|

市場調查報告書

商品編碼

1693822

日本工程塑膠:市場佔有率分析、產業趨勢與成長預測(2024-2029年)Japan Engineering Plastics - Market Share Analysis, Industry Trends & Statistics, Growth Forecasts (2024 - 2029) |

||||||

價格

※ 本網頁內容可能與最新版本有所差異。詳細情況請與我們聯繫。

簡介目錄

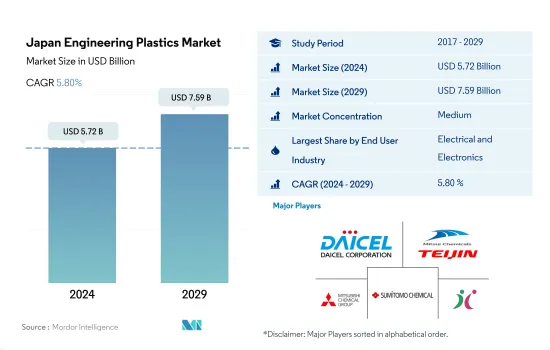

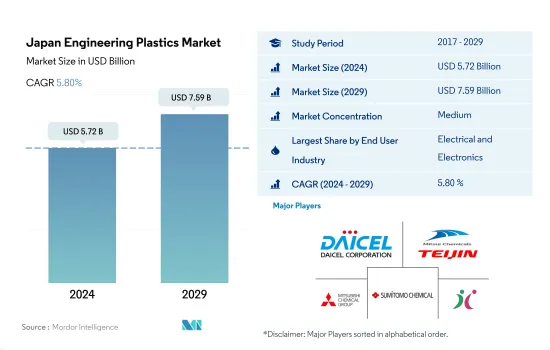

日本工程塑膠市場規模預計在 2024 年為 57.2 億美元,預計到 2029 年將達到 75.9 億美元,預測期內(2024-2029 年)的複合年成長率為 5.80%。

電氣電子產業在價值和數量上保持主導地位

- 工程塑膠的應用範圍包括航太領域的內牆板和門以及硬質和軟質包裝。日本的工程塑膠市場受到包裝、電氣/電子和汽車產業推動。 2022年工程塑膠市場容量佔包裝產業比重約26.89%,佔電子電氣產業比重約27.23%。

- 電氣和電子產業是該國最大的產業。例如,日本電子產業預計2022年國內產值將年與前一年同期比較%,達到843.4億美元。這一成長主要得益於電子元件設備出口條件有利、汽車中電子元件的使用增加以及5G技術的發展導致對電氣測量儀器的需求增加。這些因素將推動國內工程塑膠消費量增加,2022與前一年同期比較量年增率將達1.12%。

- 2022年,汽車產業佔據了25.65%的收益佔有率,成為全國第二大最具前景的產業。 2022年日本汽車產業與前一年同期比較增15.15%。這主要由於國內汽車產量增加,2022年國內汽車產量與前一年同期比較增3.49%至941萬輛。

- 航太業是該國收入成長最快的行業,預計複合年成長率為 7.69%,這歸因於航太業支出的增加,預計這將在預測期內推動對工程塑膠的需求。預計到2029年,日本航太零件製造業收入將達到約170億美元。

日本工程塑膠市場趨勢

政府採取措施支持國內電氣電子設備製造業

- 日本電子產業擅長零件和設備生產,生產固態固態電池和醫療相機等關鍵技術。預計政府在脫碳方面的努力以及以工廠自動化和遠程辦公為中心的工作方式改革功能的開發將帶來進一步的創新,而汽車行業在這兩方面表現優異。

- 2019年,受美國貿易戰導致的晶片短缺以及遠端辦公帶來的需求增加的影響,日本國內電子產品生產受到影響。 2020年,又受新冠疫情影響,日本電子元件設備和電子電路製造企業數量從上一年的約3,860家降至約3,790家,為10年來的最低水準。日本2020年家用電子電器產值為429.8億日元,工業電子產值為2556.76億日圓。

- 日本2020-2021年電氣電子設備生產收入成長19.2%。日本電子產業總產值預計2021年將達到近11兆日圓,該產業包括消費性電子、工業電子、電子元件設備等。家用電子電器佔日本經濟產出的三分之一。

- 由於美國總統和日本首相承諾提高半導體製造能力,且日本也投資創新領域,日本電子產業在預測期內可能會被提振。

日本工程塑膠產業概況

日本工程塑膠市場適度整合,前五大公司佔63.27%的市場。該市場的主要企業包括 Daicel Corporation、MCT PET Resin、三菱化學公司、住友化學、Techno-UMG 等。

其他福利

- Excel 格式的市場預測 (ME) 表

- 3個月的分析師支持

目錄

第1章執行摘要和主要發現

第2章 報告要約

第3章 引言

- 研究假設和市場定義

- 研究範圍

- 調查方法

第4章 產業主要趨勢

- 最終用戶趨勢

- 航太

- 車

- 建築與施工

- 電氣和電子

- 包裝

- 進出口趨勢

- 價格趨勢

- 回收概述

- 聚醯胺(PA)回收趨勢

- 聚碳酸酯(PC)回收趨勢

- 聚對苯二甲酸乙二醇酯(PET)的回收趨勢

- 苯乙烯共聚物(ABS、SAN)的回收趨勢

- 法律規範

- 日本

- 價值鍊和通路分析

第5章市場區隔

- 最終用戶產業

- 航太

- 車

- 建築與施工

- 電氣和電子

- 工業/機械

- 包裝

- 其他

- 樹脂類型

- 氟樹脂

- 依亞型

- 乙烯-四氟乙烯(ETFE)

- 氟化乙丙烯 (FEP)

- 聚四氟乙烯(PTFE)

- 聚氟乙烯(PVF)

- 聚二氟亞乙烯(PVDF)

- 其他子樹脂類型

- 液晶聚合物(LCP)

- 聚醯胺(PA)

- 依樹脂類型分

- 芳香聚醯胺

- 聚醯胺(PA)6

- 聚醯胺(PA)66

- 聚鄰苯二甲醯胺

- 聚丁烯對苯二甲酸酯(PBT)

- 聚碳酸酯(PC)

- 聚醚醚酮(PEEK)

- 聚對苯二甲酸乙二醇酯(PET)

- 聚醯亞胺(PI)

- 聚甲基丙烯酸甲酯(PMMA)

- 聚甲醛(POM)

- 苯乙烯共聚物(ABS和SAN)

- 氟樹脂

第6章競爭格局

- 關鍵策略趨勢

- 市場佔有率分析

- 商業狀況

- 公司簡介

- AGC Inc.

- Asahi Kasei Corporation

- Daicel Corporation

- Daikin Industries, Ltd.

- Kuraray Co., Ltd.

- Kureha Corporation

- MCT PET Resin Co Ltd

- Mitsubishi Chemical Corporation

- PBI Advanced Materials Co.,Ltd.

- Polyplastics-Evonik Corporation

- Sumitomo Chemical Co., Ltd.

- Techno-UMG Co., Ltd.

- Teijin Limited

- Toray Industries, Inc.

- UBE Corporation

第7章 CEO 的關鍵策略問題

第 8 章 附錄

- 世界概況

- 概述

- 五力分析框架(產業吸引力分析)

- 全球價值鏈分析

- 市場動態(DRO)

- 資訊來源及延伸閱讀

- 圖片列表

- 關鍵見解

- 數據包

- 詞彙表

簡介目錄

Product Code: 5000160

The Japan Engineering Plastics Market size is estimated at 5.72 billion USD in 2024, and is expected to reach 7.59 billion USD by 2029, growing at a CAGR of 5.80% during the forecast period (2024-2029).

The electrical and electronics industry to maintain its dominance in terms of both value and volume

- Engineering plastics have applications ranging from interior wall panels and doors in aerospace to rigid and flexible packaging. In Japan, the engineering plastics market is led by the packaging, electrical and electronics, and automotive industries. Packaging and electrical and electronics industries accounted for around 26.89% and 27.23% of the engineering plastics market volume in 2022.

- The electrical and electronics sector is the largest in the country. For instance, the Japanese electronics industry experienced a 2% Y-o-Y increase in domestic production in 2022, reaching a total of USD 84.34 billion. This growth was mainly attributed to the strong performance of electronic components and devices in exports, the rising usage of electronic components in vehicles, and the increasing demand for electric measuring instruments due to the growth of 5G technology. These factors led to higher consumption of engineering plastics in the country, with volume growth of 1.12% in 2022 compared to the previous year.

- In 2022, the automotive industry accounted for 25.65% of the revenue share, which made it the second largest promising industry in the country. In 2022, the Japanese automotive industry grew at a Y-o-Y rate of 15.15% compared to the previous year. This was mainly due to an increase in vehicle production in the country, which was recorded at 9.41 million units in 2022, 3.49% higher than the previous year.

- Aerospace is the fastest-growing industry in the country in terms of revenue, with a projected CAGR of 7.69%, owing to increased spending in the aerospace industry, which is expected to drive the demand for engineering plastics during the forecast period. Japan's aerospace component production revenue is expected to reach around USD 17 billion by 2029.

Japan Engineering Plastics Market Trends

Government policies to support domestic electrical and electronics production

- The Japanese electronics industry excels in the production of components and devices, creating key technologies, such as all-solid batteries and medical cameras. The government's efforts toward decarbonization and the industry's proficiency in this field will enable further innovations by developing functions geared toward factory automation and telework-led workstyle reforms.

- The country faced chip shortages caused by the trade war between the United States and China, and the increased demand that followed the move to remote working that affected the production of electronics in the country in 2019. Consecutively, due to COVID-19 pandemic-related disruptions in 2020, the number of businesses in the Japanese electronic parts, devices, and electronic circuits manufacturing industry hit a decade low of approximately 3.79 thousand establishments, a decrease from around 3.86 thousand in the previous year. The country produced consumer electronic equipment of JPY 42,908 million, by value, and industrial electronic equipment of JPY 25,5676 million, by value, in 2020.

- Japan registered an increase of 19.2% in electrical and electronics production revenue from 2020 to 2021. The total production value of the electronics industry in Japan reached close to JPY 11 trillion in 2021. The industry encompasses consumer electronic equipment, industrial electronic equipment, and electronic components and devices. Consumer electronics account for a third of Japan's economic output.

- The US President and Japanese Prime Minister pledged to bolster semiconductor manufacturing capacity, and the country is also investing in the innovation sector, which may boost the electronic industry in the country during the forecast period.

Japan Engineering Plastics Industry Overview

The Japan Engineering Plastics Market is moderately consolidated, with the top five companies occupying 63.27%. The major players in this market are Daicel Corporation, MCT PET Resin Co Ltd, Mitsubishi Chemical Corporation, Sumitomo Chemical Co., Ltd. and Techno-UMG Co., Ltd. (sorted alphabetically).

Additional Benefits:

- The market estimate (ME) sheet in Excel format

- 3 months of analyst support

TABLE OF CONTENTS

1 EXECUTIVE SUMMARY & KEY FINDINGS

2 REPORT OFFERS

3 INTRODUCTION

- 3.1 Study Assumptions & Market Definition

- 3.2 Scope of the Study

- 3.3 Research Methodology

4 KEY INDUSTRY TRENDS

- 4.1 End User Trends

- 4.1.1 Aerospace

- 4.1.2 Automotive

- 4.1.3 Building and Construction

- 4.1.4 Electrical and Electronics

- 4.1.5 Packaging

- 4.2 Import And Export Trends

- 4.3 Price Trends

- 4.4 Recycling Overview

- 4.4.1 Polyamide (PA) Recycling Trends

- 4.4.2 Polycarbonate (PC) Recycling Trends

- 4.4.3 Polyethylene Terephthalate (PET) Recycling Trends

- 4.4.4 Styrene Copolymers (ABS and SAN) Recycling Trends

- 4.5 Regulatory Framework

- 4.5.1 Japan

- 4.6 Value Chain & Distribution Channel Analysis

5 MARKET SEGMENTATION (includes market size in Value in USD and Volume, Forecasts up to 2029 and analysis of growth prospects)

- 5.1 End User Industry

- 5.1.1 Aerospace

- 5.1.2 Automotive

- 5.1.3 Building and Construction

- 5.1.4 Electrical and Electronics

- 5.1.5 Industrial and Machinery

- 5.1.6 Packaging

- 5.1.7 Other End-user Industries

- 5.2 Resin Type

- 5.2.1 Fluoropolymer

- 5.2.1.1 By Sub Resin Type

- 5.2.1.1.1 Ethylenetetrafluoroethylene (ETFE)

- 5.2.1.1.2 Fluorinated Ethylene-propylene (FEP)

- 5.2.1.1.3 Polytetrafluoroethylene (PTFE)

- 5.2.1.1.4 Polyvinylfluoride (PVF)

- 5.2.1.1.5 Polyvinylidene Fluoride (PVDF)

- 5.2.1.1.6 Other Sub Resin Types

- 5.2.2 Liquid Crystal Polymer (LCP)

- 5.2.3 Polyamide (PA)

- 5.2.3.1 By Sub Resin Type

- 5.2.3.1.1 Aramid

- 5.2.3.1.2 Polyamide (PA) 6

- 5.2.3.1.3 Polyamide (PA) 66

- 5.2.3.1.4 Polyphthalamide

- 5.2.4 Polybutylene Terephthalate (PBT)

- 5.2.5 Polycarbonate (PC)

- 5.2.6 Polyether Ether Ketone (PEEK)

- 5.2.7 Polyethylene Terephthalate (PET)

- 5.2.8 Polyimide (PI)

- 5.2.9 Polymethyl Methacrylate (PMMA)

- 5.2.10 Polyoxymethylene (POM)

- 5.2.11 Styrene Copolymers (ABS and SAN)

- 5.2.1 Fluoropolymer

6 COMPETITIVE LANDSCAPE

- 6.1 Key Strategic Moves

- 6.2 Market Share Analysis

- 6.3 Company Landscape

- 6.4 Company Profiles (includes Global Level Overview, Market Level Overview, Core Business Segments, Financials, Headcount, Key Information, Market Rank, Market Share, Products and Services, and Analysis of Recent Developments).

- 6.4.1 AGC Inc.

- 6.4.2 Asahi Kasei Corporation

- 6.4.3 Daicel Corporation

- 6.4.4 Daikin Industries, Ltd.

- 6.4.5 Kuraray Co., Ltd.

- 6.4.6 Kureha Corporation

- 6.4.7 MCT PET Resin Co Ltd

- 6.4.8 Mitsubishi Chemical Corporation

- 6.4.9 PBI Advanced Materials Co.,Ltd.

- 6.4.10 Polyplastics-Evonik Corporation

- 6.4.11 Sumitomo Chemical Co., Ltd.

- 6.4.12 Techno-UMG Co., Ltd.

- 6.4.13 Teijin Limited

- 6.4.14 Toray Industries, Inc.

- 6.4.15 UBE Corporation

7 KEY STRATEGIC QUESTIONS FOR ENGINEERING PLASTICS CEOS

8 APPENDIX

- 8.1 Global Overview

- 8.1.1 Overview

- 8.1.2 Porter's Five Forces Framework (Industry Attractiveness Analysis)

- 8.1.3 Global Value Chain Analysis

- 8.1.4 Market Dynamics (DROs)

- 8.2 Sources & References

- 8.3 List of Tables & Figures

- 8.4 Primary Insights

- 8.5 Data Pack

- 8.6 Glossary of Terms

02-2729-4219

+886-2-2729-4219