|

市場調查報告書

商品編碼

1808966

全球多元醇市場(按類型、應用、最終用途產業和地區分類)- 預測至 2030 年Polyols Market by Type (Polyether Polyols, Polyester Polyols), Application (Flexible Polyurethane Foam, Rigid Polyurethane Foam, CASE), End-use Industry (Building & Construction, Furnishing, Automotive, Electronics), and Region - Global Forecast to 2030 |

||||||

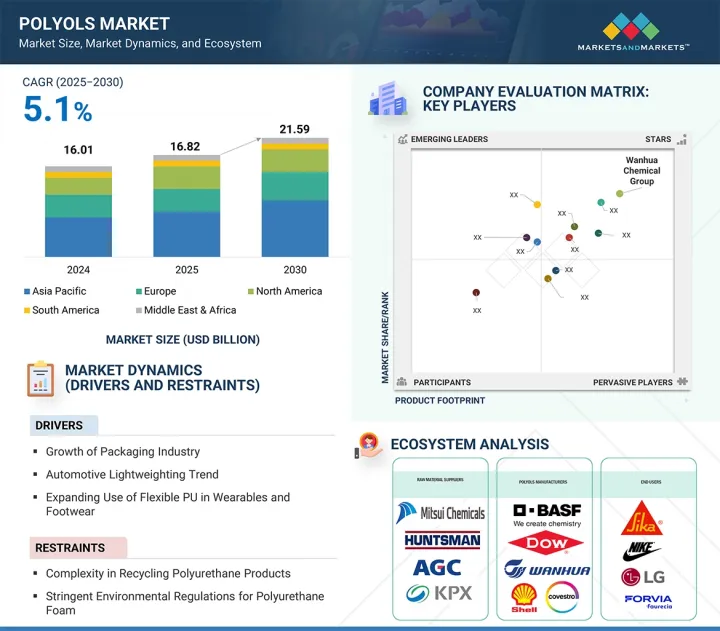

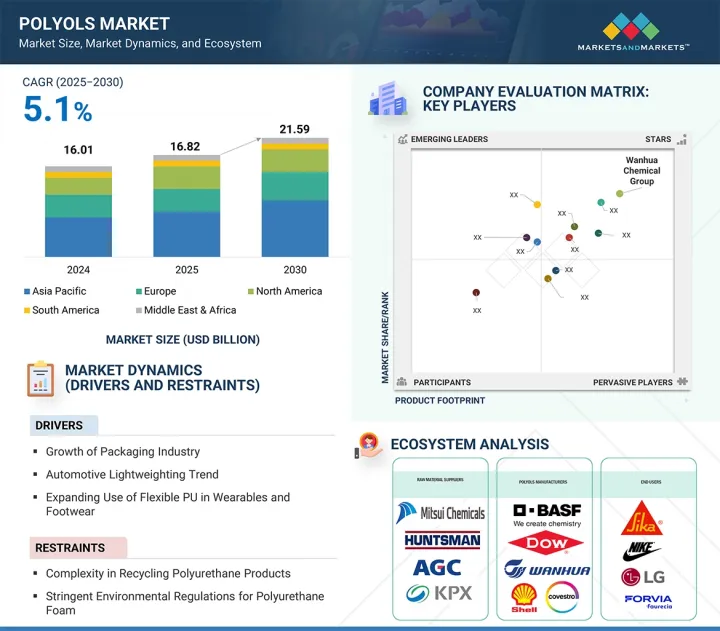

2024 年全球多元醇市場規模為 160.1 億美元,預計到 2030 年將達到 215.9 億美元,預測期內複合年成長率為 5.1%。

多元醇在聚氨酯基產品生產中的廣泛應用推動了其需求,使其成為許多行業必不可少的材料。多元醇在建築領域用於生產硬質泡沫隔熱材料節能建築提供支援。

| 調查範圍 | |

|---|---|

| 調查年份 | 2024-2030 |

| 基準年 | 2024 |

| 預測期 | 2025-2030 |

| 單元 | 百萬美元每千噸 |

| 部分 | 類型、最終用途行業、地區 |

| 目標區域 | 北美、歐洲、亞太地區、中東和非洲、南美 |

在汽車和家具領域,由多元醇製成的軟質聚氨酯泡棉能夠提升舒適度和耐用性,同時保持產品輕量化。日益成長的包裝產業也推動了對多元醇的需求,因為它們可用於生產緩衝和保護材料。此外,人們對永續高性能材料日益成長的興趣也推動了生物基多元醇的發展。整體而言,多元醇的多功能性能夠提升產品性能並減少對環境的影響,從而推動成熟市場和新興市場的需求。

按類型分類,聚醚多元醇部分將在預測期內達到最高的複合年成長率。

從類型來看,聚醚多元醇因其廣泛的應用領域,將在預測期內達到最高的複合年成長率。聚醚多元醇以其低黏度、與異氰酸酯反應迅速以及與各種添加劑的優異相容性而聞名。由於這些特性,聚醚多元醇常用於軟質和硬質泡沫。這些泡沫用於汽車座椅、床上用品、家具、隔熱材料和包裝市場,這些市場在已開發市場和新興市場的需求不斷成長。

該細分市場的強勁成長得益於對能源效率和輕量材料的日益關注,尤其是在建築和汽車市場。聚醚多元醇比聚酯多元醇具有更佳的水解穩定性和加工優勢。此外,生物基產品的出現預計將有助於聚醚多元醇超越聚酯多元醇,擴大市場佔有率,創造新的成長機會。

聚醚多元醇憑藉其穩定的生產率、卓越的性能和多樣化的配方選擇,目前在產量和價值方面均佔據主導地位。隨著各行各業越來越重視性能、成本效益和環保合規性,預計聚醚多元醇市場在整個預測期內仍將保持領先地位。

根據最終用途行業,建築和施工部門將在預測期內見證最高的複合年成長率。

按終端行業分類,預計建築施工領域在整個預測期內將經歷最高的複合年成長率,這得益於對節能材料和永續建築解決方案的需求快速成長。多元醇是硬質聚氨酯泡棉的主要原料,而硬質聚氨酯泡棉廣泛用於牆板、屋頂和地板隔熱材料以及管道隔熱材料等隔熱應用。快速的都市化、基礎設施發展和節能監管要求直接和間接地推動了對高性能隔熱材料的需求,尤其是在亞太地區和中東等新興經濟體。由多元醇製成的聚氨酯隔熱材料具備上述所有的特性,包括耐熱性、防潮性和穩定性。此外,對綠色建築認證和環境標準的認知正在刺激聚氨酯建築材料的持續採用。隨著建築實踐不斷發展,越來越強調長壽命和環保性能,多元醇對於開發滿足這些最新要求的新材料至關重要。

預計監管支持、建設活動活性化以及對永續基礎設施發展的日益關注將在整個預測期內繼續推動多元醇市場建築和施工領域的成長。

本報告分析了全球多元醇市場,提供了關鍵促進因素和限制因素、競爭格局和未來趨勢的資訊。

目錄

第1章 引言

第2章調查方法

第3章執行摘要

第4章 主要發現

- 多元醇市場為企業帶來誘人機會

- 多元醇市場按類型

- 多元醇市場按應用

- 多元醇市場(按最終用途行業分類)

- 亞太地區多元醇市場(按類型和國家)

- 多元醇市場:主要國家

第5章市場概述

- 介紹

- 市場動態

- 驅動程式

- 抑制因素

- 機會

- 任務

第6章 產業趨勢

- 影響客戶業務的趨勢/中斷

- 定價分析

- 主要企業各類型平均銷售價格趨勢(2024年)

- 各地區平均銷售價格趨勢(2021-2024)

- 價值鏈分析

- 生態系分析

- 技術分析

- 主要技術

- 互補技術

- 鄰近技術

- 生成人工智慧對多元醇市場的影響

- 專利分析

- 介紹

- 方法

- 主申請人

- 貿易分析

- 進口情形(HS 編碼 390950)

- 出口情形(HS 編碼 390950)

- 大型會議和活動(2025-2026年)

- 監管格局

- 監管機構、政府機構和其他組織

- 多元醇法規

- 波特五力分析

- 主要相關利益者和採購標準

- 案例研究分析

- 科思創利用二氧化碳基多元醇為海上工業開發永續鑄造彈性體解決方案

- 亨斯邁利用 Terrol 聚酯多元醇將塑膠廢棄物轉化為節能隔熱材料

- BASF利用低排放氣體LUPRANOL聚醚多元醇減少車內排放

- 宏觀經濟展望

- 介紹

- GDP趨勢與預測

- 全球建築趨勢

- 汽車生產週期

- 投資金籌措場景

- 2025年美國關稅對多元醇市場的影響

- 介紹

- 主要關稅稅率

- 價格影響分析

- 對各地區產生重大影響

- 對終端產業的影響

第7章 多元醇市場(依類型)

- 介紹

- 聚醚多元醇

- 聚酯多元醇

第8章 多元醇市場應用

- 介紹

- 軟質聚氨酯泡棉

- 硬質聚氨酯泡棉

- 塗料、黏合劑、密封劑、彈性體(套管)

9. 多元醇市場(依最終用途產業分類)

- 介紹

- 建築/施工

- 車

- 家具

- 包裝

- 電子的

- 其他最終用途產業

第 10 章 多元醇市場(按地區)

- 介紹

- 亞太地區

- 中國

- 印度

- 日本

- 韓國

- 泰國

- 印尼

- 其他亞太地區

- 歐洲

- 德國

- 英國

- 法國

- 義大利

- 俄羅斯

- 土耳其

- 其他歐洲國家

- 北美洲

- 美國

- 加拿大

- 墨西哥

- 中東和非洲

- 海灣合作理事會國家

- 南非

- 其他中東和非洲地區

- 南美洲

- 巴西

- 阿根廷

- 南美洲其他地區

第11章競爭格局

- 概述

- 主要參與企業的策略/優勢

- 收益分析

- 市場佔有率分析

- 公司估值及財務指標

- 品牌/產品比較

- 企業評估矩陣:主要企業(2024年)

- 公司評估矩陣:Start-Ups/中小企業(2024 年)

- 競爭場景

第12章:公司簡介

- 主要企業

- DOW

- COVESTRO AG

- BASF SE

- HUNTSMAN INTERNATIONAL LLC

- SHELL

- STEPAN COMPANY

- WANHUA CHEMICAL GROUP

- REPSOL SA

- PCC SE

- LANXESS

- 其他公司

- ZIBO DEXIN LIANBANG CHEMICAL INDUSTRY CO., LTD.

- SHANDONG LONGHUA NEW MATERIAL CO., LTD.

- ZHEJIANG HUAFON NEW MATERIALS CORP., LTD.

- SHAKUN INDUSTRIES

- INTERPUR CHEMICALS

- MANALI PETROCHEMICALS LIMITED

- POLYOLS & POLYMERS PVT LTD.

- KURARAY CO., LTD.

- SUMITOMO BAKELITE HIGH PERFORMANCE PLASTICS (SBHPP)

- ERCA ADVANCED POLYMER SOLUTIONS

- SINOCHEM HOLDINGS CORPORATION LTD.

- DAICEL CORPORATION

- EMERY OLEOCHEMICALS

- SOLVAY

- PERSTORP

- ARAMCO

- TOSOH CORPORATION

- ARKEMA

- PLUSKIM

- PURINOVA SP. Z OO

- PTT GLOBAL CHEMICAL PUBLIC COMPANY LIMITED

第13章:相鄰市場與相關市場

- 介紹

- 限制

第14章 附錄

The market for polyols was valued at USD 16.01 billion in 2024 and is projected to reach USD 21.59 billion by 2030, growing at a CAGR of 5.1% during the forecast period. Demand for polyols is driven by their widespread use in producing polyurethane-based products, which are essential materials across many industries. Polyols are utilized in construction to create rigid foam insulation that supports energy-efficient buildings.

| Scope of the Report | |

|---|---|

| Years Considered for the Study | 2024-2030 |

| Base Year | 2024 |

| Forecast Period | 2025-2030 |

| Units Considered | Value (USD Million) Volume (Kiloton) |

| Segments | Type, Application, End-Use Industry, and Region |

| Regions covered | North America, Europe, Asia Pacific, Middle East & Africa, and South America |

In the automotive and furniture sectors, flexible polyurethane foams made from polyols enhance comfort and durability while keeping products lightweight. The rising packaging industry also boosts demand for polyols, as they are used to produce cushioning and protective materials. Additionally, increasing interest in sustainable and high-performance materials is driving the development of bio-based polyols. Overall, the versatility of polyols improves product performance, reduces environmental impact, and increases demand in both established and emerging markets.

By type, polyether polyols segment to record highest CAGR during forecast period

By type, polyether polyols accounted for the highest CAGR for the forecast period due to their growing use in a wide range of applications. Polyether polyols are known for their low viscosity, quick reaction with isocyanates, and excellent compatibility with various additives. Because of these qualities, they are commonly used in both flexible and rigid foams. These foams are utilized in automotive seats, bedding, furniture, insulation materials, and packaging markets, all of which are experiencing increased demand in both developed and emerging markets.

The strong growth of this segment is further driven by increasing focus on energy efficiency and lightweight materials, especially in construction and automotive markets. Polyether polyols offer better hydrolytic stability and processing advantages over polyester polyols. Polyether polyols are also expected to gain market share over polyester polyols due to the emergence of bio-based options, creating new opportunities for growth.

Polyether polyols now dominate both in volume and value because of their ability to ensure consistent production, impressive performance, and a wide variety of formulation options. As industries increasingly prioritize performance, cost-efficiency, and environmental compliance, the polyether polyols segment is expected to remain at the forefront until the end of the forecast period.

By end-use industry, building & construction segment to exhibit highest CAGR during forecast period

The building and construction segment experienced the highest CAGR throughout the forecast period for end-use industries, driven by the rapidly growing demand for energy-efficient materials and sustainable building solutions. Polyols are a key raw material for rigid polyurethane foams, which are extensively used in insulation applications such as wall panels, roofs, floor insulation, and pipe insulation. Additionally, rapid urbanization, infrastructure development, and regulatory requirements for energy conservation have both directly and indirectly increased demand for high-performance insulation materials, especially in developing economies, notably in the Asia Pacific and Middle East regions. Polyurethane insulation made from polyols offers all these performance features, including thermal resistance, moisture barriers, and stability. Furthermore, awareness of green-building certifications and environmental standards is fueling continued adoption of polyurethane construction materials. As construction practices evolve to emphasize longer service life and environmental performance, polyols are essential in developing new materials that meet these modern requirements.

The combination of regulatory support, rising construction activity, and a growing focus on developing sustainable infrastructure will continue to drive the growth of the Building & Construction segment of the polyols market throughout the forecast period.

Asia Pacific to account for highest CAGR during forecast period

By region, Asia Pacific is projected to experience the highest CAGR over the forecast period due to rapid industrialization and urbanization, along with rapidly growing end-use industries such as construction, automotive, furniture, and packaging. Specifically, countries like China, India, South Korea, and Southeast Asian nations are growing quickly. This has led to increased infrastructure development, higher disposable incomes, and greater customers' demand for durable goods, consequently raising the demand for polyol products.

The construction industry in Asia Pacific has grown substantially due to government investments in residential, commercial, and industrial infrastructure, leading to higher consumption of polyol, a key ingredient in rigid polyurethane foams used for thermal insulation. Furthermore, the expanding automotive and furniture sectors have boosted the demand for flexible polyurethane foams used in seating, bedding, and other interior components.

Asia Pacific also has a strong manufacturing base, a dependable source of inexpensive raw materials, and greater government support for industrial development. Additionally, domestic and international companies are quickly expanding their production capacities through significantly increased R&D spending or enlarging their manufacturing capabilities to meet customer demand. All of these factors will help Asia Pacific become the largest regional market for polyols globally and the fastest growing during the forecast period.

- By Company Type: Tier 1: 45%, Tier 2: 22%, and Tier 3: 33%

- By Designation: C Level: 50%, Director Level: 25%, and Others: 25%

- By Region: North America: 45%, Europe: 20%, Asia Pacific: 20%, Middle East & Africa: 10%, and South America: 5%.

Companies Covered

DOW (US), Covestro AG (Germany), BASF SE (Germany), Huntsman International LLC (US), Shell (UK), Stepan Company (US), Wanhua Chemical Group (China), Repsol S.A. (Spain), PCC SE (Germany), and LANXESS (Germany) are some key players in polyols market.

Research Coverage

The market study examines the polyols market across various segments. It aims to estimate the market size and growth potential in different segments based on type, application, end-use industry, and region. The study also includes an in-depth competitive analysis of key market players, their company profiles, observations related to their products and business offerings, recent developments, and key growth strategies they have adopted to strengthen their position in the polyols market.

Key Benefits of Buying Report

The report is designed to help market leaders and new entrants estimate the revenue figures of the entire polyols market and its segments and sub-segments. It aims to assist stakeholders in understanding the competitive landscape, gaining insights to strengthen their business positions, and developing effective go-to-market strategies. Additionally, the report provides stakeholders with insights into the market's current trends, including key drivers, challenges, and opportunities.

The report provides insights into the following points:

- Analysis of key drivers (Growth of packaging industry and automotive light-weighting trend), restraints (Complexity in recycling polyurethane products and stringent environmental regulations for polyurethane foam), opportunities (Growing adoption of bio-based polyols and high-purity polyols for medical grade applications), and challenges (Eco-friendly alternatives) influencing the growth of the polyols market.

- Product Development/Innovation: Detailed insights into upcoming technologies, research & development activities, and new product & service launches in the polyols market

- Market Development: Comprehensive information about profitable markets - the report analyses the polyols market across varied regions

Market Diversification: Exhaustive information about new products & services, untapped geographies, recent developments, and investments in the polyols market

- Competitive Assessment: In-depth assessment of market shares, growth strategies, and service offerings of leading players like as DOW (US), Covestro AG (Germany), BASF SE (Germany), Huntsman International LLC (US), Shell (UK), Stepan Company (US), Wanhua Chemical Group (China), Repsol S.A. (Spain), PCC SE (Germany), LANXESS (Germany), and others in the polyols market. The report also helps stakeholders understand the pulse of the polyols market and provides them with information on key market drivers, restraints, challenges, and opportunities.

TABLE OF CONTENTS

1 INTRODUCTION

- 1.1 STUDY OBJECTIVES

- 1.2 MARKET DEFINITION

- 1.3 STUDY SCOPE

- 1.3.1 MARKETS COVERED AND REGIONAL SCOPE

- 1.3.2 INCLUSIONS AND EXCLUSIONS

- 1.3.3 YEARS CONSIDERED

- 1.3.4 CURRENCY CONSIDERED

- 1.3.5 UNIT CONSIDERED

- 1.4 LIMITATIONS

- 1.5 STAKEHOLDERS

- 1.6 SUMMARY OF CHANGES

2 RESEARCH METHODOLOGY

- 2.1 RESEARCH DATA

- 2.1.1 SECONDARY DATA

- 2.1.1.1 Key data from secondary sources

- 2.1.1.2 List of secondary sources

- 2.1.2 PRIMARY DATA

- 2.1.2.1 Key primary participants

- 2.1.2.2 Key data from primary sources

- 2.1.2.3 Breakdown of interviews with experts

- 2.1.2.4 Key industry insights

- 2.1.1 SECONDARY DATA

- 2.2 MARKET SIZE ESTIMATION

- 2.2.1 TOP-DOWN APPROACH

- 2.2.2 BOTTOM-UP APPROACH

- 2.2.3 BASE NUMBER CALCULATION

- 2.2.4 SUPPLY-SIDE ANALYSIS

- 2.3 GROWTH FORECAST

- 2.4 DATA TRIANGULATION

- 2.5 RESEARCH ASSUMPTIONS

- 2.6 FACTOR ANALYSIS

- 2.7 RESEARCH LIMITATIONS

- 2.8 RISK ASSESSMENT

3 EXECUTIVE SUMMARY

4 PREMIUM INSIGHTS

- 4.1 ATTRACTIVE OPPORTUNITIES FOR PLAYERS IN POLYOLS MARKET

- 4.2 POLYOLS MARKET, BY TYPE

- 4.3 POLYOLS MARKET, BY APPLICATION

- 4.4 POLYOLS MARKET, BY END-USE INDUSTRY

- 4.5 ASIA PACIFIC POLYOLS MARKET, BY TYPE AND COUNTRY

- 4.6 POLYOLS MARKET, BY KEY COUNTRY

5 MARKET OVERVIEW

- 5.1 INTRODUCTION

- 5.2 MARKET DYNAMICS

- 5.2.1 DRIVERS

- 5.2.1.1 Expanding packaging industry

- 5.2.1.2 Increasing automobile lightweighting trend

- 5.2.1.3 Rising use of flexible PU in wearables and footwear

- 5.2.2 RESTRAINTS

- 5.2.2.1 Complexity in recycling polyurethane products

- 5.2.2.2 Stringent environmental regulations associated with polyurethane foam

- 5.2.3 OPPORTUNITIES

- 5.2.3.1 Growing adoption of bio-based polyols

- 5.2.3.2 Adoption of high-purity polyols for medical-grade applications

- 5.2.4 CHALLENGES

- 5.2.4.1 Shift toward eco-friendly alternatives

- 5.2.4.2 Cross-border compliance complexity related to CASE polyols

- 5.2.1 DRIVERS

6 INDUSTRY TRENDS

- 6.1 TRENDS/DISRUPTIONS IMPACTING CUSTOMER BUSINESS

- 6.2 PRICING ANALYSIS

- 6.2.1 AVERAGE SELLING PRICE TREND OF KEY PLAYERS, BY TYPE, 2024

- 6.2.2 AVERAGE SELLING PRICE TREND, BY REGION, 2021-2024

- 6.3 VALUE CHAIN ANALYSIS

- 6.4 ECOSYSTEM ANALYSIS

- 6.5 TECHNOLOGY ANALYSIS

- 6.5.1 KEY TECHNOLOGIES

- 6.5.1.1 Poly-esterification

- 6.5.1.2 Ring-opening polymerization (ROP)

- 6.5.2 COMPLEMENTARY TECHNOLOGIES

- 6.5.2.1 Blowing agent technology

- 6.5.2.2 Recycling and recovery technology

- 6.5.3 ADJACENT TECHNOLOGIES

- 6.5.3.1 CO2-based polyols

- 6.5.3.2 Smart foams and composites

- 6.5.1 KEY TECHNOLOGIES

- 6.6 IMPACT OF GEN AI ON POLYOLS MARKET

- 6.7 PATENT ANALYSIS

- 6.7.1 INTRODUCTION

- 6.7.2 APPROACH

- 6.7.3 TOP APPLICANTS

- 6.8 TRADE ANALYSIS

- 6.8.1 IMPORT SCENARIO (HS CODE 390950)

- 6.8.2 EXPORT SCENARIO (HS CODE 390950)

- 6.9 KEY CONFERENCES AND EVENTS, 2025-2026

- 6.10 REGULATORY LANDSCAPE

- 6.10.1 REGULATORY BODIES, GOVERNMENT AGENCIES, AND OTHER ORGANIZATIONS

- 6.10.2 REGULATIONS RELATED TO POLYOLS

- 6.11 PORTER'S FIVE FORCES ANALYSIS

- 6.11.1 THREAT OF NEW ENTRANTS

- 6.11.2 THREAT OF SUBSTITUTES

- 6.11.3 BARGAINING POWER OF SUPPLIERS

- 6.11.4 BARGAINING POWER OF BUYERS

- 6.11.5 INTENSITY OF COMPETITIVE RIVALRY

- 6.12 KEY STAKEHOLDERS AND BUYING CRITERIA

- 6.12.1 KEY STAKEHOLDERS IN BUYING PROCESS

- 6.12.2 BUYING CRITERIA

- 6.13 CASE STUDY ANALYSIS

- 6.13.1 COVESTRO DEVELOPS SUSTAINABLE CAST ELASTOMER SOLUTION FOR OFFSHORE INDUSTRY USING CO2-BASED POLYOLS

- 6.13.2 HUNTSMAN TRANSFORMS PLASTIC WASTE INTO ENERGY-SAVING INSULATION THROUGH TEROL POLYESTER POLYOLS

- 6.13.3 BASF REDUCES INTERIOR CAR EMISSIONS WITH LOW-EMISSION LUPRANOL POLYETHER POLYOLS

- 6.14 MACROECONOMIC OUTLOOK

- 6.14.1 INTRODUCTION

- 6.14.2 GDP TRENDS AND FORECASTS

- 6.14.3 GLOBAL CONSTRUCTION TRENDS

- 6.14.4 AUTOMOBILE PRODUCTION CYCLES

- 6.15 INVESTMENT AND FUNDING SCENARIO

- 6.16 IMPACT OF 2025 US TARIFF ON POLYOLS MARKET

- 6.16.1 INTRODUCTION

- 6.16.2 KEY TARIFF RATES

- 6.16.3 PRICE IMPACT ANALYSIS

- 6.16.4 KEY IMPACT ON VARIOUS REGIONS

- 6.16.4.1 US

- 6.16.4.2 Europe

- 6.16.4.3 Asia Pacific

- 6.16.5 END-USE INDUSTRY IMPACT

7 POLYOLS MARKET, BY TYPE

- 7.1 INTRODUCTION

- 7.2 POLYETHER POLYOLS

- 7.2.1 HIGH REACTIVITY, VERSATILE MOLECULAR DESIGN, AND COMPATIBILITY WITH VARIOUS ISOCYANATES TO DRIVE DEMAND

- 7.3 POLYESTER POLYOLS

- 7.3.1 USE TO ENHANCE POLYURETHANE STRENGTH IN COATINGS, ELASTOMERS, AND FOAMS TO DRIVE MARKET

8 POLYOLS MARKET, BY APPLICATION

- 8.1 INTRODUCTION

- 8.2 FLEXIBLE POLYURETHANE FOAM

- 8.2.1 INCREASED USE IN CUSHIONING AND COMFORT APPLICATIONS TO DRIVE MARKET

- 8.3 RIGID POLYURETHANE FOAMS

- 8.3.1 USE IN HIGH-PERFORMANCE INSULATION SYSTEMS TO PROPEL MARKET

- 8.4 COATINGS, ADHESIVES, SEALANTS, AND ELASTOMERS (CASE)

- 8.4.1 ABILITY TO OFFER HIGH MECHANICAL PERFORMANCE, CHEMICAL RESISTANCE, AND ENVIRONMENTAL DURABILITY TO DRIVE MARKET

9 POLYOLS MARKET, BY END-USE INDUSTRY

- 9.1 INTRODUCTION

- 9.2 BUILDING & CONSTRUCTION

- 9.2.1 USE TO POWER HIGH-PERFORMANCE INSULATION SYSTEMS IN MODERN BUILDING AND CONSTRUCTION PROJECTS TO PROPEL MARKET

- 9.3 AUTOMOTIVE

- 9.3.1 ABILITY TO SUPPORT LIGHTWEIGHT, DURABLE, AND LOW-EMISSION SOLUTIONS IN AUTOMOBILE APPLICATIONS TO DRIVE DEMAND

- 9.4 FURNISHING

- 9.4.1 ENHANCEMENT OF COMFORT, DURABILITY, AND SUSTAINABILITY IN MODERN FURNISHING APPLICATIONS TO FUEL MARKET GROWTH

- 9.5 PACKAGING

- 9.5.1 ABILITY TO OFFER HIGH-PERFORMANCE, INSULATED, AND SUSTAINABLE SOLUTIONS IN ADVANCED PACKAGING APPLICATIONS TO DRIVE MARKET

- 9.6 ELECTRONICS

- 9.6.1 ADOPTION TO DELIVER ESSENTIAL PROTECTION AND INSULATION IN ADVANCED ELECTRONIC COMPONENTS TO BOOST MARKET

- 9.7 OTHER END-USE INDUSTRIES

10 POLYOLS MARKET, BY REGION

- 10.1 INTRODUCTION

- 10.2 ASIA PACIFIC

- 10.2.1 CHINA

- 10.2.1.1 New Energy Vehicle (NEV) growth, rapid urbanization, and expanding electronics industry to propel demand

- 10.2.2 INDIA

- 10.2.2.1 Rising infrastructure development investments, EV adoption, and booming furniture industry to drive demand

- 10.2.3 JAPAN

- 10.2.3.1 Growing automotive and furniture industries to fuel demand

- 10.2.4 SOUTH KOREA

- 10.2.4.1 Expanding EV industry and housing development to propel demand

- 10.2.5 THAILAND

- 10.2.5.1 Booming construction, automotive, and electronics industries to drive market

- 10.2.6 INDONESIA

- 10.2.6.1 Smart city development and industrial expansion to drive demand

- 10.2.7 REST OF ASIA PACIFIC

- 10.2.1 CHINA

- 10.3 EUROPE

- 10.3.1 GERMANY

- 10.3.1.1 Booming automotive, construction, and electronics industries to fuel demand

- 10.3.2 UK

- 10.3.2.1 Robust infrastructure development and advancements in automotive and electronics industries to drive demand

- 10.3.3 FRANCE

- 10.3.3.1 Rising urbanization and industrial resurgence to drive demand

- 10.3.4 ITALY

- 10.3.4.1 Infrastructure upgrades, industrial revival, and export growth to propel demand

- 10.3.5 RUSSIA

- 10.3.5.1 Accelerating housing targets and automotive sector rebound to fuel demand

- 10.3.6 TURKEY

- 10.3.6.1 Surging home sales, vehicle production, and furniture exports to fuel demand

- 10.3.7 REST OF EUROPE

- 10.3.1 GERMANY

- 10.4 NORTH AMERICA

- 10.4.1 US

- 10.4.1.1 Surging construction activities, EV adoption, and furniture demand to drive market

- 10.4.2 CANADA

- 10.4.2.1 Booming construction industry and EV investments to fuel demand

- 10.4.3 MEXICO

- 10.4.3.1 Increasing automobile production and electronics trade to drive demand

- 10.4.1 US

- 10.5 MIDDLE EAST & AFRICA

- 10.5.1 GCC COUNTRIES

- 10.5.1.1 Saudi Arabia

- 10.5.1.1.1 Rising infrastructure development and automotive market to propel demand

- 10.5.1.2 UAE

- 10.5.1.2.1 Expanding real estate sector and EV infrastructure growth to drive demand

- 10.5.1.3 Rest of GCC Countries

- 10.5.1.1 Saudi Arabia

- 10.5.2 SOUTH AFRICA

- 10.5.2.1 Expanding real estate sector and increasing automobile production to fuel demand

- 10.5.3 REST OF MIDDLE EAST & AFRICA

- 10.5.1 GCC COUNTRIES

- 10.6 SOUTH AMERICA

- 10.6.1 BRAZIL

- 10.6.1.1 Surging construction and EV manufacturing investments to drive demand

- 10.6.2 ARGENTINA

- 10.6.2.1 Residential expansion and EV adoption accelerating material needs to drive demand

- 10.6.3 REST OF SOUTH AMERICA

- 10.6.1 BRAZIL

11 COMPETITIVE LANDSCAPE

- 11.1 OVERVIEW

- 11.2 KEY PLAYER STRATEGIES/RIGHT TO WIN

- 11.3 REVENUE ANALYSIS

- 11.4 MARKET SHARE ANALYSIS

- 11.5 COMPANY VALUATION AND FINANCIAL METRICS

- 11.6 BRAND/PRODUCT COMPARISON

- 11.7 COMPANY EVALUATION MATRIX: KEY PLAYERS, 2024

- 11.7.1 STARS

- 11.7.2 EMERGING LEADERS

- 11.7.3 PERVASIVE PLAYERS

- 11.7.4 PARTICIPANTS

- 11.7.5 COMPANY FOOTPRINT: KEY PLAYERS, 2024

- 11.7.5.1 Company footprint

- 11.7.5.2 Region footprint

- 11.7.5.3 Type footprint

- 11.7.5.4 Application footprint

- 11.7.5.5 End-use industry footprint

- 11.8 COMPANY EVALUATION MATRIX: STARTUPS/SMES, 2024

- 11.8.1 PROGRESSIVE COMPANIES

- 11.8.2 RESPONSIVE COMPANIES

- 11.8.3 DYNAMIC COMPANIES

- 11.8.4 STARTING BLOCKS

- 11.8.5 COMPETITIVE BENCHMARKING: STARTUPS/SMES, 2024

- 11.8.5.1 Detailed list of key startups/SMEs

- 11.8.5.2 Competitive benchmarking of key startups/SMEs

- 11.9 COMPETITIVE SCENARIO

- 11.9.1 PRODUCT LAUNCHES

- 11.9.2 DEALS

- 11.9.3 EXPANSIONS

12 COMPANY PROFILES

- 12.1 KEY PLAYERS

- 12.1.1 DOW

- 12.1.1.1 Business overview

- 12.1.1.2 Products/Solutions/Services offered

- 12.1.1.3 Recent developments

- 12.1.1.3.1 Product launches

- 12.1.1.3.2 Expansions

- 12.1.1.3.3 Others

- 12.1.1.4 MnM view

- 12.1.1.4.1 Key strengths/Right to win

- 12.1.1.4.2 Strategic choices

- 12.1.1.4.3 Weaknesses/Competitive threats

- 12.1.2 COVESTRO AG

- 12.1.2.1 Business overview

- 12.1.2.2 Products/Solutions/Services offered

- 12.1.2.3 Recent developments

- 12.1.2.3.1 Product launches

- 12.1.2.3.2 Deals

- 12.1.2.3.3 Others

- 12.1.2.4 MnM view

- 12.1.2.4.1 Key strengths/Right to win

- 12.1.2.4.2 Strategic choices

- 12.1.2.4.3 Weaknesses/Competitive threats

- 12.1.3 BASF SE

- 12.1.3.1 Business overview

- 12.1.3.2 Products/Solutions/Services offered

- 12.1.3.3 Recent developments

- 12.1.3.3.1 Product launches

- 12.1.3.3.2 Deals

- 12.1.3.3.3 Expansions

- 12.1.3.4 MnM view

- 12.1.3.4.1 Key strengths/Right to win

- 12.1.3.4.2 Strategic choices

- 12.1.3.4.3 Weaknesses/Competitive threats

- 12.1.4 HUNTSMAN INTERNATIONAL LLC

- 12.1.4.1 Business overview

- 12.1.4.2 Products/Solutions/Services offered

- 12.1.4.3 Recent developments

- 12.1.4.3.1 Deals

- 12.1.4.3.2 Expansions

- 12.1.4.4 MnM view

- 12.1.4.4.1 Key strengths/Right to win

- 12.1.4.4.2 Strategic choices

- 12.1.4.4.3 Weaknesses/Competitive threats

- 12.1.5 SHELL

- 12.1.5.1 Business overview

- 12.1.5.2 Products/Solutions/Services offered

- 12.1.5.3 Recent developments

- 12.1.5.3.1 Deals

- 12.1.5.3.2 Expansions

- 12.1.5.4 MnM view

- 12.1.5.4.1 Key strengths/Right to win

- 12.1.5.4.2 Strategic choices

- 12.1.5.4.3 Weaknesses/Competitive threats

- 12.1.6 STEPAN COMPANY

- 12.1.6.1 Business overview

- 12.1.6.2 Products/Solutions/Services offered

- 12.1.6.3 Recent developments

- 12.1.6.3.1 Product launches

- 12.1.6.3.2 Deals

- 12.1.6.3.3 Expansions

- 12.1.6.4 MnM view

- 12.1.7 WANHUA CHEMICAL GROUP

- 12.1.7.1 Business overview

- 12.1.7.2 Products/Solutions/Services offered

- 12.1.7.3 Recent developments

- 12.1.7.3.1 Product launches

- 12.1.7.3.2 Deals

- 12.1.7.3.3 Expansions

- 12.1.7.4 MnM view

- 12.1.8 REPSOL S.A.

- 12.1.8.1 Business overview

- 12.1.8.2 Products/Solutions/Services offered

- 12.1.8.3 Recent developments

- 12.1.8.3.1 Product launches

- 12.1.8.3.2 Deals

- 12.1.8.3.3 Expansions

- 12.1.8.4 MnM view

- 12.1.9 PCC SE

- 12.1.9.1 Business overview

- 12.1.9.2 Products/Solutions/Services offered

- 12.1.9.3 Recent developments

- 12.1.9.3.1 Product launches

- 12.1.9.3.2 Deals

- 12.1.9.3.3 Expansions

- 12.1.9.4 MnM view

- 12.1.10 LANXESS

- 12.1.10.1 Business overview

- 12.1.10.2 Products/Solutions/Services offered

- 12.1.10.3 Recent developments

- 12.1.10.3.1 Product launches

- 12.1.10.3.2 Expansions

- 12.1.10.3.3 Others

- 12.1.10.4 MnM view

- 12.1.1 DOW

- 12.2 OTHER PLAYERS

- 12.2.1 ZIBO DEXIN LIANBANG CHEMICAL INDUSTRY CO., LTD.

- 12.2.2 SHANDONG LONGHUA NEW MATERIAL CO., LTD.

- 12.2.3 ZHEJIANG HUAFON NEW MATERIALS CORP., LTD.

- 12.2.4 SHAKUN INDUSTRIES

- 12.2.5 INTERPUR CHEMICALS

- 12.2.6 MANALI PETROCHEMICALS LIMITED

- 12.2.7 POLYOLS & POLYMERS PVT LTD.

- 12.2.8 KURARAY CO., LTD.

- 12.2.9 SUMITOMO BAKELITE HIGH PERFORMANCE PLASTICS (SBHPP)

- 12.2.10 ERCA ADVANCED POLYMER SOLUTIONS

- 12.2.11 SINOCHEM HOLDINGS CORPORATION LTD.

- 12.2.12 DAICEL CORPORATION

- 12.2.13 EMERY OLEOCHEMICALS

- 12.2.14 SOLVAY

- 12.2.15 PERSTORP

- 12.2.16 ARAMCO

- 12.2.17 TOSOH CORPORATION

- 12.2.18 ARKEMA

- 12.2.19 PLUSKIM

- 12.2.20 PURINOVA SP. Z O.O.

- 12.2.21 PTT GLOBAL CHEMICAL PUBLIC COMPANY LIMITED

13 ADJACENT AND RELATED MARKET

- 13.1 INTRODUCTION

- 13.2 LIMITATIONS

- 13.2.1 POLYURETHANE FOAM MARKET

- 13.2.1.1 Market definition

- 13.2.1.2 Polyurethane foam market, by type

- 13.2.1.3 Polyurethane foam market, by end-use industry

- 13.2.1.4 Polyurethane foam market, by region

- 13.2.1 POLYURETHANE FOAM MARKET

14 APPENDIX

- 14.1 DISCUSSION GUIDE

- 14.2 KNOWLEDGESTORE: MARKETSANDMARKETS' SUBSCRIPTION PORTAL

- 14.3 CUSTOMIZATION OPTIONS

- 14.4 RELATED REPORTS

- 14.5 AUTHOR DETAILS

List of Tables

- TABLE 1 AVERAGE SELLING PRICE TREND OF POLYOLS OFFERED BY KEY PLAYERS, BY TYPE, 2024 (USD/KG)

- TABLE 2 AVERAGE SELLING PRICE TREND OF POLYOLS, BY REGION, 2021-2024 (USD/KG)

- TABLE 3 ROLES OF COMPANIES IN POLYOLS ECOSYSTEM

- TABLE 4 POLYOLS MARKET: LIST OF MAJOR PATENTS, 2024

- TABLE 5 IMPORT DATA FOR HS CODE 390950-COMPLIANT PRODUCTS (POLYURETHANE), BY COUNTRY, 2020-2024 (USD THOUSAND)

- TABLE 6 EXPORT DATA FOR HS CODE 390950-COMPLIANT PRODUCTS (POLYURETHANE), BY COUNTRY, 2020-2024 (USD THOUSAND)

- TABLE 7 POLYOLS MARKET: KEY CONFERENCES AND EVENTS, 2025-2026

- TABLE 8 NORTH AMERICA: LIST OF REGULATORY BODIES, GOVERNMENT AGENCIES, AND OTHER ORGANIZATIONS

- TABLE 9 SOUTH AMERICA: LIST OF REGULATORY BODIES, GOVERNMENT AGENCIES, AND OTHER ORGANIZATIONS

- TABLE 10 EUROPE: LIST OF REGULATORY BODIES, GOVERNMENT AGENCIES, AND OTHER ORGANIZATIONS

- TABLE 11 ASIA PACIFIC: LIST OF REGULATORY BODIES, GOVERNMENT AGENCIES, AND OTHER ORGANIZATIONS

- TABLE 12 MIDDLE EAST & AFRICA: LIST OF REGULATORY BODIES, GOVERNMENT AGENCIES, AND OTHER ORGANIZATIONS

- TABLE 13 POLYOLS MARKET: PORTER'S FIVE FORCES ANALYSIS

- TABLE 14 INFLUENCE OF STAKEHOLDERS IN BUYING PROCESS, BY END-USE INDUSTRY

- TABLE 15 KEY BUYING CRITERIA, BY END-USE INDUSTRY

- TABLE 16 GLOBAL GDP GROWTH PROJECTION, 2021-2028 (USD TRILLION)

- TABLE 17 KEY TARIFF RATES ON POLYETHER POLYOL IMPORTS INTO US, 2025

- TABLE 18 COMPARISON BETWEEN POLYETHER POLYOLS AND POLYESTER POLYOLS

- TABLE 19 POLYOLS MARKET, BY TYPE, 2021-2023 (KILOTON)

- TABLE 20 POLYOLS MARKET, BY TYPE, 2021-2023 (USD MILLION)

- TABLE 21 POLYOLS MARKET, BY TYPE, 2024-2030 (KILOTON)

- TABLE 22 POLYOLS MARKET, BY TYPE, 2024-2030 (USD MILLION)

- TABLE 23 POLYOLS MARKET, BY APPLICATION, 2021-2023 (KILOTON)

- TABLE 24 POLYOLS MARKET, BY APPLICATION, 2021-2023 (USD MILLION)

- TABLE 25 POLYOLS MARKET, BY APPLICATION, 2024-2030 (KILOTON)

- TABLE 26 POLYOLS MARKET, BY APPLICATION, 2024-2030 (USD MILLION)

- TABLE 27 POLYOLS MARKET, BY END-USE INDUSTRY, 2021-2023 (KILOTON)

- TABLE 28 POLYOLS MARKET, BY END-USE INDUSTRY, 2021-2023 (USD MILLION)

- TABLE 29 POLYOLS MARKET, BY END-USE INDUSTRY, 2024-2030 (KILOTON)

- TABLE 30 POLYOLS MARKET, BY END-USE INDUSTRY, 2024-2030 (USD MILLION)

- TABLE 31 POLYOLS MARKET, BY REGION, 2021-2023 (KILOTON)

- TABLE 32 POLYOLS MARKET, BY REGION, 2024-2030 (KILOTON)

- TABLE 33 POLYOLS MARKET, BY REGION, 2021-2023 (USD MILLION)

- TABLE 34 POLYOLS MARKET, BY REGION, 2024-2030 (USD MILLION)

- TABLE 35 ASIA PACIFIC: POLYOLS MARKET, BY COUNTRY, 2021-2023 (KILOTON)

- TABLE 36 ASIA PACIFIC: POLYOLS MARKET, BY COUNTRY, 2024-2030 (KILOTON)

- TABLE 37 ASIA PACIFIC: POLYOLS MARKET, BY COUNTRY, 2021-2023 (USD MILLION)

- TABLE 38 ASIA PACIFIC: POLYOLS MARKET, BY COUNTRY, 2024-2030 (USD MILLION)

- TABLE 39 ASIA PACIFIC: POLYOLS MARKET, BY TYPE, 2021-2023 (KILOTON)

- TABLE 40 ASIA PACIFIC: POLYOLS MARKET, BY TYPE, 2024-2030 (KILOTON)

- TABLE 41 ASIA PACIFIC: POLYOLS MARKET, BY TYPE, 2021-2023 (USD MILLION)

- TABLE 42 ASIA PACIFIC: POLYOLS MARKET, BY TYPE, 2024-2030 (USD MILLION)

- TABLE 43 ASIA PACIFIC: POLYOLS MARKET, BY APPLICATION, 2021-2023 (KILOTON)

- TABLE 44 ASIA PACIFIC: POLYOLS MARKET, BY APPLICATION, 2024-2030 (KILOTON)

- TABLE 45 ASIA PACIFIC: POLYOLS MARKET, BY APPLICATION, 2021-2023 (USD MILLION)

- TABLE 46 ASIA PACIFIC: POLYOLS MARKET, BY APPLICATION, 2024-2030 (USD MILLION)

- TABLE 47 ASIA PACIFIC: POLYOLS MARKET, BY END-USE INDUSTRY, 2021-2023 (KILOTON)

- TABLE 48 ASIA PACIFIC: POLYOLS MARKET, BY END-USE INDUSTRY, 2024-2030 (KILOTON)

- TABLE 49 ASIA PACIFIC: POLYOLS MARKET, BY END-USE INDUSTRY, 2021-2023 (USD MILLION)

- TABLE 50 ASIA PACIFIC: POLYOLS MARKET, BY END-USE INDUSTRY, 2024-2030 (USD MILLION)

- TABLE 51 CHINA: POLYOLS MARKET, BY TYPE, 2021-2023 (KILOTON)

- TABLE 52 CHINA: POLYOLS MARKET, BY TYPE, 2024-2030 (KILOTON)

- TABLE 53 CHINA: POLYOLS MARKET, BY TYPE, 2021-2023 (USD MILLION)

- TABLE 54 CHINA: POLYOLS MARKET, BY TYPE, 2024-2030 (USD MILLION)

- TABLE 55 CHINA: POLYOLS MARKET, BY APPLICATION, 2021-2023 (KILOTON)

- TABLE 56 CHINA: POLYOLS MARKET, BY APPLICATION, 2024-2030 (KILOTON)

- TABLE 57 CHINA: POLYOLS MARKET, BY APPLICATION, 2021-2023 (USD MILLION)

- TABLE 58 CHINA: POLYOLS MARKET, BY APPLICATION, 2024-2030 (USD MILLION)

- TABLE 59 INDIA: POLYOLS MARKET, BY TYPE, 2021-2023 (KILOTON)

- TABLE 60 INDIA: POLYOLS MARKET, BY TYPE, 2024-2030 (KILOTON)

- TABLE 61 INDIA: POLYOLS MARKET, BY TYPE, 2021-2023 (USD MILLION)

- TABLE 62 INDIA: POLYOLS MARKET, BY TYPE, 2024-2030 (USD MILLION)

- TABLE 63 INDIA: POLYOLS MARKET, BY APPLICATION, 2021-2023 (KILOTON)

- TABLE 64 INDIA: POLYOLS MARKET, BY APPLICATION, 2024-2030 (KILOTON)

- TABLE 65 INDIA: POLYOLS MARKET, BY APPLICATION, 2021-2023 (USD MILLION)

- TABLE 66 INDIA: POLYOLS MARKET, BY APPLICATION, 2024-2030 (USD MILLION)

- TABLE 67 JAPAN: POLYOLS MARKET, BY TYPE, 2021-2023 (KILOTON)

- TABLE 68 JAPAN: POLYOLS MARKET, BY TYPE, 2024-2030 (KILOTON)

- TABLE 69 JAPAN: POLYOLS MARKET, BY TYPE, 2021-2023 (USD MILLION)

- TABLE 70 JAPAN: POLYOLS MARKET, BY TYPE, 2024-2030 (USD MILLION)

- TABLE 71 JAPAN: POLYOLS MARKET, BY APPLICATION, 2021-2023 (KILOTON)

- TABLE 72 JAPAN: POLYOLS MARKET, BY APPLICATION, 2024-2030 (KILOTON)

- TABLE 73 JAPAN: POLYOLS MARKET, BY APPLICATION, 2021-2023 (USD MILLION)

- TABLE 74 JAPAN: POLYOLS MARKET, BY APPLICATION, 2024-2030 (USD MILLION)

- TABLE 75 SOUTH KOREA: POLYOLS MARKET, BY TYPE, 2021-2023 (KILOTON)

- TABLE 76 SOUTH KOREA: POLYOLS MARKET, BY TYPE, 2024-2030 (KILOTON)

- TABLE 77 SOUTH KOREA: POLYOLS MARKET, BY TYPE, 2021-2023 (USD MILLION)

- TABLE 78 SOUTH KOREA: POLYOLS MARKET, BY TYPE, 2024-2030 (USD MILLION)

- TABLE 79 SOUTH KOREA: POLYOLS MARKET, BY APPLICATION, 2021-2023 (KILOTON)

- TABLE 80 SOUTH KOREA: POLYOLS MARKET, BY APPLICATION, 2024-2030 (KILOTON)

- TABLE 81 SOUTH KOREA: POLYOLS MARKET, BY APPLICATION, 2021-2023 (USD MILLION)

- TABLE 82 SOUTH KOREA: POLYOLS MARKET, BY APPLICATION, 2024-2030 (USD MILLION)

- TABLE 83 THAILAND: POLYOLS MARKET, BY TYPE, 2021-2023 (KILOTON)

- TABLE 84 THAILAND: POLYOLS MARKET, BY TYPE, 2024-2030 (KILOTON)

- TABLE 85 THAILAND: POLYOLS MARKET, BY TYPE, 2021-2023 (USD MILLION)

- TABLE 86 THAILAND: POLYOLS MARKET, BY TYPE, 2024-2030 (USD MILLION)

- TABLE 87 THAILAND: POLYOLS MARKET, BY APPLICATION, 2021-2023 (KILOTON)

- TABLE 88 THAILAND: POLYOLS MARKET, BY APPLICATION, 2024-2030 (KILOTON)

- TABLE 89 THAILAND: POLYOLS MARKET, BY APPLICATION, 2021-2023 (USD MILLION)

- TABLE 90 THAILAND: POLYOLS MARKET, BY APPLICATION, 2024-2030 (USD MILLION)

- TABLE 91 INDONESIA: POLYOLS MARKET, BY TYPE, 2021-2023 (KILOTON)

- TABLE 92 INDONESIA: POLYOLS MARKET, BY TYPE, 2024-2030 (KILOTON)

- TABLE 93 INDONESIA: POLYOLS MARKET, BY TYPE, 2021-2023 (USD MILLION)

- TABLE 94 INDONESIA: POLYOLS MARKET, BY TYPE, 2024-2030 (USD MILLION)

- TABLE 95 INDONESIA: POLYOLS MARKET, BY APPLICATION, 2021-2023 (KILOTON)

- TABLE 96 INDONESIA: POLYOLS MARKET, BY APPLICATION, 2024-2030 (KILOTON)

- TABLE 97 INDONESIA: POLYOLS MARKET, BY APPLICATION, 2021-2023 (USD MILLION)

- TABLE 98 INDONESIA: POLYOLS MARKET, BY APPLICATION, 2024-2030 (USD MILLION)

- TABLE 99 REST OF ASIA PACIFIC: POLYOLS MARKET, BY TYPE, 2021-2023 (KILOTON)

- TABLE 100 REST OF ASIA PACIFIC: POLYOLS MARKET, BY TYPE, 2024-2030 (KILOTON)

- TABLE 101 REST OF ASIA PACIFIC: POLYOLS MARKET, BY TYPE, 2021-2023 (USD MILLION)

- TABLE 102 REST OF ASIA PACIFIC: POLYOLS MARKET, BY TYPE, 2024-2030 (USD MILLION)

- TABLE 103 REST OF ASIA PACIFIC: POLYOLS MARKET, BY APPLICATION, 2021-2023 (KILOTON)

- TABLE 104 REST OF ASIA PACIFIC: POLYOLS MARKET, BY APPLICATION, 2024-2030 (KILOTON)

- TABLE 105 REST OF ASIA PACIFIC: POLYOLS MARKET, BY APPLICATION, 2021-2023 (USD MILLION)

- TABLE 106 REST OF ASIA PACIFIC: POLYOLS MARKET, BY APPLICATION, 2024-2030 (USD MILLION)

- TABLE 107 EUROPE: POLYOLS MARKET, BY COUNTRY, 2021-2023 (KILOTON)

- TABLE 108 EUROPE: POLYOLS MARKET, BY COUNTRY, 2024-2030 (KILOTON)

- TABLE 109 EUROPE: POLYOLS MARKET, BY COUNTRY, 2021-2023 (USD MILLION)

- TABLE 110 EUROPE: POLYOLS MARKET, BY COUNTRY, 2024-2030 (USD MILLION)

- TABLE 111 EUROPE: POLYOLS MARKET, BY TYPE, 2021-2023 (KILOTON)

- TABLE 112 EUROPE: POLYOLS MARKET, BY TYPE, 2024-2030 (KILOTON)

- TABLE 113 EUROPE: POLYOLS MARKET, BY TYPE, 2021-2023 (USD MILLION)

- TABLE 114 EUROPE: POLYOLS MARKET, BY TYPE, 2024-2030 (USD MILLION)

- TABLE 115 EUROPE: POLYOLS MARKET, BY APPLICATION, 2021-2023 (KILOTON)

- TABLE 116 EUROPE: POLYOLS MARKET, BY APPLICATION, 2024-2030 (KILOTON)

- TABLE 117 EUROPE: POLYOLS MARKET, BY APPLICATION, 2021-2023 (USD MILLION)

- TABLE 118 EUROPE: POLYOLS MARKET, BY APPLICATION, 2024-2030 (USD MILLION)

- TABLE 119 EUROPE: POLYOLS MARKET, BY END-USE INDUSTRY, 2021-2023 (KILOTON)

- TABLE 120 EUROPE: POLYOLS MARKET, BY END-USE INDUSTRY, 2024-2030 (KILOTON)

- TABLE 121 EUROPE: POLYOLS MARKET, BY END-USE INDUSTRY, 2021-2023 (USD MILLION)

- TABLE 122 EUROPE: POLYOLS MARKET, BY END-USE INDUSTRY, 2024-2030 (USD MILLION)

- TABLE 123 GERMANY: POLYOLS MARKET, BY TYPE, 2021-2023 (KILOTON)

- TABLE 124 GERMANY: POLYOLS MARKET, BY TYPE, 2024-2030 (KILOTON)

- TABLE 125 GERMANY: POLYOLS MARKET, BY TYPE, 2021-2023 (USD MILLION)

- TABLE 126 GERMANY: POLYOLS MARKET, BY TYPE, 2024-2030 (USD MILLION)

- TABLE 127 GERMANY: POLYOLS MARKET, BY APPLICATION, 2021-2023 (KILOTON)

- TABLE 128 GERMANY: POLYOLS MARKET, BY APPLICATION, 2024-2030 (KILOTON)

- TABLE 129 GERMANY: POLYOLS MARKET, BY APPLICATION, 2021-2023 (USD MILLION)

- TABLE 130 GERMANY: POLYOLS MARKET, BY APPLICATION, 2024-2030 (USD MILLION)

- TABLE 131 UK: POLYOLS MARKET, BY TYPE, 2021-2023 (KILOTON)

- TABLE 132 UK: POLYOLS MARKET, BY TYPE, 2024-2030 (KILOTON)

- TABLE 133 UK: POLYOLS MARKET, BY TYPE, 2021-2023 (USD MILLION)

- TABLE 134 UK: POLYOLS MARKET, BY TYPE, 2024-2030 (USD MILLION)

- TABLE 135 UK: POLYOLS MARKET, BY APPLICATION, 2021-2023 (KILOTON)

- TABLE 136 UK: POLYOLS MARKET, BY APPLICATION, 2024-2030 (KILOTON)

- TABLE 137 UK: POLYOLS MARKET, BY APPLICATION, 2021-2023 (USD MILLION)

- TABLE 138 UK: POLYOLS MARKET, BY APPLICATION, 2024-2030 (USD MILLION)

- TABLE 139 FRANCE: POLYOLS MARKET, BY TYPE, 2021-2023 (KILOTON)

- TABLE 140 FRANCE: POLYOLS MARKET, BY TYPE, 2024-2030 (KILOTON)

- TABLE 141 FRANCE: POLYOLS MARKET, BY TYPE, 2021-2023 (USD MILLION)

- TABLE 142 FRANCE: POLYOLS MARKET, BY TYPE, 2024-2030 (USD MILLION)

- TABLE 143 FRANCE: POLYOLS MARKET, BY APPLICATION, 2021-2023 (KILOTON)

- TABLE 144 FRANCE: POLYOLS MARKET, BY APPLICATION, 2024-2030 (KILOTON)

- TABLE 145 FRANCE: POLYOLS MARKET, BY APPLICATION, 2021-2023 (USD MILLION)

- TABLE 146 FRANCE: POLYOLS MARKET, BY APPLICATION, 2024-2030 (USD MILLION)

- TABLE 147 ITALY: POLYOLS MARKET, BY TYPE, 2021-2023 (KILOTON)

- TABLE 148 ITALY: POLYOLS MARKET, BY TYPE, 2024-2030 (KILOTON)

- TABLE 149 ITALY: POLYOLS MARKET, BY TYPE, 2021-2023 (USD MILLION)

- TABLE 150 ITALY: POLYOLS MARKET, BY TYPE, 2024-2030 (USD MILLION)

- TABLE 151 ITALY: POLYOLS MARKET, BY APPLICATION, 2021-2023 (KILOTON)

- TABLE 152 ITALY: POLYOLS MARKET, BY APPLICATION, 2024-2030 (KILOTON)

- TABLE 153 ITALY: POLYOLS MARKET, BY APPLICATION, 2021-2023 (USD MILLION)

- TABLE 154 ITALY: POLYOLS MARKET, BY APPLICATION, 2024-2030 (USD MILLION)

- TABLE 155 RUSSIA: POLYOLS MARKET, BY TYPE, 2021-2023 (KILOTON)

- TABLE 156 RUSSIA: POLYOLS MARKET, BY TYPE, 2024-2030 (KILOTON)

- TABLE 157 RUSSIA: POLYOLS MARKET, BY TYPE, 2021-2023 (USD MILLION)

- TABLE 158 RUSSIA: POLYOLS MARKET, BY TYPE, 2024-2030 (USD MILLION)

- TABLE 159 RUSSIA: POLYOLS MARKET, BY APPLICATION, 2021-2023 (KILOTON)

- TABLE 160 RUSSIA: POLYOLS MARKET, BY APPLICATION, 2024-2030 (KILOTON)

- TABLE 161 RUSSIA: POLYOLS MARKET, BY APPLICATION, 2021-2023 (USD MILLION)

- TABLE 162 RUSSIA: POLYOLS MARKET, BY APPLICATION, 2024-2030 (USD MILLION)

- TABLE 163 TURKEY: POLYOLS MARKET, BY TYPE, 2021-2023 (KILOTON)

- TABLE 164 TURKEY: POLYOLS MARKET, BY TYPE, 2024-2030 (KILOTON)

- TABLE 165 TURKEY: POLYOLS MARKET, BY TYPE, 2021-2023 (USD MILLION)

- TABLE 166 TURKEY: POLYOLS MARKET, BY TYPE, 2024-2030 (USD MILLION)

- TABLE 167 TURKEY: POLYOLS MARKET, BY APPLICATION, 2021-2023 (KILOTON)

- TABLE 168 TURKEY: POLYOLS MARKET, BY APPLICATION, 2024-2030 (KILOTON)

- TABLE 169 TURKEY: POLYOLS MARKET, BY APPLICATION, 2021-2023 (USD MILLION)

- TABLE 170 TURKEY: POLYOLS MARKET, BY APPLICATION, 2024-2030 (USD MILLION)

- TABLE 171 REST OF EUROPE: POLYOLS MARKET, BY TYPE, 2021-2023 (KILOTON)

- TABLE 172 REST OF EUROPE: POLYOLS MARKET, BY TYPE, 2024-2030 (KILOTON)

- TABLE 173 REST OF EUROPE: POLYOLS MARKET, BY TYPE, 2021-2023 (USD MILLION)

- TABLE 174 REST OF EUROPE: POLYOLS MARKET, BY TYPE, 2024-2030 (USD MILLION)

- TABLE 175 REST OF EUROPE: POLYOLS MARKET, BY APPLICATION, 2021-2023 (KILOTON)

- TABLE 176 REST OF EUROPE: POLYOLS MARKET, BY APPLICATION, 2024-2030 (KILOTON)

- TABLE 177 REST OF EUROPE: POLYOLS MARKET, BY APPLICATION, 2021-2023 (USD MILLION)

- TABLE 178 REST OF EUROPE: POLYOLS MARKET, BY APPLICATION, 2024-2030 (USD MILLION)

- TABLE 179 NORTH AMERICA: POLYOLS MARKET, BY COUNTRY, 2021-2023 (KILOTON)

- TABLE 180 NORTH AMERICA: POLYOLS MARKET, BY COUNTRY, 2024-2030 (KILOTON)

- TABLE 181 NORTH AMERICA: POLYOLS MARKET, BY COUNTRY, 2021-2023 (USD MILLION)

- TABLE 182 NORTH AMERICA: POLYOLS MARKET, BY COUNTRY, 2024-2030 (USD MILLION)

- TABLE 183 NORTH AMERICA: POLYOLS MARKET, BY TYPE, 2021-2023 (KILOTON)

- TABLE 184 NORTH AMERICA: POLYOLS MARKET, BY TYPE, 2024-2030 (KILOTON)

- TABLE 185 NORTH AMERICA: POLYOLS MARKET, BY TYPE, 2021-2023 (USD MILLION)

- TABLE 186 NORTH AMERICA: POLYOLS MARKET, BY TYPE, 2024-2030 (USD MILLION)

- TABLE 187 NORTH AMERICA: POLYOLS MARKET, BY APPLICATION, 2021-2023 (KILOTON)

- TABLE 188 NORTH AMERICA: POLYOLS MARKET, BY APPLICATION, 2024-2030 (KILOTON)

- TABLE 189 NORTH AMERICA: POLYOLS MARKET, BY APPLICATION, 2021-2023 (USD MILLION)

- TABLE 190 NORTH AMERICA: POLYOLS MARKET, BY APPLICATION, 2024-2030 (USD MILLION)

- TABLE 191 NORTH AMERICA: POLYOLS MARKET, BY END-USE INDUSTRY, 2021-2023 (KILOTON)

- TABLE 192 NORTH AMERICA: POLYOLS MARKET, BY END-USE INDUSTRY, 2024-2030 (KILOTON)

- TABLE 193 NORTH AMERICA: POLYOLS MARKET, BY END-USE INDUSTRY, 2021-2023 (USD MILLION)

- TABLE 194 NORTH AMERICA: POLYOLS MARKET, BY END-USE INDUSTRY, 2024-2030 (USD MILLION)

- TABLE 195 US: POLYOLS MARKET, BY TYPE, 2021-2023 (KILOTON)

- TABLE 196 US: POLYOLS MARKET, BY TYPE, 2024-2030 (KILOTON)

- TABLE 197 US: POLYOLS MARKET, BY TYPE, 2021-2023 (USD MILLION)

- TABLE 198 US: POLYOLS MARKET, BY TYPE, 2024-2030 (USD MILLION)

- TABLE 199 US: POLYOLS MARKET, BY APPLICATION, 2021-2023 (KILOTON)

- TABLE 200 US: POLYOLS MARKET, BY APPLICATION, 2024-2030 (KILOTON)

- TABLE 201 US: POLYOLS MARKET, BY APPLICATION, 2021-2023 (USD MILLION)

- TABLE 202 US: POLYOLS MARKET, BY APPLICATION, 2024-2030 (USD MILLION)

- TABLE 203 CANADA: POLYOLS MARKET, BY TYPE, 2021-2023 (KILOTON)

- TABLE 204 CANADA: POLYOLS MARKET, BY TYPE, 2024-2030 (KILOTON)

- TABLE 205 CANADA: POLYOLS MARKET, BY TYPE, 2021-2023 (USD MILLION)

- TABLE 206 CANADA: POLYOLS MARKET, BY TYPE, 2024-2030 (USD MILLION)

- TABLE 207 CANADA: POLYOLS MARKET, BY APPLICATION, 2021-2023 (KILOTON)

- TABLE 208 CANADA: POLYOLS MARKET, BY APPLICATION, 2024-2030 (KILOTON)

- TABLE 209 CANADA: POLYOLS MARKET, BY APPLICATION, 2021-2023 (USD MILLION)

- TABLE 210 CANADA: POLYOLS MARKET, BY APPLICATION, 2024-2030 (USD MILLION)

- TABLE 211 MEXICO: POLYOLS MARKET, BY TYPE, 2021-2023 (KILOTON)

- TABLE 212 MEXICO: POLYOLS MARKET, BY TYPE, 2024-2030 (KILOTON)

- TABLE 213 MEXICO: POLYOLS MARKET, BY TYPE, 2021-2023 (USD MILLION)

- TABLE 214 MEXICO: POLYOLS MARKET, BY TYPE, 2024-2030 (USD MILLION)

- TABLE 215 MEXICO: POLYOLS MARKET, BY APPLICATION, 2021-2023 (KILOTON)

- TABLE 216 MEXICO: POLYOLS MARKET, BY APPLICATION, 2024-2030 (KILOTON)

- TABLE 217 MEXICO: POLYOLS MARKET, BY APPLICATION, 2021-2023 (USD MILLION)

- TABLE 218 MEXICO: POLYOLS MARKET, BY APPLICATION, 2024-2030 (USD MILLION)

- TABLE 219 MIDDLE EAST & AFRICA: POLYOLS MARKET, BY COUNTRY, 2021-2023 (KILOTON)

- TABLE 220 MIDDLE EAST & AFRICA: POLYOLS MARKET, BY COUNTRY, 2024-2030 (KILOTON)

- TABLE 221 MIDDLE EAST & AFRICA: POLYOLS MARKET, BY COUNTRY, 2021-2023 (USD MILLION)

- TABLE 222 MIDDLE EAST & AFRICA: POLYOLS MARKET, BY COUNTRY, 2024-2030 (USD MILLION)

- TABLE 223 MIDDLE EAST & AFRICA: POLYOLS MARKET, BY TYPE, 2021-2023 (KILOTON)

- TABLE 224 MIDDLE EAST & AFRICA: POLYOLS MARKET, BY TYPE, 2024-2030 (KILOTON)

- TABLE 225 MIDDLE EAST & AFRICA: POLYOLS MARKET, BY TYPE, 2021-2023 (USD MILLION)

- TABLE 226 MIDDLE EAST & AFRICA: POLYOLS MARKET, BY TYPE, 2024-2030 (USD MILLION)

- TABLE 227 MIDDLE EAST & AFRICA: POLYOLS MARKET, BY APPLICATION, 2021-2023 (KILOTON)

- TABLE 228 MIDDLE EAST & AFRICA: POLYOLS MARKET, BY APPLICATION, 2024-2030 (KILOTON)

- TABLE 229 MIDDLE EAST & AFRICA: POLYOLS MARKET, BY APPLICATION, 2021-2023 (USD MILLION)

- TABLE 230 MIDDLE EAST & AFRICA: POLYOLS MARKET, BY APPLICATION, 2024-2030 (USD MILLION)

- TABLE 231 MIDDLE EAST & AFRICA: POLYOLS MARKET, BY END-USE INDUSTRY, 2021-2023 (KILOTON)

- TABLE 232 MIDDLE EAST & AFRICA: POLYOLS MARKET, BY END-USE INDUSTRY, 2024-2030 (KILOTON)

- TABLE 233 MIDDLE EAST & AFRICA: POLYOLS MARKET, BY END-USE INDUSTRY, 2021-2023 (USD MILLION)

- TABLE 234 MIDDLE EAST & AFRICA: POLYOLS MARKET, BY END-USE INDUSTRY, 2024-2030 (USD MILLION)

- TABLE 235 GCC COUNTRIES: POLYOLS MARKET, BY TYPE, 2021-2023 (KILOTON)

- TABLE 236 GCC COUNTRIES: POLYOLS MARKET, BY TYPE, 2024-2030 (KILOTON)

- TABLE 237 GCC COUNTRIES: POLYOLS MARKET, BY TYPE, 2021-2023 (USD MILLION)

- TABLE 238 GCC COUNTRIES: POLYOLS MARKET, BY TYPE, 2024-2030 (USD MILLION)

- TABLE 239 GCC COUNTRIES: POLYOLS MARKET, BY APPLICATION, 2021-2023 (KILOTON)

- TABLE 240 GCC COUNTRIES: POLYOLS MARKET, BY APPLICATION, 2024-2030 (KILOTON)

- TABLE 241 GCC COUNTRIES: POLYOLS MARKET, BY APPLICATION, 2021-2023 (USD MILLION)

- TABLE 242 GCC COUNTRIES: POLYOLS MARKET, BY APPLICATION, 2024-2030 (USD MILLION)

- TABLE 243 SAUDI ARABIA: POLYOLS MARKET, BY TYPE, 2021-2023 (KILOTON)

- TABLE 244 SAUDI ARABIA: POLYOLS MARKET, BY TYPE, 2024-2030 (KILOTON)

- TABLE 245 SAUDI ARABIA: POLYOLS MARKET, BY TYPE, 2021-2023 (USD MILLION)

- TABLE 246 SAUDI ARABIA: POLYOLS MARKET, BY TYPE, 2024-2030 (USD MILLION)

- TABLE 247 SAUDI ARABIA: POLYOLS MARKET, BY APPLICATION, 2021-2023 (KILOTON)

- TABLE 248 SAUDI ARABIA: POLYOLS MARKET, BY APPLICATION, 2024-2030 (KILOTON)

- TABLE 249 SAUDI ARABIA: POLYOLS MARKET, BY APPLICATION, 2021-2023 (USD MILLION)

- TABLE 250 SAUDI ARABIA: POLYOLS MARKET, BY APPLICATION, 2024-2030 (USD MILLION)

- TABLE 251 UAE: POLYOLS MARKET, BY TYPE, 2021-2023 (KILOTON)

- TABLE 252 UAE: POLYOLS MARKET, BY TYPE, 2024-2030 (KILOTON)

- TABLE 253 UAE: POLYOLS MARKET, BY TYPE, 2021-2023 (USD MILLION)

- TABLE 254 UAE: POLYOLS MARKET, BY TYPE, 2024-2030 (USD MILLION)

- TABLE 255 UAE: POLYOLS MARKET, BY APPLICATION, 2021-2023 (KILOTON)

- TABLE 256 UAE: POLYOLS MARKET, BY APPLICATION, 2024-2030 (KILOTON)

- TABLE 257 UAE: POLYOLS MARKET, BY APPLICATION, 2021-2023 (USD MILLION)

- TABLE 258 UAE: POLYOLS MARKET, BY APPLICATION, 2024-2030 (USD MILLION)

- TABLE 259 REST OF GCC COUNTRIES: POLYOLS MARKET, BY TYPE, 2021-2023 (KILOTON)

- TABLE 260 REST OF GCC COUNTRIES: POLYOLS MARKET, BY TYPE, 2024-2030 (KILOTON)

- TABLE 261 REST OF GCC COUNTRIES: POLYOLS MARKET, BY TYPE, 2021-2023 (USD MILLION)

- TABLE 262 REST OF GCC COUNTRIES: POLYOLS MARKET, BY TYPE, 2024-2030 (USD MILLION)

- TABLE 263 REST OF GCC COUNTRIES: POLYOLS MARKET, BY APPLICATION, 2021-2023 (KILOTON)

- TABLE 264 REST OF GCC COUNTRIES: POLYOLS MARKET, BY APPLICATION, 2024-2030 (KILOTON)

- TABLE 265 REST OF GCC COUNTRIES: POLYOLS MARKET, BY APPLICATION, 2021-2023 (USD MILLION)

- TABLE 266 REST OF GCC COUNTRIES: POLYOLS MARKET, BY APPLICATION, 2024-2030 (USD MILLION)

- TABLE 267 SOUTH AFRICA: POLYOLS MARKET, BY TYPE, 2021-2023 (KILOTON)

- TABLE 268 SOUTH AFRICA: POLYOLS MARKET, BY TYPE, 2024-2030 (KILOTON)

- TABLE 269 SOUTH AFRICA: POLYOLS MARKET, BY TYPE, 2021-2023 (USD MILLION)

- TABLE 270 SOUTH AFRICA: POLYOLS MARKET, BY TYPE, 2024-2030 (USD MILLION)

- TABLE 271 SOUTH AFRICA: POLYOLS MARKET, BY APPLICATION, 2021-2023 (KILOTON)

- TABLE 272 SOUTH AFRICA: POLYOLS MARKET, BY APPLICATION, 2024-2030 (KILOTON)

- TABLE 273 SOUTH AFRICA: POLYOLS MARKET, BY APPLICATION, 2021-2023 (USD MILLION)

- TABLE 274 SOUTH AFRICA: POLYOLS MARKET, BY APPLICATION, 2024-2030 (USD MILLION)

- TABLE 275 REST OF MIDDLE EAST & AFRICA: POLYOLS MARKET, BY TYPE, 2021-2023 (KILOTON)

- TABLE 276 REST OF MIDDLE EAST & AFRICA: POLYOLS MARKET, BY TYPE, 2024-2030 (KILOTON)

- TABLE 277 REST OF MIDDLE EAST & AFRICA: POLYOLS MARKET, BY TYPE, 2021-2023 (USD MILLION)

- TABLE 278 REST OF MIDDLE EAST & AFRICA: POLYOLS MARKET, BY TYPE, 2024-2030 (USD MILLION)

- TABLE 279 REST OF MIDDLE EAST & AFRICA: POLYOLS MARKET, BY APPLICATION, 2021-2023 (KILOTON)

- TABLE 280 REST OF MIDDLE EAST & AFRICA: POLYOLS MARKET, BY APPLICATION, 2024-2030 (KILOTON)

- TABLE 281 REST OF MIDDLE EAST & AFRICA: POLYOLS MARKET, BY APPLICATION, 2021-2023 (USD MILLION)

- TABLE 282 REST OF MIDDLE EAST & AFRICA: POLYOLS MARKET, BY APPLICATION, 2024-2030 (USD MILLION)

- TABLE 283 SOUTH AMERICA: POLYOLS MARKET, BY COUNTRY, 2021-2023 (KILOTON)

- TABLE 284 SOUTH AMERICA: POLYOLS MARKET, BY COUNTRY, 2024-2030 (KILOTON)

- TABLE 285 SOUTH AMERICA: POLYOLS MARKET, BY COUNTRY, 2021-2023 (USD MILLION)

- TABLE 286 SOUTH AMERICA: POLYOLS MARKET, BY COUNTRY, 2024-2030 (USD MILLION)

- TABLE 287 SOUTH AMERICA: POLYOLS MARKET, BY TYPE, 2021-2023 (KILOTON)

- TABLE 288 SOUTH AMERICA: POLYOLS MARKET, BY TYPE, 2024-2030 (KILOTON)

- TABLE 289 SOUTH AMERICA: POLYOLS MARKET, BY TYPE, 2021-2023 (USD MILLION)

- TABLE 290 SOUTH AMERICA: POLYOLS MARKET, BY TYPE, 2024-2030 (USD MILLION)

- TABLE 291 SOUTH AMERICA: POLYOLS MARKET, BY APPLICATION, 2021-2023 (KILOTON)

- TABLE 292 SOUTH AMERICA: POLYOLS MARKET, BY APPLICATION, 2024-2030 (KILOTON)

- TABLE 293 SOUTH AMERICA: POLYOLS MARKET, BY APPLICATION, 2021-2023 (USD MILLION)

- TABLE 294 SOUTH AMERICA: POLYOLS MARKET, BY APPLICATION, 2024-2030 (USD MILLION)

- TABLE 295 SOUTH AMERICA: POLYOLS MARKET, BY END-USE INDUSTRY, 2021-2023 (KILOTON)

- TABLE 296 SOUTH AMERICA: POLYOLS MARKET, BY END-USE INDUSTRY, 2024-2030 (KILO TON)

- TABLE 297 SOUTH AMERICA: POLYOLS MARKET, BY END-USE INDUSTRY, 2021-2023 (USD MILLION)

- TABLE 298 SOUTH AMERICA: POLYOLS MARKET, BY END-USE INDUSTRY, 2024-2030 (USD MILLION)

- TABLE 299 BRAZIL: POLYOLS MARKET, BY TYPE, 2021-2023 (KILOTON)

- TABLE 300 BRAZIL: POLYOLS MARKET, BY TYPE, 2024-2030 (KILOTON)

- TABLE 301 BRAZIL: POLYOLS MARKET, BY TYPE, 2021-2023 (USD MILLION)

- TABLE 302 BRAZIL: POLYOLS MARKET, BY TYPE, 2024-2030 (USD MILLION)

- TABLE 303 BRAZIL: POLYOLS MARKET, BY APPLICATION, 2021-2023 (KILOTON)

- TABLE 304 BRAZIL: POLYOLS MARKET, BY APPLICATION, 2024-2030 (KILOTON)

- TABLE 305 BRAZIL: POLYOLS MARKET, BY APPLICATION, 2021-2023 (USD MILLION)

- TABLE 306 BRAZIL: POLYOLS MARKET, BY APPLICATION, 2024-2030 (USD MILLION)

- TABLE 307 ARGENTINA: POLYOLS MARKET, BY TYPE, 2021-2023 (KILOTON)

- TABLE 308 ARGENTINA: POLYOLS MARKET, BY TYPE, 2024-2030 (KILOTON)

- TABLE 309 ARGENTINA: POLYOLS MARKET, BY TYPE, 2021-2023 (USD MILLION)

- TABLE 310 ARGENTINA: POLYOLS MARKET, BY TYPE, 2024-2030 (USD MILLION)

- TABLE 311 ARGENTINA: POLYOLS MARKET, BY APPLICATION, 2021-2023 (KILOTON)

- TABLE 312 ARGENTINA: POLYOLS MARKET, BY APPLICATION, 2024-2030 (KILOTON)

- TABLE 313 ARGENTINA: POLYOLS MARKET, BY APPLICATION, 2021-2023 (USD MILLION)

- TABLE 314 ARGENTINA: POLYOLS MARKET, BY APPLICATION, 2024-2030 (USD MILLION)

- TABLE 315 REST OF SOUTH AMERICA: POLYOLS MARKET, BY TYPE, 2021-2023 (KILOTON)

- TABLE 316 REST OF SOUTH AMERICA: POLYOLS MARKET, BY TYPE, 2024-2030 (KILOTON)

- TABLE 317 REST OF SOUTH AMERICA: POLYOLS MARKET, BY TYPE, 2021-2023 (USD MILLION)

- TABLE 318 REST OF SOUTH AMERICA: POLYOLS MARKET, BY TYPE, 2024-2030 (USD MILLION)

- TABLE 319 REST OF SOUTH AMERICA: POLYOLS MARKET, BY APPLICATION, 2021-2023 (KILOTON)

- TABLE 320 REST OF SOUTH AMERICA: POLYOLS MARKET, BY APPLICATION, 2024-2030 (KILOTON)

- TABLE 321 REST OF SOUTH AMERICA: POLYOLS MARKET, BY APPLICATION, 2021-2023 (USD MILLION)

- TABLE 322 REST OF SOUTH AMERICA: POLYOLS MARKET, BY APPLICATION, 2024-2030 (USD MILLION)

- TABLE 323 POLYOLS MARKET: OVERVIEW OF STRATEGIES ADOPTED BY MARKET PLAYERS, JANUARY 2021-JUNE 2025

- TABLE 324 POLYOLS MARKET: DEGREE OF COMPETITION, 2024

- TABLE 325 POLYOLS MARKET: REGION FOOTPRINT

- TABLE 326 POLYOLS MARKET: TYPE FOOTPRINT

- TABLE 327 POLYOLS MARKET: APPLICATION FOOTPRINT

- TABLE 328 POLYOLS MARKET: END-USE INDUSTRY FOOTPRINT

- TABLE 329 POLYOLS MARKET: DETAILED LIST OF KEY STARTUPS/SMES

- TABLE 330 POLYOLS MARKET: COMPETITIVE BENCHMARKING OF KEY STARTUPS/SMES (1/2)

- TABLE 331 POLYOLS MARKET: COMPETITIVE BENCHMARKING OF KEY STARTUPS/SMES (2/2)

- TABLE 332 POLYOLS MARKET: PRODUCT LAUNCHES, JANUARY 2021-MAY 2025

- TABLE 333 POLYOLS MARKET: DEALS, JANUARY 2021-MAY 2025

- TABLE 334 POLYOLS MARKET: EXPANSIONS, JANUARY 2021-MAY 2025

- TABLE 335 DOW: COMPANY OVERVIEW

- TABLE 336 DOW: PRODUCTS/SOLUTIONS/SERVICES OFFERED

- TABLE 337 DOW: PRODUCTS LAUNCHES

- TABLE 338 DOW: EXPANSIONS

- TABLE 339 DOW: OTHERS

- TABLE 340 COVESTRO AG: COMPANY OVERVIEW

- TABLE 341 COVESTRO AG: PRODUCTS/SOLUTIONS/SERVICES OFFERED

- TABLE 342 COVESTRO AG: PRODUCT LAUNCHES

- TABLE 343 COVESTRO AG: DEALS

- TABLE 344 COVESTRO AG: OTHERS

- TABLE 345 BASF SE: COMPANY OVERVIEW

- TABLE 346 BASF SE: PRODUCTS/SOLUTIONS/SERVICES OFFERED

- TABLE 347 BASF SE: PRODUCT LAUNCHES

- TABLE 348 BASF SE: DEALS

- TABLE 349 BASF SE: EXPANSIONS

- TABLE 350 HUNTSMAN INTERNATIONAL LLC: COMPANY OVERVIEW

- TABLE 351 HUNTSMAN INTERNATIONAL LLC: PRODUCTS/SOLUTIONS/SERVICES OFFERED

- TABLE 352 HUNTSMAN INTERNATIONAL LLC: DEALS

- TABLE 353 HUNTSMAN INTERNATIONAL LLC: EXPANSIONS

- TABLE 354 SHELL: COMPANY OVERVIEW

- TABLE 355 SHELL: PRODUCTS/SOLUTIONS/SERVICES OFFERED

- TABLE 356 SHELL: DEALS

- TABLE 357 SHELL: EXPANSIONS

- TABLE 358 STEPAN COMPANY: COMPANY OVERVIEW

- TABLE 359 STEPAN COMPANY: PRODUCTS/SOLUTIONS/SERVICES OFFERED

- TABLE 360 STEPAN COMPANY: PRODUCT LAUNCHES

- TABLE 361 STEPAN COMPANY: DEALS

- TABLE 362 STEPAN COMPANY: EXPANSIONS

- TABLE 363 WANHUA CHEMICAL GROUP: COMPANY OVERVIEW

- TABLE 364 WANHUA CHEMICAL GROUP: PRODUCTS/SOLUTIONS/SERVICES OFFERED

- TABLE 365 WANHUA CHEMICAL GROUP: PRODUCT LAUNCHES

- TABLE 366 WANHUA CHEMICAL GROUP: DEALS

- TABLE 367 WANHUA CHEMICAL GROUP: EXPANSIONS

- TABLE 368 REPSOL S.A.: COMPANY OVERVIEW

- TABLE 369 REPSOL S.A.: PRODUCTS/SOLUTIONS/SERVICES OFFERED

- TABLE 370 REPSOL S.A.: PRODUCT LAUNCHES

- TABLE 371 REPSOL S.A.: DEALS

- TABLE 372 REPSOL S.A.: EXPANSIONS

- TABLE 373 PCC SE: COMPANY OVERVIEW

- TABLE 374 PCC SE: PRODUCTS/SOLUTIONS/SERVICES OFFERED

- TABLE 375 PCC SE: PRODUCT LAUNCHES

- TABLE 376 PCC SE: DEALS

- TABLE 377 PCC SE: EXPANSIONS

- TABLE 378 LANXESS: COMPANY OVERVIEW

- TABLE 379 LANXESS: PRODUCTS/SOLUTIONS/SERVICES OFFERED

- TABLE 380 LANXESS: PRODUCT LAUNCHES

- TABLE 381 PCC SE: EXPANSIONS

- TABLE 382 LANXESS: OTHERS

- TABLE 383 ZIBO DEXIN LIANBANG CHEMICAL INDUSTRY CO., LTD.: COMPANY OVERVIEW

- TABLE 384 SHANDONG LONGHUA NEW MATERIAL CO., LTD: COMPANY OVERVIEW

- TABLE 385 ZHEJIANG HUAFON NEW MATERIALS CORP., LTD.: COMPANY OVERVIEW

- TABLE 386 SHAKUN INDUSTRIES: COMPANY OVERVIEW

- TABLE 387 INTERPUR CHEMICALS: COMPANY OVERVIEW

- TABLE 388 MANALI PETROCHEMICALS LIMITED: COMPANY OVERVIEW

- TABLE 389 POLYOLS & POLYMERS PVT LTD: COMPANY OVERVIEW

- TABLE 390 KURARAY CO., LTD.: COMPANY OVERVIEW

- TABLE 391 SUMITOMO BAKELITE HIGH PERFORMANCE PLASTICS (SBHPP): COMPANY OVERVIEW

- TABLE 392 ERCA ADVANCED POLYMER SOLUTIONS: COMPANY OVERVIEW

- TABLE 393 SINOCHEM HOLDINGS CORPORATION LTD.: COMPANY OVERVIEW

- TABLE 394 DAICEL CORPORATION: COMPANY OVERVIEW

- TABLE 395 EMERY OLEOCHEMICALS LLC: COMPANY OVERVIEW

- TABLE 396 SOLVAY: COMPANY OVERVIEW

- TABLE 397 PERSTORP: COMPANY OVERVIEW

- TABLE 398 ARAMCO: COMPANY OVERVIEW

- TABLE 399 TOSOH CORPORATION: COMPANY OVERVIEW

- TABLE 400 ARKEMA: COMPANY OVERVIEW

- TABLE 401 PLUSKIM: COMPANY OVERVIEW

- TABLE 402 PURINOVA SP. Z O.O.: COMPANY OVERVIEW

- TABLE 403 PTT GLOBAL CHEMICAL PUBLIC COMPANY LIMITED: COMPANY OVERVIEW

- TABLE 404 POLYURETHANE FOAM MARKET, BY TYPE, 2018-2022 (KILOTON)

- TABLE 405 POLYURETHANE FOAM MARKET, BY TYPE, 2023-2028 (KILOTON)

- TABLE 406 POLYURETHANE FOAM MARKET, BY TYPE, 2018-2022 (USD MILLION)

- TABLE 407 POLYURETHANE FOAM MARKET, BY TYPE, 2023-2028 (USD MILLION)

- TABLE 408 POLYURETHANE FOAM MARKET, BY END-USE INDUSTRY, 2018-2022 (KILOTON)

- TABLE 409 POLYURETHANE FOAM MARKET, BY END-USE INDUSTRY, 2023-2028 (KILOTON)

- TABLE 410 POLYURETHANE FOAM MARKET, BY END-USE INDUSTRY, 2018-2022 (USD MILLION)

- TABLE 411 POLYURETHANE FOAM MARKET, BY END-USE INDUSTRY, 2023-2028 (USD MILLION)

- TABLE 412 POLYURETHANE FOAM MARKET, BY REGION, 2018-2022 (KILOTON)

- TABLE 413 POLYURETHANE FOAM MARKET, BY REGION, 2023-2028 (KILOTON)

- TABLE 414 POLYURETHANE FOAM MARKET, BY REGION, 2018-2022 (USD MILLION)

- TABLE 415 POLYURETHANE FOAM MARKET, BY REGION, 2023-2028 (USD MILLION)

List of Figures

- FIGURE 1 POLYOLS MARKET: SEGMENTATION AND REGIONAL SCOPE

- FIGURE 2 POLYOLS MARKET: RESEARCH DESIGN

- FIGURE 3 MARKET SIZE ESTIMATION: TOP-DOWN APPROACH

- FIGURE 4 MARKET SIZE ESTIMATION: BOTTOM-UP APPROACH

- FIGURE 5 POLYOLS MARKET: SUPPLY SIDE

- FIGURE 6 POLYOLS MARKET: DATA TRIANGULATION

- FIGURE 7 POLYETHER POLYOLS SEGMENT TO DOMINATE MARKET DURING FORECAST PERIOD

- FIGURE 8 FLEXIBLE POLYURETHANE FOAM SEGMENT TO DOMINATE MARKET DURING FORECAST PERIOD

- FIGURE 9 BUILDING & CONSTRUCTION SEGMENT TO DOMINATE MARKET DURING FORECAST PERIOD

- FIGURE 10 ASIA PACIFIC TO DOMINATE POLYOLS MARKET DURING FORECAST PERIOD

- FIGURE 11 GROWING ADOPTION OF BIO-BASED AND HIGH-PURITY POLYOLS IN MEDICAL-GRADE APPLICATIONS TO CREATE LUCRATIVE OPPORTUNITIES FOR MARKET PLAYERS

- FIGURE 12 POLYETHER POLYOLS SEGMENT TO LEAD MARKET DURING FORECAST PERIOD

- FIGURE 13 FLEXIBLE POLYURETHANE FOAM SEGMENT TO ACCOUNT FOR LARGEST MARKET SHARE IN 2030

- FIGURE 14 BUILDING & CONSTRUCTION SEGMENT TO ACCOUNT FOR LARGEST MARKET SHARE IN 2030

- FIGURE 15 POLYETHER POLYOLS SEGMENT AND CHINA ACCOUNTED FOR LARGEST SHARES OF ASIA PACIFIC POLYOLS MARKET IN 2024

- FIGURE 16 INDIA TO RECORD HIGHEST CAGR DURING FORECAST PERIOD

- FIGURE 17 POLYOLS MARKET: DRIVERS, RESTRAINTS, OPPORTUNITIES, AND CHALLENGES

- FIGURE 18 ESTIMATED GLOBAL RETAIL E-COMMERCE GROWTH, 2023-2027 (%)

- FIGURE 19 TRENDS/DISRUPTIONS IMPACTING CUSTOMER BUSINESS

- FIGURE 20 AVERAGE SELLING PRICE TREND OF POLYOLS OFFERED BY KEY PLAYERS, BY TYPE, 2024 (USD/KG)

- FIGURE 21 AVERAGE SELLING PRICE TREND OF POLYOLS, BY REGION, 2021-2024 (USD/KG)

- FIGURE 22 POLYOLS MARKET: VALUE CHAIN ANALYSIS

- FIGURE 23 POLYOLS MARKET: ECOSYSTEM ANALYSIS

- FIGURE 24 LIST OF MAJOR PATENTS RELATED TO POLYOLS, 2014-2024

- FIGURE 25 REGIONAL ANALYSIS OF PATENTS GRANTED FOR POLYOLS, 2014-2024

- FIGURE 26 IMPORT DATA RELATED TO HS CODE 390950-COMPLIANT PRODUCTS (POLYURETHANE), BY KEY COUNTRY, 2020-2024 (USD THOUSAND)

- FIGURE 27 EXPORT DATA RELATED TO HS CODE 390950-COMPLIANT PRODUCTS (POLYURETHANE), BY KEY COUNTRY, 2020-2024 (USD THOUSAND)

- FIGURE 28 POLYOLS MARKET: PORTER'S FIVE FORCES ANALYSIS

- FIGURE 29 INFLUENCE OF STAKEHOLDERS ON BUYING PROCESS, BY END-USE INDUSTRY

- FIGURE 30 KEY BUYING CRITERIA, BY END-USE INDUSTRY

- FIGURE 31 ANNUAL PERCENTAGE GROWTH OF GLOBAL CONSTRUCTION INDUSTRY, 2018-2024

- FIGURE 32 GLOBAL ELECTRIC CAR SALES, 2018-2024 (MILLION UNITS)

- FIGURE 33 INVESTOR DEAL AND FUNDING TREND, 2020-2024 (USD MILLION)

- FIGURE 34 POLYETHER POLYOLS SEGMENT TO HOLD LARGER MARKET SHARE IN 2025

- FIGURE 35 FLEXIBLE POLYURETHANE FOAM SEGMENT TO HOLD LARGEST MARKET SHARE IN 2025

- FIGURE 36 BUILDING & CONSTRUCTION SEGMENT TO HOLD LARGEST MARKET SHARE IN 2025

- FIGURE 37 ASIA PACIFIC TO BE FASTEST-GROWING MARKET FOR POLYOLS DURING FORECAST PERIOD

- FIGURE 38 ASIA PACIFIC: POLYOLS MARKET SNAPSHOT

- FIGURE 39 EUROPE: POLYOLS MARKET SNAPSHOT

- FIGURE 40 POLYOLS MARKET: REVENUE ANALYSIS OF KEY PLAYERS, 2020-2024 (USD BILLION)

- FIGURE 41 POLYOLS MARKET SHARE ANALYSIS, 2024

- FIGURE 42 POLYOLS MARKET: COMPANY VALUATION, 2024 (USD BILLION)

- FIGURE 43 POLYOLS MARKET: FINANCIAL MATRIX (EV/EBITDA RATIO), 2025

- FIGURE 44 POLYOLS MARKET: YEAR-TO-DATE PRICE AND FIVE-YEAR STOCK BETA, 2020-2025

- FIGURE 45 POLYOLS MARKET: BRAND/PRODUCT COMPARISON

- FIGURE 46 POLYOLS MARKET: COMPANY EVALUATION MATRIX (KEY PLAYERS), 2024

- FIGURE 47 POLYOLS MARKET: COMPANY FOOTPRINT

- FIGURE 48 POLYOLS MARKET: COMPANY EVALUATION MATRIX (STARTUPS/SMES), 2024

- FIGURE 49 DOW: COMPANY SNAPSHOT

- FIGURE 50 COVESTRO AG: COMPANY SNAPSHOT

- FIGURE 51 BASF SE: COMPANY SNAPSHOT

- FIGURE 52 HUNTSMAN INTERNATIONAL LLC: COMPANY SNAPSHOT

- FIGURE 53 SHELL: COMPANY SNAPSHOT

- FIGURE 54 STEPAN COMPANY: COMPANY SNAPSHOT

- FIGURE 55 WANHUA CHEMICAL GROUP: COMPANY SNAPSHOT

- FIGURE 56 REPSOL S.A.: COMPANY SNAPSHOT

- FIGURE 57 PCC SE: COMPANY SNAPSHOT

- FIGURE 58 LANXESS: COMPANY SNAPSHOT