|

市場調查報告書

商品編碼

1687164

PVC 穩定劑:市場佔有率分析、產業趨勢與統計、成長預測(2025-2030 年)PVC Stabilizers - Market Share Analysis, Industry Trends & Statistics, Growth Forecasts (2025 - 2030) |

||||||

※ 本網頁內容可能與最新版本有所差異。詳細情況請與我們聯繫。

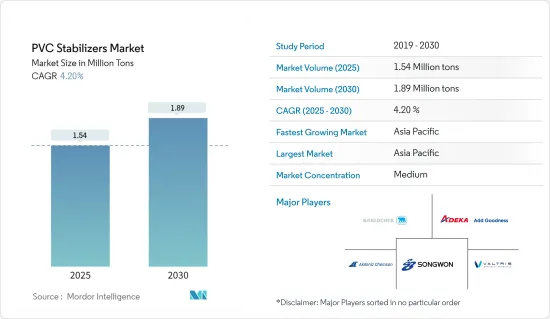

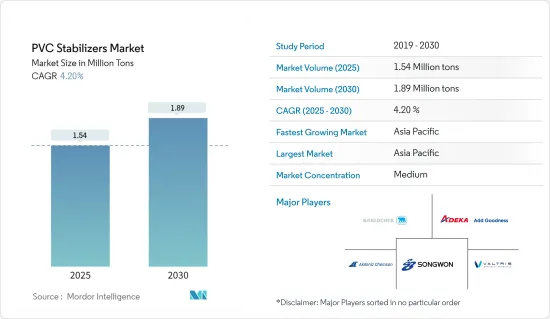

PVC 穩定劑市場規模預計在 2025 年為 154 萬噸,預計到 2030 年將達到 189 萬噸,預測期內(2025-2030 年)的複合年成長率為 4.2%。

COVID-19 疫情對 PVC 穩定劑市場產生了不利影響。全球停工和嚴格的政府監管迫使大多數製造工廠關閉,造成了毀滅性的挫折。儘管如此,預計市場將在 2021 年復甦,並在未來幾年大幅成長。

主要亮點

- 短期內,PVC管路、管材和配件對穩定劑的需求增加以及汽車工業中穩定劑使用量的增加是推動PVC穩定劑需求的主要因素。

- 然而,健康危害和政府對使用鉛基穩定劑的嚴格規定預計將阻礙市場成長。

- 然而,有機錫穩定劑作為環保選擇的日益廣泛使用預計將為市場研究創造新的機會。

- 亞太地區佔據全球 PVC 穩定劑市場的主導地位。亞太市場的成長動力源自於該地區各國各類終端用戶產業(包括建築業)對 PVC 穩定劑日益成長的需求。中國和印度是該地區市場的主要貢獻者。

PVC穩定劑市場趨勢

建築業佔據市場主導地位

- 聚氯乙烯(PVC)是建設產業的主要塑膠。它堅固而輕便,能夠抵抗天氣、化學腐蝕和磨損。由 PVC 製成的常見產品包括管道、電纜、窗框、地板材料和屋頂。

- PVC 管在用水和污水系統中發揮著至關重要的作用。它們確保流暢、無摩擦的流動,並能防止積聚、結垢和腐蝕。特別是,PVC 管道被認為是輸送飲用水的安全管道,安裝在地下時的使用壽命可超過 100 年。此外,它還具有成本效益,可以回收8到10次。

- 牛津經濟研究院預測全球建築產出將呈現強勁成長軌跡,從目前的4.2兆美元增加到2037年的13.9兆美元以上。

- 中國佔全球主導地位,生產了全球50-60%的PVC管道。特別是,它是聚氯乙烯聚合物製成的硬質管、管材和軟管的最大出口國。

- 2023年,中國建築業實際價值成長6.5%。國家統計局表示,今年前九個月,該產業對經濟的貢獻比去年同期成長了7.2%。

- 據投資印度稱,都市化趨勢表明,到 2030 年,超過 40% 的人口將居住在都市區,需要額外 2,500 萬住宅中產階級和經濟適用住宅。此外,根據住宅和城市事務部的數據,在 AMRUT 計劃下,約有 134,000 戶家庭獲得了供水,約有 102,000 戶家庭獲得了排污服務。

- 在美國,由於美國政府的目標是到 2030 年將排放在 2005 年的基礎上減少 50-52%,以符合《巴黎協定》,因此未來幾年 PVC 生產可能會受到影響。因此,美國PVC 產業正在準備採取重大措施抑制溫室氣體 (GHG)排放,並計劃在 2050 年實現碳中和。

- 此外,2023 年 12 月,美國環保署 (EPA) 準備宣布監管 PVC 的計劃,改變處置要求的性質。

- 據歐洲乙烯基製造商委員會稱,窗戶、管道、地板材料和屋頂薄膜等建築產品佔歐洲 PVC 的 70%。 PVC 是歐洲建設產業的主要塑膠。

- 德國強勁的經濟正在引發對商業空間的需求激增。尤其是,人們對高品質、符合 ESG 標準的辦公大樓的興趣日益濃厚,主要租金的上漲就是明證。預計 2023 年第三季將有 246,000平方公尺的辦公空間運作,到 2024 年總投入營運總合180 萬平方公尺。

- 鑑於這些發展,全球建設產業的興起預示著未來幾年 PVC 穩定劑的前景看好。

亞太地區佔市場主導地位

- 由於中國和印度等國家的建築和汽車等行業的需求激增,亞太地區引領 PVC 穩定劑市場。

- PVC 管道和地板材料具有耐用、美觀靈活、易於安裝、易於清潔和可回收等優點。在建設產業,PVC 屋頂材料因其維護要求低、使用壽命超過 30 年而廣受歡迎。

- 中國香港住宅委員會已推出多項措施推動廉價住宅建設。當局的目標是到 2030 年的 10 年內提供 301,000 套公共住宅。

- 此外,日本建設產業近年來也成為PVC穩定劑的主要消費者。日本正在進行一些引人注目的建設計劃,包括三菱地所將在東京車站附近建設的日本高層建築,該摩天大樓預計於 2027 年竣工,將包括 50 套豪華公寓,預計月租金將達到 43,000 美元。

- PVC 通常用於汽車工業,例如傳統汽車和電動車的引擎蓋下和內裝。

- 中國是世界上最大的汽車製造國之一。根據OICA預測,2023年中國乘用車產量將達2,600萬輛,較2022年成長10%以上。

- 此外,OICA表示,印度2023年的汽車產量將達585萬輛,較2022年成長7%以上。該國的乘用車產量預計將達到478萬輛,比2022年成長7.9%,從而支持市場成長。

- 根據通訊資料,受產量上升以及國內外需求復甦的推動,中國電子製造業在 2024 年前四個月表現良好。根據工業與資訊化部的報告,2024年1至4月,中國電子產業主要企業利潤總額總合去年同期成長75.8%,達到人民幣1,442億元(約203億美元)。

- 印度包裝產業協會(PIAI)預測,預測期內印度包裝產業將實現22%的強勁成長。此外,到 2025 年,印度包裝市場規模將達到 2,048.1 億美元,在此期間的複合年成長率高達 26.7%。這一激增證實了未來幾年印度對 PVC 穩定劑的需求將持續成長。

- 鑑於這種動態和政府的推動,預測期內亞太地區 PVC 穩定劑市場的需求將會成長。

PVC 穩定劑產業概況

PVC 穩定劑市場因其性質而部分分散。主要企業(不分先後順序)包括 Baerlocher GmbH、ADEKA Corporation、Akdeniz Chemson、SONGWON 和 Valtris Specialty Chemicals。

其他福利:

- Excel 格式的市場預測 (ME) 表

- 3 個月的分析師支持

目錄

第 1 章 簡介

- 調查前提條件

- 研究範圍

第2章調查方法

第3章執行摘要

第4章 市場動態

- 驅動程式

- PVC 管、管材和配件穩定劑的需求不斷增加

- 在汽車產業的應用日益廣泛

- 其他促進因素

- 限制因素

- 健康危害和政府對使用鉛基穩定劑的嚴格規定

- 其他阻礙因素

- 產業價值鏈分析

- 波特五力分析

- 供應商的議價能力

- 買家的議價能力

- 新進入者的威脅

- 替代品的威脅

- 競爭程度

第5章 市場區隔

- 按類型

- 鈣基

- 鉛基

- 錫基

- 鋇基

- 其他類型

- 按最終用戶產業

- 建築和施工

- 車

- 電氣和電子

- 包裝

- 鞋類

- 其他最終用戶產業

- 按地區

- 亞太地區

- 中國

- 印度

- 日本

- 韓國

- 馬來西亞

- 泰國

- 印尼

- 越南

- 其他亞太地區

- 北美洲

- 美國

- 加拿大

- 墨西哥

- 歐洲

- 德國

- 英國

- 法國

- 義大利

- 西班牙

- 北歐國家

- 土耳其

- 俄羅斯

- 其他歐洲國家

- 南美洲

- 巴西

- 阿根廷

- 哥倫比亞

- 南美洲其他地區

- 中東和非洲

- 沙烏地阿拉伯

- 卡達

- 阿拉伯聯合大公國

- 奈及利亞

- 埃及

- 南非

- 其他中東和非洲地區

- 亞太地區

第6章 競爭格局

- 併購、合資、合作、協議

- 市場佔有率(%)**/排名分析

- 主要企業策略

- 公司簡介

- Adeka Corporation

- Akdeniz Chemson

- Baerlocher GmbH

- Clariant

- Galata Chemicals

- Goldstab Organics Pvt. Ltd

- KD Chem Co. Ltd

- Kunshan Maijisen Composite Materials Co. Ltd

- Pau Tai Industrial Corp.

- PMC Group Inc.

- Ra Chemicals Pvt. Ltd

- Reagens SpA

- Shandong Jinchangshu New Material Technology Co. Ltd

- SONGWON

- Timah

- Valtris Specialty Chemicals

- Vikas Ecotech Ltd

第7章 市場機會與未來趨勢

- 增加使用有機錫穩定劑作為環保選擇

- 其他機會

The PVC Stabilizers Market size is estimated at 1.54 million tons in 2025, and is expected to reach 1.89 million tons by 2030, at a CAGR of 4.2% during the forecast period (2025-2030).

The COVID-19 pandemic adversely affected the PVC stabilizers market. Global lockdowns and severe government rules resulted in a catastrophic setback, as most production hubs were shut down. Nonetheless, the market recovered in 2021 and is expected to rise significantly in the coming years.

Key Highlights

- Over the short term, growing demand for stabilizers for PVC pipes, tubings, and fittings and increasing use in the automotive industry are the major factors driving demand for PVC stabilizers.

- However, health hazards and stringent government regulations regarding the use of lead-based stabilizers are expected to hinder the market's growth.

- Nevertheless, the rising usage of organo-tin stabilizers as an environmentally friendly option is expected to create new opportunities for the market studied.

- Asia-Pacific dominates the global PVC stabilizers market. Rising demand for PVC stabilizers in different end-user industries, including building and construction in the countries of this region, is driving the Asia-Pacific market. China and India are the major contributors to this regional market.

PVC Stabilizers Market Trends

The Building and Construction Segment to Dominate the Market

- Polyvinyl chloride (PVC) stands out as the predominant plastic in the building and construction industry. Its robust yet lightweight nature ensures durability against weathering, chemical corrosion, and abrasion. Common products crafted from PVC include pipes, cables, window profiles, flooring, and roofing.

- PVC pipes play a pivotal role in water, waste, and sewage systems. They resist build-up, scaling, and corrosion, ensuring a smooth, friction-free flow. Notably, PVC pipes are deemed safe for transporting drinking water, boasting a service life exceeding 100 years for underground installations. Additionally, they are cost-effective and can be recycled 8-10 times.

- Oxford Economics forecasts a robust growth trajectory for global construction output, projecting an increase from over USD 4.2 trillion currently to a staggering USD 13.9 trillion by 2037, predominantly fueled by the construction powerhouses of China, the United States, and India.

- China dominates the global landscape, producing 50-60% of the world's PVC pipes. Notably, it stands as the foremost exporter of rigid tubes, pipes, and hoses crafted from vinyl chloride polymers.

- In 2023, China's construction industry witnessed a 6.5% growth in actual value. The industry's economic contribution surged by 7.2% Y-o-Y during the initial nine months, as highlighted by the National Bureau of Statistics (NBS).

- As per Invest India, urbanization trends suggest that by 2030, over 40% of the population will reside in urban locales, driving the need for an additional 25 million mid-end and affordable housing units. Furthermore, according to the Ministry of Housing & Urban Affairs, around 134 lakh water tap connections and 102 lakh sewer/septage connections have been provided under the AMRUT scheme.

- PVC production in the United States is likely to be affected in the coming years due to the US government's target of reducing emissions by 50-52% from 2005 benchmarks by 2030, aligning with the Paris Agreement. Consequently, the US PVC industry is gearing up for substantial measures to curtail greenhouse gas (GHG) emissions, eyeing carbon neutrality by 2050.

- Furthermore, in December 2023, the US Environmental Protection Agency (EPA) unveiled plans to regulate PVC, a move poised to reshape disposal mandates.

- According to the European Council of Vinyl Manufacturers, windows, pipes, flooring, roofing membranes, and other building products use 70% of all European PVC. It is the leading plastic in the European building and construction industry.

- Germany's robust economy is driving a surge in demand for commercial spaces. Notably, there has been a growing interest in high-quality, ESG-compliant office buildings, evident from rising prime rents. In Q3 2023, 246,000 sq. m of office space came online, with forecasts suggesting a total of 1.8 million sq. m in 2024.

- Given these dynamics, the global construction industry's prominence suggests a bullish outlook for PVC stabilizers over the coming years.

Asia-Pacific to Dominate the Market

- Asia-Pacific leads the PVC stabilizers market, driven by surging demand from industries like construction and automotive in countries like China and India.

- PVC pipes and flooring offer benefits like durability, aesthetic flexibility, easy installation, simple cleaning, and recyclability. In the building and construction industry, PVC roofing is favored for its low maintenance and longevity, lasting over 30 years.

- The housing authorities of Hong Kong, China, have launched several measures to push the construction of low-cost housing. The officials aim to provide 301,000 public housing units in 10 years till 2030.

- In addition, Japan's construction industry has been another major consumer of PVC stabilizers in recent times. Japan is witnessing notable construction projects, including Mitsubishi State's endeavor of erecting the nation's tallest building near Tokyo station, featuring 50 luxury apartments projected to earn USD 43,000 monthly in rent, with a completion target of 2027.

- PVC is commonly used in under-the-hood applications, interiors, and other areas in conventional vehicles and electric vehicles in the automotive industry.

- China is one of the largest automotive manufacturers worldwide. According to OICA, in 2023, the production of passenger vehicles in China stood at 26 million units, an increase of more than 10% compared to 2022.

- Moreover, according to the OICA, in 2023, the total production of vehicles in India stood at 5.85 million units, registering an increase of more than 7% compared to 2022. The production of passenger vehicles in the country stood at 4.78 million units, registering an increase of 7.9% compared to the year 2022, thereby supporting the growth of the market.

- As per data from Xinhua News Agency, China's electronics manufacturing industry showcased robust performance in the initial four months of 2024, buoyed by rising production and a rebound in both domestic and global demand. Major companies in China's electronics industry, as reported by the Ministry of Industry and Information Technology, saw their combined profits surge by 75.8% Y-o-Y, reaching CNY 144.2 billion (~USD 20.3 billion) from January to April 2024.

- The Packaging Industry Association of India (PIAI) projects the Indian packaging industry to grow at a robust 22% during the forecast period. Furthermore, the Indian packaging market is on track to hit USD 204.81 billion by 2025, boasting an impressive CAGR of 26.7% until then. This surge underscores a rising demand for PVC stabilizers across India over the coming years.

- Given these dynamics and government backing, Asia-Pacific is poised to register heightened demand in the PVC stabilizers market during the forecast period.

PVC Stabilizers Industry Overview

The PVC stabilizers market is partially fragmented by nature. The major players (not in any particular order) include Baerlocher GmbH, Adeka Corporation, Akdeniz Chemson, SONGWON, and Valtris Specialty Chemicals.

Additional Benefits:

- The market estimate (ME) sheet in Excel format

- 3 months of analyst support

TABLE OF CONTENTS

1 INTRODUCTION

- 1.1 Study Assumptions

- 1.2 Scope of the Study

2 RESEARCH METHODOLOGY

3 EXECUTIVE SUMMARY

4 MARKET DYNAMICS

- 4.1 Drivers

- 4.1.1 Growing Demand for Stabilizers for PVC Pipes, Tubings and Fittings

- 4.1.2 Increasing Use In the Automotive Industry

- 4.1.3 Other Drivers

- 4.2 Restraints

- 4.2.1 Health Hazards and Stringent Government Regulations Regarding the Use of Lead-based Stabilizers

- 4.2.2 Other Restraints

- 4.3 Industry Value Chain Analysis

- 4.4 Porter's Five Forces Analysis

- 4.4.1 Bargaining Power of Suppliers

- 4.4.2 Bargaining Power of Buyers

- 4.4.3 Threat of New Entrants

- 4.4.4 Threat of Substitute Products and Services

- 4.4.5 Degree of Competition

5 MARKET SEGMENTATION (Market Size in Volume)

- 5.1 By Type

- 5.1.1 Calcium-based

- 5.1.2 Lead-based

- 5.1.3 Tin-based

- 5.1.4 Barium-based

- 5.1.5 Other Types

- 5.2 By End-user Industry

- 5.2.1 Building and Construction

- 5.2.2 Automotive

- 5.2.3 Electrical and Electronics

- 5.2.4 Packaging

- 5.2.5 Footwear

- 5.2.6 Other End-user Industries

- 5.3 By Geography

- 5.3.1 Asia-Pacific

- 5.3.1.1 China

- 5.3.1.2 India

- 5.3.1.3 Japan

- 5.3.1.4 South Korea

- 5.3.1.5 Malaysia

- 5.3.1.6 Thailand

- 5.3.1.7 Indonesia

- 5.3.1.8 Vietnam

- 5.3.1.9 Rest of Asia-Pacific

- 5.3.2 North America

- 5.3.2.1 United States

- 5.3.2.2 Canada

- 5.3.2.3 Mexico

- 5.3.3 Europe

- 5.3.3.1 Germany

- 5.3.3.2 United Kingdom

- 5.3.3.3 France

- 5.3.3.4 Italy

- 5.3.3.5 Spain

- 5.3.3.6 NORDIC Countries

- 5.3.3.7 Turkey

- 5.3.3.8 Russia

- 5.3.3.9 Rest of Europe

- 5.3.4 South America

- 5.3.4.1 Brazil

- 5.3.4.2 Argentina

- 5.3.4.3 Colombia

- 5.3.4.4 Rest of South America

- 5.3.5 Middle East and Africa

- 5.3.5.1 Saudi Arabia

- 5.3.5.2 Qatar

- 5.3.5.3 United Arab Emirates

- 5.3.5.4 Nigeria

- 5.3.5.5 Egypt

- 5.3.5.6 South Africa

- 5.3.5.7 Rest of Middle East and Africa

- 5.3.1 Asia-Pacific

6 COMPETITIVE LANDSCAPE

- 6.1 Mergers and Acquisitions, Joint Ventures, Collaborations, and Agreements

- 6.2 Market Share (%)**/Ranking Analysis

- 6.3 Strategies Adopted by Leading Players

- 6.4 Company Profiles

- 6.4.1 Adeka Corporation

- 6.4.2 Akdeniz Chemson

- 6.4.3 Baerlocher GmbH

- 6.4.4 Clariant

- 6.4.5 Galata Chemicals

- 6.4.6 Goldstab Organics Pvt. Ltd

- 6.4.7 KD Chem Co. Ltd

- 6.4.8 Kunshan Maijisen Composite Materials Co. Ltd

- 6.4.9 Pau Tai Industrial Corp.

- 6.4.10 PMC Group Inc.

- 6.4.11 Ra Chemicals Pvt. Ltd

- 6.4.12 Reagens SpA

- 6.4.13 Shandong Jinchangshu New Material Technology Co. Ltd

- 6.4.14 SONGWON

- 6.4.15 Timah

- 6.4.16 Valtris Specialty Chemicals

- 6.4.17 Vikas Ecotech Ltd

7 MARKET OPPORTUNITIES AND FUTURE TRENDS

- 7.1 Rising Usage of Organo-tin Stabilizers as an Environment-friendly Option

- 7.2 Other Opportunities