|

市場調查報告書

商品編碼

1822295

全球離心機市場按應用、容量、最終用途行業、轉子類型、速度、類型和地區分類 - 預測至 2030 年Centrifuge Market by Type (Laboratory, Industrial), Rotor Type (Fixed-Angle, Swinging Bucket), Application (Fluid Clarification, Dewatering), End-use Industry (Pharmaceutical, Food & Beverage), Speed, Capacity, & Region - Global Forecast to 2030 |

||||||

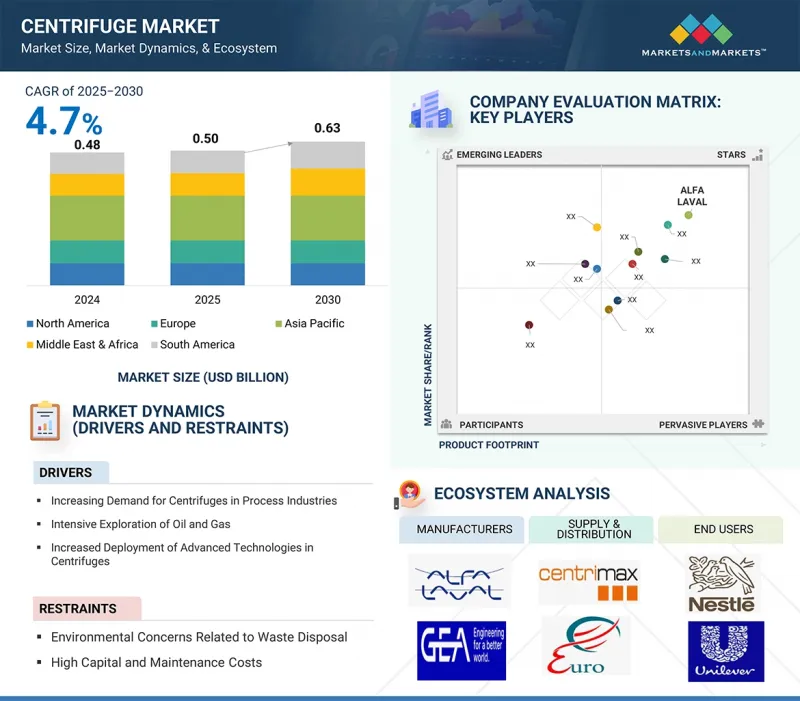

離心機市場預計將從 2025 年的 5 億美元成長到 2030 年的 6.3 億美元,複合年成長率為 4.7%。

| 調查範圍 | |

|---|---|

| 調查年份 | 2021-2030 |

| 基準年 | 2024 |

| 預測期 | 2025-2030 |

| 目標單位 | 金額(百萬美元/十億美元)和數量(單位) |

| 部分 | 按應用、容量、最終用途行業、轉子類型、速度、類型、地區 |

| 目標區域 | 北美、歐洲、亞太地區、中東和非洲、南美 |

由於製藥、生物技術、食品和飲料、化學、採礦、污水處理等行業的需求不斷成長,離心機市場正在穩步成長。全球人口的成長、快速的都市化和嚴格的環境法規正在推動各行各業採用先進的分離技術來提高效率、品質和合規性。

在製藥和生物技術領域,藥物製造和診斷中對精確分離的需求正在擴大離心機的使用範圍;而在食品加工領域,對高品質、無污染產品的需求正在推動需求成長。離心機在採礦業中用於礦物回收,在污水處理廠中用於污泥脫水和資源回收。自動化、節能設計和增強的製程控制等技術進步進一步推動了離心機的應用。由於工業擴張、城市基礎設施建設和醫療保健投資的增加,亞太地區引領市場發展;而由於技術創新和法規遵從,北美和歐洲的需求保持穩定。儘管面臨設備成本和維護需求上升等挑戰,全球離心機市場預計將在工業現代化和資源效率追求的支持下持續擴張。可再生能源、生物技術研究和精密製造領域的新興應用將進一步增強這一成長動能。

工業離心機因其在製藥、食品飲料、化學製造、石油天然氣和污水處理等大型加工行業的廣泛應用而呈現強勁成長勢頭。這些離心機專為連續高通量運作而設計,能夠高效分離固體,並在工業規模上實現顆粒澄清。工業自動化程度的提高、品質標準的日益嚴格以及生產設施對高效廢棄物管理的需求推動了工業離心機需求的成長。在製藥業,工業離心機對於活性藥物成分 (API) 的生產至關重要;而在食品業,它們則用於牛奶澄清、果汁提取和食用油精煉等工藝。污水處理廠也嚴重依賴工業離心機進行污泥脫水和污水管理。節能馬達、增強的安全系統和物聯網監控等設計改進正在推動其應用。新興國家製造地的擴張以及清潔工業流程法規的不斷加強,進一步推動了市場成長。

小容量離心機(定義為處理能力低於 10 立方公尺/小時的離心機)因其適用於專業精密應用,在離心機市場中成長最快。這類離心機廣泛應用於研究實驗室、臨床診斷、中試生產和利基工業流程,這些領域對高精度、可控的樣品處理和緊湊的設計至關重要。它們佔地相對較小,便攜性,易於整合到現有設施中,使其成為空間和預算受限的實驗室和小規模生產單位的理想選擇。此外,對客製化、專用離心機的需求日益成長,尤其是在製藥、生物技術、食品加工和環境測試領域,這進一步加速了它們的普及。全球個人化醫療的興起、對研發活動的日益重視以及新興國家小規模製造業的擴張也是關鍵的成長動力。此外,小容量離心機通常需要較低的資本投入和維護成本,因此對注重成本的最終用戶具有吸引力。改進的轉子設計、數位控制和能源效率等技術進步正在擴大其容量並使其適合更複雜的分離任務。

中速離心機的轉速為 5,000 至 20,000 RPM,由於其多功能性和廣泛的應用範圍,在離心機市場中成長最快。這些離心機在分離效率和樣品完整性之間取得了最佳平衡,使其適用於工業和實驗室環境。在生物技術和製藥領域,中速離心機用於細胞收穫、蛋白質純化和疫苗製造,在這些領域中,精確分離而不損壞精細的生物材料至關重要。在工業過程中,中速離心機在污水處理、食品和飲料澄清以及化學加工中發揮關鍵作用,可實現有效分離,同時最大限度地減少零件磨損。它們能夠處理各種各樣的物料輸送,從生物樣本到工業泥漿,這正在推動各個行業的需求。此外,中速離心機通常比超高速型號消耗更少的能源,從而節省成本並實現營運永續性。轉子平衡增強、自動控制和改進的安全機制等技術創新進一步提高了效率和易用性。生物製藥生產的擴張、研發投入的增加以及對擴充性且高效的分離解決方案的需求也推動了該行業的成長。

定角轉子離心機憑藉其高效能、多功能以及在工業和實驗室中的廣泛應用,在離心機市場中成長最快。定角轉子以相對於旋轉軸的固定角度(通常為 25-40 度)固定樣品,使顆粒能夠沿著管壁快速沉積。這種設計在實現高分離效率的同時,最大限度地縮短了運行時間,使其成為細胞沉澱、亞細胞成分分離、核酸純化以及工業工作流程中大體積處理等應用的理想選擇。在生物製藥生產中,定角轉子是高產量細胞培養收穫和蛋白質分離的首選。與水平轉子相比,其堅固的設計可支援更高的轉速和離心力,使其適用於各種黏度和密度的樣品。食品加工、化學品製造和污水處理等行業因其耐用性和成本效益而擴大採用此類離心機。轉子材料(例如耐腐蝕合金和輕質複合材料)的進步提高了性能並延長了使用壽命。此外,與具有自動控制和增強安全機制的現代離心機系統的兼容性也推動了需求。

流體澄清領域在離心機市場中成長最快,這得益於其在需要高純度流體的各行各業中發揮的關鍵作用。流體澄清涉及有效去除液體中的懸浮固體、雜質和其他顆粒物,以確保下游製程中一致的品質和性能。該應用在食品和飲料行業尤為重要,用於果汁、葡萄酒和啤酒的澄清;在製藥行業,用於活性成分和注射液的純化;在生物技術行業,用於從有價值的生物分子中分離細胞碎片。此外,化學和石化產業也依賴流體澄清來維持製程效率和產品完整性。對法規遵循、產品安全和品質標準的日益重視正在推動其應用。此外,離心機技術的進步,例如高速、自動化和就地清洗 (CIP) 系統,正在提高澄清效率,同時減少停機時間。水處理舉措的不斷擴展,尤其是在都市區和工業環境中,進一步推動了對流體淨化離心機的需求。新興經濟體的工業產量不斷增加,環境法規也越來越嚴格,對這項成長做出了重大貢獻。

隨著工業界越來越重視效率、永續性和精確度,使用離心機進行流體淨化變得至關重要,確保其作為市場價值成長最快的應用領域的地位。

人口成長、老化以及慢性病和感染疾病的流行推動了全球對藥品、疫苗和生技藥品的需求成長,因此製藥業是離心機市場成長最快的終端應用領域。離心機在製藥生產中發揮關鍵作用,特別是在原料藥生技藥品成分、血液成分、細胞培養和生物製劑的分離、純化和澄清過程中。生物製藥和個人化醫療的快速成長進一步加速了離心機的採用,特別是高速離心機和超速離心機。此外,COVID-19 大流行凸顯了疫苗生產和研究對先進離心機技術的需求。嚴格的監管要求和製藥業向連續生產的轉變也推動了對高性能自動離心機的投資,以確保精度、無菌和合規性。

亞太地區是離心機市場成長最快的地區,這得益於快速的工業化進程、不斷擴大的產能以及對基礎設施和加工工業的大量投資。中國、印度、日本和韓國等國家在製藥、生物技術、食品飲料、化學加工和污水處理等領域正經歷強勁成長,而這些領域都嚴重依賴離心機技術。人口成長和可支配收入的提高推動了醫療保健需求的不斷成長,這推動了對製藥和生物加工離心機的需求。政府在清潔水、廢棄物管理和環境合規方面的措施正在加速其在市政和工業污水處理中的應用。此外,亞太地區正在成為製造和研發中心,跨國公司紛紛建立生產設施,以提高本地運轉率並降低成本。競爭激烈的勞動力市場、優惠的貿易政策以及不斷成長的出口也促進了市場擴張。該地區強勁的經濟成長、城市發展和產業多元化使其成為全球離心機產業的主要成長引擎。

本報告研究了全球離心機市場,並提供了按應用、容量、最終用途行業、轉子類型、速度、類型和地區分類的趨勢資訊,以及參與市場的公司概況。

目錄

第1章 引言

第2章調查方法

第3章執行摘要

第4章重要考察

第5章 市場概況

- 介紹

- 市場動態

- 生成式人工智慧對離心機市場的影響

第6章 產業趨勢

- 介紹

- 影響客戶業務的趨勢/中斷

- 供應鏈分析

- 2025年美國關稅對離心機市場的影響

- 投資金籌措場景

- 定價分析

- 生態系分析

- 技術分析

- 專利分析

- 過去 10 年的出版趨勢

- 法律地位

- 貿易分析

- 2025-2026年主要會議和活動

- 關稅和監管狀況

- 波特五力分析

- 主要相關人員和採購標準

- 總體經濟指標

- 案例研究分析

第7章離心機市場(依應用)

- 介紹

- 固體管理

- 泥漿清理

- 脫水

- 液體澄清

- 其他

第8章離心機市場(按容量)

- 介紹

- 小容量離心機(小於10m3/H)

- 中容量離心機(10-50 m3/H)

- 大容量離心機(50m3/H以上)

9. 離心機市場(依最終用途產業)

- 介紹

- 製藥

- 食品/飲料

- 石油和天然氣

- 化學品

- 水和污水處理

- 其他

第 10 章離心機市場(按轉子類型)

- 介紹

- 定角轉子離心機

- 吊桶式離心機

- 立式和臥式離心機

- 其他

第 11 章離心機市場(按速度)

- 介紹

- 低速(低於 5,000 RPM)

- 中速(5,000 至 20,000 RPM)

- 高速(超過 20,000 RPM)

第12章離心機市場(按類型)

- 介紹

- 實驗室離心機

- 工業離心機

- 臥螺離心機

- 高速分離機

- 其他

第 13 章:離心機市場(按地區)

- 介紹

- 亞太地區

- 中國

- 日本

- 印度

- 韓國

- 其他

- 北美洲

- 美國

- 加拿大

- 墨西哥

- 歐洲

- 德國

- 義大利

- 法國

- 英國

- 西班牙

- 其他

- 中東和非洲

- 海灣合作理事會國家

- 南非

- 其他

- 南美洲

- 阿根廷

- 巴西

- 其他

第14章競爭格局

- 介紹

- 主要參與企業的策略/優勢,2021 年 1 月至 2025 年 8 月

- 2024年市佔率分析

- 2020-2024年收益分析

- 品牌/產品比較

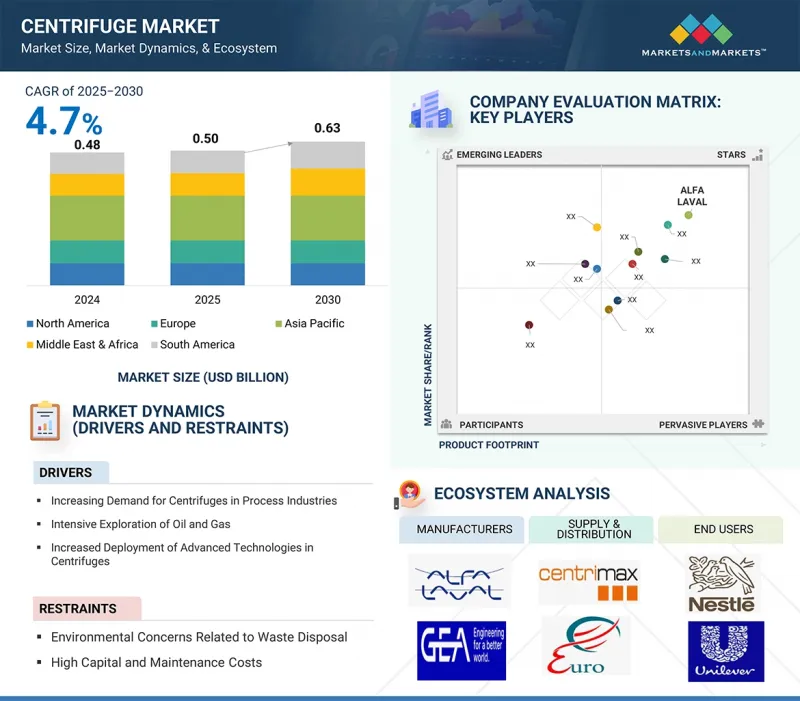

- 公司估值矩陣:2024 年關鍵參與企業

- 公司估值矩陣:Start-Ups/中小企業,2024 年

- 競爭場景

第15章:公司簡介

- 主要參與企業

- ALFA LAVAL

- GEA GROUP AKTIENGESELLSCHAFT

- ANDRITZ

- FLSMIDTH A/S

- KUBOTA CORPORATION

- FLOTTWEG SE

- SPX FLOW, INC.

- MITSUBISHI KAKOKI KAISHA, LTD.

- FERRUM AG

- SIEBTECHNIK GMBH

- 其他公司

- SIGMA LABORZENTRIFUGEN GMBH

- BECKMAN COULTER, INC.

- EPPENDORF SE

- THERMO FISHER SCIENTIFIC INC.

- ANDREAS HETTICH GMBH

- PIERALISI MAIP SPA

- THOMAS BROADBENT & SONS LTD.

- ROUSSELET ROBATEL

- HEINKEL PROCESS TECHNOLOGY GMBH

- COLE-PARMER INSTRUMENT COMPANY, LLC

- HAUS CENTRIFUGE TECHNOLOGIES

- GTECH

- WESTERN STATES

- B&P LITTLEFORD

- ELGIN SEPARATION SOLUTIONS

第16章 附錄

The centrifuge market is projected to grow from USD 0.50 billion in 2025 to USD 0.63 billion by 2030, at a CAGR of 4.7%.

| Scope of the Report | |

|---|---|

| Years Considered for the Study | 2021-2030 |

| Base Year | 2024 |

| Forecast Period | 2025-2030 |

| Units Considered | Value (USD Million/Billion) and Volume (Units) |

| Segments | Type, Speed, Rotor Type, Capacity, Application, End-use Industry, and Region |

| Regions covered | North America, Europe, Asia Pacific, the Middle East & Africa, and South America |

The centrifuge market is experiencing steady growth driven by rising demand across industries such as pharmaceuticals, biotechnology, food and beverage, chemicals, mining, and wastewater treatment. Increasing global population, rapid urbanization, and stricter environmental regulations are prompting industries to adopt advanced separation technologies for improved efficiency, quality, and compliance.

In pharmaceuticals and biotechnology, the need for precise separation in drug manufacturing and diagnostics is expanding centrifuge usage, while in food processing, the demand is fueled by the need for high-quality, contaminant-free products. The mining sector uses centrifuges for mineral recovery, and wastewater treatment plants rely on them for sludge dewatering and resource recovery. Technological advancements, including automation, energy-efficient designs, and enhanced process control, are further boosting adoption. Asia Pacific leads market growth due to industrial expansion, urban infrastructure development, and rising healthcare investments, while North America and Europe see steady demand driven by innovation and regulatory compliance. Despite challenges such as high equipment costs and maintenance requirements, the global centrifuge market is poised for sustained expansion, supported by industrial modernization and the push for resource efficiency. This growth is further reinforced by emerging applications in renewable energy, biotechnology research, and precision manufacturing.

" Industrial centrifuge is projected to register the fastest growth in the centrifuge market in terms of value during the forecast period."

Industrial centrifuges are witnessing strong growth due to their widespread adoption in large-scale processing industries, including pharmaceuticals, food & beverage, chemical manufacturing, oil & gas, and wastewater treatment. These machines are designed for continuous, high-throughput operations, enabling efficient separation of solids from liquids, liquids from liquids, and particle clarification at an industrial scale. Their rising demand is driven by increasing industrial automation, stricter quality standards, and the need for efficient waste management in production facilities. In the pharmaceutical sector, industrial centrifuges are critical for producing active pharmaceutical ingredients (APIs), while in the food industry, they are used for processes such as milk clarification, juice extraction, and edible oil purification. Wastewater treatment plants also rely heavily on industrial centrifuges for sludge dewatering and effluent management. Advancements in design, such as energy-efficient motors, enhanced safety systems, and IoT-enabled monitoring, are boosting their adoption. The expansion of manufacturing bases in emerging economies, combined with regulatory pushes for cleaner industrial processes, further fuels market growth. As industries increasingly focus on operational efficiency and sustainable practices, industrial centrifuges are becoming indispensable, leading to their position as the fastest-growing type segment in the global centrifuge market.

"Small capacity (< 10 m3/hour) segment to register the fastest growth in the centrifuge market in terms of value during the forecast period."

The small capacity centrifuge segment, defined as units with a throughput of less than 10 m3/hour, is experiencing the fastest growth in the centrifuge market due to its suitability for specialized, precision-driven applications. These centrifuges are widely used in research laboratories, clinical diagnostics, pilot-scale production, and niche industrial processes where high accuracy, controlled sample handling, and compact design are critical. Their relatively low operational footprint, portability, and ease of integration into existing facilities make them ideal for laboratories and small-scale production units with space and budget constraints. Moreover, the rising demand for customized, application-specific centrifugation, especially in pharmaceuticals, biotechnology, food processing, and environmental testing, has further accelerated adoption. The global surge in personalized medicine, increased focus on R&D activities, and expansion of small-scale manufacturing in emerging economies are also key growth drivers. Additionally, small capacity centrifuges often require lower capital investment and offer reduced maintenance costs, appealing to cost-sensitive end users. Technological advancements, such as improved rotor designs, digital controls, and energy efficiency, have expanded their capabilities, making them suitable for more complex separation tasks. As industries increasingly value flexibility, precision, and operational efficiency, small capacity centrifuges are set to maintain their strong growth trajectory during the forecast period.

"Medium speed (5,000-20,000 RPM) segment to register the highest growth in the centrifuge market, in terms of value, during the forecast period."

The medium-speed centrifuge segment, operating between 5,000 and 20,000 RPM, is witnessing the fastest growth in the centrifuge market due to its versatility and broad application range. These centrifuges strike an optimal balance between separation efficiency and sample integrity, making them suitable for both industrial and laboratory settings. In biotechnology and pharmaceuticals, medium-speed centrifuges are used for cell harvesting, protein purification, and vaccine production, where precise separation without damaging sensitive biological materials is essential. In industrial processes, they play a critical role in wastewater treatment, food and beverage clarification, and chemical processing, where moderate speeds ensure effective separation with reduced wear on components. Their adaptability to handle a wide variety of materials, from biological samples to industrial slurries, has expanded their demand across diverse sectors. Furthermore, medium-speed centrifuges typically consume less energy than ultra-high-speed models, offering cost savings and operational sustainability. Technological innovations, such as enhanced rotor balancing, automated controls, and improved safety mechanisms, have further increased their efficiency and user-friendliness. The growth is also driven by expanding biopharmaceutical manufacturing, increased investment in research, and the need for scalable yet efficient separation solutions. As industries seek cost-effective, versatile centrifugation options, the medium-speed category is positioned for sustained high growth.

"Fixed-angle rotor centrifuge segment to register the highest growth in the centrifuge market in terms of value during the forecast period."

The fixed-angle rotor centrifuge segment is experiencing the fastest growth in the rotor type category of the centrifuge market due to its efficiency, versatility, and widespread industrial and laboratory adoption. Fixed-angle rotors hold samples at a constant angle (typically 25°-40°) relative to the axis of rotation, enabling rapid sedimentation of particles along the tube wall. This design minimizes run time while delivering high separation efficiency, making it ideal for applications such as pelleting cells, separating subcellular components, purifying nucleic acids, and processing large volumes in industrial workflows. In biopharmaceutical manufacturing, fixed-angle rotors are favored for high-yield cell culture harvesting and protein isolation. Their robust design supports higher speeds and greater centrifugal forces compared to swinging-bucket rotors, making them suitable for a wide range of viscosities and densities. Industrial sectors, including food processing, chemical manufacturing, and wastewater treatment, are increasingly adopting these centrifuges for their durability and cost-effectiveness. Advances in rotor materials, such as corrosion-resistant alloys and lightweight composites, have enhanced performance and extended service life. Additionally, their compatibility with modern centrifuge systems featuring automated controls and enhanced safety mechanisms is driving demand. As industries prioritize speed, efficiency, and reliability, fixed-angle rotor centrifuges are becoming a preferred choice, fueling their rapid market growth.

"Fluid clarification segment to register the highest growth in the centrifuge market during the forecast period."

The fluid clarification segment is witnessing the fastest growth in the centrifuge market due to its critical role across industries requiring high-purity liquids. Fluid clarification involves the efficient removal of suspended solids, impurities, and other particulates from liquids, ensuring consistent quality and performance in downstream processes. This application is particularly vital in the food & beverage industry for juice, wine, and beer clarification; in pharmaceuticals for purifying active ingredients and injectable solutions; and in biotechnology for separating cell debris from valuable biomolecules. The chemical and petrochemical industries also rely on fluid clarification to maintain process efficiency and product integrity. The growing emphasis on regulatory compliance, product safety, and quality standards is driving adoption. Additionally, advances in centrifuge technology, such as high-speed, automated, and clean-in-place (CIP) systems, have enhanced clarification efficiency while reducing operational downtime. Expanding water treatment initiatives, especially in urban and industrial settings, are further boosting demand for centrifuges in fluid purification. Emerging economies, with their rising industrial output and stricter environmental regulations, are contributing significantly to this growth. As industries increasingly prioritize efficiency, sustainability, and precision, fluid clarification using centrifuges is becoming indispensable, securing its position as the fastest-growing application segment in terms of market value.

"Pharmaceutical industry to witness the fastest growth in the centrifuge market in terms of value during the forecast period."

The pharmaceutical industry is the fastest-growing end-use segment for the centrifuge market due to increasing global demand for medicines, vaccines, and biologics, driven by rising population, aging demographics, and the prevalence of chronic and infectious diseases. Centrifuges play a critical role in drug manufacturing, particularly in separation, purification, and clarification processes for active pharmaceutical ingredients (APIs), blood components, cell cultures, and biologics. The rapid growth of biopharmaceuticals and personalized medicine has further accelerated centrifuge adoption, especially high-speed and ultracentrifuges. Additionally, the COVID-19 pandemic highlighted the need for advanced centrifugation technologies for vaccine production and research. Stringent regulatory requirements and the shift toward continuous manufacturing in pharma have also driven investments in high-performance, automated centrifuges that ensure precision, sterility, and compliance. Emerging markets, such as India and China, are boosting pharmaceutical production capacity, creating significant opportunities for centrifuge manufacturers to cater to both large-scale and specialty drug manufacturing needs.

"Asia Pacific is projected to be the fastest-growing region in the centrifuge market, in terms of value, during the forecast period."

Asia Pacific is the fastest-growing region in the centrifuge market due to rapid industrialization, expanding manufacturing capacity, and significant investments in infrastructure and process industries. Countries like China, India, Japan, and South Korea are witnessing strong growth in pharmaceuticals, biotechnology, food and beverage, chemical processing, and wastewater treatment, all of which rely heavily on centrifuge technology. Rising healthcare needs, fueled by large populations and increasing disposable incomes, are boosting demand for pharmaceutical and bioprocessing centrifuges. Government initiatives for clean water, waste management, and environmental compliance are accelerating adoption in municipal and industrial wastewater treatment. Additionally, the Asia Pacific is becoming a hub for manufacturing and R&D, attracting global players to set up production facilities, thereby improving local availability and reducing costs. Competitive labor markets, favorable trade policies, and growing exports also contribute to market expansion. The region's robust economic growth, urban development, and industrial diversification establish it as the leading growth engine for the global centrifuge industry.

In-depth interviews were conducted with chief executive officers (CEOs), marketing directors, other innovation and technology directors, and executives from various key organizations operating in the centrifuge market, and information was gathered from secondary research to determine and verify the market size of several segments.

- By Company Type: Tier 1 - 50%, Tier 2 - 30%, and Tier 3 - 20%

- By Designation: Managers - 15%, Directors - 20%, and Others - 65%

- By Region: North America - 20%, Europe - 30%, Asia Pacific - 40%, Middle East & Africa - 5%, and South America - 5%

The centrifuge market comprises major players such as ALFA LAVAL (Sweden), GEA Group Aktiengesellschaft (Germany), ANDRITZ (Austria), FLSmidth A/S (Denmark), KUBOTA Corporation (Japan), Flottweg SE (Germany), SPX FLOW, Inc. (US), Mitsubishi Kakoki Kaisha, Ltd. (Japan), Ferrum AG (Switzerland), and SIEBTECHNIK GmbH (Germany). The study includes an in-depth competitive analysis of these key players in the centrifuge market, with their company profiles, recent developments, and key market strategies.

Research Coverage

This report segments the centrifuge market by type, speed, rotor type, capacity, application, end-use industry, and region, and estimates the overall market value across various regions. It has also conducted a detailed analysis of key industry players to provide insights into their business overviews, products and services, key strategies, and expansions associated with the centrifuge market.

Key Benefits of Buying This Report

This research report is focused on various levels of analysis - industry analysis (industry trends), market ranking analysis of top players, and company profiles, which together provide an overall view of the competitive landscape, emerging and high-growth segments of the centrifuge market, high-growth regions, and market drivers, restraints, opportunities, and challenges.

The report provides insights on the following pointers:

- Analysis of drivers (increasing demand for centrifuges in process industries, intensive exploration of oil and gas, and increased deployment of advanced technologies in centrifuges), restraints (environmental concerns related to waste disposal and high capital and maintenance costs), opportunities (growth in pharmaceutical and biotechnology sectors), and challenges (increasing competition from alternative technologies).

- Market Penetration: Comprehensive information on the centrifuge offered by top players in the centrifuge market.

- Product Development/Innovation: Detailed insights on upcoming technologies, research & development activities, product launches, expansions, investments, collaborations, and partnerships in the market.

- Market Development: Comprehensive information about lucrative emerging markets. The report analyzes the centrifuge market across regions.

- Market Capacity: Wherever possible, the production capacities of companies producing centrifuges are provided, along with upcoming capacities for the centrifuge market.

- Competitive Assessment: In-depth assessment of market shares, strategies, products, and manufacturing capabilities of leading players in the centrifuge market.

TABLE OF CONTENTS

1 INTRODUCTION

- 1.1 STUDY OBJECTIVES

- 1.2 MARKET DEFINITION

- 1.3 STUDY SCOPE

- 1.3.1 MARKETS COVERED AND REGIONAL SNAPSHOT

- 1.3.2 INCLUSIONS AND EXCLUSIONS

- 1.3.3 YEARS CONSIDERED

- 1.3.4 CURRENCY CONSIDERED

- 1.3.5 UNITS CONSIDERED

- 1.4 LIMITATIONS

- 1.5 STAKEHOLDERS

- 1.6 SUMMARY OF CHANGES

2 RESEARCH METHODOLOGY

- 2.1 RESEARCH DATA

- 2.1.1 SECONDARY DATA

- 2.1.1.1 Key data from secondary sources

- 2.1.2 PRIMARY DATA

- 2.1.2.1 Key data from primary sources

- 2.1.2.2 Key primary sources

- 2.1.2.3 Key participants for interviews with experts

- 2.1.2.4 Breakdown of interviews with experts

- 2.1.2.5 Key industry insights

- 2.1.1 SECONDARY DATA

- 2.2 BASE NUMBER CALCULATION

- 2.2.1 SUPPLY-SIDE ANALYSIS

- 2.2.2 DEMAND-SIDE ANALYSIS

- 2.3 GROWTH FORECAST

- 2.3.1 SUPPLY SIDE

- 2.3.2 DEMAND SIDE

- 2.4 MARKET SIZE ESTIMATION

- 2.4.1 BOTTOM-UP APPROACH

- 2.4.2 TOP-DOWN APPROACH

- 2.5 DATA TRIANGULATION

- 2.6 RESEARCH ASSUMPTIONS

- 2.7 GROWTH FORECAST

- 2.8 RISK ASSESSMENT

- 2.9 FACTOR ANALYSIS

3 EXECUTIVE SUMMARY

4 PREMIUM INSIGHTS

- 4.1 ATTRACTIVE OPPORTUNITIES FOR PLAYERS IN CENTRIFUGE MARKET

- 4.2 CENTRIFUGE MARKET, BY TYPE

- 4.3 CENTRIFUGE MARKET, BY SPEED

- 4.4 CENTRIFUGE MARKET, BY APPLICATION

- 4.5 CENTRIFUGE MARKET, BY CAPACITY

- 4.6 CENTRIFUGE MARKET, BY ROTOR TYPE

- 4.7 CENTRIFUGE MARKET, BY END-USE INDUSTRY

- 4.8 CENTRIFUGE MARKET, BY COUNTRY

5 MARKET OVERVIEW

- 5.1 INTRODUCTION

- 5.2 MARKET DYNAMICS

- 5.2.1 DRIVERS

- 5.2.1.1 Critical role in enhancing efficiency, productivity, and quality across sectors

- 5.2.1.2 Intensive oil & gas exploration

- 5.2.1.3 Increased deployment of advanced technologies

- 5.2.2 RESTRAINTS

- 5.2.2.1 Environmental concerns related to waste disposal

- 5.2.2.2 High capital and maintenance costs

- 5.2.3 OPPORTUNITIES

- 5.2.3.1 Growth of pharmaceutical and biotechnology sectors

- 5.2.4 CHALLENGES

- 5.2.4.1 Increasing competition from alternative technologies

- 5.2.1 DRIVERS

- 5.3 IMPACT OF GENERATIVE AI ON CENTRIFUGE MARKET

- 5.3.1 INTRODUCTION

- 5.3.2 PREDICTIVE MAINTENANCE AND OPERATIONAL EFFICIENCY

- 5.3.3 ACCELERATED DESIGN AND PROTOTYPING OF CENTRIFUGES

- 5.3.4 PROCESS OPTIMIZATION IN END-USE INDUSTRIES

- 5.3.5 ENHANCED CUSTOMER SUPPORT AND TRAINING

- 5.3.6 MARKET INTELLIGENCE AND DEMAND FORECASTING

6 INDUSTRY TRENDS

- 6.1 INTRODUCTION

- 6.2 TRENDS/DISRUPTIONS IMPACTING CUSTOMER BUSINESS

- 6.2.1 REVENUE SHIFT AND NEW REVENUE POCKETS FOR CENTRIFUGE MANUFACTURERS

- 6.3 SUPPLY CHAIN ANALYSIS

- 6.3.1 RAW MATERIAL SUPPLIERS

- 6.3.2 MANUFACTURERS

- 6.3.3 DISTRIBUTORS

- 6.3.4 END USERS

- 6.4 IMPACT OF 2025 US TARIFFS ON CENTRIFUGE MARKET

- 6.4.1 INTRODUCTION

- 6.4.2 KEY TARIFF RATES

- 6.4.3 PRICE IMPACT ANALYSIS

- 6.4.4 IMPACT ON COUNTRY/REGION

- 6.4.4.1 US

- 6.4.4.2 Europe

- 6.4.4.3 Asia Pacific

- 6.4.5 IMPACT ON END-USE INDUSTRIES

- 6.5 INVESTMENT AND FUNDING SCENARIO

- 6.6 PRICING ANALYSIS

- 6.6.1 AVERAGE SELLING PRICE TREND, BY REGION, 2021-2024

- 6.6.2 AVERAGE SELLING PRICE TREND OF KEY PLAYERS, BY TOP THREE TYPES, 2024

- 6.7 ECOSYSTEM ANALYSIS

- 6.8 TECHNOLOGY ANALYSIS

- 6.8.1 KEY TECHNOLOGIES

- 6.8.2 COMPLEMENTARY TECHNOLOGIES

- 6.8.3 ADJACENT TECHNOLOGIES

- 6.9 PATENT ANALYSIS

- 6.9.1 METHODOLOGY

- 6.9.2 GRANTED PATENTS, 2015-2024

- 6.10 PUBLICATION TRENDS FOR LAST TEN YEARS

- 6.10.1 INSIGHTS

- 6.11 LEGAL STATUS

- 6.11.1 LEGAL STATUS SEARCH WAS CONDUCTED TO DETERMINE IF PATENTS ARE ACTIVE, INACTIVE, OR ABANDONED

- 6.11.2 JURISDICTION ANALYSIS

- 6.11.3 TOP APPLICANTS

- 6.11.4 KEY PATENTS FOR CENTRIFUGES

- 6.12 TRADE ANALYSIS

- 6.12.1 IMPORT SCENARIO (HS CODE 842119)

- 6.12.2 EXPORT SCENARIO (HS CODE 842119)

- 6.13 KEY CONFERENCES AND EVENTS, 2025-2026

- 6.14 TARIFF AND REGULATORY LANDSCAPE

- 6.14.1 TARIFF AND REGULATIONS RELATED TO CENTRIFUGES

- 6.14.2 REGULATORY BODIES, GOVERNMENT AGENCIES, AND OTHER ORGANIZATIONS

- 6.14.3 REGULATIONS RELATED TO CENTRIFUGE MARKET

- 6.15 PORTER'S FIVE FORCES ANALYSIS

- 6.15.1 THREAT OF NEW ENTRANTS

- 6.15.2 THREAT OF SUBSTITUTES

- 6.15.3 BARGAINING POWER OF SUPPLIERS

- 6.15.4 BARGAINING POWER OF BUYERS

- 6.15.5 INTENSITY OF COMPETITIVE RIVALRY

- 6.16 KEY STAKEHOLDERS AND BUYING CRITERIA

- 6.16.1 KEY STAKEHOLDERS IN BUYING PROCESS

- 6.16.2 BUYING CRITERIA

- 6.17 MACROECONOMIC INDICATORS

- 6.17.1 GDP TRENDS AND FORECAST OF MAJOR ECONOMIES

- 6.18 CASE STUDY ANALYSIS

- 6.18.1 EPPENDORF'S SUSTAINABLE CENTRIFUGE INNOVATION

- 6.18.2 BECKMAN COULTER'S DEVELOPMENT OF AI-ENABLED CENTRIFUGES

- 6.18.3 ALFA LAVAL'S WATER TREATMENT CENTRIFUGE DEPLOYMENT

7 CENTRIFUGE MARKET, BY APPLICATION

- 7.1 INTRODUCTION

- 7.2 SOLID CONTROL

- 7.2.1 RISING DEMAND FOR EFFICIENT DRILLING FLUID MANAGEMENT AND ENVIRONMENTAL COMPLIANCE TO DRIVE MARKET

- 7.3 MUD CLEANING

- 7.3.1 INCREASING DEMAND FOR EFFICIENT DRILLING FLUID PURIFICATION AND COST-EFFECTIVE MUD RECYCLING TO BOOST MARKET

- 7.4 DEWATERING

- 7.4.1 EFFICIENT WASTE MANAGEMENT AND WATER RECOVERY IN WASTEWATER, MINING, AND CHEMICAL INDUSTRIES TO FUEL MARKET

- 7.5 FLUID CLARIFICATION

- 7.5.1 REQUIREMENT OF HIGH-PURITY AND STRINGENT QUALITY STANDARDS IN PHARMACEUTICALS, FOOD, AND BIOTECHNOLOGY TO PROPEL MARKET

- 7.6 OTHER APPLICATIONS

- 7.6.1 CELL HARVESTING

- 7.6.2 MATERIAL TESTING

8 CENTRIFUGE MARKET, BY CAPACITY

- 8.1 INTRODUCTION

- 8.2 SMALL CAPACITY CENTRIFUGES (<10 M3/H)

- 8.2.1 RISING ADOPTION IN CLINICAL DIAGNOSTICS, RESEARCH, PHARMACEUTICAL AND BIOTECH APPLICATIONS TO DRIVE DEMAND

- 8.3 MEDIUM CAPACITY CENTRIFUGES (10-50 M3/H)

- 8.3.1 INCREASING DEMAND IN PHARMACEUTICALS, FOOD PROCESSING, AND WASTEWATER TREATMENT TO BOOST MARKET

- 8.4 LARGE CAPACITY CENTRIFUGES (>50 M3/H)

- 8.4.1 GROWING USE IN LARGE-SCALE INDUSTRIES TO PROPEL MARKET

9 CENTRIFUGE MARKET, BY END-USE INDUSTRY

- 9.1 INTRODUCTION

- 9.2 PHARMACEUTICAL

- 9.2.1 ADVANCED DRUG PURIFICATION AND STERILE MANUFACTURING PROCESSES TO DRIVE MARKET

- 9.3 FOOD & BEVERAGES

- 9.3.1 RISING DEMAND FOR HIGH-QUALITY, CONTAMINATION-FREE PRODUCTS TO BOOST MARKET

- 9.4 OIL & GAS

- 9.4.1 EFFICIENT SEPARATION OF CRUDE OIL COMPONENTS AND REMOVAL OF DRILLING MUD CONTAMINANTS TO PROPEL DEMAND

- 9.5 CHEMICALS

- 9.5.1 INCREASING PRODUCTION OF HIGH-PURITY SPECIALTY CHEMICALS TO FOSTER MARKET GROWTH

- 9.6 WATER & WASTEWATER TREATMENT

- 9.6.1 INTENSIFYING ENVIRONMENTAL REGULATIONS AND URBAN WASTEWATER CHALLENGES TO DRIVE DEMAND

- 9.7 OTHER END-USE INDUSTRIES

- 9.7.1 MINING AND MINERAL PROCESSING

- 9.7.2 ENERGY & POWER

- 9.7.3 TEXTILE

10 CENTRIFUGE MARKET, BY ROTOR TYPE

- 10.1 INTRODUCTION

- 10.2 FIXED-ANGLE ROTOR CENTRIFUGES

- 10.2.1 GROWING DEMAND FOR HIGH-SPEED AND EFFICIENT SEPARATION IN FINE PARTICLE RECOVERY AND MICROFILTRATION PRE-TREATMENT TO DRIVE MARKET

- 10.3 SWINGING BUCKET CENTRIFUGES

- 10.3.1 INCREASING USE IN CLINICAL DIAGNOSTICS, BLOOD PROCESSING, AND CELL CULTURE TO FUEL MARKET GROWTH

- 10.4 VERTICAL & HORIZONTAL CENTRIFUGES

- 10.4.1 EXPANDING APPLICATIONS IN LARGE-SCALE INDUSTRIAL SEPARATION AND FOOD PROCESSING TO BOOST DEMAND

- 10.5 OTHER ROTOR TYPES

- 10.5.1 ZONAL ROTORS

- 10.5.2 CONTINUOUS-FLOW ROTORS

- 10.5.3 AIR-DRIVEN ROTORS

11 CENTRIFUGE MARKET, BY SPEED

- 11.1 INTRODUCTION

- 11.2 LOW SPEED (BELOW 5,000 RPM)

- 11.2.1 WIDESPREAD ADOPTION IN CLINICAL DIAGNOSTICS AND ACADEMIC LABORATORIES TO BOOST MARKET

- 11.3 MEDIUM SPEED ( 5,000 RPM - 20,000 RPM)

- 11.3.1 INCREASING DEMAND IN PHARMACEUTICAL RESEARCH AND BIOPROCESSING TO DRIVE MARKET

- 11.4 HIGH SPEED ( ABOVE 20,000 RPM)

- 11.4.1 RISING APPLICATIONS IN GENOMICS, PROTEOMICS, AND ADVANCED MOLECULAR BIOLOGY TO PROPEL GROWTH

12 CENTRIFUGE MARKET, BY TYPE

- 12.1 INTRODUCTION

- 12.2 LABORATORY CENTRIFUGES

- 12.2.1 MICRO CENTRIFUGE

- 12.2.1.1 Increasing demand for rapid small-volume sample processing to drive growth

- 12.2.2 REFRIGERATED CENTRIFUGE

- 12.2.2.1 Rising need for temperature-sensitive sample preservation in proteomic and genomic research to propel market

- 12.2.3 ULTRACENTRIFUGE

- 12.2.3.1 Growing applications in separating nanoparticles, viruses, and macromolecules to fuel market

- 12.2.1 MICRO CENTRIFUGE

- 12.3 INDUSTRIAL CENTRIFUGES

- 12.3.1 SEDIMENTATION CENTRIFUGE

- 12.3.1.1 Expanding industrial use for high-volume sludge dewatering and mineral processing to support market growth

- 12.3.2 FILTRATION CENTRIFUGE

- 12.3.2.1 Rising demand for efficient solid-liquid separation in chemical and pharmaceutical manufacturing to propel market

- 12.3.1 SEDIMENTATION CENTRIFUGE

- 12.4 DECANTER CENTRIFUGES

- 12.4.1 INCREASING WASTEWATER TREATMENT AND FOOD PROCESSING APPLICATIONS TO DRIVE MARKET

- 12.5 HIGH SPEED SEPARATORS

- 12.5.1 DEMAND IN DAIRY, BEVERAGE, AND BIOFUEL INDUSTRIES TO PROPEL MARKET GROWTH

- 12.6 OTHER TYPES

- 12.6.1 PUSHER CENTRIFUGES

- 12.6.2 SCRAPER CENTRIFUGES

- 12.6.3 CONTINUOUS-FLOW CENTRIFUGES

13 CENTRIFUGE MARKET, BY REGION

- 13.1 INTRODUCTION

- 13.2 ASIA PACIFIC

- 13.2.1 CHINA

- 13.2.1.1 Rapid industrialization and pharmaceutical innovation to drive market

- 13.2.2 JAPAN

- 13.2.2.1 Technological advancements in carbon-neutral energy-efficient centrifuge designs to fuel market

- 13.2.3 INDIA

- 13.2.3.1 Rising government investments in water treatment infrastructure to boost demand

- 13.2.4 SOUTH KOREA

- 13.2.4.1 Increased R&D funding for biotechnology and environmental projects to propel adoption

- 13.2.5 REST OF ASIA PACIFIC

- 13.2.1 CHINA

- 13.3 NORTH AMERICA

- 13.3.1 US

- 13.3.1.1 Escalating pharmaceutical production and government R&D funding to propel market growth

- 13.3.2 CANADA

- 13.3.2.1 Expanding oil & gas activities and clean energy initiatives to drive adoption

- 13.3.3 MEXICO

- 13.3.3.1 Growing food & beverage exports and investments in mining to fuel market expansion

- 13.3.1 US

- 13.4 EUROPE

- 13.4.1 GERMANY

- 13.4.1.1 Escalating pharmaceutical R&D investments to propel market expansion

- 13.4.2 ITALY

- 13.4.2.1 Rising exports of foods and beverages to boost market

- 13.4.3 FRANCE

- 13.4.3.1 Stringent EU water treatment regulations to drive adoption

- 13.4.4 UK

- 13.4.4.1 Innovative automation technologies to fuel market

- 13.4.5 SPAIN

- 13.4.5.1 Increased focus on sustainable chemical production to enhance demand

- 13.4.6 REST OF EUROPE

- 13.4.1 GERMANY

- 13.5 MIDDLE EAST & AFRICA

- 13.5.1 GCC COUNTRIES

- 13.5.1.1 UAE

- 13.5.1.1.1 Increasing water treatment initiatives under Vision 2021 to propel market growth

- 13.5.1.2 Saudi Arabia

- 13.5.1.2.1 Ambitious industrial diversification under Vision 2030 to drive adoption

- 13.5.1.3 Rest of GCC Countries

- 13.5.1.1 UAE

- 13.5.2 SOUTH AFRICA

- 13.5.2.1 Rising demand for water management solutions to boost market

- 13.5.3 REST OF MIDDLE EAST & AFRICA

- 13.5.1 GCC COUNTRIES

- 13.6 SOUTH AMERICA

- 13.6.1 ARGENTINA

- 13.6.1.1 Rising water treatment needs to drive market

- 13.6.2 BRAZIL

- 13.6.2.1 Robust growth in agricultural exports to propel market

- 13.6.3 REST OF SOUTH AMERICA

- 13.6.1 ARGENTINA

14 COMPETITIVE LANDSCAPE

- 14.1 INTRODUCTION

- 14.2 KEY PLAYER STRATEGIES/RIGHT TO WIN, JANUARY 2021-AUGUST 2025

- 14.3 MARKET SHARE ANALYSIS, 2024

- 14.3.1 MARKET SHARE OF KEY PLAYERS, 2024

- 14.4 REVENUE ANALYSIS, 2020-2024

- 14.5 BRAND/PRODUCT COMPARISON

- 14.6 COMPANY EVALUATION MATRIX: KEY PLAYERS, 2024

- 14.6.1 STARS

- 14.6.2 EMERGING LEADERS

- 14.6.3 PERVASIVE PLAYERS

- 14.6.4 PARTICIPANTS

- 14.6.5 COMPANY FOOTPRINT: KEY PLAYERS, 2024

- 14.6.5.1 Company footprint

- 14.6.5.2 Region footprint

- 14.6.5.3 Type footprint

- 14.6.5.4 Application footprint

- 14.6.5.5 End-use industry footprint

- 14.7 COMPANY EVALUATION MATRIX: STARTUPS/SMES, 2024

- 14.7.1 PROGRESSIVE COMPANIES

- 14.7.2 RESPONSIVE COMPANIES

- 14.7.3 DYNAMIC COMPANIES

- 14.7.4 STARTING BLOCKS

- 14.7.5 COMPETITIVE BENCHMARKING: STARTUPS/SMES, 2024

- 14.7.5.1 Detailed list of key startups/SMEs, 2024

- 14.7.5.2 Competitive benchmarking of key startups/SMEs, 2024

- 14.7.6 VALUATION AND FINANCIAL METRICS OF KEY CENTRIFUGE VENDORS

- 14.8 COMPETITIVE SCENARIO

- 14.8.1 PRODUCT LAUNCHES

- 14.8.2 DEALS

- 14.8.3 EXPANSIONS

15 COMPANY PROFILES

- 15.1 KEY PLAYERS

- 15.1.1 ALFA LAVAL

- 15.1.1.1 Products/Solutions/Services offered

- 15.1.1.2 Recent developments

- 15.1.1.2.1 Product launches

- 15.1.1.2.2 Deals

- 15.1.1.3 MnM view

- 15.1.1.3.1 Right to win

- 15.1.1.3.2 Strategic choices

- 15.1.1.3.3 Weaknesses and competitive threats

- 15.1.2 GEA GROUP AKTIENGESELLSCHAFT

- 15.1.2.1 Business overview

- 15.1.2.2 Products/Solutions/Services offered

- 15.1.2.3 Recent developments

- 15.1.2.3.1 Product launches

- 15.1.2.3.2 Deals

- 15.1.2.3.3 Expansions

- 15.1.2.4 MnM view

- 15.1.2.4.1 Right to win

- 15.1.2.4.2 Strategic choices

- 15.1.2.4.3 Weaknesses and competitive threats

- 15.1.3 ANDRITZ

- 15.1.3.1 Business overview

- 15.1.3.2 Products/Solutions/Services offered

- 15.1.3.3 Recent developments

- 15.1.3.3.1 Product launches

- 15.1.3.4 MnM view

- 15.1.3.4.1 Right to win

- 15.1.3.4.2 Strategic choices

- 15.1.3.4.3 Weaknesses and competitive threats

- 15.1.4 FLSMIDTH A/S

- 15.1.4.1 Business overview

- 15.1.4.2 Products/Solutions/Services offered

- 15.1.4.3 Recent developments

- 15.1.4.3.1 Deals

- 15.1.4.4 MnM view

- 15.1.4.4.1 Right to win

- 15.1.4.4.2 Strategic choices

- 15.1.4.4.3 Weaknesses and competitive threats

- 15.1.5 KUBOTA CORPORATION

- 15.1.5.1 Business overview

- 15.1.5.2 Products/Solutions/Services offered

- 15.1.5.3 MnM view

- 15.1.5.3.1 Right to win

- 15.1.5.3.2 Strategic choices

- 15.1.5.3.3 Weaknesses and competitive threats

- 15.1.6 FLOTTWEG SE

- 15.1.6.1 Business overview

- 15.1.6.2 Products/Solutions/Services offered

- 15.1.6.3 Recent developments

- 15.1.6.3.1 Deals

- 15.1.6.3.2 Expansions

- 15.1.6.4 MnM view

- 15.1.6.4.1 Right to win

- 15.1.6.4.2 Strategic choices

- 15.1.6.4.3 Weaknesses and competitive threats

- 15.1.7 SPX FLOW, INC.

- 15.1.7.1 Business overview

- 15.1.7.2 Products/Solutions/Services offered

- 15.1.7.3 Recent developments

- 15.1.7.3.1 Deals

- 15.1.7.3.2 Expansions

- 15.1.7.4 MnM view

- 15.1.7.4.1 Right to win

- 15.1.7.4.2 Strategic choices

- 15.1.7.4.3 Weaknesses and competitive threats

- 15.1.8 MITSUBISHI KAKOKI KAISHA, LTD.

- 15.1.8.1 Business overview

- 15.1.8.2 Products/Solutions/Services offered

- 15.1.8.3 MnM view

- 15.1.8.3.1 Right to win

- 15.1.8.3.2 Strategic choices

- 15.1.8.3.3 Weaknesses and competitive threats

- 15.1.9 FERRUM AG

- 15.1.9.1 Business overview

- 15.1.9.2 Products/Solutions/Services offered

- 15.1.9.3 MnM view

- 15.1.9.3.1 Right to win

- 15.1.9.3.2 Strategic choices

- 15.1.9.3.3 Weaknesses and competitive threats

- 15.1.10 SIEBTECHNIK GMBH

- 15.1.10.1 Business overview

- 15.1.10.2 Products/Solutions/Services offered

- 15.1.10.3 MnM view

- 15.1.10.3.1 Right to win

- 15.1.10.3.2 Strategic choices

- 15.1.10.3.3 Weaknesses and competitive threats

- 15.1.1 ALFA LAVAL

- 15.2 OTHER PLAYERS

- 15.2.1 SIGMA LABORZENTRIFUGEN GMBH

- 15.2.2 BECKMAN COULTER, INC.

- 15.2.3 EPPENDORF SE

- 15.2.4 THERMO FISHER SCIENTIFIC INC.

- 15.2.5 ANDREAS HETTICH GMBH

- 15.2.6 PIERALISI MAIP SPA

- 15.2.7 THOMAS BROADBENT & SONS LTD.

- 15.2.8 ROUSSELET ROBATEL

- 15.2.9 HEINKEL PROCESS TECHNOLOGY GMBH

- 15.2.10 COLE-PARMER INSTRUMENT COMPANY, LLC

- 15.2.11 HAUS CENTRIFUGE TECHNOLOGIES

- 15.2.12 GTECH

- 15.2.13 WESTERN STATES

- 15.2.14 B&P LITTLEFORD

- 15.2.15 ELGIN SEPARATION SOLUTIONS

16 APPENDIX

- 16.1 DISCUSSION GUIDE

- 16.2 KNOWLEDGESTORE: MARKETSANDMARKETS' SUBSCRIPTION PORTAL

- 16.3 CUSTOMIZATION OPTIONS

- 16.4 RELATED REPORTS

- 16.5 AUTHOR DETAILS

List of Tables

- TABLE 1 AVERAGE SELLING PRICE, BY REGION, 2021-2024 (USD/UNIT)

- TABLE 2 AVERAGE SELLING PRICE OF KEY PLAYERS, BY TOP THREE TYPES (USD/UNIT)

- TABLE 3 CENTRIFUGE MARKET: ROLES OF COMPANIES IN ECOSYSTEM

- TABLE 4 CENTRIFUGE MARKET: KEY TECHNOLOGIES

- TABLE 5 CENTRIFUGE MARKET: COMPLEMENTARY TECHNOLOGIES

- TABLE 6 CENTRIFUGE MARKET: ADJACENT TECHNOLOGIES

- TABLE 7 TOTAL NUMBER OF PATENTS

- TABLE 8 MAJOR PATENT OWNERS FOR CENTRIFUGES

- TABLE 9 CENTRIFUGE MARKET: MAJOR PATENTS

- TABLE 10 CENTRIFUGE MARKET: KEY CONFERENCES AND EVENTS, 2025-2026

- TABLE 11 TARIFFS RELATED TO CENTRIFUGES, BY COUNTRY, 2025

- TABLE 12 NORTH AMERICA: REGULATORY BODIES, GOVERNMENT AGENCIES, AND OTHER ORGANIZATIONS

- TABLE 13 EUROPE: REGULATORY BODIES, GOVERNMENT AGENCIES, AND OTHER ORGANIZATIONS

- TABLE 14 ASIA PACIFIC: REGULATORY BODIES, GOVERNMENT AGENCIES, AND OTHER ORGANIZATIONS

- TABLE 15 MIDDLE EAST & AFRICA: REGULATORY BODIES, GOVERNMENT AGENCIES, AND OTHER ORGANIZATIONS

- TABLE 16 SOUTH AMERICA: REGULATORY BODIES, GOVERNMENT AGENCIES, AND OTHER ORGANIZATIONS

- TABLE 17 CENTRIFUGE MARKET: REGULATIONS/STANDARDS

- TABLE 18 IMPACT OF PORTERS FIVE FORCES ON CENTRIFUGE MARKET

- TABLE 19 INFLUENCE OF KEY STAKEHOLDERS ON BUYING PROCESS FOR TOP THREE END-USE INDUSTRIES

- TABLE 20 KEY BUYING CRITERIA FOR TOP THREE END-USE INDUSTRIES

- TABLE 21 GDP TRENDS AND FORECAST, BY KEY COUNTRY, 2021-2030 (USD MILLION)

- TABLE 22 CENTRIFUGE MARKET, BY APPLICATION, 2021-2024 (USD MILLION)

- TABLE 23 CENTRIFUGE MARKET, BY APPLICATION, 2025-2030 (USD MILLION)

- TABLE 24 CENTRIFUGE MARKET, BY CAPACITY, 2021-2024 (USD MILLION)

- TABLE 25 CENTRIFUGE MARKET, BY CAPACITY, 2025-2030 (USD MILLION)

- TABLE 26 CENTRIFUGE MARKET, BY END-USE INDUSTRY, 2021-2024 (USD MILLION)

- TABLE 27 CENTRIFUGE MARKET, BY END-USE INDUSTRY, 2025-2030 (USD MILLION)

- TABLE 28 CENTRIFUGE MARKET, BY ROTOR TYPE, 2021-2024 (USD MILLION)

- TABLE 29 CENTRIFUGE MARKET, BY ROTOR TYPE, 2025-2030 (USD MILLION)

- TABLE 30 CENTRIFUGE MARKET, BY SPEED, 2021-2024 (USD MILLION)

- TABLE 31 CENTRIFUGE MARKET, BY SPEED, 2025-2030 (USD MILLION)

- TABLE 32 CENTRIFUGE MARKET, BY TYPE, 2021-2024 (USD MILLION)

- TABLE 33 CENTRIFUGE MARKET, BY TYPE, 2025-2030 (USD MILLION)

- TABLE 34 CENTRIFUGE MARKET, BY REGION, 2021-2024 (USD MILLION)

- TABLE 35 CENTRIFUGE MARKET, BY REGION, 2025-2030 (USD MILLION)

- TABLE 36 CENTRIFUGE MARKET, BY REGION, 2021-2024 (UNIT)

- TABLE 37 CENTRIFUGE MARKET, BY REGION, 2025-2030 (UNIT)

- TABLE 38 ASIA PACIFIC: CENTRIFUGE MARKET, BY COUNTRY, 2021-2024 (USD MILLION)

- TABLE 39 ASIA PACIFIC: CENTRIFUGE MARKET, BY COUNTRY, 2025-2030 (USD MILLION)

- TABLE 40 ASIA PACIFIC: CENTRIFUGE MARKET, BY APPLICATION, 2021-2024 (USD MILLION)

- TABLE 41 ASIA PACIFIC: CENTRIFUGE MARKET, BY APPLICATION, 2025-2030 (USD MILLION)

- TABLE 42 ASIA PACIFIC: CENTRIFUGE MARKET, BY END-USE INDUSTRY, 2021-2024 (USD MILLION)

- TABLE 43 ASIA PACIFIC: CENTRIFUGE MARKET, BY END-USE INDUSTRY, 2025-2030 (USD MILLION)

- TABLE 44 ASIA PACIFIC: CENTRIFUGE MARKET, BY TYPE, 2021-2024 (USD MILLION)

- TABLE 45 ASIA PACIFIC: CENTRIFUGE MARKET, BY TYPE, 2025-2030 (USD MILLION)

- TABLE 46 ASIA PACIFIC: CENTRIFUGE MARKET, BY SPEED, 2021-2024 (USD MILLION)

- TABLE 47 ASIA PACIFIC: CENTRIFUGE MARKET, BY SPEED, 2025-2030 (USD MILLION)

- TABLE 48 ASIA PACIFIC: CENTRIFUGE MARKET, BY ROTOR TYPE, 2021-2024 (USD MILLION)

- TABLE 49 ASIA PACIFIC: CENTRIFUGE MARKET, BY ROTOR TYPE, 2025-2030 (USD MILLION)

- TABLE 50 ASIA PACIFIC: CENTRIFUGE MARKET, BY CAPACITY, 2021-2024 (USD MILLION)

- TABLE 51 ASIA PACIFIC: CENTRIFUGE MARKET, BY CAPACITY, 2025-2030 (USD MILLION)

- TABLE 52 CHINA: CENTRIFUGE MARKET, BY END-USE INDUSTRY, 2021-2024 (USD MILLION)

- TABLE 53 CHINA: CENTRIFUGE MARKET, BY END-USE INDUSTRY, 2025-2030 (USD MILLION)

- TABLE 54 JAPAN: CENTRIFUGE MARKET, BY END-USE INDUSTRY, 2021-2024 (USD MILLION)

- TABLE 55 JAPAN: CENTRIFUGE MARKET, BY END-USE INDUSTRY, 2025-2030 (USD MILLION)

- TABLE 56 INDIA: CENTRIFUGE MARKET, BY END-USE INDUSTRY, 2021-2024 (USD MILLION)

- TABLE 57 INDIA: CENTRIFUGE MARKET, BY END-USE INDUSTRY, 2025-2030 (USD MILLION)

- TABLE 58 SOUTH KOREA: CENTRIFUGE MARKET, BY END-USE INDUSTRY, 2021-2024 (USD MILLION)

- TABLE 59 SOUTH KOREA: CENTRIFUGE MARKET, BY END-USE INDUSTRY, 2025-2030 (USD MILLION)

- TABLE 60 REST OF ASIA PACIFIC: CENTRIFUGE MARKET, BY END-USE INDUSTRY, 2021-2024 (USD MILLION)

- TABLE 61 REST OF ASIA PACIFIC: CENTRIFUGE MARKET, BY END-USE INDUSTRY, 2025-2030 (USD MILLION)

- TABLE 62 NORTH AMERICA: CENTRIFUGE MARKET, BY COUNTRY, 2021-2024 (USD MILLION)

- TABLE 63 NORTH AMERICA: CENTRIFUGE MARKET, BY COUNTRY, 2025-2030 (USD MILLION)

- TABLE 64 NORTH AMERICA: CENTRIFUGE MARKET, BY APPLICATION, 2021-2024 (USD MILLION)

- TABLE 65 NORTH AMERICA: CENTRIFUGE MARKET, BY APPLICATION, 2025-2030 (USD MILLION)

- TABLE 66 NORTH AMERICA: CENTRIFUGE MARKET, BY END-USE INDUSTRY, 2021-2024 (USD MILLION)

- TABLE 67 NORTH AMERICA: CENTRIFUGE MARKET, BY END-USE INDUSTRY, 2025-2030 (USD MILLION)

- TABLE 68 NORTH AMERICA: CENTRIFUGE MARKET, BY TYPE, 2021-2024 (USD MILLION)

- TABLE 69 NORTH AMERICA: CENTRIFUGE MARKET, BY TYPE, 2025-2030 (USD MILLION)

- TABLE 70 NORTH AMERICA: CENTRIFUGE MARKET, BY SPEED, 2021-2024 (USD MILLION)

- TABLE 71 NORTH AMERICA: CENTRIFUGE MARKET, BY SPEED, 2025-2030 (USD MILLION)

- TABLE 72 NORTH AMERICA: CENTRIFUGE MARKET, BY ROTOR TYPE, 2021-2024 (USD MILLION)

- TABLE 73 NORTH AMERICA: CENTRIFUGE MARKET, BY ROTOR TYPE, 2025-2030 (USD MILLION)

- TABLE 74 NORTH AMERICA: CENTRIFUGE MARKET, BY CAPACITY, 2021-2024 (USD MILLION)

- TABLE 75 NORTH AMERICA: CENTRIFUGE MARKET, BY CAPACITY, 2025-2030 (USD MILLION)

- TABLE 76 US: CENTRIFUGE MARKET, BY END-USE INDUSTRY, 2021-2024 (USD MILLION)

- TABLE 77 US: CENTRIFUGE MARKET, BY END-USE INDUSTRY, 2025-2030 (USD MILLION)

- TABLE 78 CANADA: CENTRIFUGE MARKET, BY END-USE INDUSTRY, 2021-2024 (USD MILLION)

- TABLE 79 CANADA: CENTRIFUGE MARKET, BY END-USE INDUSTRY, 2025-2030 (USD MILLION)

- TABLE 80 MEXICO: CENTRIFUGE MARKET, BY END-USE INDUSTRY, 2021-2024 (USD MILLION)

- TABLE 81 MEXICO: CENTRIFUGE MARKET, BY END-USE INDUSTRY, 2025-2030 (USD MILLION)

- TABLE 82 EUROPE: CENTRIFUGE MARKET, BY COUNTRY, 2021-2024 (USD MILLION)

- TABLE 83 EUROPE: CENTRIFUGE MARKET, BY COUNTRY, 2025-2030 (USD MILLION)

- TABLE 84 EUROPE: CENTRIFUGE MARKET, BY APPLICATION, 2021-2024 (USD MILLION)

- TABLE 85 EUROPE: CENTRIFUGE MARKET, BY APPLICATION, 2025-2030 (USD MILLION)

- TABLE 86 EUROPE: CENTRIFUGE MARKET, BY END-USE INDUSTRY, 2021-2024 (USD MILLION)

- TABLE 87 EUROPE: CENTRIFUGE MARKET, BY END-USE INDUSTRY, 2025-2030 (USD MILLION)

- TABLE 88 EUROPE: CENTRIFUGE MARKET, BY TYPE, 2021-2024 (USD MILLION)

- TABLE 89 EUROPE: CENTRIFUGE MARKET, BY TYPE, 2025-2030 (USD MILLION)

- TABLE 90 EUROPE: CENTRIFUGE MARKET, BY SPEED, 2021-2024 (USD MILLION)

- TABLE 91 EUROPE: CENTRIFUGE MARKET, BY SPEED, 2025-2030 (USD MILLION)

- TABLE 92 EUROPE: CENTRIFUGE MARKET, BY ROTOR TYPE, 2021-2024 (USD MILLION)

- TABLE 93 EUROPE: CENTRIFUGE MARKET, BY ROTOR TYPE, 2025-2030 (USD MILLION)

- TABLE 94 EUROPE: CENTRIFUGE MARKET, BY CAPACITY, 2021-2024 (USD MILLION)

- TABLE 95 EUROPE: CENTRIFUGE MARKET, BY CAPACITY, 2025-2030 (USD MILLION)

- TABLE 96 GERMANY: CENTRIFUGE MARKET, BY END-USE INDUSTRY, 2021-2024 (USD MILLION)

- TABLE 97 GERMANY: CENTRIFUGE MARKET, BY END-USE INDUSTRY, 2025-2030 (USD MILLION)

- TABLE 98 ITALY: CENTRIFUGE MARKET, BY END-USE INDUSTRY, 2021-2024 (USD MILLION)

- TABLE 99 ITALY: CENTRIFUGE MARKET, BY END-USE INDUSTRY, 2025-2030 (USD MILLION)

- TABLE 100 FRANCE: CENTRIFUGE MARKET, BY END-USE INDUSTRY, 2021-2024 (USD MILLION)

- TABLE 101 FRANCE: CENTRIFUGE MARKET, BY END-USE INDUSTRY, 2025-2030 (USD MILLION)

- TABLE 102 UK: CENTRIFUGE MARKET, BY END-USE INDUSTRY, 2021-2024 (USD MILLION)

- TABLE 103 UK: CENTRIFUGE MARKET, BY END-USE INDUSTRY, 2025-2030 (USD MILLION)

- TABLE 104 SPAIN: CENTRIFUGE MARKET, BY END-USE INDUSTRY, 2021-2024 (USD MILLION)

- TABLE 105 SPAIN: CENTRIFUGE MARKET, BY END-USE INDUSTRY, 2025-2030 (USD MILLION)

- TABLE 106 REST OF EUROPE: CENTRIFUGE MARKET, BY END-USE INDUSTRY, 2021-2024 (USD MILLION)

- TABLE 107 REST OF EUROPE: CENTRIFUGE MARKET, BY END-USE INDUSTRY, 2025-2030 (USD MILLION)

- TABLE 108 MIDDLE EAST & AFRICA: CENTRIFUGE MARKET, BY COUNTRY, 2021-2024 (USD MILLION)

- TABLE 109 MIDDLE EAST & AFRICA: CENTRIFUGE MARKET, BY COUNTRY, 2025-2030 (USD MILLION)

- TABLE 110 MIDDLE EAST & AFRICA: CENTRIFUGE MARKET, BY APPLICATION, 2021-2024 (USD MILLION)

- TABLE 111 MIDDLE EAST & AFRICA: CENTRIFUGE MARKET, BY APPLICATION, 2025-2030 (USD MILLION)

- TABLE 112 MIDDLE EAST & AFRICA: CENTRIFUGE MARKET, BY END-USE INDUSTRY, 2021-2024 (USD MILLION)

- TABLE 113 MIDDLE EAST & AFRICA: CENTRIFUGE MARKET, BY END-USE INDUSTRY, 2025-2030 (USD MILLION)

- TABLE 114 MIDDLE EAST & AFRICA: CENTRIFUGE MARKET, BY TYPE, 2021-2024 (USD MILLION)

- TABLE 115 MIDDLE EAST & AFRICA: CENTRIFUGE MARKET, BY TYPE, 2025-2030 (USD MILLION)

- TABLE 116 MIDDLE EAST & AFRICA: CENTRIFUGE MARKET, BY SPEED, 2021-2024 (USD MILLION)

- TABLE 117 MIDDLE EAST & AFRICA: CENTRIFUGE MARKET, BY SPEED, 2025-2030 (USD MILLION)

- TABLE 118 MIDDLE EAST & AFRICA: CENTRIFUGE MARKET, BY ROTOR TYPE, 2021-2024 (USD MILLION)

- TABLE 119 MIDDLE EAST & AFRICA: CENTRIFUGE MARKET, BY ROTOR TYPE, 2025-2030 (USD MILLION)

- TABLE 120 MIDDLE EAST & AFRICA: CENTRIFUGE MARKET, BY CAPACITY, 2021-2024 (USD MILLION)

- TABLE 121 MIDDLE EAST & AFRICA: CENTRIFUGE MARKET, BY CAPACITY, 2025-2030 (USD MILLION)

- TABLE 122 UAE: CENTRIFUGE MARKET, BY END-USE INDUSTRY, 2021-2024 (USD MILLION)

- TABLE 123 UAE: CENTRIFUGE MARKET, BY END-USE INDUSTRY, 2025-2030 (USD MILLION)

- TABLE 124 SAUDI ARABIA: CENTRIFUGE MARKET, BY END-USE INDUSTRY, 2021-2024 (USD MILLION)

- TABLE 125 SAUDI ARABIA: CENTRIFUGE MARKET, BY END-USE INDUSTRY, 2025-2030 (USD MILLION)

- TABLE 126 REST OF GCC: CENTRIFUGE MARKET, BY END-USE INDUSTRY, 2021-2024 (USD MILLION)

- TABLE 127 REST OF GCC: CENTRIFUGE MARKET, BY END-USE INDUSTRY, 2025-2030 (USD MILLION)

- TABLE 128 SOUTH AFRICA: CENTRIFUGE MARKET, BY END-USE INDUSTRY, 2021-2024 (USD MILLION)

- TABLE 129 SOUTH AFRICA: CENTRIFUGE MARKET, BY END-USE INDUSTRY, 2025-2030 (USD MILLION)

- TABLE 130 REST OF MIDDLE EAST & AFRICA: CENTRIFUGE MARKET, BY END-USE INDUSTRY, 2021-2024 (USD MILLION)

- TABLE 131 REST OF MIDDLE EAST & AFRICA: CENTRIFUGE MARKET, BY END-USE INDUSTRY, 2025-2030 (USD MILLION)

- TABLE 132 SOUTH AMERICA: CENTRIFUGE MARKET, BY COUNTRY, 2021-2024 (USD MILLION)

- TABLE 133 SOUTH AMERICA: CENTRIFUGE MARKET, BY COUNTRY, 2025-2030 (USD MILLION)

- TABLE 134 SOUTH AMERICA: CENTRIFUGE MARKET, BY APPLICATION, 2021-2024 (USD MILLION)

- TABLE 135 SOUTH AMERICA: CENTRIFUGE MARKET, BY APPLICATION, 2025-2030 (USD MILLION)

- TABLE 136 SOUTH AMERICA: CENTRIFUGE MARKET, BY END-USE INDUSTRY, 2021-2024 (USD MILLION)

- TABLE 137 SOUTH AMERICA: CENTRIFUGE MARKET, BY END-USE INDUSTRY, 2025-2030 (USD MILLION)

- TABLE 138 SOUTH AMERICA: CENTRIFUGE MARKET, BY TYPE, 2021-2024 (USD MILLION)

- TABLE 139 SOUTH AMERICA: CENTRIFUGE MARKET, BY TYPE, 2025-2030 (USD MILLION)

- TABLE 140 SOUTH AMERICA: CENTRIFUGE MARKET, BY SPEED, 2021-2024 (USD MILLION)

- TABLE 141 SOUTH AMERICA: CENTRIFUGE MARKET, BY SPEED, 2025-2030 (USD MILLION)

- TABLE 142 SOUTH AMERICA: CENTRIFUGE MARKET, BY ROTOR TYPE, 2021-2024 (USD MILLION)

- TABLE 143 SOUTH AMERICA: CENTRIFUGE MARKET, BY ROTOR TYPE, 2025-2030 (USD MILLION)

- TABLE 144 SOUTH AMERICA: CENTRIFUGE MARKET, BY CAPACITY, 2021-2024 (USD MILLION)

- TABLE 145 SOUTH AMERICA: CENTRIFUGE MARKET, BY CAPACITY, 2025-2030 (USD MILLION)

- TABLE 146 ARGENTINA: CENTRIFUGE MARKET, BY END-USE INDUSTRY, 2021-2024 (USD MILLION)

- TABLE 147 ARGENTINA: CENTRIFUGE MARKET, BY END-USE INDUSTRY, 2025-2030 (USD MILLION)

- TABLE 148 BRAZIL: CENTRIFUGE MARKET, BY END-USE INDUSTRY, 2021-2024 (USD MILLION)

- TABLE 149 BRAZIL: CENTRIFUGE MARKET, BY END-USE INDUSTRY, 2025-2030 (USD MILLION)

- TABLE 150 REST OF SOUTH AMERICA: CENTRIFUGE MARKET, BY END-USE INDUSTRY, 2021-2024 (USD MILLION)

- TABLE 151 REST OF SOUTH AMERICA: CENTRIFUGE MARKET, BY END-USE INDUSTRY, 2025-2030 (USD MILLION)

- TABLE 152 OVERVIEW OF STRATEGIES ADOPTED BY KEY CENTRIFUGE MANUFACTURERS, JANUARY 2021-AUGUST 2025

- TABLE 153 CENTRIFUGE MARKET: DEGREE OF COMPETITION

- TABLE 154 CENTRIFUGE MARKET: REGION FOOTPRINT

- TABLE 155 CENTRIFUGE MARKET: TYPE FOOTPRINT

- TABLE 156 CENTRIFUGE MARKET: APPLICATION FOOTPRINT

- TABLE 157 CENTRIFUGE MARKET: END-USE INDUSTRY FOOTPRINT

- TABLE 158 CENTRIFUGE MARKET: DETAILED LIST OF KEY STARTUPS/SMES, 2024

- TABLE 159 CENTRIFUGE MARKET: COMPETITIVE BENCHMARKING OF KEY STARTUPS/ SMES, 2024

- TABLE 160 CENTRIFUGE MARKET: PRODUCT LAUNCHES, JANUARY 2021- AUGUST 2025

- TABLE 161 CENTRIFUGE MARKET: DEALS, JANUARY 2021- AUGUST 2025

- TABLE 162 CENTRIFUGE MARKET: EXPANSIONS, JANUARY 2021-AUGUST 2025

- TABLE 163 ALFA LAVAL: COMPANY OVERVIEW

- TABLE 164 ALFA LAVAL: PRODUCTS/SOLUTIONS/SERVICES OFFERED

- TABLE 165 ALFA LAVAL: PRODUCT LAUNCHES, JANUARY 2021-AUGUST 2025

- TABLE 166 ALFA LAVAL: DEALS, JANUARY 2021-AUGUST 2025

- TABLE 167 GEA GROUP AKTIENGESELLSCHAFT: COMPANY OVERVIEW

- TABLE 168 GEA GROUP AKTIENGESELLSCHAFT: PRODUCTS/SOLUTIONS/SERVICES OFFERED

- TABLE 169 GEA GROUP AKTIENGESELLSCHAFT: PRODUCT LAUNCHES, JANUARY 2021-AUGUST 2025

- TABLE 170 GEA GROUP AKTIENGESELLSCHAFT: DEALS, JANUARY 2021-JULY 2025

- TABLE 171 GEA GROUP AKTIENGESELLSCHAFT: EXPANSIONS, JANUARY 2021-AUGUST 2025

- TABLE 172 ANDRITZ: COMPANY OVERVIEW

- TABLE 173 ANDRITZ: PRODUCTS/SOLUTIONS/SERVICES OFFERED

- TABLE 174 ANDRITZ: PRODUCT LAUNCHES, JANUARY 2021-AUGUST 2025

- TABLE 175 FLSMIDTH A/S: COMPANY OVERVIEW

- TABLE 176 FLSMIDTH A/S: PRODUCTS/SOLUTIONS/SERVICES OFFERED

- TABLE 177 FLSMIDTH A/S: DEALS, JANUARY 2021-AUGUST 2025

- TABLE 178 KUBOTA CORPORATION: COMPANY OVERVIEW

- TABLE 179 KUBOTA CORPORATION: PRODUCT/SOLUTIONS/SERVICES OFFERED

- TABLE 180 FLOTTWEG SE: COMPANY OVERVIEW

- TABLE 181 FLOTTWEG SE: PRODUCTS/SOLUTIONS/SERVICES OFFERED

- TABLE 182 FLOTTWEG SE: DEALS, JANUARY 2021-AUGUST 2025

- TABLE 183 FLOTTWEG SE: EXPANSIONS, JANUARY 2021-AUGUST 2025

- TABLE 184 SPX FLOW, INC.: COMPANY OVERVIEW

- TABLE 185 SPX FLOW, INC.: PRODUCTS/SOLUTIONS/SERVICES OFFERED

- TABLE 186 SPX FLOW, INC.: DEALS, JANUARY 2021-AUGUST 2025

- TABLE 187 SPX FLOW, INC.: EXPANSIONS, JANUARY 2021-AUGUST 2025

- TABLE 188 MITSUBISHI KAKOKI KAISHA, LTD.: COMPANY OVERVIEW

- TABLE 189 MITSUBISHI KAKOKI KAISHA, LTD.: PRODUCTS/SOLUTIONS/SERVICES OFFERED

- TABLE 190 FERRUM AG: COMPANY OVERVIEW

- TABLE 191 FERRUM AG: PRODUCTS/SOLUTIONS/SERVICES OFFERED

- TABLE 192 SIEBTECHNIK GMBH: COMPANY OVERVIEW

- TABLE 193 SIEBTECHNIK GMBH: PRODUCTS/SOLUTIONS/SERVICES OFFERED

- TABLE 194 SIGMA LABORZENTRIFUGEN GMBH: COMPANY OVERVIEW

- TABLE 195 BECKMAN COULTER, INC.: COMPANY OVERVIEW

- TABLE 196 EPPENDORF SE: COMPANY OVERVIEW

- TABLE 197 THERMO FISHER SCIENTIFIC INC.: COMPANY OVERVIEW

- TABLE 198 ANDREAS HETTICH GMBH: COMPANY OVERVIEW

- TABLE 199 PIERALISI MAIP SPA: COMPANY OVERVIEW

- TABLE 200 THOMAS BROADBENT & SONS LTD.: COMPANY OVERVIEW

- TABLE 201 ROUSSELET ROBATEL: COMPANY OVERVIEW

- TABLE 202 HEINKEL PROCESS TECHNOLOGY GMBH: COMPANY OVERVIEW

- TABLE 203 COLE-PARMER INSTRUMENT COMPANY, LLC: COMPANY OVERVIEW

- TABLE 204 HAUS CENTRIFUGE TECHNOLOGIES: COMPANY OVERVIEW

- TABLE 205 GTECH: COMPANY OVERVIEW

- TABLE 206 WESTERN STATES: COMPANY OVERVIEW

- TABLE 207 B&P LITTLEFORD : COMPANY OVERVIEW

- TABLE 208 ELGIN SEPARATION SOLUTIONS: COMPANY OVERVIEW

List of Figures

- FIGURE 1 CENTRIFUGE MARKET SEGMENTATION AND REGIONAL SNAPSHOT

- FIGURE 2 CENTRIFUGE MARKET: RESEARCH DESIGN

- FIGURE 3 MARKET SIZE ESTIMATION METHODOLOGY: SUPPLY-SIDE APPROACH

- FIGURE 4 MARKET SIZE ESTIMATION METHODOLOGY: DEMAND-SIDE APPROACH

- FIGURE 5 MARKET SIZE ESTIMATION METHODOLOGY: REVENUE OF MARKET PLAYERS, 2024

- FIGURE 6 MARKET SIZE ESTIMATION METHODOLOGY: BOTTOM-UP APPROACH

- FIGURE 7 MARKET SIZE ESTIMATION METHODOLOGY: TOP-DOWN APPROACH

- FIGURE 8 CENTRIFUGE MARKET: DATA TRIANGULATION

- FIGURE 9 MEDIUM SPEED (5,000 RPM-20,000 RPM) SEGMENT TO LEAD MARKET BETWEEN 2025 AND 2030

- FIGURE 10 FLUID CLARIFICATION SEGMENT TO GROW AT HIGHEST CAGR BETWEEN 2025 AND 2030

- FIGURE 11 INDUSTRIAL CENTRIFUGES SEGMENT TO LEAD MARKET BETWEEN 2025 AND 2030

- FIGURE 12 FIXED-ANGLE ROTOR CENTRIFUGES SEGMENT TO GROW AT HIGHEST CAGR BETWEEN 2025 AND 2030

- FIGURE 13 SMALL CAPACITY SEGMENT TO LEAD MARKET BETWEEN 2025 AND 2030

- FIGURE 14 PHARMACEUTICAL SEGMENT TO GROW AT HIGHEST CAGR BETWEEN 2025 AND 2030

- FIGURE 15 ASIA PACIFIC DOMINATED CENTRIFUGE MARKET IN 2024

- FIGURE 16 RISING DEMAND FROM PHARMACEUTICAL, FOOD & BEVERAGES, AND CHEMICAL SECTORS TO DRIVE MARKET

- FIGURE 17 INDUSTRIAL CENTRIFUGES TO BE FASTEST-GROWING TYPE DURING FORECAST PERIOD

- FIGURE 18 MEDIUM SPEED ( 5,000 RPM-20,000 RPM) TO BE FASTEST-GROWING SEGMENT DURING FORECAST PERIOD

- FIGURE 19 FLUID CLARIFICATION TO BE FASTEST-GROWING APPLICATION SEGMENT DURING FORECAST PERIOD

- FIGURE 20 SMALL CAPACITY (<10 M3/HOUR) TO BE FASTEST-GROWING CAPACITY SEGMENT DURING FORECAST PERIOD

- FIGURE 21 FIXED-ANGLE ROTOR CENTRIFUGES TO BE FASTEST-GROWING SEGMENT DURING FORECAST PERIOD

- FIGURE 22 PHARMACEUTICAL TO BE FASTEST-GROWING END-USE INDUSTRY SEGMENT DURING FORECAST PERIOD

- FIGURE 23 CHINA TO BE FASTEST-GROWING MARKET DURING FORECAST PERIOD

- FIGURE 24 DRIVERS, RESTRAINTS, OPPORTUNITIES AND CHALLENGES IN CENTRIFUGE MARKET

- FIGURE 25 USE OF GENERATIVE AI IN CENTRIFUGE MARKET

- FIGURE 26 REVENUE SHIFT IN CENTRIFUGE MARKET

- FIGURE 27 CENTRIFUGE MARKET: SUPPLY CHAIN ANALYSIS

- FIGURE 28 CENTRIFUGE MARKET: INVESTMENT AND FUNDING SCENARIO

- FIGURE 29 CENTRIFUGE MARKET: AVERAGE SELLING PRICE TREND, BY REGION, 2021-2024

- FIGURE 30 AVERAGE SELLING PRICE TREND FOR TOP THREE TYPES, BY KEY PLAYERS, 2024

- FIGURE 31 CENTRIFUGE MARKET ECOSYSTEM

- FIGURE 32 PATENTS GRANTED IN LAST TEN YEARS

- FIGURE 33 PATENT ANALYSIS, BY LEGAL STATUS

- FIGURE 34 REGIONAL ANALYSIS OF CENTRIFUGE-RELATED PATENTS GRANTED, 2024

- FIGURE 35 TOP 10 PATENT APPLICANTS IN LAST TEN YEARS

- FIGURE 36 IMPORT DATA RELATED TO HS CODE 842119-COMPLIANT PRODUCTS, BY KEY COUNTRY, 2021-2024 (USD THOUSAND)

- FIGURE 37 EXPORT DATA RELATED TO HS CODE 842119-COMPLIANT PRODUCTS, BY KEY COUNTRY, 2021-2024 (USD THOUSAND)

- FIGURE 38 PORTER'S FIVE FORCES ANALYSIS: CENTRIFUGE MARKET

- FIGURE 39 INFLUENCE OF STAKEHOLDERS ON BUYING PROCESS FOR TOP THREE END-USE INDUSTRIES

- FIGURE 40 KEY BUYING CRITERIA FOR END-USE INDUSTRIES

- FIGURE 41 FLUID CLARIFICATION SEGMENT TO LEAD CENTRIFUGE MARKET DURING FORECAST PERIOD

- FIGURE 42 SMALL CAPACITY SEGMENT TO LEAD CENTRIFUGE MARKET DURING FORECAST PERIOD

- FIGURE 43 PHARMACEUTICALS SEGMENT TO LEAD CENTRIFUGE MARKET DURING FORECAST PERIOD

- FIGURE 44 FIXED-ANGLE ROTOR CENTRIFUGES SEGMENT TO LEAD CENTRIFUGE MARKET DURING FORECAST PERIOD

- FIGURE 45 MEDIUM SPEED SEGMENT TO LEAD CENTRIFUGE MARKET DURING FORECAST PERIOD

- FIGURE 46 INDUSTRIAL CENTRIFUGE SEGMENT TO LEAD CENTRIFUGE MARKET DURING FORECAST PERIOD

- FIGURE 47 ASIA PACIFIC TO BE FASTEST-GROWING MARKET DURING FORECAST PERIOD

- FIGURE 48 ASIA PACIFIC: CENTRIFUGE MARKET SNAPSHOT

- FIGURE 49 NORTH AMERICA: CENTRIFUGE MARKET SNAPSHOT

- FIGURE 50 EUROPE: CENTRIFUGE MARKET SNAPSHOT

- FIGURE 51 CENTRIFUGE MARKET: SHARE OF KEY PLAYERS, 2024

- FIGURE 52 REVENUE ANALYSIS OF KEY PLAYERS, 2020-2024

- FIGURE 53 BRAND/PRODUCT COMPARATIVE ANALYSIS, BY SEGMENT

- FIGURE 54 CENTRIFUGE MARKET: COMPANY EVALUATION MATRIX, KEY PLAYERS, 2024

- FIGURE 55 CENTRIFUGE MARKET: COMPANY FOOTPRINT

- FIGURE 56 CENTRIFUGE MARKET: COMPANY EVALUATION MATRIX STARTUPS/SMES, 2024

- FIGURE 57 EV/EBITDA OF KEY VENDORS

- FIGURE 58 YEAR-TO-DATE (YTD) PRICE TOTAL RETURN

- FIGURE 59 ALFA LAVAL: COMPANY SNAPSHOT

- FIGURE 60 GEA GROUP AKTIENGESELLSCHAFT: COMPANY SNAPSHOT

- FIGURE 61 ANDRITZ: COMPANY SNAPSHOT

- FIGURE 62 FLSMIDTH A/S: COMPANY SNAPSHOT

- FIGURE 63 KUBOTA CORPORATION: COMPANY SNAPSHOT

- FIGURE 64 MITSUBISHI KAKOKI KAISHA, LTD.: COMPANY SNAPSHOT