|

市場調查報告書

商品編碼

1636266

德國電動汽車電池製造設備:市場佔有率分析、產業趨勢、成長預測(2025-2030)Germany Electric Vehicle Battery Manufacturing Equipment - Market Share Analysis, Industry Trends & Statistics, Growth Forecasts (2025 - 2030) |

||||||

價格

※ 本網頁內容可能與最新版本有所差異。詳細情況請與我們聯繫。

簡介目錄

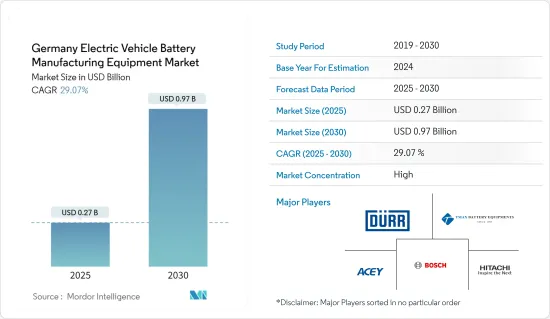

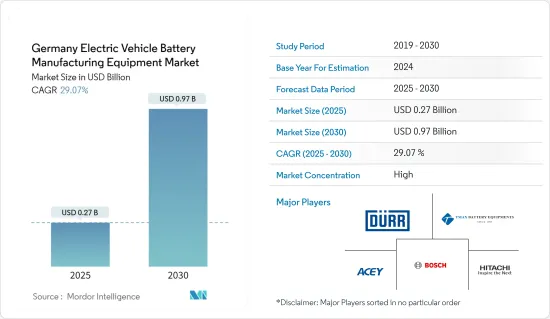

德國電動車電池製造設備市場規模預計2025年為2.7億美元,預計2030年將達9.7億美元,預測期間(2025-2030年)複合年成長率為29.07%。

主要亮點

- 從中期來看,電動車的普及以及政府法規和政策支持等因素預計將推動市場發展。

- 另一方面,來自現有市場的競爭預計將阻礙預測期內的市場成長。

- 供應鏈本地化預計將在未來幾年為市場帶來重大商機。

德國電動汽車電池製造設備市場趨勢

電動車的擴張

- 德國是歐洲最大的汽車市場和汽車創新的領導者,處於電動車革命的前沿。根據國際能源總署(IEA)預測,德國電動車銷量將從2019年的10.8萬輛增加至2023年的70萬輛,增幅超過540%。

- 隨著越來越多的消費者轉向電動車,電池(尤其是鋰離子電池)的生產將需要擴大規模以滿足不斷成長的需求。例如,2024年3月,Northvolt宣布計畫投資49億美元在海德附近興建新廠。計劃於 2026 年開始生產,預計該計劃將創造約 3,000 個就業機會。電池生產的擴張自然會導致對高效、大規模製造這些電池所需的專用設備的需求增加。

- 近年來,德國電動車市場經歷了顯著成長。在環保意識增強和擁有電動車帶來的經濟效益的推動下,電動車註冊數量正在迅速增加。 Kraftfahrt-Bundesamt(KBA)預計,德國註冊電動車數量將從2019年的63,281輛增加到2023年的524,219輛,四年內成長超過700%。此外,越來越多的德國人正在註冊新的電動車,到 2024 年 5 月註冊量將超過 140,700 輛。

- 德國政府的雄心勃勃的目標進一步凸顯了電動車市場的成長潛力。例如,德國政府計劃到 2030 年在德國道路上擁有至少 1500 萬輛電動車,這進一步增加了對強大電池製造基礎設施的需求。這將鼓勵對滿足預期需求所需的製造設備的投資。

- 隨著製造商擴大生產以滿足市場需求並利用不斷擴大的電動車市場帶來的機遇,對先進高效製造設備的需求持續成長,這將為德國電動車行業的成長發揮重要作用。

鋰離子電池領域佔市場主導地位

- 鋰離子電池是一種二次電池,以其能量密度高、壽命長、重量輕而聞名。透過在電極之間移動鋰離子,可以有效地儲存和釋放能量。

- 2023年,該產業的市場規模(產量和進口減去出口)成長32%,達到232億歐元(248.4億美元)。這一成長是由主要用於電動車的鋰離子電池推動的。

- 鋰離子電池在電動車 (EV) 中至關重要,因為它們具有高能量密度,可實現更長的行駛里程和高效的性能。它們的長循環壽命和快速充電能力使其成為電動車的理想動力來源,支持其在汽車行業的廣泛應用。隨著德國不斷擴大電動車生產規模,對與鋰離子技術相容的先進電池製造設備的需求不斷增加。

- 強化這項優勢的關鍵因素之一是鋰離子電池價格的下降。過去十年,技術的進步、規模經濟和製造流程的改進顯著降低了鋰離子電池的成本。

- 在全球範圍內,鋰離子電池的價格在過去十年中大幅下降。 2023年,鋰離子電池的平均價格約為每千瓦時139美元。與2013年相比,2023年價格將下降82%以上。

- 彭博新能源財經預測,隨著採礦和精製能的增加以及鋰價格開始回落,電池成本將在 2025 年再次開始下降。根據 BNEF 的 2023 年電池價格研究,預計到 2025 年,全球平均電池組價格將降至 113 美元/千瓦時以下,到 2030 年,全球整體電池組價格將降至 80 美元/千瓦時以下。

- 這些成本的降低使得電動車變得更加實惠和容易獲得,從而加速了其在全國的普及。隨著越來越多的消費者和企業轉向電動車,鋰離子電池的產量和需求激增,進一步鞏固了電池製造設備市場。

- 因此,在國內需求以及該國成為歐洲電動車供應鏈關鍵參與企業的雄心壯志的推動下,德國的鋰離子電池製造設備市場預計將擴大。

德國電動汽車電池製造設備產業概況

德國的電動車電池製造設備市場正在變得半固體。主要企業(排名不分先後)包括Duer AG、日立、ACEY新能源科技、Robert Bosch Manufacturing Solutions GmbH、廈門天邁電池設備有限公司。

其他好處

- Excel 格式的市場預測 (ME) 表

- 3 個月分析師支持

目錄

第1章簡介

- 調查範圍

- 市場定義

- 研究場所

第 2 章執行摘要

第3章調查方法

第4章市場概況

- 介紹

- 2029年之前的市場規模與需求預測(單位:美元)

- 最新趨勢和發展

- 政府法規和措施

- 市場動態

- 促進因素

- 電動車的擴張

- 政府支持性法規和措施

- 抑制因素

- 與現有市場的競爭

- 促進因素

- 供應鏈分析

- PESTLE分析

- 投資分析

第5章市場區隔

- 按流程

- 混合

- 塗層

- 日曆

- 狹縫/電極加工

- 其他

- 透過電池

- 鋰離子

- 鉛酸電池

- 鎳氫電池

- 其他電池

第6章 競爭狀況

- 併購、合資、聯盟、協議

- 主要企業策略

- 公司簡介

- Duerr AG

- Schuler AG

- Hitachi Ltd

- Xiamen Tmax Battery Equipments Limited

- ACEY New Energy Technology

- IPG Photonics Corporation

- Wuxi Lead Intelligent Equipment Co. Ltd

- Targray Technology International Inc.

- Xiamen Lith Machine Limited

- Robert Bosch Manufacturing Solutions GmbH

- 市場排名/佔有率(%)分析

- 其他知名公司名單

第7章 市場機會及未來趨勢

- 供應鏈本地化

簡介目錄

Product Code: 50003548

The Germany Electric Vehicle Battery Manufacturing Equipment Market size is estimated at USD 0.27 billion in 2025, and is expected to reach USD 0.97 billion by 2030, at a CAGR of 29.07% during the forecast period (2025-2030).

Key Highlights

- Over the medium term, factors such as the increasing adoption of electric vehicles and supportive government regulations and policies are expected to drive the market.

- On the other hand, competition from established markets are likely to hinder market growth during the forecast period.

- Nevertheless, localization of supply chains are expected to provide significant opportunities for the market in the coming years.

Germany Electric Vehicle Battery Manufacturing Equipment Market Trends

Increasing Adoption of Electric Vehicles

- As Europe's largest automotive market and a leader in automotive innovation, Germany is at the forefront of the electric mobility revolution. According to the International Energy Agency, Germany's electric vehicle sales grew from 108,000 in 2019 to 700,000 in 2023, representing an increase of more than 540%.

- As more consumers shift toward EVs, the production of batteries, particularly lithium-ion batteries, will need to scale up to meet the increasing demand. For instance, in March 2024, Northvolt announced plans to invest USD 4.9 billion in a new plant near Heide. Production is scheduled to begin in 2026, and the project is anticipated to create approximately 3,000 jobs. This expansion in battery production will naturally lead to a higher demand for the specialized equipment required to manufacture these batteries efficiently and at scale.

- In recent years, the German EV market has seen impressive growth. The number of electric vehicle registrations has surged, supported by a growing awareness of environmental issues and the financial benefits of owning an EV. According to the Kraftfahrt-Bundesamt (KBA), electric car registrations in Germany grew from 63,281 in 2019 to 524,219 in 2023, representing an increase of more than 700% within four years. Further, more Germans are registering for new electric cars, with over 140,700 registrations till May 2024.

- The German government's ambitious targets further underscore the growth potential of the EV market. For instance, the German government planned to have at least 15 million electric cars on German roads by 2030, further intensifying the need for a robust battery manufacturing infrastructure. This, in turn, drives investment in the necessary manufacturing equipment to meet the anticipated demand.

- As manufacturers scale up production to meet market demands and capitalize on the opportunities presented by the expanding EV market, the demand for advanced and efficient manufacturing equipment will continue to rise, playing a critical role in the growth of the EV industry in Germany.

Lithium-Ion Batteries Segment to Dominate the Market

- Lithium-ion batteries are rechargeable batteries known for their high energy density, long lifespan, and lightweight. They work by moving lithium ions between electrodes to store and release energy efficiently.

- In 2023, the industry's market volumes, including production plus imports minus exports, rose by 32% to EUR 23.2 billion (USD 24.84 billion). This growth was primarily driven by the dominant segment of lithium-ion batteries used in electric mobility.

- Lithium-ion batteries are crucial in electric vehicles (EVs) because they provide high energy density, allowing for longer driving ranges and efficient performance. Their long cycle life and fast charging capabilities make them ideal for powering EVs, supporting their widespread use in the automotive industry. As Germany continues to scale up its EV production, the demand for advanced battery manufacturing equipment tailored to Li-Ion technology is rising.

- One of the key factors reinforcing this dominance is the declining price of lithium-ion batteries. Over the past decade, the cost of lithium-ion batteries has dropped significantly due to technological advancements, economies of scale, and improved manufacturing processes.

- Globally, the price of lithium-ion batteries declined steeply over the past ten years. In 2023, the price of an average lithium-ion battery was valued at around USD 139 per kWh. It witnessed a decrease in the price of more than 82% in 2023 compared to 2013.

- BloombergNEF anticipates that battery costs will begin to decline again in 2025 as more extraction and refinery capacity become operational and lithium prices begin to ease. By 2025, the average pack price is expected to drop below USD 113/kWh and USD 80/kWh by 2030 globally, according to BNEF's 2023 Battery Price Survey.

- This cost reduction has made electric vehicles more affordable and accessible, accelerating their adoption nationwide. As more consumers and companies transition to EVs, the production and demand for lithium-ion batteries have surged, further solidifying the market for battery manufacturing equipment.

- As a result, the market for lithium-ion battery manufacturing equipment in Germany is expected to expand, driven domestic demand and the country's ambition to become a key player in the European EV supply chain.

Germany Electric Vehicle Battery Manufacturing Equipment Industry Overview

The German electric vehicle battery manufacturing equipment market is semi-consolidated. Some of the major players (not in particular order) include Duerr AG, Hitachi Ltd, ACEY New Energy Technology, Robert Bosch Manufacturing Solutions GmbH, and Xiamen Tmax Battery Equipments Limited.

Additional Benefits:

- The market estimate (ME) sheet in Excel format

- 3 months of analyst support

TABLE OF CONTENTS

1 INTRODUCTION

- 1.1 Scope of the Study

- 1.2 Market Definition

- 1.3 Study Assumption

2 EXECUTIVE SUMMARY

3 RESEARCH METHODOLOGY

4 MARKET OVERVIEW

- 4.1 Introduction

- 4.2 Market Size and Demand Forecast in USD, till 2029

- 4.3 Recent Trends and Developments

- 4.4 Government Policies and Regulations

- 4.5 Market Dynamics

- 4.5.1 Drivers

- 4.5.1.1 Increasing Adoption of Electric Vehicles

- 4.5.1.2 Supportive Government Regulations and Policies

- 4.5.2 Restraints

- 4.5.2.1 Competition From Established Markets

- 4.5.1 Drivers

- 4.6 Supply Chain Analysis

- 4.7 PESTLE Analysis

- 4.8 Investment Analysis

5 MARKET SEGMENTATION

- 5.1 By Process

- 5.1.1 Mixing

- 5.1.2 Coating

- 5.1.3 Calendaring

- 5.1.4 Slitting and Electrode Making

- 5.1.5 Other Processes

- 5.2 By Battery

- 5.2.1 Lithium-ion

- 5.2.2 Lead-acid

- 5.2.3 Nickel Metal Hydride Battery

- 5.2.4 Other Batteries

6 COMPETITIVE LANDSCAPE

- 6.1 Mergers and Acquisitions, Joint Ventures, Collaborations, and Agreements

- 6.2 Strategies Adopted by Leading Players

- 6.3 Company Profiles

- 6.3.1 Duerr AG

- 6.3.2 Schuler AG

- 6.3.3 Hitachi Ltd

- 6.3.4 Xiamen Tmax Battery Equipments Limited

- 6.3.5 ACEY New Energy Technology

- 6.3.6 IPG Photonics Corporation

- 6.3.7 Wuxi Lead Intelligent Equipment Co. Ltd

- 6.3.8 Targray Technology International Inc.

- 6.3.9 Xiamen Lith Machine Limited

- 6.3.10 Robert Bosch Manufacturing Solutions GmbH

- 6.4 Market Ranking/Share (%) Analysis

- 6.5 List of Other Prominent Companies

7 MARKET OPPORTUNITIES AND FUTURE TRENDS

- 7.1 Localization of Supply Chains

02-2729-4219

+886-2-2729-4219