|

市場調查報告書

商品編碼

1861049

全球鋁釬硬焊市場按產品類型、最終用途產業和地區分類-預測至2032年Aluminum Brazing Market by Product Type, Product Form, End-use Industry, and Region - Global Forecast to 2032 |

||||||

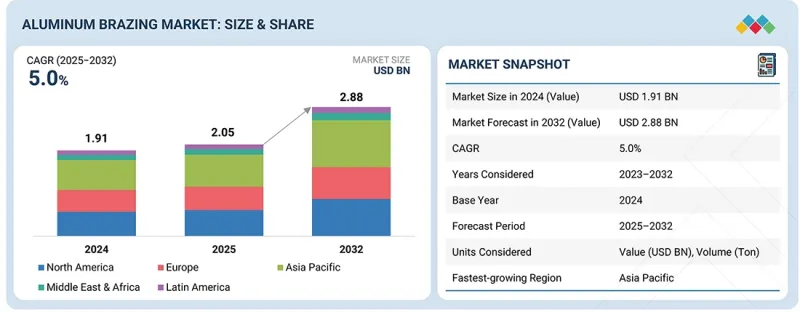

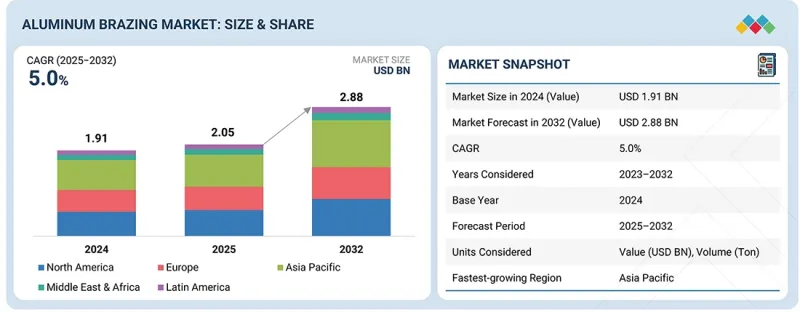

預計到 2025 年,鋁釬硬焊市場規模將達到 20.5 億美元,到 2032 年將達到 28.8 億美元,2025 年至 2032 年的複合年成長率為 5.0%。

按產品類型分類,鋁鋅合金細分市場在整個鋁釬硬焊市場中佔據第三大佔有率。

| 調查範圍 | |

|---|---|

| 調查年度 | 2023-2032 |

| 基準年 | 2024 |

| 預測期 | 2025-2032 |

| 考慮單位 | 金額(百萬美元)和數量(噸) |

| 部分 | 按產品類型、最終用途產業和地區分類 |

| 目標區域 | 北美、歐洲、亞太地區、拉丁美洲、中東和非洲、海灣合作理事會國家 |

這些合金具有優異的潤濕性、低熔點和卓越的耐腐蝕性,對於在暖通空調製冷、汽車熱交換器和電子應用中製造高強度、密封性良好的接頭至關重要。它們與鋁基材的相容性還能最大限度地減少電流腐蝕,使其成為CAB等大量生產過程的理想選擇。這些合金能夠實現經濟高效的製造,並確保高效的流動性和牢固的接頭完整性。

由於鋁釬焊絲在輕型汽車和暖通空調(HVAC)等對效率和溫度控管要求極高的領域中應用日益廣泛,預計鋁硬焊市場將呈現第二高的複合年成長率。在汽車產業,為提高燃油效率和減少排放氣體而轉向輕型車的趨勢,推動了對鋁釬焊絲的強勁需求。製造技術的進步,包括自動化和人工智慧在精確硬焊控制方面的應用,提高了生產效率和接頭質量,進一步促進了市場成長。此外,對永續性和節能系統的日益重視,也推動了鋁釬焊絲作為多個工業領域首選連接材料的應用。

在預測期內,電氣和電子行業的鋁釬焊市場預計將實現第二高的複合年成長率。此終端應用領域的市場成長主要受電子組件對輕量化、耐用且耐腐蝕元件日益成長的需求所驅動。電子設備的微型化以及冷卻系統和電路元件對精確可靠連接的需求,都推動了這一成長。鋁硬焊技術的不斷進步有望提高電子製造中硬焊的品質和效率,從而進一步促進市場擴張。該領域的持續技術創新以及消費性電子和通訊產量的不斷成長,也為強勁的需求做出了貢獻。

預計歐洲鋁硬焊市場將實現第三高的複合年成長率,這主要得益於汽車、工業以及航太和國防領域的強勁需求。歐盟嚴格的環境法規,例如旨在推廣節能輕量材料以減少二氧化碳排放的「歐洲綠色交易」,正在推動市場成長。對電動車、可再生能源計劃和先進製造技術的投資將進一步刺激需求。德國、法國、義大利和英國等國的政府獎勵措施以及對永續生產方式的重視,正在推動各行業採用鋁釬焊合金和助焊劑。

本報告分析了全球鋁硬焊市場,提供了按產品類型、最終用途行業和地區分類的趨勢資訊,以及參與該市場的公司的概況。

目錄

第1章 引言

第2章調查方法

第3章執行摘要

第4章重要考察

第5章 市場概覽

- 介紹

- 市場動態

- 波特五力分析

- 主要相關人員和採購標準

- 定價分析

- 宏觀經濟展望

- 價值鏈分析

- 生態系分析

- 貿易分析

- 技術分析

- 專利分析

- 監管狀態

- 2025年至2027年的重要會議和活動

- 案例研究分析

- 影響客戶業務的趨勢/干擾因素

- 生成式人工智慧/人工智慧對鋁釬硬焊市場的影響

- 投資和資金籌措方案

- 美國關稅對鋁硬焊市場的影響

6. 鋁釬硬焊市場(依產品類型分類)

- 介紹

- 鋁矽合金

- 鋁鋅合金

- 鋁銅合金

- 鋁鎂合金

- 其他

第7章 鋁釬硬焊市場(依產品類型分類)

- 介紹

- 床單

- 貼上

- 金屬絲

- 桿

- 其他

8. 鋁釬硬焊市場(依終端用戶產業分類)

- 介紹

- 車

- 航太與國防

- 工業的

- 電機與電子工程

- 其他

9. 各地區鋁釬硬焊市場

- 介紹

- 北美洲

- 歐洲

- 亞太地區

- 中東和非洲

- 拉丁美洲

第10章 競爭格局

- 介紹

- 主要參與企業的策略/優勢,2020-2025 年

- 2020-2024年收入分析

- 2024年市佔率分析

- 品牌/產品對比

- 公司估值矩陣:主要參與企業,2024 年

- 公司估值矩陣:Start-Ups/中小企業,2024 年

- 估值和財務指標

- 競爭場景

第11章 公司概況

- 主要參與企業

- SOLVAY

- HONEYWELL INTERNATIONAL INC.

- LUCAS-MILHAUPT LLC

- HARRIS PRODUCTS GROUP(THE LINCOLN ELECTRIC COMPANY)

- SUNKWANG AMPA

- PRINCE & IZANT COMPANY

- NIHON SUPERIOR CO., LTD.

- AIMTEK, INC.

- ZHEJIANG YATONG NEW MATERIALS CO., LTD.

- VBC GROUP

- INDIAN SOLDER AND BRAZE ALLOYS PVT. LTD.

- SENTES-BIR AS

- STELLA SRL

- PIETRO GALLIANI BRAZING SPA

- HANGZHOU HUAGUANG ADVANCED WELDING MATERIALS CO., LTD.

- HEBEI YUGUANG WELDING CO., LTD

- CASTOLIN EUTECTIC

- 其他公司

- ZHONGSHAN HUALE WEIDING COMPOUND CO., LTD.

- MATHURE METAL WORKS PVT. LTD.

- KINZOKU YOUZAI CO., LTD.

- NAVIKA SILVER BRAZING ALLOYS

- BRAZING TECHNOLOGIES, INC.

- LINBRAZE SRL

- SELECTARC GROUP

- SALDFLUX SRL

- SANHUAN MATERIALS

- SALDOBRASE SRL

第12章附錄

The aluminum brazing market is estimated to be USD 2.05 billion in 2025 and is projected to reach USD 2.88 billion by 2032, at a CAGR of 5.0% from 2025 to 2032. Based on product type, the aluminum-zinc alloys segment accounted for the third-largest share of the overall aluminum brazing market.

| Scope of the Report | |

|---|---|

| Years Considered for the Study | 2023-2032 |

| Base Year | 2024 |

| Forecast Period | 2025-2032 |

| Units Considered | Value (USD Million) and Volume (Ton) |

| Segments | Product Type, Product Form, End-use Industry, and Region |

| Regions covered | North America, Europe, Asia Pacific, Latin America, Middle East & Africa, and GCC Countries |

These alloys offer superior wettability, lower melting points, and excellent corrosion resistance, which are critical for producing high-strength, leak-proof joints in HVACR, automotive heat exchangers, and electronics applications. Their compatibility with aluminum base materials also minimizes galvanic corrosion, making them ideal for large-volume production processes such as controlled atmosphere brazing (CAB). These alloys support cost-effective manufacturing due to their efficient flow and strong joint integrity.

"The wires segment is projected to be the second-fastest-growing segment during the forecast period."

The wires segment of the aluminum brazing market is projected to witness the second-highest CAGR due to their increasing use in lightweight automotive and HVAC applications, where efficiency and thermal management are critical. The automotive industry's shift toward lightweight vehicles to improve fuel efficiency and reduce emissions drives strong demand for aluminum brazing wires. Advancements in manufacturing technologies, including automation and AI for precise brazing control, enhance production efficiency and joint quality, further propelling growth. The growing emphasis on sustainability and energy-efficient systems also supports the adoption of aluminum brazing wires as preferred joining materials in multiple industrial sectors.

"The electrical & electronics segment is projected to register the second-highest growth rate during the forecast period."

The aluminum brazing market in the electrical & electronics segment is projected to register the second-highest CAGR during the forecast period. The market in this end-use segment is driven by the rising demand for lightweight, durable, and corrosion-resistant components in electronic assemblies. The miniaturization of electronic devices and the need for precise, reliable joints in cooling systems and circuit components drive this growth. Growing advancements in aluminum brazing technologies are projected to enhance the quality and efficiency of brazing in electronics manufacturing, further propelling market expansion. The sector's continuous innovation and increasing production volumes in consumer electronics and telecommunications also contribute to the strong demand.

"Europe is projected to register the third-highest CAGR in the aluminum brazing market during the forecast period."

Europe is projected to register the third-highest CAGR in the aluminum brazing market due to the significant demand from the automotive, industrial, and aerospace & defense sectors. The market growth is supported by stringent environmental regulations in the EU, such as the European Green Deal, which promotes energy-efficient and lightweight materials to reduce carbon emissions. Investments in electric vehicles, renewable energy projects, and advanced manufacturing technologies further stimulate demand. Government incentives and a focus on sustainable production methods drive the adoption of aluminum brazing alloys and flux across various industries in countries like Germany, France, Italy, and the UK.

This study has been validated through primary interviews with industry experts globally. The primary sources have been divided into the following three categories:

- By Company Type: Tier 1 - 40%, Tier 2 - 33%, and Tier 3 - 27%

- By Designation: C-level - 50%, Director-level - 30%, and Managers - 20%

- By Region: North America - 20%, Europe - 15%, Asia Pacific - 50%, the Middle East & Africa - 10%, and Latin America - 5%

The report provides a comprehensive analysis of the following companies:

Prominent companies in this market include Solvay (Belgium), Honeywell International Inc. (US), Lucas-Milhaupt LLC (US), Harris Products Group (The Lincoln Electric Company) (US), Sunkwang AMPA (South Korea), Prince & Izant Company (US), Nihon Superior Co., Ltd. (Japan), Aimtek, Inc. (US), Zhejiang Yatong New Materials Co., Ltd. (China), VBC Group (UK), Indian Solder and Braze Alloys Pvt. Ltd. (India), Sentes-BIR A.S. (Turkey), Stella S.r.l. (Italy), Pietro Galliani Brazing S.p.A. (Italy), Hangzhou Huaguang Advanced Welding Materials Co., Ltd. (China), Hebei Yuguang Welding Co., Ltd. (China), and Castolin Eutectic (Germany).

Research Coverage

This research report categorizes the aluminum brazing market by product type (aluminum-silicon alloys, aluminum-zinc alloys, aluminum-copper alloys, aluminum-magnesium alloys, other aluminum alloys), product form (sheet, paste, wires, rods, other product forms), end-use industry (automotive, aerospace & defense, industrial, electrical & electronics, other end-use industries), and region (North America, Europe, Asia Pacific, Middle East & Africa, and Latin America). The scope of the report includes detailed information about the major factors influencing the growth of the aluminum brazing market, such as drivers, restraints, challenges, and opportunities. A thorough examination of the key industry players has been conducted to provide insights into their business overview, solutions and services, key strategies, and recent developments in the aluminum brazing market. This report includes a competitive analysis of upcoming startups in the aluminum brazing market ecosystem.

Reasons to buy this report

The report will help market leaders/new entrants in this market with information on the closest approximations of the revenue numbers for the overall aluminum brazing market and the subsegments. It will also help stakeholders understand the competitive landscape and gain more insights to better position their businesses and plan suitable go-to-market strategies. The report also helps stakeholders understand the pulse of the market and provides them with information on key market drivers, restraints, challenges, and opportunities.

The report provides insights on the following pointers:

- Analysis of key drivers (Increasing demand for aluminum brazing in electric vehicles), restraints (Oxide layer barrier in aluminum brazing), opportunities (Growing adoption in renewable energy projects), and challenges (Volatility in raw material prices) influencing the growth of the aluminum brazing market

- Product Development/Innovation: Detailed insights on upcoming technologies, research & development activities, and product launches in the aluminum brazing market

- Market Development: Comprehensive information about lucrative markets - the report analyzes the aluminum brazing market across varied regions.

- Market Diversification: Exhaustive information about services, untapped geographies, recent developments, and investments in the aluminum brazing market

- Competitive Assessment: In-depth assessment of market shares, growth strategies, and product offerings of leading players like Solvay (Belgium), Honeywell International Inc. (US), Lucas-Milhaupt LLC (US), Harris Products Group (The Lincoln Electric Company) (US), Sunkwang AMPA (South Korea), Prince & Izant Company (US), Nihon Superior Co., Ltd. (Japan), Aimtek, Inc. (US), Zhejiang Yatong New Materials Co., Ltd. (China), VBC Group (UK), Indian Solder and Braze Alloys Pvt. Ltd. (India), Sentes-BIR A.S. (Turkey), Stella S.r.l. (Italy), Pietro Galliani Brazing S.p.A. (Italy), Hangzhou Huaguang Advanced Welding Materials Co., Ltd. (China), Hebei Yuguang Welding Co., Ltd. (China), and Castolin Eutectic (Germany)

TABLE OF CONTENTS

1 INTRODUCTION

- 1.1 STUDY OBJECTIVES

- 1.2 MARKET DEFINITION

- 1.3 STUDY SCOPE

- 1.3.1 MARKETS COVERED AND REGIONAL SCOPE

- 1.3.2 INCLUSIONS AND EXCLUSIONS

- 1.3.3 YEARS CONSIDERED

- 1.3.4 CURRENCY CONSIDERED

- 1.3.5 UNITS CONSIDERED

- 1.4 LIMITATIONS

- 1.5 STAKEHOLDERS

2 RESEARCH METHODOLOGY

- 2.1 RESEARCH DATA

- 2.1.1 SECONDARY DATA

- 2.1.1.1 Key data from secondary sources

- 2.1.2 PRIMARY DATA

- 2.1.2.1 Key data from primary sources

- 2.1.2.2 Key primary interview participants

- 2.1.2.3 Breakdown of primary interviews

- 2.1.2.4 Key industry insights

- 2.1.1 SECONDARY DATA

- 2.2 MARKET SIZE ESTIMATION

- 2.2.1 BOTTOM-UP APPROACH

- 2.2.2 TOP-DOWN APPROACH

- 2.3 BASE NUMBER CALCULATION

- 2.3.1 APPROACH 1: DEMAND-SIDE ANALYSIS

- 2.3.2 APPROACH 2: SUPPLY-SIDE ANALYSIS

- 2.4 FORECAST NUMBER CALCULATION

- 2.5 DATA TRIANGULATION

- 2.6 FACTOR ANALYSIS

- 2.7 RESEARCH ASSUMPTIONS

- 2.8 RESEARCH LIMITATIONS AND RISK ASSESSMENT

3 EXECUTIVE SUMMARY

4 PREMIUM INSIGHTS

- 4.1 ATTRACTIVE OPPORTUNITIES FOR PLAYERS IN ALUMINUM BRAZING MARKET

- 4.2 ALUMINUM BRAZING MARKET, BY PRODUCT FORM AND REGION

- 4.3 ALUMINUM BRAZING MARKET, BY PRODUCT TYPE

- 4.4 ALUMINUM BRAZING MARKET, BY END-USE INDUSTRY

- 4.5 ALUMINUM BRAZING MARKET, BY KEY COUNTRY

5 MARKET OVERVIEW

- 5.1 INTRODUCTION

- 5.2 MARKET DYNAMICS

- 5.2.1 DRIVERS

- 5.2.1.1 Increasing demand for aluminum brazing in electric vehicles

- 5.2.1.2 Growing use in HVACR applications

- 5.2.2 RESTRAINTS

- 5.2.2.1 Oxide layer barrier in aluminum brazing

- 5.2.2.2 Dissolution and erosion of base metals during brazing

- 5.2.2.3 Availability of alternative methods

- 5.2.3 OPPORTUNITIES

- 5.2.3.1 Growing adoption in renewable energy projects

- 5.2.3.2 Next-gen aluminum brazing technology for space exploration

- 5.2.3.3 Rising shift toward sustainable solutions

- 5.2.4 CHALLENGES

- 5.2.4.1 Volatility in raw material prices

- 5.2.4.2 Environmental and regulatory compliance

- 5.2.1 DRIVERS

- 5.3 PORTER'S FIVE FORCES ANALYSIS

- 5.3.1 THREAT OF NEW ENTRANTS

- 5.3.2 THREAT OF SUBSTITUTES

- 5.3.3 BARGAINING POWER OF SUPPLIERS

- 5.3.4 BARGAINING POWER OF BUYERS

- 5.3.5 INTENSITY OF COMPETITIVE RIVALRY

- 5.4 KEY STAKEHOLDERS AND BUYING CRITERIA

- 5.4.1 KEY STAKEHOLDERS IN BUYING PROCESS

- 5.4.2 BUYING CRITERIA

- 5.5 PRICING ANALYSIS

- 5.5.1 AVERAGE SELLING PRICE TREND OF KEY PLAYERS, BY END-USE INDUSTRY, 2024

- 5.5.2 AVERAGE SELLING PRICE TREND, BY REGION, 2023-2024

- 5.6 MACROECONOMIC OUTLOOK

- 5.6.1 INTRODUCTION

- 5.6.2 GDP TRENDS AND FORECAST

- 5.6.3 TRENDS IN GLOBAL AUTOMOTIVE INDUSTRY

- 5.7 VALUE CHAIN ANALYSIS

- 5.8 ECOSYSTEM ANALYSIS

- 5.9 TRADE ANALYSIS

- 5.9.1 EXPORT SCENARIO (HS CODE 8311)

- 5.9.2 IMPORT SCENARIO (HS CODE 8311)

- 5.10 TECHNOLOGY ANALYSIS

- 5.10.1 KEY TECHNOLOGIES

- 5.10.1.1 Torch brazing

- 5.10.1.2 Dip brazing

- 5.10.1.3 Furnace brazing

- 5.10.1.4 Vacuum and controlled atmosphere brazing

- 5.10.2 COMPLEMENTARY TECHNOLOGIES

- 5.10.2.1 Induction brazing

- 5.10.1 KEY TECHNOLOGIES

- 5.11 PATENT ANALYSIS

- 5.11.1 INTRODUCTION

- 5.11.2 METHODOLOGY

- 5.11.3 DOCUMENT TYPES

- 5.11.4 INSIGHTS

- 5.11.5 LEGAL STATUS

- 5.11.6 JURISDICTION ANALYSIS

- 5.11.7 TOP APPLICANTS

- 5.12 REGULATORY LANDSCAPE

- 5.12.1 REGULATORY BODIES, GOVERNMENT AGENCIES, AND OTHER ORGANIZATIONS

- 5.13 KEY CONFERENCES AND EVENTS, 2025-2027

- 5.14 CASE STUDY ANALYSIS

- 5.14.1 HONEYWELL'S JETFLUX TECHNOLOGY REVOLUTIONIZES ALUMINUM BRAZING FOR RENEWABLE ENERGY

- 5.14.2 BRAZING HIGH-MAGNESIUM AA6082 TO AA1050 USING NOCOLOK CS FLUX

- 5.14.3 BREAKING OXIDE BARRIER: MAGNESIUM-DRIVEN FLUX-FREE BRAZING FOR ALUMINUM SHEETS

- 5.15 TRENDS/DISRUPTIONS IMPACTING CUSTOMER BUSINESS

- 5.16 IMPACT OF GEN AI/AI ON ALUMINUM BRAZING MARKET

- 5.16.1 TOP USE CASES AND MARKET POTENTIAL

- 5.16.2 CASE STUDIES OF AI IMPLEMENTATION IN ALUMINUM BRAZING MARKET

- 5.17 INVESTMENT AND FUNDING SCENARIO

- 5.18 US TARIFF IMPACT - ALUMINUM BRAZING MARKET

- 5.18.1 INTRODUCTION

- 5.18.2 KEY TARIFF RATES

- 5.18.3 PRICE IMPACT ANALYSIS

- 5.18.4 IMPACT ON MAJOR COUNTRIES/REGIONS

- 5.18.4.1 US

- 5.18.4.2 Europe

- 5.18.4.3 Asia Pacific

- 5.18.5 IMPACT ON END-USE INDUSTRIES

6 ALUMINUM BRAZING MARKET, BY PRODUCT TYPE

- 6.1 INTRODUCTION

- 6.2 ALUMINUM-SILICON ALLOYS

- 6.2.1 EXCELLENT WETTING BEHAVIOR AND STRENGTH TO DRIVE MARKET

- 6.3 ALUMINUM-ZINC ALLOYS

- 6.3.1 HIGH-STRENGTH JOINTS FOR INDUSTRIAL APPLICATIONS TO FUEL DEMAND

- 6.4 ALUMINUM-COPPER ALLOYS

- 6.4.1 ENHANCED STRENGTH AND CORROSION RESISTANCE TO PROPEL DEMAND

- 6.5 ALUMINUM-MAGNESIUM ALLOYS

- 6.5.1 POST-BRAZE STRENGTH AND MACHINABILITY IMPROVEMENTS TO FUEL ADOPTION

- 6.6 OTHER ALUMINUM ALLOYS

7 ALUMINUM BRAZING MARKET, BY PRODUCT FORM

- 7.1 INTRODUCTION

- 7.2 SHEETS

- 7.2.1 IMPROVED STRUCTURAL STRENGTH AND EXCELLENT FORMABILITY TO DRIVE DEMAND

- 7.3 PASTE

- 7.3.1 CONSISTENT AND HIGH-QUALITY JOINTS IN ALUMINUM ALLOYS TO FUEL ADOPTION

- 7.4 WIRES

- 7.4.1 EFFECTIVE HANDLING AND SUPERIOR CORROSION RESISTANCE TO FUEL DEMAND

- 7.5 RODS

- 7.5.1 LOW TEMPERATURE AND FLUX-CORE RODS TO PROPEL DEMAND

- 7.6 OTHER PRODUCT FORMS

8 ALUMINUM BRAZING MARKET, BY END-USE INDUSTRY

- 8.1 INTRODUCTION

- 8.2 AUTOMOTIVE

- 8.2.1 DEMAND FOR LIGHTWEIGHT AUTOMOTIVE STRUCTURES TO DRIVE MARKET

- 8.3 AEROSPACE & DEFENSE

- 8.3.1 SUPERIOR THERMAL & ELECTRICAL CONDUCTIVITY TO FUEL DEMAND

- 8.4 INDUSTRIAL

- 8.4.1 DURABLE AND LIGHTWEIGHT INDUSTRIAL EQUIPMENT TO PROPEL DEMAND

- 8.5 ELECTRICAL & ELECTRONICS

- 8.5.1 ENHANCED THERMAL AND ELECTRICAL PERFORMANCE TO BOOST DEMAND

- 8.6 OTHER END-USE INDUSTRIES

9 ALUMINUM BRAZING MARKET, BY REGION

- 9.1 INTRODUCTION

- 9.2 NORTH AMERICA

- 9.2.1 NORTH AMERICA: ALUMINUM BRAZING MARKET, BY PRODUCT TYPE

- 9.2.2 NORTH AMERICA: ALUMINUM BRAZING MARKET, BY PRODUCT FORM

- 9.2.3 NORTH AMERICA: ALUMINUM BRAZING MARKET, BY END-USE INDUSTRY

- 9.2.4 NORTH AMERICA: ALUMINUM BRAZING MARKET, BY COUNTRY

- 9.2.4.1 US

- 9.2.4.1.1 Presence of major aluminum brazing material manufacturers to drive market

- 9.2.4.2 Canada

- 9.2.4.2.1 Government initiatives and investments to propel market

- 9.2.4.1 US

- 9.3 EUROPE

- 9.3.1 EUROPE: ALUMINUM BRAZING MARKET, BY PRODUCT TYPE

- 9.3.2 EUROPE: ALUMINUM BRAZING MARKET, BY PRODUCT FORM

- 9.3.3 EUROPE: ALUMINUM BRAZING MARKET, BY END-USE INDUSTRY

- 9.3.4 EUROPE: ALUMINUM BRAZING MARKET, BY COUNTRY

- 9.3.4.1 Germany

- 9.3.4.1.1 Presence of major automotive manufacturers to drive market

- 9.3.4.2 France

- 9.3.4.2.1 Strategic partnership for innovative brazing solutions to fuel demand

- 9.3.4.3 UK

- 9.3.4.3.1 Increasing demand for lightweight and high-performance materials to drive market

- 9.3.4.4 Italy

- 9.3.4.4.1 Technological innovations to drive market

- 9.3.4.5 Spain

- 9.3.4.5.1 Growing adoption of aluminum brazing alloys in automotive components to drive market

- 9.3.4.6 Rest of Europe

- 9.3.4.1 Germany

- 9.4 ASIA PACIFIC

- 9.4.1 ASIA PACIFIC: ALUMINUM BRAZING MARKET, BY PRODUCT TYPE

- 9.4.2 ASIA PACIFIC: ALUMINUM BRAZING MARKET, BY PRODUCT FORM

- 9.4.3 ASIA PACIFIC: ALUMINUM BRAZING MARKET, BY END-USE INDUSTRY

- 9.4.4 ASIA PACIFIC: ALUMINUM BRAZING MARKET, BY COUNTRY

- 9.4.4.1 China

- 9.4.4.1.1 Large number of domestic manufacturers to drive market

- 9.4.4.2 Japan

- 9.4.4.2.1 Growing demand from electronics industry to drive market

- 9.4.4.3 India

- 9.4.4.3.1 Rapid industrialization and urbanization to drive market

- 9.4.4.4 South Korea

- 9.4.4.4.1 Ongoing research & development of aluminum brazing materials to accelerate demand

- 9.4.4.5 Rest of Asia Pacific

- 9.4.4.1 China

- 9.5 MIDDLE EAST & AFRICA

- 9.5.1 MIDDLE EAST & AFRICA: ALUMINUM BRAZING MARKET, BY PRODUCT TYPE

- 9.5.2 MIDDLE EAST & AFRICA: ALUMINUM BRAZING MARKET, BY PRODUCT FORM

- 9.5.3 MIDDLE EAST & AFRICA: ALUMINUM BRAZING MARKET, BY END-USE INDUSTRY

- 9.5.4 MIDDLE EAST & AFRICA: ALUMINUM BRAZING MARKET, BY COUNTRY

- 9.5.4.1 GCC Countries

- 9.5.4.1.1 UAE

- 9.5.4.1.1.1 Increasing infrastructure development projects to propel market

- 9.5.4.1.2 Saudi Arabia

- 9.5.4.1.2.1 Government initiatives focusing on industrial diversification to fuel demand

- 9.5.4.1.3 Rest of GCC Countries

- 9.5.4.1.1 UAE

- 9.5.4.2 South Africa

- 9.5.4.2.1 Growing construction & infrastructure sector to drive market

- 9.5.4.3 Rest of Middle East & Africa

- 9.5.4.1 GCC Countries

- 9.6 LATIN AMERICA

- 9.6.1 LATIN AMERICA: ALUMINUM BRAZING MARKET, BY PRODUCT TYPE

- 9.6.2 LATIN AMERICA: ALUMINUM BRAZING MARKET, BY PRODUCT FORM

- 9.6.3 LATIN AMERICA: ALUMINUM BRAZING MARKET, BY END-USE INDUSTRY

- 9.6.4 LATIN AMERICA: ALUMINUM BRAZING MARKET, BY COUNTRY

- 9.6.4.1 Brazil

- 9.6.4.1.1 High-value construction projects to drive demand

- 9.6.4.2 Mexico

- 9.6.4.2.1 Ongoing investment and technological innovations to drive market

- 9.6.4.3 Rest of Latin America

- 9.6.4.1 Brazil

10 COMPETITIVE LANDSCAPE

- 10.1 INTRODUCTION

- 10.2 KEY PLAYERS' STRATEGIES/RIGHT TO WIN, 2020-2025

- 10.3 REVENUE ANALYSIS, 2020-2024

- 10.4 MARKET SHARE ANALYSIS, 2024

- 10.5 BRAND/PRODUCT COMPARISON

- 10.6 COMPANY EVALUATION MATRIX: KEY PLAYERS, 2024

- 10.6.1 STARS

- 10.6.2 EMERGING LEADERS

- 10.6.3 PERVASIVE PLAYERS

- 10.6.4 PARTICIPANTS

- 10.6.5 COMPANY FOOTPRINT: KEY PLAYERS, 2024

- 10.6.5.1 Company footprint

- 10.6.5.2 Region footprint

- 10.6.5.3 Product type footprint

- 10.6.5.4 Product form footprint

- 10.6.5.5 End-use industry footprint

- 10.7 COMPANY EVALUATION MATRIX: STARTUPS/SMES, 2024

- 10.7.1 PROGRESSIVE COMPANIES

- 10.7.2 RESPONSIVE COMPANIES

- 10.7.3 DYNAMIC COMPANIES

- 10.7.4 STARTING BLOCKS

- 10.7.5 COMPETITIVE BENCHMARKING: STARTUPS/SMES, 2024

- 10.7.5.1 Detailed list of key startups/SMEs

- 10.7.5.2 Competitive benchmarking of key startups/SMEs

- 10.8 COMPANY VALUATION AND FINANCIAL METRICS

- 10.9 COMPETITIVE SCENARIO

- 10.9.1 DEALS

11 COMPANY PROFILES

- 11.1 KEY PLAYERS

- 11.1.1 SOLVAY

- 11.1.1.1 Business overview

- 11.1.1.2 Products offered

- 11.1.1.3 MnM view

- 11.1.1.3.1 Key strengths

- 11.1.1.3.2 Strategic choices

- 11.1.1.3.3 Weaknesses and competitive threats

- 11.1.2 HONEYWELL INTERNATIONAL INC.

- 11.1.2.1 Business overview

- 11.1.2.2 Products offered

- 11.1.2.3 MnM view

- 11.1.2.3.1 Key strengths

- 11.1.2.3.2 Strategic choices

- 11.1.2.3.3 Weaknesses and competitive threats

- 11.1.3 LUCAS-MILHAUPT LLC

- 11.1.3.1 Business overview

- 11.1.3.2 Products offered

- 11.1.3.3 MnM view

- 11.1.3.3.1 Key strengths

- 11.1.3.3.2 Strategic choices

- 11.1.3.3.3 Weaknesses and competitive threats

- 11.1.4 HARRIS PRODUCTS GROUP (THE LINCOLN ELECTRIC COMPANY)

- 11.1.4.1 Business overview

- 11.1.4.2 Products offered

- 11.1.4.3 Recent developments

- 11.1.4.3.1 Deals

- 11.1.4.4 MnM view

- 11.1.4.4.1 Key strengths

- 11.1.4.4.2 Strategic choices

- 11.1.4.4.3 Weaknesses and competitive threats

- 11.1.5 SUNKWANG AMPA

- 11.1.5.1 Business overview

- 11.1.5.2 Products offered

- 11.1.5.3 Recent developments

- 11.1.5.3.1 Deals

- 11.1.5.4 MnM view

- 11.1.5.4.1 Key strengths

- 11.1.5.4.2 Strategic choices

- 11.1.5.4.3 Weaknesses and competitive threats

- 11.1.6 PRINCE & IZANT COMPANY

- 11.1.6.1 Business overview

- 11.1.6.2 Products offered

- 11.1.6.3 Recent developments

- 11.1.6.3.1 Deals

- 11.1.6.4 MnM view

- 11.1.6.4.1 Key strengths

- 11.1.6.4.2 Strategic choices

- 11.1.6.4.3 Weaknesses and competitive threats

- 11.1.7 NIHON SUPERIOR CO., LTD.

- 11.1.7.1 Business overview

- 11.1.7.2 Products offered

- 11.1.8 AIMTEK, INC.

- 11.1.8.1 Business overview

- 11.1.8.2 Products offered

- 11.1.9 ZHEJIANG YATONG NEW MATERIALS CO., LTD.

- 11.1.9.1 Business overview

- 11.1.9.2 Products offered

- 11.1.10 VBC GROUP

- 11.1.10.1 Business overview

- 11.1.10.2 Products offered

- 11.1.11 INDIAN SOLDER AND BRAZE ALLOYS PVT. LTD.

- 11.1.11.1 Business overview

- 11.1.11.2 Products offered

- 11.1.12 SENTES-BIR A.S.

- 11.1.12.1 Business overview

- 11.1.12.2 Products offered

- 11.1.13 STELLA S.R.L.

- 11.1.13.1 Business overview

- 11.1.13.2 Products offered

- 11.1.14 PIETRO GALLIANI BRAZING S.P.A.

- 11.1.14.1 Business overview

- 11.1.14.2 Products offered

- 11.1.15 HANGZHOU HUAGUANG ADVANCED WELDING MATERIALS CO., LTD.

- 11.1.15.1 Business overview

- 11.1.15.2 Products offered

- 11.1.16 HEBEI YUGUANG WELDING CO., LTD

- 11.1.16.1 Business overview

- 11.1.16.2 Products offered

- 11.1.17 CASTOLIN EUTECTIC

- 11.1.17.1 Business overview

- 11.1.17.2 Products offered

- 11.1.1 SOLVAY

- 11.2 OTHER PLAYERS

- 11.2.1 ZHONGSHAN HUALE WEIDING COMPOUND CO., LTD.

- 11.2.2 MATHURE METAL WORKS PVT. LTD.

- 11.2.3 KINZOKU YOUZAI CO., LTD.

- 11.2.4 NAVIKA SILVER BRAZING ALLOYS

- 11.2.5 BRAZING TECHNOLOGIES, INC.

- 11.2.6 LINBRAZE S.R.L.

- 11.2.7 SELECTARC GROUP

- 11.2.8 SALDFLUX SRL

- 11.2.9 SANHUAN MATERIALS

- 11.2.10 SALDOBRASE SRL

12 APPENDIX

- 12.1 DISCUSSION GUIDE

- 12.2 KNOWLEDGESTORE: MARKETSANDMARKETS' SUBSCRIPTION PORTAL

- 12.3 CUSTOMIZATION OPTIONS

- 12.4 RELATED REPORTS

- 12.5 AUTHOR DETAILS

List of Tables

- TABLE 1 ALUMINUM BRAZING MARKET: PORTER'S FIVE FORCES ANALYSIS

- TABLE 2 INFLUENCE OF STAKEHOLDERS ON BUYING PROCESS FOR TOP THREE END-USE INDUSTRIES

- TABLE 3 KEY BUYING CRITERIA FOR TOP THREE END-USE INDUSTRIES

- TABLE 4 AVERAGE SELLING PRICE TREND OF KEY PLAYERS IN ALUMINUM BRAZING MARKET, BY END-USE INDUSTRY, 2024 (USD/KG)

- TABLE 5 AVERAGE SELLING PRICE TREND OF ALUMINUM BRAZING, BY REGION, 2023-2024 (USD/KG)

- TABLE 6 GDP PERCENTAGE CHANGE, BY KEY COUNTRY, 2021-2029

- TABLE 7 ROLE OF COMPANIES IN ALUMINUM BRAZING ECOSYSTEM

- TABLE 8 EXPORT DATA RELATED TO HS CODE 8311-COMPLIANT PRODUCTS, BY KEY COUNTRY, 2023-2025 (USD THOUSAND)

- TABLE 9 IMPORT DATA RELATED TO HS CODE 8311-COMPLIANT PRODUCTS, BY KEY COUNTRY, 2023-2025 (USD THOUSAND)

- TABLE 10 ALUMINUM BRAZING MARKET: TOTAL NUMBER OF PATENTS, 2015-2024

- TABLE 11 LIST OF PATENTS BY DENSO CORPORATION, 2021-2024

- TABLE 12 LIST OF PATENTS BY MITSUBISHI ALUMINUM, 2021-2024

- TABLE 13 ALUMINUM BRAZING MARKET: TOP 10 PATENT OWNERS IN LAST 10 YEARS (US)

- TABLE 14 NORTH AMERICA: REGULATORY BODIES, GOVERNMENT AGENCIES, AND OTHER ORGANIZATIONS

- TABLE 15 EUROPE: REGULATORY BODIES, GOVERNMENT AGENCIES, AND OTHER ORGANIZATIONS

- TABLE 16 ASIA PACIFIC: REGULATORY BODIES, GOVERNMENT AGENCIES, AND OTHER ORGANIZATIONS

- TABLE 17 ALUMINUM BRAZING MARKET: KEY CONFERENCES AND EVENTS, 2025-2027

- TABLE 18 TOP USE CASES AND MARKET POTENTIAL

- TABLE 19 CASE STUDIES OF AI IMPLEMENTATION IN ALUMINUM BRAZING MARKET

- TABLE 20 US ADJUSTED RECIPROCAL TARIFF RATES

- TABLE 21 KEY PRODUCT-RELATED TARIFF EFFECTIVE FOR ALUMINUM BRAZING, 2024 VS. 2025

- TABLE 22 EXPECTED CHANGE IN PRICES AND LIKELY IMPACT ON END-USE MARKETS DUE TO TARIFF IMPACT

- TABLE 23 ALUMINUM BRAZING MARKET, BY PRODUCT TYPE, 2023-2032 (USD MILLION)

- TABLE 24 ALUMINUM BRAZING MARKET, BY PRODUCT TYPE, 2023-2032 (TON)

- TABLE 25 ALUMINUM-SILICON ALLOYS: ALUMINUM BRAZING MARKET, BY REGION, 2023-2032 (USD MILLION)

- TABLE 26 ALUMINUM-SILICON ALLOYS: ALUMINUM BRAZING MARKET, BY REGION, 2023-2032 (TON)

- TABLE 27 ALUMINUM-ZINC ALLOYS: ALUMINUM BRAZING MARKET, BY REGION, 2023-2032 (USD MILLION)

- TABLE 28 ALUMINUM-ZINC ALLOYS: ALUMINUM BRAZING MARKET, BY REGION, 2023-2032 (TON)

- TABLE 29 ALUMINUM-COPPER ALLOYS: ALUMINUM BRAZING MARKET, BY REGION, 2023-2032 (USD MILLION)

- TABLE 30 ALUMINUM-COPPER ALLOYS: ALUMINUM BRAZING MARKET, BY REGION, 2023-2032 (TON)

- TABLE 31 ALUMINUM-MAGNESIUM ALLOYS: ALUMINUM BRAZING MARKET, BY REGION, 2023-2032 (USD MILLION)

- TABLE 32 ALUMINUM-MAGNESIUM ALLOYS: ALUMINUM BRAZING MARKET, BY REGION, 2023-2032 (TON)

- TABLE 33 OTHER ALUMINUM ALLOYS: ALUMINUM BRAZING MARKET, BY REGION, 2023-2032 (USD MILLION)

- TABLE 34 OTHER ALUMINUM ALLOYS: ALUMINUM BRAZING MARKET, BY REGION, 2023-2032 (TON)

- TABLE 35 ALUMINUM BRAZING MARKET, BY PRODUCT FORM, 2023-2032 (USD MILLION)

- TABLE 36 ALUMINUM BRAZING MARKET, BY PRODUCT FORM, 2023-2032 (TON)

- TABLE 37 SHEETS: ALUMINUM BRAZING MARKET, BY REGION, 2023-2032 (USD MILLION)

- TABLE 38 SHEETS: ALUMINUM BRAZING MARKET, BY REGION, 2023-2032 (TON)

- TABLE 39 PASTE: ALUMINUM BRAZING MARKET, BY REGION, 2023-2032 (USD MILLION)

- TABLE 40 PASTE: ALUMINUM BRAZING MARKET, BY REGION, 2023-2032 (TON)

- TABLE 41 WIRES: ALUMINUM BRAZING MARKET, BY REGION, 2023-2032 (USD MILLION)

- TABLE 42 WIRES: ALUMINUM BRAZING MARKET, BY REGION, 2023-2032 (TON)

- TABLE 43 RODS: ALUMINUM BRAZING MARKET, BY REGION, 2023-2032 (USD MILLION)

- TABLE 44 RODS: ALUMINUM BRAZING MARKET, BY REGION, 2023-2032 (TON)

- TABLE 45 OTHER PRODUCT FORMS: ALUMINUM BRAZING MARKET, BY REGION, 2023-2032 (USD MILLION)

- TABLE 46 OTHER PRODUCT FORMS: ALUMINUM BRAZING MARKET, BY REGION, 2023-2032 (TON)

- TABLE 47 ALUMINUM BRAZING MARKET, BY END-USE INDUSTRY, 2023-2032 (USD MILLION)

- TABLE 48 ALUMINUM BRAZING MARKET, BY END-USE INDUSTRY, 2023-2032 (TON)

- TABLE 49 AUTOMOTIVE: ALUMINUM BRAZING MARKET, BY REGION, 2023-2032 (USD MILLION)

- TABLE 50 AUTOMOTIVE: ALUMINUM BRAZING MARKET, BY REGION, 2023-2032 (TON)

- TABLE 51 AEROSPACE & DEFENSE: ALUMINUM BRAZING MARKET, BY REGION, 2023-2032 (USD MILLION)

- TABLE 52 AEROSPACE & DEFENSE: ALUMINUM BRAZING MARKET, BY REGION, 2023-2032 (TON)

- TABLE 53 INDUSTRIAL: ALUMINUM BRAZING MARKET, BY REGION, 2023-2032 (USD MILLION)

- TABLE 54 INDUSTRIAL: ALUMINUM BRAZING MARKET, BY REGION, 2023-2032 (TON)

- TABLE 55 ELECTRICAL & ELECTRONICS: ALUMINUM BRAZING MARKET, BY REGION, 2023-2032 (USD MILLION)

- TABLE 56 ELECTRICAL & ELECTRONICS: ALUMINUM BRAZING MARKET, BY REGION, 2023-2032 (TON)

- TABLE 57 OTHER END-USE INDUSTRIES: ALUMINUM BRAZING MARKET, BY REGION, 2023-2032 (USD MILLION)

- TABLE 58 OTHER END-USE INDUSTRIES: ALUMINUM BRAZING MARKET, BY REGION, 2023-2032 (TON)

- TABLE 59 ALUMINUM BRAZING MARKET, BY REGION, 2023-2032 (USD MILLION)

- TABLE 60 ALUMINUM BRAZING MARKET, BY REGION, 2023-2032 (TON)

- TABLE 61 NORTH AMERICA: ALUMINUM BRAZING MARKET, BY PRODUCT TYPE, 2023-2032 (USD MILLION)

- TABLE 62 NORTH AMERICA: ALUMINUM BRAZING MARKET, BY PRODUCT TYPE, 2023-2032 (TON)

- TABLE 63 NORTH AMERICA: ALUMINUM BRAZING MARKET, BY PRODUCT FORM, 2023-2032 (USD MILLION)

- TABLE 64 NORTH AMERICA: ALUMINUM BRAZING MARKET, BY PRODUCT FORM, 2023-2032 (TON)

- TABLE 65 NORTH AMERICA: ALUMINUM BRAZING MARKET, BY END-USE INDUSTRY, 2023-2032 (USD MILLION)

- TABLE 66 NORTH AMERICA: ALUMINUM BRAZING MARKET, BY END-USE INDUSTRY, 2023-2032 (TON)

- TABLE 67 NORTH AMERICA: ALUMINUM BRAZING MARKET, BY COUNTRY, 2023-2032 (USD MILLION)

- TABLE 68 NORTH AMERICA: ALUMINUM BRAZING MARKET, BY COUNTRY, 2023-2032 (TON)

- TABLE 69 US: ALUMINUM BRAZING MARKET, BY END-USE INDUSTRY, 2023-2032 (USD MILLION)

- TABLE 70 US: ALUMINUM BRAZING MARKET, BY END-USE INDUSTRY, 2023-2032 (TON)

- TABLE 71 CANADA: ALUMINUM BRAZING MARKET, BY END-USE INDUSTRY, 2023-2032 (USD MILLION)

- TABLE 72 CANADA: ALUMINUM BRAZING MARKET, BY END-USE INDUSTRY, 2023-2032 (TON)

- TABLE 73 EUROPE: ALUMINUM BRAZING MARKET, BY PRODUCT TYPE, 2023-2032 (USD MILLION)

- TABLE 74 EUROPE: ALUMINUM BRAZING MARKET, BY PRODUCT TYPE, 2023-2032 (TON)

- TABLE 75 EUROPE: ALUMINUM BRAZING MARKET, BY PRODUCT FORM, 2023-2032 (USD MILLION)

- TABLE 76 EUROPE: ALUMINUM BRAZING MARKET, BY PRODUCT FORM, 2023-2032 (TON)

- TABLE 77 EUROPE: ALUMINUM BRAZING MARKET, BY END-USE INDUSTRY, 2023-2032 (USD MILLION)

- TABLE 78 EUROPE: ALUMINUM BRAZING MARKET, BY END-USE INDUSTRY, 2023-2032 (TON)

- TABLE 79 EUROPE: ALUMINUM BRAZING MARKET, BY COUNTRY, 2023-2032 (USD MILLION)

- TABLE 80 EUROPE: ALUMINUM BRAZING MARKET, BY COUNTRY, 2023-2032 (TON)

- TABLE 81 GERMANY: ALUMINUM BRAZING MARKET, BY END-USE INDUSTRY, 2023-2032 (USD MILLION)

- TABLE 82 GERMANY: ALUMINUM BRAZING MARKET, BY END-USE INDUSTRY, 2023-2032 (TON)

- TABLE 83 FRANCE: ALUMINUM BRAZING MARKET, BY END-USE INDUSTRY, 2023-2032 (USD MILLION)

- TABLE 84 FRANCE: ALUMINUM BRAZING MARKET, BY END-USE INDUSTRY, 2023-2032 (TON)

- TABLE 85 UK: ALUMINUM BRAZING MARKET, BY END-USE INDUSTRY, 2023-2032 (USD MILLION)

- TABLE 86 UK: ALUMINUM BRAZING MARKET, BY END-USE INDUSTRY, 2023-2032 (TON)

- TABLE 87 ITALY: ALUMINUM BRAZING MARKET, BY END-USE INDUSTRY, 2023-2032 (USD MILLION)

- TABLE 88 ITALY: ALUMINUM BRAZING MARKET, BY END-USE INDUSTRY, 2023-2032 (TON)

- TABLE 89 SPAIN: ALUMINUM BRAZING MARKET, BY END-USE INDUSTRY, 2023-2032 (USD MILLION)

- TABLE 90 SPAIN: ALUMINUM BRAZING MARKET, BY END-USE INDUSTRY, 2023-2032 (TON)

- TABLE 91 REST OF EUROPE: ALUMINUM BRAZING MARKET, BY END-USE INDUSTRY, 2023-2032 (USD MILLION)

- TABLE 92 REST OF EUROPE: ALUMINUM BRAZING MARKET, BY END-USE INDUSTRY, 2023-2032 (TON)

- TABLE 93 ASIA PACIFIC: ALUMINUM BRAZING MARKET, BY PRODUCT TYPE, 2023-2032 (USD MILLION)

- TABLE 94 ASIA PACIFIC: ALUMINUM BRAZING MARKET, BY PRODUCT TYPE, 2023-2032 (TON)

- TABLE 95 ASIA PACIFIC: ALUMINUM BRAZING MARKET, BY PRODUCT FORM, 2023-2032 (USD MILLION)

- TABLE 96 ASIA PACIFIC: ALUMINUM BRAZING MARKET, BY PRODUCT FORM, 2023-2032 (TON)

- TABLE 97 ASIA PACIFIC: ALUMINUM BRAZING MARKET, BY END-USE INDUSTRY, 2023-2032 (USD MILLION)

- TABLE 98 ASIA PACIFIC: ALUMINUM BRAZING MARKET, BY END-USE INDUSTRY, 2023-2032 (TON)

- TABLE 99 ASIA PACIFIC: ALUMINUM BRAZING MARKET, BY COUNTRY, 2023-2032 (USD MILLION)

- TABLE 100 ASIA PACIFIC: ALUMINUM BRAZING MARKET, BY COUNTRY, 2023-2032 (TON)

- TABLE 101 CHINA: ALUMINUM BRAZING MARKET, BY END-USE INDUSTRY, 2023-2032 (USD MILLION)

- TABLE 102 CHINA: ALUMINUM BRAZING MARKET, BY END-USE INDUSTRY, 2023-2032 (TON)

- TABLE 103 JAPAN: ALUMINUM BRAZING MARKET, BY END-USE INDUSTRY, 2023-2032 (USD MILLION)

- TABLE 104 JAPAN: ALUMINUM BRAZING MARKET, BY END-USE INDUSTRY, 2023-2032 (TON)

- TABLE 105 INDIA: ALUMINUM BRAZING MARKET, BY END-USE INDUSTRY, 2023-2032 (USD MILLION)

- TABLE 106 INDIA: ALUMINUM BRAZING MARKET, BY END-USE INDUSTRY, 2023-2032 (TON)

- TABLE 107 SOUTH KOREA: ALUMINUM BRAZING MARKET, BY END-USE INDUSTRY, 2023-2032 (USD MILLION)

- TABLE 108 SOUTH KOREA: ALUMINUM BRAZING MARKET, BY END-USE INDUSTRY, 2023-2032 (TON)

- TABLE 109 REST OF ASIA PACIFIC: ALUMINUM BRAZING MARKET, BY END-USE INDUSTRY, 2023-2032 (USD MILLION)

- TABLE 110 REST OF ASIA PACIFIC: ALUMINUM BRAZING MARKET, BY END-USE INDUSTRY, 2023-2032 (TON)

- TABLE 111 MIDDLE EAST & AFRICA: ALUMINUM BRAZING MARKET, BY PRODUCT TYPE, 2023-2032 (USD MILLION)

- TABLE 112 MIDDLE EAST & AFRICA: ALUMINUM BRAZING MARKET, BY PRODUCT TYPE, 2023-2032 (TON)

- TABLE 113 MIDDLE EAST & AFRICA: ALUMINUM BRAZING MARKET, BY PRODUCT FORM, 2023-2032 (USD MILLION)

- TABLE 114 MIDDLE EAST & AFRICA: ALUMINUM BRAZING MARKET, BY PRODUCT FORM, 2023-2032 (TON)

- TABLE 115 MIDDLE EAST & AFRICA: ALUMINUM BRAZING MARKET, BY END-USE INDUSTRY, 2023-2032 (USD MILLION)

- TABLE 116 MIDDLE EAST & AFRICA: ALUMINUM BRAZING MARKET, BY END-USE INDUSTRY, 2023-2032 (TON)

- TABLE 117 MIDDLE EAST & AFRICA: ALUMINUM BRAZING MARKET, BY COUNTRY, 2023-2032 (USD MILLION)

- TABLE 118 MIDDLE EAST & AFRICA: ALUMINUM BRAZING MARKET, BY COUNTRY, 2023-2032 (TON)

- TABLE 119 UAE: ALUMINUM BRAZING MARKET, BY END-USE INDUSTRY, 2023-2032 (USD MILLION)

- TABLE 120 UAE: ALUMINUM BRAZING MARKET, BY END-USE INDUSTRY, 2023-2032 (TON)

- TABLE 121 SAUDI ARABIA: ALUMINUM BRAZING MARKET, BY END-USE INDUSTRY, 2023-2032 (USD MILLION)

- TABLE 122 SAUDI ARABIA: ALUMINUM BRAZING MARKET, BY END-USE INDUSTRY, 2023-2032 (TON)

- TABLE 123 REST OF GCC COUNTRIES: ALUMINUM BRAZING MARKET, BY END-USE INDUSTRY, 2023-2032 (USD MILLION)

- TABLE 124 REST OF GCC COUNTRIES: ALUMINUM BRAZING MARKET, BY END-USE INDUSTRY, 2023-2032 (TON)

- TABLE 125 SOUTH AFRICA: ALUMINUM BRAZING MARKET, BY END-USE INDUSTRY, 2023-2032 (USD MILLION)

- TABLE 126 SOUTH AFRICA: ALUMINUM BRAZING MARKET, BY END-USE INDUSTRY, 2023-2032 (TON)

- TABLE 127 REST OF MIDDLE EAST & AFRICA: ALUMINUM BRAZING MARKET, BY END-USE INDUSTRY, 2023-2032 (USD MILLION)

- TABLE 128 REST OF MIDDLE EAST & AFRICA: ALUMINUM BRAZING MARKET, BY END-USE INDUSTRY, 2023-2032 (TON)

- TABLE 129 LATIN AMERICA: ALUMINUM BRAZING MARKET, BY PRODUCT TYPE, 2023-2032 (USD MILLION)

- TABLE 130 LATIN AMERICA: ALUMINUM BRAZING MARKET, BY PRODUCT TYPE, 2023-2032 (TON)

- TABLE 131 LATIN AMERICA: ALUMINUM BRAZING MARKET, BY PRODUCT FORM, 2023-2032 (USD MILLION)

- TABLE 132 LATIN AMERICA: ALUMINUM BRAZING MARKET, BY PRODUCT FORM, 2023-2032 (TON)

- TABLE 133 LATIN AMERICA: ALUMINUM BRAZING MARKET, BY END-USE INDUSTRY, 2023-2032 (USD MILLION)

- TABLE 134 LATIN AMERICA: ALUMINUM BRAZING MARKET, BY END-USE INDUSTRY, 2023-2032 (TON)

- TABLE 135 LATIN AMERICA: ALUMINUM BRAZING MARKET, BY COUNTRY, 2023-2032 (USD MILLION)

- TABLE 136 LATIN AMERICA: ALUMINUM BRAZING MARKET, BY COUNTRY, 2023-2032 (TON)

- TABLE 137 BRAZIL: ALUMINUM BRAZING MARKET, BY END-USE INDUSTRY, 2023-2032 (USD MILLION)

- TABLE 138 BRAZIL: ALUMINUM BRAZING MARKET, BY END-USE INDUSTRY, 2023-2032 (TON)

- TABLE 139 MEXICO: ALUMINUM BRAZING MARKET, BY END-USE INDUSTRY, 2023-2032 (USD MILLION)

- TABLE 140 MEXICO: ALUMINUM BRAZING MARKET, BY END-USE INDUSTRY, 2023-2032 (TON)

- TABLE 141 REST OF LATIN AMERICA: ALUMINUM BRAZING MARKET, BY END-USE INDUSTRY, 2023-2032 (USD MILLION)

- TABLE 142 REST OF LATIN AMERICA: ALUMINUM BRAZING MARKET, BY END-USE INDUSTRY, 2023-2032 (TON)

- TABLE 143 KEY PLAYERS' STRATEGIES/RIGHT TO WIN, 2020-2025

- TABLE 144 ALUMINUM BRAZING MARKET: DEGREE OF COMPETITION, 2024

- TABLE 145 ALUMINUM BRAZING MARKET: REGION FOOTPRINT

- TABLE 146 ALUMINUM BRAZING MARKET: PRODUCT TYPE FOOTPRINT

- TABLE 147 ALUMINUM BRAZING MARKET: PRODUCT FORM FOOTPRINT

- TABLE 148 ALUMINUM BRAZING MARKET: END-USE INDUSTRY FOOTPRINT

- TABLE 149 ALUMINUM BRAZING MARKET: DETAILED LIST OF KEY STARTUPS/SMES

- TABLE 150 ALUMINUM BRAZING MARKET: COMPETITIVE BENCHMARKING OF KEY STARTUPS/SMES (1/2)

- TABLE 151 ALUMINUM BRAZING MARKET: COMPETITIVE BENCHMARKING OF KEY STARTUPS/SMES (2/2)

- TABLE 152 ALUMINUM BRAZING MARKET: DEALS, JANUARY 2020-SEPTEMBER 2025

- TABLE 153 SOLVAY: COMPANY OVERVIEW

- TABLE 154 SOLVAY: PRODUCTS OFFERED

- TABLE 155 HONEYWELL INTERNATIONAL INC.: COMPANY OVERVIEW

- TABLE 156 HONEYWELL INTERNATIONAL INC.: PRODUCTS OFFERED

- TABLE 157 LUCAS-MILHAUPT LLC: COMPANY OVERVIEW

- TABLE 158 LUCAS-MILHAUPT LLC: PRODUCTS OFFERED

- TABLE 159 HARRIS PRODUCTS GROUP (THE LINCOLN ELECTRIC COMPANY): COMPANY OVERVIEW

- TABLE 160 HARRIS PRODUCTS GROUP (THE LINCOLN ELECTRIC COMPANY): PRODUCTS OFFERED

- TABLE 161 HARRIS PRODUCTS GROUP (THE LINCOLN ELECTRIC COMPANY): DEALS

- TABLE 162 SUNKWANG AMPA: COMPANY OVERVIEW

- TABLE 163 SUNKWANG AMPA: PRODUCTS OFFERED

- TABLE 164 SUNKWANG AMPA: DEALS

- TABLE 165 PRINCE & IZANT COMPANY: COMPANY OVERVIEW

- TABLE 166 PRINCE & IZANT COMPANY: PRODUCTS OFFERED

- TABLE 167 PRINCE & IZANT COMPANY: DEALS

- TABLE 168 NIHON SUPERIOR CO., LTD.: COMPANY OVERVIEW

- TABLE 169 NIHON SUPERIOR CO., LTD.: PRODUCTS OFFERED

- TABLE 170 AIMTEK, INC.: COMPANY OVERVIEW

- TABLE 171 AIMTEK, INC.: PRODUCTS OFFERED

- TABLE 172 ZHEJIANG YATONG NEW MATERIALS CO., LTD.: COMPANY OVERVIEW

- TABLE 173 ZHEJIANG YATONG NEW MATERIALS CO., LTD.: PRODUCTS OFFERED

- TABLE 174 VBC GROUP: COMPANY OVERVIEW

- TABLE 175 VBC GROUP: PRODUCTS OFFERED

- TABLE 176 INDIAN SOLDER AND BRAZE ALLOYS PVT. LTD.: COMPANY OVERVIEW

- TABLE 177 INDIAN SOLDER AND BRAZE ALLOYS PVT. LTD.: PRODUCTS OFFERED

- TABLE 178 SENTES-BIR A.S.: COMPANY OVERVIEW

- TABLE 179 SENTES-BIR A.S.: PRODUCTS OFFERED

- TABLE 180 STELLA S.R.L.: COMPANY OVERVIEW

- TABLE 181 STELLA S.R.L.: PRODUCTS OFFERED

- TABLE 182 PIETRO GALLIANI BRAZING S.P.A.: COMPANY OVERVIEW

- TABLE 183 PIETRO GALLIANI BRAZING S.P.A.: PRODUCTS OFFERED

- TABLE 184 HANGZHOU HUAGUANG ADVANCED WELDING MATERIALS CO., LTD.: COMPANY OVERVIEW

- TABLE 185 HANGZHOU HUAGUANG ADVANCED WELDING MATERIALS CO., LTD.: PRODUCTS OFFERED

- TABLE 186 HEBEI YUGUANG WELDING CO., LTD.: COMPANY OVERVIEW

- TABLE 187 HEBEI YUGUANG WELDING CO., LTD.: PRODUCTS OFFERED

- TABLE 188 CASTOLIN EUTECTIC: COMPANY OVERVIEW

- TABLE 189 CASTOLIN EUTECTIC: PRODUCTS OFFERED

- TABLE 190 ZHONGSHAN HUALE WEIDING COMPOUND CO., LTD.: COMPANY OVERVIEW

- TABLE 191 MATHURE METAL WORKS PVT. LTD.: COMPANY OVERVIEW

- TABLE 192 KINZOKU YOUZAI CO., LTD.: COMPANY OVERVIEW

- TABLE 193 NAVIKA SILVER BRAZING ALLOYS: COMPANY OVERVIEW

- TABLE 194 BRAZING TECHNOLOGIES, INC.: COMPANY OVERVIEW

- TABLE 195 LINBRAZE S.R.L.: COMPANY OVERVIEW

- TABLE 196 SELECTARC GROUP: COMPANY OVERVIEW

- TABLE 197 SALDFLUX SRL: COMPANY OVERVIEW

- TABLE 198 SANHUAN MATERIALS: COMPANY OVERVIEW

- TABLE 199 SALDOBRASE SRL: COMPANY OVERVIEW

List of Figures

- FIGURE 1 ALUMINUM BRAZING MARKET: SEGMENTATION AND REGIONAL SCOPE

- FIGURE 2 ALUMINUM BRAZING MARKET: RESEARCH DESIGN

- FIGURE 3 MARKET SIZE ESTIMATION METHODOLOGY: BOTTOM-UP APPROACH

- FIGURE 4 MARKET SIZE ESTIMATION METHODOLOGY: TOP-DOWN APPROACH

- FIGURE 5 ALUMINUM BRAZING MARKET: DATA TRIANGULATION

- FIGURE 6 ALUMINUM-SILICON ALLOYS SEGMENT DOMINATED MARKET IN 2024

- FIGURE 7 SHEETS SEGMENT ACCOUNTED FOR LARGEST MARKET SHARE IN 2024

- FIGURE 8 AUTOMOTIVE INDUSTRY ACCOUNTED FOR LARGEST SHARE OF ALUMINUM BRAZING MARKET IN 2024

- FIGURE 9 ASIA PACIFIC TO REGISTER HIGHEST CAGR DURING FORECAST PERIOD

- FIGURE 10 HIGH DEMAND FROM AUTOMOTIVE SEGMENT TO DRIVE MARKET

- FIGURE 11 SHEETS SEGMENT ACCOUNTED FOR LARGEST MARKET SHARE IN 2024

- FIGURE 12 ALUMINUM-SILICON ALLOYS SEGMENT DOMINATED MARKET IN 2024

- FIGURE 13 AUTOMOTIVE SEGMENT ACCOUNTED FOR LARGEST MARKET SHARE IN 2024

- FIGURE 14 INDIA TO BE FASTEST-GROWING ALUMINUM BRAZING MARKET DURING FORECAST PERIOD

- FIGURE 15 ALUMINUM BRAZING MARKET: DRIVERS, RESTRAINTS, OPPORTUNITIES, AND CHALLENGES

- FIGURE 16 ALUMINUM BRAZING MARKET: PORTER'S FIVE FORCES ANALYSIS

- FIGURE 17 INFLUENCE OF STAKEHOLDERS ON BUYING PROCESS FOR TOP THREE END-USE INDUSTRIES

- FIGURE 18 BUYING CRITERIA FOR TOP THREE END-USE INDUSTRIES

- FIGURE 19 ALUMINUM BRAZING MARKET: VALUE CHAIN ANALYSIS

- FIGURE 20 ALUMINUM BRAZING MARKET: KEY STAKEHOLDERS IN ECOSYSTEM

- FIGURE 21 EXPORT DATA FOR HS CODE 8311-COMPLIANT PRODUCTS, BY KEY COUNTRY, 2023-2025 (USD THOUSAND)

- FIGURE 22 IMPORT DATA FOR HS CODE 8311-COMPLIANT PRODUCTS, BY KEY COUNTRY, 2023-2025 (USD THOUSAND)

- FIGURE 23 PATENT ANALYSIS, BY DOCUMENT TYPE, 2015-2024

- FIGURE 24 PATENT PUBLICATION TREND, 2015-2024

- FIGURE 25 LEGAL STATUS OF PATENTS, 2015-2024

- FIGURE 26 CHINA REGISTERED HIGHEST PERCENTAGE OF PATENTS BETWEEN 2015 AND 2024

- FIGURE 27 UACJ CORPORATION REGISTERED HIGHEST PERCENTAGE OF PATENTS, 2015-2024

- FIGURE 28 TRENDS/DISRUPTIONS IMPACTING CUSTOMER BUSINESS

- FIGURE 29 ALUMINUM BRAZING MARKET: DEALS AND FUNDING, 2021-2024 (USD MILLION)

- FIGURE 30 ALUMINUM-COPPER ALLOYS SEGMENT TO REGISTER HIGHEST CAGR DURING FORECAST PERIOD

- FIGURE 31 PASTE SEGMENT TO REGISTER HIGHEST CAGR DURING FORECAST PERIOD

- FIGURE 32 AEROSPACE & DEFENSE SEGMENT TO REGISTER HIGHEST CAGR DURING FORECAST PERIOD

- FIGURE 33 INDIA TO REGISTER HIGHEST GROWTH IN ALUMINUM BRAZING MARKET DURING FORECAST PERIOD

- FIGURE 34 NORTH AMERICA: ALUMINUM BRAZING MARKET SNAPSHOT

- FIGURE 35 EUROPE: ALUMINUM BRAZING MARKET SNAPSHOT

- FIGURE 36 ASIA PACIFIC: ALUMINUM BRAZING MARKET SNAPSHOT

- FIGURE 37 REVENUE ANALYSIS OF KEY PLAYERS, 2020-2024 (USD MILLION)

- FIGURE 38 MARKET SHARE ANALYSIS OF KEY PLAYERS, 2024

- FIGURE 39 TOP TRENDING BRANDS/PRODUCTS

- FIGURE 40 BRAND/PRODUCT COMPARISON

- FIGURE 41 ALUMINUM BRAZING MARKET: COMPANY EVALUATION MATRIX (KEY PLAYERS), 2024

- FIGURE 42 ALUMINUM BRAZING MARKET: COMPANY FOOTPRINT

- FIGURE 43 ALUMINUM BRAZING MARKET: COMPANY EVALUATION MATRIX (STARTUPS/SMES), 2024

- FIGURE 44 ALUMINUM BRAZING MARKET: COMPANY VALUATION

- FIGURE 45 ALUMINUM BRAZING MARKET: FINANCIAL METRICS (EV/EBITDA)

- FIGURE 46 YEAR-TO-DATE (YTD) PRICE TOTAL RETURN AND FIVE-YEAR STOCK BETA

- FIGURE 47 SOLVAY: COMPANY SNAPSHOT

- FIGURE 48 HONEYWELL INTERNATIONAL INC.: COMPANY SNAPSHOT

- FIGURE 49 HARRIS PRODUCTS GROUP (THE LINCOLN ELECTRIC COMPANY): COMPANY SNAPSHOT

- FIGURE 50 HANGZHOU HUAGUANG ADVANCED WELDING MATERIALS CO., LTD.: COMPANY SNAPSHOT