and Joinery

- 5.3.4 Transportation

- 5.3.5 Healthcare

- 5.3.6 Electrical and Electronics

- 5.3.7 Other End-user Industries

- 5.4 By Substrate

- 5.4.1 Paper and Paperboard

- 5.4.2 Plastics and Films

- 5.4.3 Wood and Composites

- 5.4.4 Metals

- 5.4.5 Glass and Ceramics

- 5.4.6 Others

- 5.5 By Geography

- 5.5.1 Asia-Pacific

- 5.5.1.1 China

- 5.5.1.2 India

- 5.5.1.3 Japan

- 5.5.1.4 South Korea

- 5.5.1.5 ASEAN

- 5.5.1.6 Rest of Asia-Pacific

- 5.5.2 North America

- 5.5.2.1 United States

- 5.5.2.2 Canada

- 5.5.2.3 Mexico

- 5.5.3 Europe

- 5.5.3.1 Germany

- 5.5.3.2 France

- 5.5.3.3 United Kingdom

- 5.5.3.4 Italy

- 5.5.3.5 Rest of Europe

- 5.5.4 South America

- 5.5.4.1 Brazil

- 5.5.4.2 Argentina

- 5.5.4.3 Rest of South America

- 5.5.5 Middle East and Africa

- 5.5.5.1 Saudi Arabia

- 5.5.5.2 South Africa

- 5.5.5.3 Rest of Middle East and Africa

- 5.5.1 Asia-Pacific

6 Competitive Landscape

- 6.1 Market Concentration

- 6.2 Strategic Moves (Mergers and Acquisitions, JVs, Expansions)

- 6.3 Market Share Analysis

- 6.4 Company Profiles {(includes Global level Overview, Market level overview, Core Segments, Financials as available, Strategic Information, Market Rank/Share for key companies, Products and Services, and Recent Developments)}

- 6.4.1 3M

- 6.4.2 Arkema

- 6.4.3 Ashland

- 6.4.4 Avery Dennison Corporation

- 6.4.5 Benson Polymers Pvt Ltd.

- 6.4.6 DIC CORPORATION

- 6.4.7 Dow

- 6.4.8 Dymax

- 6.4.9 Evonik Industries AG

- 6.4.10 H.B. Fuller Company

- 6.4.11 Henkel AG & Co. KGaA

- 6.4.12 Jowat SE

- 6.4.13 MAPEI S.p.A.

- 6.4.14 Parker Hannifin Corp

- 6.4.15 Pidilite Industries Ltd.

- 6.4.16 PPG Industries, Inc.

- 6.4.17 Sika AG

- 6.4.18 Soudal Group

- 6.4.19 Wacker Chemie AG

7 Market Opportunities and Future Outlook

- 7.1 White-space and Unmet-Need Assessment

- 7.2 Rising Demand for Sustainable and Eco-Friendly Products