|

市場調查報告書

商品編碼

1433825

SLS(選擇性雷射燒結):市場佔有率分析、產業趨勢與統計、成長預測(2024-2029)Selective Laser Sintering - Market Share Analysis, Industry Trends & Statistics, Growth Forecasts (2024 - 2029) |

||||||

※ 本網頁內容可能與最新版本有所差異。詳細情況請與我們聯繫。

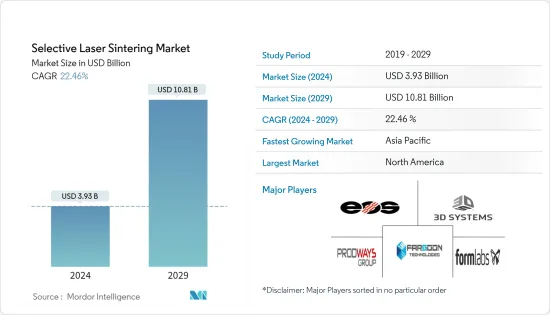

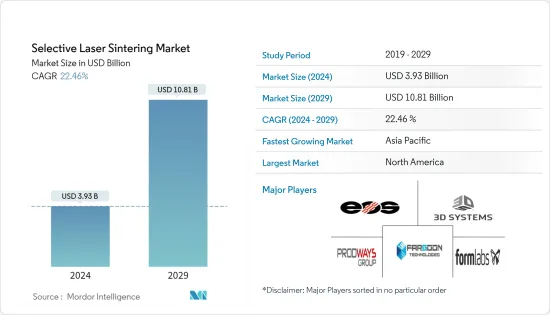

預計2024年SLS(選擇性雷射燒結)市場規模為39.3億美元,預計2029年將達到108.1億美元,複合年成長率預計為22.46%。

SLS 是一種積層製造(AM) 技術,是一種將高功率雷射光束定向到粉末材料床(通常是尼龍或聚醯胺)以燒結所需物體各層的製程。此層完成後,物體上覆蓋一層新的粉末,並燒結另一層。

主要亮點

- 由於已開發國家的研發設施的存在,預計 SLS 設備市場將受到需求不斷成長的推動。雷射燒結印表機的日益普及是由於可以使用非金屬粉末來創建原型模型和零件。雷射燒結印表機在列印金屬零件時也是最準確的。

- 由於與用於列印應用的其他技術相比,SLS 具有多種優勢,因此被認為是最受歡迎的技術之一,預計在預測期內將出現強勁成長。

- SLS以尼龍粉末作為原料,作為光固化成形法中所使用的光敏樹脂的替代。世界各地的公司和研究機構已經確定使用這種材料和技術來解決樹脂暴露在陽光下變得脆弱等問題。此外,SLS 也被證明具有成本和材料友善性,因為它在列印後不需要專用的支撐結構。此外,SLS 提高了耐用性,並且可以像功能部件和原型一樣發揮作用。

- SLS 進一步在航太、國防和汽車等各個垂直領域中廣泛應用。隨著航太發展模式轉移,越來越多的國家準備發射人造衛星,SLS列印的需求預計將增加。

- 各種航太公司正在採用這項技術來促進高效生產。例如,在航空航太領域,美國太空總署和私人公司正在致力於用更少的零件製造火箭引擎(在相對論性太空的情況下,是整個火箭)。這些零件是使用 SLS 以及金屬粉末(例如耐高溫的鉻鎳鐵合金銅超合金粉末)的鋪設和熔化逐層建造的。 SLS 技術有幾個優點。例如,可以在短短幾天內將多個零件列印為一個統一的零件,從而減少螺母、螺栓和焊接的數量,從而減輕火箭的重量。如果火箭在測試過程中出現故障,可以對 3D 建模軟體進行更改以建立新火箭並快速設定另一次測試。

- 此外,2021 年 12 月,積層製造零件製造商 Primaeam Solutions Pvt Ltd 在印度清奈開設了一個新的積層製造客戶經驗中心—醫療保健創新與孵化中心。這個佔地 10,000 平方英尺的中心提供電子束熔化 (EBM)、SLS (SLM)、熔融沉積建模(FDM)、光固化成形法(SLA)、多射流融合(MJF)、纖維增強連續絲製造(CFF)等服務。技術,我們將成為積層製造服務行業的傑出參與者。

- COVID-19 大流行對世界各地的中小企業和大型企業造成了經濟混亂。這是因為製造業的很大一部分涉及工廠車間的工作,人們在工廠車間進行密切接觸以提高生產率。

SLS市場趨勢

航太和國防工業預計將佔據主要市場佔有率

- 航太是目前大多數技術的早期採用者。飛機和引擎製造商都依靠 3D 列印技術來開發輕量化零件以提高效率。

北美預計將佔據主要市場佔有率

- 北美是許多開發、採用和投資積層製造的公司的所在地。該地區對原型製作的需求不斷成長,這是該地區市場的主要驅動力。此外,北美對 SLS 的需求受到各行業對研發和測試的日益關注的推動。

- 據加拿大統計局稱,加拿大企業計劃在2021年花費219億美元用於內部工業研發,2022年花費224億美元。這種研發成長預計將提振北美 SLS 市場。

- 該地區的公司正在組建策略聯盟,為更廣泛的客戶群提供解決方案。例如,2022年5月,美國Essentium Inc與藍色雷射解決方案供應商Nuburu合作開發基於藍色雷射的金屬積層製造平台。

- 因此,製造商有望能夠製造出具有高解析度和快速吞吐量的生產級金屬零件。此外,作為協議的一部分,Nubl 將許可積層製造專利。

- 3D 列印等新技術的日益使用預計也將推動該地區的 SLS 市場。例如,根據世界經濟論壇的數據,到2022年,美國接受調查的企業中有47%預計將使用3D列印技術。

SLS產業概述

SLS 市場主要由在全球營運的老牌公司和一些在整合市場空間中爭奪注意力的區域參與者組成。包括 3D Systems Inc.、EOS GmbH Electro Optical Systems、Ricoh Company Ltd. 和 Fathom Manufacturing 在內的多家在該領域擁有豐富專業知識的參與者的加入,預計將進一步加劇競爭對手之間的競爭。

- 2022 年 6 月 - 3D Systems 和 EMS GRILTECH 宣佈建立策略合作夥伴關係,以加強積層製造材料的開發。兩家公司推出了 Durafoam PAx Natural,這是一種新型尼龍共聚物,設計用於商用 SLS 印表機。

- 2021 年 11 月 - 贏創工業股份公司宣布擴大其 RESOMER PrintPowder 聚合物生產線,可實現植入式醫療設備的 3D 列印。這種新型粉末可在全球範圍內使用 SLS 方法進行 3D 列印。這種新型粉末具有廣泛的可客製化機械性能和劣化率,使其可用於更複雜和客製化的醫療設備,包括各種整形外科、牙科和軟組織應用。

- 2021 年 2 月 - 3D Systems 宣佈在南卡羅來納州羅克山擴建計劃,在現有總部園區基礎上增加 100,000 平方英尺。此次擴建將整合材料製造、品質和物流業務,並創建和擴大材料開發實驗室,以提高業務效率、加速解決方案開發並縮短上市時間。

其他福利:

- Excel 格式的市場預測 (ME) 表

- 3 個月的分析師支持

目錄

第1章簡介

- 研究假設和市場定義

- 調查範圍

第2章調查方法

第3章執行摘要

第4章市場洞察

- 市場概況

- 產業吸引力-波特五力分析

- 供應商的議價能力

- 買方議價能力

- 新進入者的威脅

- 替代品的威脅

- 競爭公司之間敵對關係的強度

- COVID-19 市場影響評估

- 3D列印技術分析(FDM、SLA、SLS;材料與技術的定性分析;桌上型工業SLS和傳統工業SLS列印機的比較)

第5章市場動態

- 市場促進因素

- 縮短最終產品進入市場的時間

- 各地區政府措施的活性化

- 市場挑戰

- 額外的資本投資和大規模生產的限制

第6章市場區隔

- 按材質

- 金屬

- 塑膠

- 按成分

- 硬體

- 軟體

- 服務

- 按最終用戶產業

- 車

- 航太/國防

- 衛生保健

- 電子產品

- 其他

- 按地區

- 北美洲

- 歐洲

- 亞太地區

- 世界其他地區

第7章 競爭形勢

- 公司簡介

- 3D Systems Inc.

- EOS GmbH Electro Optical Systems

- Farsoon Technologies

- Prodways Group

- Formlabs Inc.

- Ricoh Company Ltd

- Concept Laser GmbH(General Electric)

- Renishaw PLC

- Sinterit Sp. Zoo

- Sintratec AG

- Sharebot SRL

- Red Rock SLS

第8章投資分析

第9章市場的未來

The Selective Laser Sintering Market size is estimated at USD 3.93 billion in 2024, and is expected to reach USD 10.81 billion by 2029, growing at a CAGR of 22.46% during the forecast period (2024-2029).

Selective Laser Sintering (SLS), an additive manufacturing (AM) technique, is a process in which a high-powered laser beam is aimed into powdered material (typically nylon or polyamide) bed to sinter a layer of the desired object. Following the completion of that layer, the object is covered with a new layer of powder, and another layer is sintered.

Key Highlights

- The market for SLS equipment is anticipated to be driven by the rising demand from developed countries, owing to the presence of research and development facilities in the countries. The adoption of laser sintering printers has increased due to the ease of availability of non-metal powders to create prototype models and parts. Also, laser sintering printers are the most precise when printing metal parts.

- Selective Laser Sintering (SLS) has been identified as one of the most-preferred technology and is expected to witness robust growth during the forecast period, owing to its various benefits over other technologies used for printing applications.

- SLS utilizes nylon powder as raw material as a substitute for the photosensitive resin used in Stereolithography. Companies and research organizations across the globe have been identified to take advantage of this material and technology to tackle concerns, such as the brittle nature of the resin when exposed to sunlight. In addition, SLS has also been proven to be cost and material friendly, as it does not require any dedicated support structure post-printing. In addition, SLS provides enhanced durability and can perform as well as either functional parts or prototypes.

- SLS further finds a wide array of applications across various verticals, such as aerospace, defense, and automotive, among others. With space exploration witnessing a paradigm shift, the demand for SLS printing is expected to mount, with an increasing number of countries gearing up to launch satellites.

- Various aerospace companies are adopting the technology to foster efficient production. For instance, in the space flight branch of aerospace, NASA and private companies are working to build rocket engines (and even entire rockets in the case of Relativity Space) with fewer parts, which is a crucial capability of 3D printing and a way to reduce production time and costs. Using selective laser sintering and the laying down and melting of metal powder (for example, Inconel copper super alloy power that can withstand high temperatures), parts are built up layer by layer. The SLS technique offers several benefits, like multiple parts can be printed as one unified part in just days; the rocket's weight can be reduced with fewer nuts, bolts, and welds. If the rocket proves faulty during a test, changes can be made to the 3D modeling software for a new rocket, and another test can be quickly set up.

- Further, in December 2021, Primaeam Solutions Pvt Ltd, an additive parts manufacturing company, inaugurated its new Additive Manufacturing Customer Experience Centre, Innovation & Incubation Centre for Healthcare, in Chennai, India. The 10,000 sq. ft. center would allow the company to develop its position as a prominent player in the additive manufacturing service bureau with technologies such as Electron Beam Melting (EBM), Selective Laser Sintering (SLM), Fused Deposition Modelling (FDM), Stereolithography (SLA), Multi Jet Fusion (MJF), and Continuous Filament Fabrication with Fiber reinforcement (CFF).

- The COVID-19 pandemic outbreak has created economic turmoil for small, medium, and large-scale industries worldwide. Adding to the woes, country-wise lockdown inflicted by the governments across the globe (to minimize the spread of the virus) has further resulted in industries taking a hit and disruption in supply chain and manufacturing operations across the world, as a large part of manufacturing includes work on the factory floor, where people are in close contact as they collaborate to boost the productivity.

Selective Laser Sintering (SLS) Market Trends

Aerospace and Defense Industry is Expected to Hold Significant Market Share

- The aerospace industry has an early rate of adoption of most of the technologies in the current generation. Both aircraft and engine manufacturers have been relying on 3D printing technology in order to develop lightweight parts to gain efficiency.

- 3D printing has been used by the National Aeronautics and Space Administration (NASA) for decades for the purposes of prototyping and creating functional parts and, most recently, for building construction systems for the Moon and Mars.

- Bell Textron Inc. was one of the first aerospace companies to experiment with additive manufacturing. The first use of SLS was for quick prototypes of tooling and experimental parts. However, as the additive manufacturing industry progressed, the company understood the need to allow the additive manufacturing industry to mature. Since the start of additive efforts, Bell Textron has produced over 550 parts widely spread among its products with just SLS. While a majority of parts produced are experimental, it is to be noted that over 200 of those 550 parts are for production purposes.

- Moreover, in July 2022, GKN Aerospace expanded its range of metal additive manufacturing machines at the company's global technology center in the United Kingdom by installing RenAM 500 Flex. The RenAM 500Q Flex is a four-laser Additive Manufacturing machine that is expected to optimize Additive Manufacturing for aerospace applications.

- Furthermore, according to the US Census Bureau, it is expected that the revenue of aerospace products and parts manufacturing in the United States will amount to about USD 264.4 billion by 2024. Moreover, It is likely that the revenue of aerospace products and parts manufacturing in Canada will amount to approximately USD 19.3 billion by 2024. Such developments would drive the market's growth positively.

- According to Stockholm International Peace Research Institute (SIPRI), the United States led the ranking of countries with maximum military spending in 2021, with 801 USD billion dedicated to the military, which was 38 percent of the global military expenditure of USD 2.1 trillion.

North America is Expected to Hold Major Market Share

- North America is home to many companies developing, adopting, or investing in additive manufacturing. There has been a growth in the demand for prototyping in the region which has been majorly driving the market in the region. Further, the demand for SLS in North America is driven by a higher focus on research and development and increased testing in various industries.

- According to Statistics Canada, Canadian businesses intend to spend USD 21.9 billion on in-house industrial research and development in 2021, while USD 22.4 billion is expected to be spent in 2022. Such growth in research and development is expected to push the market for Selective Laser Sintering in North America.

- Companies in the region are doing strategic collaborations to provide their solutions to a broader customer base. For instance, in May 2022, Essentium Inc, a US-based company, partnered with Nuburu, a blue laser solution provider, to develop a blue laser-based metal Additive Manufacturing platform.

- The resulting machine is hoped to enable manufacturers to create production-grade metal parts with high resolution and fast throughput. Further, as a part of the contract, Nuburu will license its additive manufacturing application patents.

- The increase in the usage of new technologies, such as 3D printing, is also expected to drive the market of SLS in the region. For instance, according to World Economic Forum, it is expected that by 2022, 47% of the surveyed companies in the United States will use 3D printing technology.

Selective Laser Sintering (SLS) Industry Overview

The Selective Laser Sintering Market majorly comprises incumbents operating globally, along with a few regional players vying for attention in a consolidated market space. The presence of several players, such as 3D Systems Inc., EOS GmbH Electro Optical Systems, Ricoh Company Ltd., and Fathom Manufacturing, among others with considerable expertise in the field, is expected to intensify the competitive rivalry further.

- June 2022 - 3D Systems and EMS GRILTECH announced the strategic partnership to enhance additive manufacturing materials development. Both companies will introduce a novel nylon copolymer - DuraForm PAx Natural- designed to be used with any commercially-available selective laser sintering (SLS) printer.

- November 2021 - Evonik Industries AG announced that it offers a broader range of RESOMER PrintPowder polymers to enable the 3D printing of personalized implantable medical devices. The new powders are available globally for 3D printing through selective laser sintering (SLS). Due to a broader range of customizable mechanical properties and degradation rates, the new powders could be used for more complex and tailored medical devices, including diverse orthopedic, dental, or soft tissue applications.

- February 2021 - 3D Systems announced the expansion plan of its Rock Hill, South Carolina, location, adding 100,000 square feet to its existing headquarters campus. This expansion will enable the company to consolidate its materials manufacturing, quality, and logistics operations, with new and expanded materials development laboratories to improve operational efficiencies, accelerate solution development, and reduce time to market.

Additional Benefits:

- The market estimate (ME) sheet in Excel format

- 3 months of analyst support

TABLE OF CONTENTS

1 INTRODUCTION

- 1.1 Study Assumptions and Market Definition

- 1.2 Scope of the Study

2 RESEARCH METHODOLOGY

3 EXECUTIVE SUMMARY

4 MARKET INSIGHTS

- 4.1 Market Overview

- 4.2 Industry Attractiveness - Porters Five Forces Analysis

- 4.2.1 Bargaining Power of Suppliers

- 4.2.2 Bargaining Power of Buyers

- 4.2.3 Threat of New Entrants

- 4.2.4 Threat of Substitutes

- 4.2.5 Intensity of Competitive Rivalry

- 4.3 Assessment of Impact of COVID-19 on the Market

- 4.4 Analysis of 3D Printing Technologies (FDM, SLA, SLS; Qualitative Analysis on Materials and Technologies; Benchtop Industrial SLS Vs Traditional Industrial SLS Printers)

5 MARKET DYNAMICS

- 5.1 Market Drivers

- 5.1.1 Reduced Time for the End Product to Reach the Market

- 5.1.2 Increased Government Initiatives Across Various Regions

- 5.2 Market Challenges

- 5.2.1 Additional Capital Expenditure and Restrictions in Mass Production

6 MARKET SEGMENTATION

- 6.1 By Material

- 6.1.1 Metal

- 6.1.2 Plastic

- 6.2 By Component

- 6.2.1 Hardware

- 6.2.2 Software

- 6.2.3 Services

- 6.3 By End-user Industry

- 6.3.1 Automotive

- 6.3.2 Aerospace and Defense

- 6.3.3 Healthcare

- 6.3.4 Electronics

- 6.3.5 Other End-user Industries

- 6.4 By Geography

- 6.4.1 North America

- 6.4.2 Europe

- 6.4.3 Asia Pacific

- 6.4.4 Rest of the World

7 COMPETITIVE LANDSCAPE

- 7.1 Company Profiles

- 7.1.1 3D Systems Inc.

- 7.1.2 EOS GmbH Electro Optical Systems

- 7.1.3 Farsoon Technologies

- 7.1.4 Prodways Group

- 7.1.5 Formlabs Inc.

- 7.1.6 Ricoh Company Ltd

- 7.1.7 Concept Laser GmbH (General Electric)

- 7.1.8 Renishaw PLC

- 7.1.9 Sinterit Sp. Zoo

- 7.1.10 Sintratec AG

- 7.1.11 Sharebot SRL

- 7.1.12 Red Rock SLS