|

市場調查報告書

商品編碼

1431090

精密車床加工產品製造:市場佔有率分析、產業趨勢/統計、成長預測(2024-2029)Precision Turned Product Manufacturing - Market Share Analysis, Industry Trends & Statistics, Growth Forecasts (2024 - 2029) |

||||||

※ 本網頁內容可能與最新版本有所差異。詳細情況請與我們聯繫。

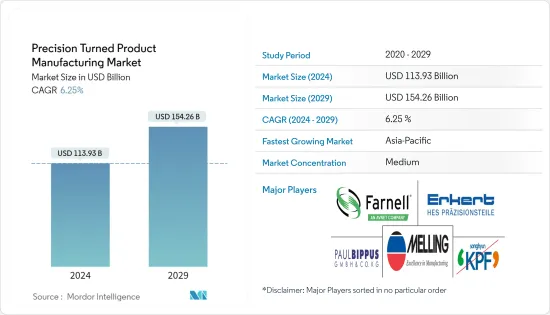

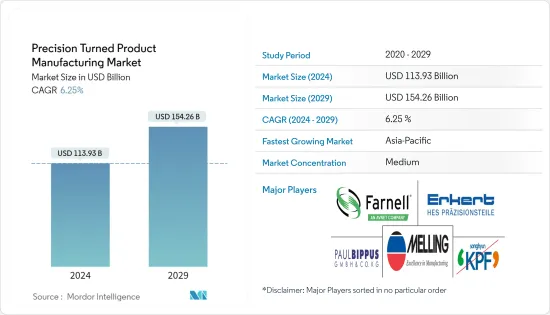

精密車削產品製造市場規模預計到 2024 年為 1,139.3 億美元,預計到 2029 年將達到 1,542.6 億美元,在預測期內(2024-2029 年)複合年成長率為 6.25%。

對尖端加工解決方案的需求正在推動銷售成長,重點是減少停機時間以提高生產速度、精度和製作流程。工業4.0鼓勵製造設備與其他業務功能合作,並利用製造機器和生產精密工程機械創建複雜的自適應自動化系統。因此,隨著工業4.0在未來幾年的蓬勃發展,該領域存在著許多機會。

航太業,包括民用和國防市場的所有系統、電子和設備的研究、開發和製造,目前正在經歷全球成長,並且不太可能經歷衰退壓力。然而,全球頂級商用航太OEM預測,到2023年或2024年初,全球客運量將恢復到2019年的水準。這可能會導致訂單增加,以滿足不斷成長的積壓,從而提高行業收益。這一成長的原因之一可以歸因於烏克蘭戰爭爆發後國防預算的增加,這增加了世界對軍事裝備的需求。

精密工程機械因其電腦控制的精度而變得越來越受歡迎,這提高了製造過程的效率和生產率。技術在進步,精密工程的範圍在擴大。精密工程機械可實現流程自動化,減少加工零件所需的時間。

機械師可以將代碼輸入電腦,機器就可以運行,無需人工干預或控制。事實證明,機器人,也稱為工業自動化機器 (IAM),在許多方面對離散製造商和系列製造商都有好處。其中一些好處包括提高效率和更有效率的製造流程。

精密車床產品製造的市場趨勢

汽車產業引領市場

汽車行業是精密加工零件的最大用戶,因此確保準確和嚴格的公差非常重要。為了使汽車零件正常工作,它們必須安裝到位並且品質指定,如果沒有按照適當的規格進行加工,可能會導致燃油經濟性降低、引擎故障和事故等問題。這是有性別的。精密車床零件應用於汽車業,如節氣門控制軸、低通濾波器、液壓閥、閥門殼體、感知器殼體、溫度感知器殼體、壓力感知器殼體、管接頭、感知器金屬殼等用於各種目的。我們確保零件準確、耐用且功能正常,幫助您的汽車平穩、安全地運作。

2022 年全球汽車產量將達到約 8,500 萬輛。與前一年相比,這一數字增加了約 6%。由於人口成長、都市化和個性化,這一數字預計將繼續成長。

隨著電子商務的發展,物流運輸對輕、中、重型商用卡車的需求大幅增加。物流業不再只是一個服務供應商,而是提供以客戶為導向的解決方案。因此,對商用卡車運輸的需求呈指數級成長。

工業4.0將徹底改變製造業

工業4.0實現生產現代化並增強西方工業部門的競爭力。它以改進的機器人技術和自動化、新型態的人機互動、大量資料的累積以及增強的連接性為中心。借助物聯網和高效自動化機器人技術,製造商可以收集、分析大量資料並採取行動。

隨著越來越多的資料被記錄、分析和存儲,以及智慧型設備數量的增加,連接和通訊可能變得更加重要。企業需要在內部以及與外部合作夥伴進行互通和共用資料,以實現更高級的營運。

使用數位疊加,混合實境設備可以將現場工作人員與具有必要技能的第三方聯繫起來,讓工作人員能夠逐步學習如何進行維修。

過去,試圖保持競爭力的製造公司不得不將業務外包給低工資國家。技術進步現在使富裕國家能夠參與競爭。

精密車床產品製造業概況

市場上有很多大公司。市場是分散的,因為沒有競爭對手控制市場的很大一部分。競爭對手正在製定新的策略來維護自己的主導地位。

Premier Farnell Corp.、HES Prazisionsteile Hermann Erkert GmbH、KPF 和 Melling Tool Co.KG 是一些活躍於該領域的主要企業。

其他福利:

- Excel 格式的市場預測 (ME) 表

- 3 個月的分析師支持

目錄

第1章簡介

- 調查背景

- 研究假設和市場定義

第2章調查方法

第3章執行摘要

第4章市場動態與洞察

- 目前的市場狀況

- 市場動態

- 市場促進因素

- 航太的成長推動市場

- 汽車產業引領市場

- 市場限制因素

- 缺乏技術純熟勞工

- 機會

- 到 2025 年,工業 4.0 將徹底改變製造業

- 市場促進因素

- 產業吸引力-波特五力分析

- 價值鏈/供應鏈分析

- 政府法規和舉措

- 科技趨勢

- COVID-19 對市場的影響

第5章市場區隔

- 按操作

- 手動操作

- 數控操作

- 按機器類型

- 自動螺絲機

- 旋轉傳送機

- 電腦數值控制(CNC)

- 車床或車削中心

- 依材料類型

- 塑膠

- 鋼

- 其他材料類型

- 按最終用途

- 車

- 電子產品

- 防禦

- 衛生保健

- 按地區

- 北美洲

- 美國

- 加拿大

- 墨西哥

- 歐洲

- 德國

- 法國

- 英國

- 義大利

- 西班牙

- 俄羅斯

- 其他歐洲國家

- 亞太地區

- 中國

- 日本

- 印度

- 孟加拉

- 土耳其

- 韓國

- 澳洲

- 印尼

- 其他亞太地區

- 中東/非洲

- 埃及

- 南非

- 沙烏地阿拉伯

- 其他中東和非洲

- 世界其他地區

- 北美洲

第6章 競爭形勢

- 公司簡介

- Melling Tool Co.

- Kksp Precision Machining

- E&H Precision

- Greystone of Lincoln

- RW Screw Products

- Zhejiang Ronnie Precision Machine Co. Ltd

- Astro Machine Works

- Cox Manufacturing Company

- EJ Basler Co.

- Hall Industries Incorporated

- Supreme Machined Products Company

- Alpha Grainger Mfg

- C & M Machine Products

- Alger Precision Machining

- Tompkins Products Inc.

第7章 市場的未來

第8章附錄

The Precision Turned Product Manufacturing Market size is estimated at USD 113.93 billion in 2024, and is expected to reach USD 154.26 billion by 2029, growing at a CAGR of 6.25% during the forecast period (2024-2029).

The demand for cutting-edge machining solutions is driving sales growth, and the focus on reducing downtime to increase production speed, accuracy, and machining processes is also driving growth. Industry 4.0 encourages manufacturing facilities to link up with other business functions to create complex and adaptive automation systems that use manufacturing and production precision engineering machinery. So, there are lots of opportunities in the sector as Industry 4.0 flourishes in the coming years.

The aerospace industry, which includes R&D and manufacturing of the full range of systems, electronics, and equipment for both civilian and defense markets, is currently experiencing global growth and is unlikely to experience recessionary pressures. However, the world's top commercial aerospace OEMs predict that by 2023 or early 2024, global passenger traffic is expected to return to 2019 levels. This could lead to ramp-ups to address growing backlogs and boost industry revenue. One of the reasons for this increase can be attributed to the increase in defense budgets after the outbreak of war in Ukraine, which led to an increase in global demand for military equipment.

Because of their computerized precision, precision engineering machines are becoming increasingly popular as manufacturing processes become more efficient and productive. Technology is advancing, and the scope of precision engineering is expanding. Precision engineering machines allow for automated processes and, therefore, reduce the time required for component machining.

Once the codes are fed into the computer by the machinist, the machines can run without manual intervention and control. Robots, also known as industrial automated machines (IAMs), have proven to be beneficial for discrete and continuous manufacturers alike in a variety of ways. Some of these benefits include increased efficiency and more efficient manufacturing processes.

Precision Turned Product Manufacturing Market Trends

Automotive Industry is driving the market

The auto industry is the biggest user of precision machined parts, so it's important to make sure they're accurate and with tight tolerances. Automotive parts need to fit into place and be of good quality to work properly, and if they're not machined to the right specifications, it can lead to problems like lower fuel efficiency, engine failure, and accidents. Precision-turned components are used in the auto industry for a variety of purposes, like throttle control shafts, low pass filters, hydraulic valves, valve housings, sensor housings, temperature sensor housings, pressure sensor housings, pipe joints, sensor metal shells, etc. They make sure the parts are accurate, durable, and work properly, which helps keep your car running smoothly and safely.

There were approximately 85 million motor vehicles produced in the world in 2022. This represents an increase of about 6% compared to the previous year. It is expected that this number will continue to increase in the coming years due to the growing population, urbanization, and personalization.

With the growth of e-commerce, the demand for small, medium, and large commercial trucks in logistics and transportation has increased significantly. The logistics industry is no longer just about providing services but providing customer-oriented solutions. Therefore, the demand for commercial trucks for transportation has increased exponentially.

Industry 4.0 Revolutionizing the Manufacturing Industry

Industry 4.0 involves modernizing production and enhancing the competitiveness of the Western industrial sector. It is centered on improved robotics and automation, new human-machine interaction forms, massive data troves, and increasing connectivity. With the help of IoT and highly effective, automated robotics, manufacturers can gather, analyze, and take action on enormous stockpiles of data.

Connectivity and communication may become more crucial as the amount of data being recorded, analyzed, and stored, along with the number of smart devices, increases. Companies require their data to be interoperable and shared both within an organization and with outside partners to enable higher levels of operations.

Through the use of digital overlays, mixed reality devices can link the person on site with a third party with the necessary skills so they can learn how to make the repairs step-by-step.

In the past, manufacturing companies that wanted to stay competitive had to outsource to low-wage countries. Richer nations are now able to compete because of technological advancements.

Precision Turned Product Manufacturing Industry Overview

There are many major players in the market. Since none of the competitors control a sizable portion of the market, it is fragmented. The rivals are coming up with new strategies to assert their superiority.

Premier Farnell Corp., HES Prazisionsteile Hermann Erkert GmbH, KPF, Melling Tool Co., and Paul Bippus GmbH & Co. KG are a few of the key companies active in the sector.

Additional Benefits:

- The market estimate (ME) sheet in Excel format

- 3 months of analyst support

TABLE OF CONTENTS

1 INTRODUCTION

- 1.1 Study Background

- 1.2 Study Assumptions and Market Definition

2 RESEARCH METHODOLOGY

3 EXECUTIVE SUMMARY

4 MARKET INSIGHTS AND DYNAMICS

- 4.1 Current Market Scenario

- 4.2 Market Dynamics

- 4.2.1 Market Drivers

- 4.2.1.1 Growth of the Aerospace Industry driving the market

- 4.2.1.2 Automotive Industry is driving the market

- 4.2.2 Market Restraints

- 4.2.2.1 Skilled Labor Shortage

- 4.2.3 Opportunities

- 4.2.3.1 Industry 4.0 Revolutionizing the Manufacturing Industry By 2025

- 4.2.1 Market Drivers

- 4.3 Industry Attractiveness - Porter's Five Forces Analysis

- 4.4 Value Chain/Supply Chain Analysis

- 4.5 Government Regulations and Initiatives

- 4.6 Technological Trends

- 4.7 Impact of COVID-19 on the Market

5 MARKET SEGMENTATION

- 5.1 By Operation

- 5.1.1 Manual Operation

- 5.1.2 CNC Operation

- 5.2 By Machine Types

- 5.2.1 Automatic Screw Machines

- 5.2.2 Rotary Transfer Machines

- 5.2.3 Computer Numerically Controlled (CNC)

- 5.2.4 Lathes or Turning centers

- 5.3 By Material Type

- 5.3.1 Plastic

- 5.3.2 Steel

- 5.3.3 Other Material Types

- 5.4 By End Use

- 5.4.1 Automobile

- 5.4.2 Electronics

- 5.4.3 Defense

- 5.4.4 Healthcare

- 5.5 By Geography

- 5.5.1 North America

- 5.5.1.1 United States

- 5.5.1.2 Canada

- 5.5.1.3 Mexico

- 5.5.2 Europe

- 5.5.2.1 Germany

- 5.5.2.2 France

- 5.5.2.3 United Kingdom

- 5.5.2.4 Italy

- 5.5.2.5 Spain

- 5.5.2.6 Russia

- 5.5.2.7 Rest of Europe

- 5.5.3 Asia-Pacific

- 5.5.3.1 China

- 5.5.3.2 Japan

- 5.5.3.3 India

- 5.5.3.4 Bangladesh

- 5.5.3.5 Turkey

- 5.5.3.6 South Korea

- 5.5.3.7 Australia

- 5.5.3.8 Indonesia

- 5.5.3.9 Rest of Asia-Pacific

- 5.5.4 Middle-East and Africa

- 5.5.4.1 Egypt

- 5.5.4.2 South Africa

- 5.5.4.3 Saudi Arabia

- 5.5.4.4 Rest of Middle-East and Africa

- 5.5.5 Rest of the World

- 5.5.1 North America

6 COMPETITIVE LANDSCAPE

- 6.1 Market Concentration Overview

- 6.2 Company Profiles

- 6.2.1 Melling Tool Co.

- 6.2.2 Kksp Precision Machining

- 6.2.3 E&H Precision

- 6.2.4 Greystone of Lincoln

- 6.2.5 R W Screw Products

- 6.2.6 Zhejiang Ronnie Precision Machine Co. Ltd

- 6.2.7 Astro Machine Works

- 6.2.8 Cox Manufacturing Company

- 6.2.9 E. J. Basler Co.

- 6.2.10 Hall Industries Incorporated

- 6.2.11 Supreme Machined Products Company

- 6.2.12 Alpha Grainger Mfg

- 6.2.13 C & M Machine Products

- 6.2.14 Alger Precision Machining

- 6.2.15 Tompkins Products Inc.*