|

市場調查報告書

商品編碼

1876531

汽車數位孿生硬體市場機會、成長促進因素、產業趨勢分析及預測(2025-2034年)Automotive Digital Twin Hardware Market Opportunity, Growth Drivers, Industry Trend Analysis, and Forecast 2025 - 2034 |

||||||

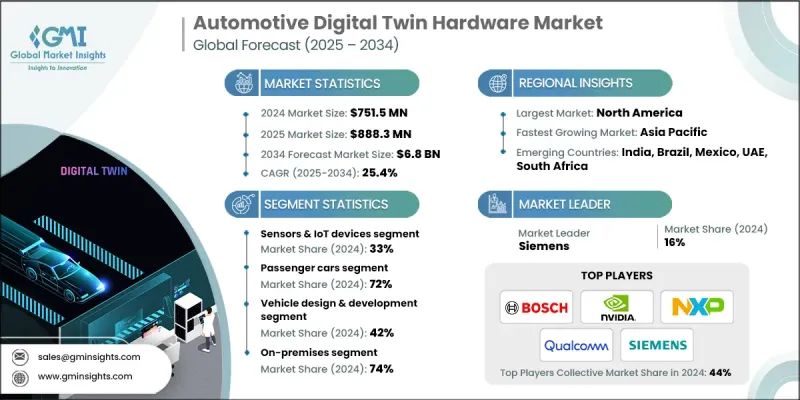

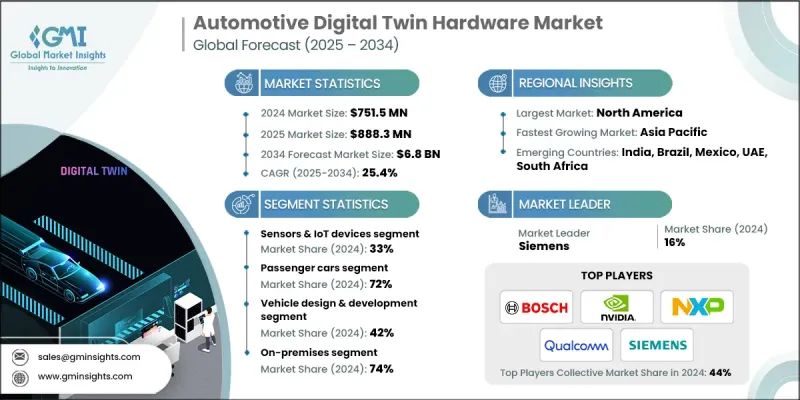

2024 年全球汽車數位孿生硬體市場價值為 7.515 億美元,預計到 2034 年將以 25.4% 的複合年成長率成長至 68 億美元。

隨著汽車原始設備製造商 (OEM) 和一級供應商採用包括高效能運算 (HPC) 單元、感測器、GPU 和邊緣伺服器在內的先進系統,對數位孿生硬體的需求正在加速成長。這些硬體組件能夠在虛擬環境中模擬真實車輛的行為,使製造商能夠分析生產結果、簡化組裝流程並提高資源利用率。數位孿生平台也能讓工程師在將組裝工作流程部署到生產線之前,對其進行虛擬測試和驗證,從而提高工作效率。物聯網/工業物聯網 (IoT/IIoT)、人工智慧和工業 4.0 技術的日益普及正在改變汽車製造業,推動了對強大的數位孿生硬體解決方案的需求。隨著車輛發展成為能夠產生海量感測器資料的軟體定義系統,數位孿生硬體能夠促進即時資料處理、預測分析和營運最佳化。隨著工業 4.0 計畫強調自動化、精準化和預測性維護,物聯網感測器、邊緣運算設備和工業控制器在汽車工廠中的整合不斷成長,從而對能夠模擬和處理即時工廠資料的強大運算基礎設施產生了強勁的需求。

| 市場範圍 | |

|---|---|

| 起始年份 | 2024 |

| 預測年份 | 2025-2034 |

| 起始值 | 7.515億美元 |

| 預測值 | 68億美元 |

| 複合年成長率 | 25.4% |

2024年,感測器和物聯網設備細分市場佔據33%的市場佔有率,預計2025年至2034年將以25.5%的複合年成長率成長。該細分市場在採集溫度、振動和壓力等即時指標方面發揮著至關重要的作用,從而能夠模擬汽車資產的物理性能。隨著自動駕駛技術的日益普及,包括LiDAR、雷達和微機電系統(MEMS)組件在內的先進感測器的應用正在加速,從而支持更強大的預測建模和故障診斷能力。

2024年,乘用車市佔率達72%,預計2025年至2034年間將以25.7%的複合年成長率成長。這一主導地位歸功於系統互聯性的提升、電氣化趨勢以及駕駛輔助系統的進步。汽車製造商正在部署GPU、物聯網感測器和邊緣運算系統,以進行即時車輛仿真,從而提高設計精度和生產效率。向軟體定義汽車的轉型日益增強,也進一步凸顯了對數位孿生技術的需求,這些技術能夠支援預測性維護、虛擬驗證和空中軟體更新。

預計到2024年,北美汽車數位孿生硬體市場將佔據34%的佔有率。該地區的成長主要得益於互聯、自動駕駛和電動車技術的廣泛應用。汽車原始設備製造商(OEM)和零件供應商正大力投資於GPU加速運算、低延遲邊緣硬體和物聯網感測器網路,以實現數位化工廠環境和即時模擬。人工智慧加速處理器和模組化硬體系統的快速發展,進一步提升了整個區域汽車生態系統的設計精度、營運效率和生產可靠性。

全球汽車數位孿生硬體市場的主要參與者包括博世、大陸集團、通用電氣、IBM、Molex、英偉達、恩智浦半導體、PTC、高通和西門子。這些領先企業正致力於透過多項策略措施拓展其全球業務。他們大力投資研發,開發可擴展的高效能運算平台,並整合人工智慧驅動的模擬工具,以提供即時分析和預測性洞察。與汽車製造商和技術供應商的策略合作與夥伴關係,幫助他們共同開發客製化的數位孿生解決方案,以最佳化生產和設計。此外,各公司也著重提升製造能力和區域分銷網路,以強化其供應鏈。

目錄

第1章:方法論

- 市場範圍和定義

- 研究設計

- 研究方法

- 資料收集方法

- 資料探勘來源

- 全球的

- 地區/國家

- 基準估算和計算

- 基準年計算

- 市場估算的關鍵趨勢

- 初步研究和驗證

- 原始資料

- 預測模型

- 研究假設和局限性

第2章:執行概要

第3章:行業洞察

- 產業生態系分析

- 供應商格局

- 利潤率分析

- 成本結構

- 每個階段的價值增加

- 影響價值鏈的因素

- 中斷

- 產業影響因素

- 成長促進因素

- 高效能運算 (HPC) 和 GPU 硬體的整合

- 邊緣運算和物聯網/工業物聯網設備的採用

- 人工智慧和機器學習硬體的進步

- 自動駕駛和連網汽車研發的擴展

- 工業4.0和智慧製造的採用

- 產業陷阱與挑戰

- 高昂的硬體和基礎設施成本

- 異質系統間的資料互通性

- 市場機遇

- AI加速仿真硬體

- 邊緣運算和雲端運算基礎設施的整合

- 電動車和電池系統中數位孿生硬體的擴展

- 採用 5G 和超低延遲網路

- 成長促進因素

- 成長潛力分析

- 監管環境

- 聯邦監管環境

- 國際標準(ISO、SAE)

- 網路安全要求

- 安全和合規標準

- 資料隱私法規

- 環境標準

- 區域監管差異

- 波特的分析

- PESTEL 分析

- 技術與創新格局

- 人工智慧整合

- 合成資料和模擬

- 量子計算應用

- 先進的安全技術

- 邊緣運算演進

- 5G及未來連接

- 永續性技術

- 價格趨勢分析

- 總擁有成本 (TCO) 分析

- 硬體購置成本

- 實施和整合成本

- 營運和維護成本

- 培訓和支援費用

- 專利分析

- 依技術領域分析專利組合

- 專利申請趨勢與創新活動

- 競爭性專利情報

- 永續性和環境方面

- 永續實踐

- 減少廢棄物策略

- 生產中的能源效率

- 環保舉措

- 碳足跡考量

- 客戶旅程圖

- 意識和發現階段

- 評估和甄選階段

- 實施和整合階段

- 運行和最佳化階段

- 投資報酬率(ROI)框架

- 投資報酬率計算方法

- 投資回收期分析

- 淨現值(NPV)模型

- 風險調整後收益

- 投資和融資分析

- 創投趨勢

- 策略性企業投資

- 政府資助計劃

- 併購活動和估值

- IPO市場動態

- 私募股權參與

第4章:競爭格局

- 介紹

- 公司市佔率分析

- 北美洲

- 歐洲

- 亞太地區

- 拉丁美洲

- MEA

- 主要市場參與者的競爭分析

- 競爭定位矩陣

- 戰略展望矩陣

- 關鍵進展

- 併購

- 合作夥伴關係與合作

- 新產品發布

- 擴張計劃和資金

第5章:市場估算與預測:依組件分類,2021-2034年

- 主要趨勢

- 感測器和物聯網設備

- 邊緣運算設備

- 連接和網路硬體

- 執行器和控制系統

- 高效能運算/仿真硬體

第6章:市場估價與預測:依車輛類型分類,2021-2034年

- 主要趨勢

- 搭乘用車

- 掀背車

- 轎車

- SUV

- 商用車輛

- 輕型商用車(LCV)

- 中型商用車(MCV)

- 重型商用車(HCV)

- 電動車(EV)

第7章:市場估計與預測:依應用領域分類,2021-2034年

- 主要趨勢

- 車輛設計與開發

- 製造與生產最佳化

- 預測性維護

- 自動駕駛汽車測試

- 供應鍊和車隊管理

第8章:市場估算與預測:依部署模式分類,2021-2034年

- 主要趨勢

- 雲

- 現場

- 混合

第9章:市場估計與預測:依地區分類,2021-2034年

- 主要趨勢

- 北美洲

- 美國

- 加拿大

- 歐洲

- 英國

- 德國

- 法國

- 義大利

- 西班牙

- 俄羅斯

- 北歐

- 亞太地區

- 中國

- 印度

- 日本

- 韓國

- 澳新銀行

- 東南亞

- 拉丁美洲

- 巴西

- 墨西哥

- 阿根廷

- MEA

- 南非

- 沙烏地阿拉伯

- 阿拉伯聯合大公國

第10章:公司簡介

- 全球參與者

- Siemens

- DSpace

- NVIDIA

- PTC

- IBM

- Bosch

- Intel

- NXP Semiconductors

- General Electric

- 區域玩家

- Keysight Technologies

- Altair Engineering

- ETAS

- Vector Informatik

- National Instruments

- Ansys

- Qualcomm

- Continental

- Molex

- 新興參與者

- Threedy

- Neural Concept

- Applied Intuition

- Cognata

- Luminar Technologies

- Mobileye Global

The Global Automotive Digital Twin Hardware Market was valued at USD 751.5 million in 2024 and is estimated to grow at a CAGR of 25.4% to reach USD 6.8 billion by 2034.

The demand for digital twin hardware is accelerating as automotive OEMs and Tier-1 suppliers embrace advanced systems, including high-performance computing (HPC) units, sensors, GPUs, and edge servers. These hardware components replicate real-world vehicle behavior in virtual settings, allowing manufacturers to analyze production outcomes, streamline assembly processes, and improve resource utilization. Digital twin platforms also enhance workforce efficiency by enabling engineers to test and validate assembly workflows virtually before implementing them on production lines. The rising adoption of IoT/IIoT, artificial intelligence, and Industry 4.0 technologies is transforming automotive manufacturing, driving the need for robust digital twin hardware solutions. As vehicles evolve into software-defined systems that generate massive sensor data, digital twin hardware facilitates real-time data processing, predictive analytics, and operational optimization. With Industry 4.0 initiatives emphasizing automation, precision, and predictive maintenance, the integration of IoT sensors, edge computing devices, and industrial controllers within automotive plants continues to grow, creating strong demand for powerful computing infrastructure capable of simulating and processing real-time factory data.

| Market Scope | |

|---|---|

| Start Year | 2024 |

| Forecast Year | 2025-2034 |

| Start Value | $751.5 Million |

| Forecast Value | $6.8 Billion |

| CAGR | 25.4% |

The sensors and IoT devices segment held a 33% share in 2024 and is anticipated to grow at a CAGR of 25.5% from 2025 to 2034. This segment plays a critical role in capturing real-time metrics such as temperature, vibration, and pressure to replicate the physical performance of automotive assets. With the increasing adoption of autonomous driving technologies, the use of advanced sensors including LiDAR, radar, and MEMS components is accelerating, supporting enhanced predictive modeling and fault diagnostics.

The passenger cars segment held 72% share in 2024 and will grow at a CAGR of 25.7% between 2025 and 2034. This dominance is attributed to greater system connectivity, electrification trends, and advancements in driver assistance systems. Automotive manufacturers are deploying GPUs, IoT-enabled sensors, and edge computing systems to conduct real-time vehicle simulations, improving both design precision and production efficiency. The growing shift toward software-defined vehicles is reinforcing the need for digital twin technologies that support predictive maintenance, virtual validation, and over-the-air software updates.

North America Automotive Digital Twin Hardware Market held 34% share in 2024. The region's growth is driven by the strong adoption of connected, autonomous, and electric vehicle technologies. Automotive OEMs and component suppliers are heavily investing in GPU-powered computing, low-latency edge hardware, and IoT sensor networks to enable digitalized factory environments and real-time simulation. The rapid development of AI-accelerated processors and modular hardware systems is further enhancing design accuracy, operational efficiency, and production reliability across the regional automotive ecosystem.

Key players active in the Global Automotive Digital Twin Hardware Market include Bosch, Continental, General Electric, IBM, Molex, NVIDIA, NXP Semiconductors, PTC, Qualcomm, and Siemens. Leading companies in the Global Automotive Digital Twin Hardware Market are focusing on several strategic initiatives to expand their global presence. They are investing heavily in R&D to develop scalable, high-performance computing platforms and integrating AI-driven simulation tools to deliver real-time analytics and predictive insights. Strategic collaborations and partnerships with automakers and technology providers are helping them co-develop customized digital twin solutions for production and design optimization. Companies are also emphasizing the expansion of manufacturing capabilities and regional distribution networks to strengthen their supply chains.

Table of Contents

Chapter 1 Methodology

- 1.1 Market scope and definition

- 1.2 Research design

- 1.2.1 Research approach

- 1.2.2 Data collection methods

- 1.3 Data mining sources

- 1.3.1 Global

- 1.3.2 Regional/Country

- 1.4 Base estimates and calculations

- 1.4.1 Base year calculation

- 1.4.2 Key trends for market estimation

- 1.5 Primary research and validation

- 1.5.1 Primary sources

- 1.6 Forecast model

- 1.7 Research assumptions and limitations

Chapter 2 Executive Summary

- 2.1 Industry 3600 synopsis, 2021 - 2034

- 2.2 Key market trends

- 2.2.1 Regional

- 2.2.2 Component

- 2.2.3 Vehicle

- 2.2.4 Application

- 2.2.5 Deployment Mode

- 2.3 TAM Analysis, 2025-2034

- 2.4 CXO perspectives: Strategic imperatives

- 2.4.1 Executive decision points

- 2.4.2 Critical success factors

- 2.5 Future outlook and strategic recommendations

Chapter 3 Industry Insights

- 3.1 Industry ecosystem analysis

- 3.1.1 Supplier landscape

- 3.1.2 Profit margin analysis

- 3.1.3 Cost structure

- 3.1.4 Value addition at each stage

- 3.1.5 Factor affecting the value chain

- 3.1.6 Disruptions

- 3.2 Industry impact forces

- 3.2.1 Growth drivers

- 3.2.1.1 Integration of high-performance computing (HPC) and GPU hardware

- 3.2.1.2 Adoption of edge computing and IoT/IIoT devices

- 3.2.1.3 Advancements in AI and machine learning hardware

- 3.2.1.4 Expansion of autonomous and connected vehicle development

- 3.2.1.5 Industry 4.0 and smart manufacturing adoption

- 3.2.2 Industry pitfalls and challenges

- 3.2.2.1 High hardware and infrastructure costs

- 3.2.2.2 Data interoperability across heterogeneous systems

- 3.2.3 Market opportunities

- 3.2.3.1 AI-accelerated simulation hardware

- 3.2.3.2 Integration of edge and cloud computing infrastructure

- 3.2.3.3 Expansion of digital twin hardware in EV and battery systems

- 3.2.3.4 Adoption of 5G and ultra-low latency networks

- 3.2.1 Growth drivers

- 3.3 Growth potential analysis

- 3.4 Regulatory landscape

- 3.4.1 Federal regulatory environment

- 3.4.2 International standards (ISO, SAE)

- 3.4.3 Cybersecurity requirements

- 3.4.4 Safety and compliance standards

- 3.4.5 Data privacy regulations

- 3.4.6 Environmental standards

- 3.4.7 Regional regulatory variations

- 3.5 Porter's analysis

- 3.6 PESTEL analysis

- 3.7 Technology and innovation landscape

- 3.7.1 Artificial intelligence integration

- 3.7.2 Synthetic data and simulation

- 3.7.3 Quantum computing applications

- 3.7.4 Advanced security technologies

- 3.7.5 Edge computing evolution

- 3.7.6 5G and beyond connectivity

- 3.7.7 Sustainability technologies

- 3.8 Price trend analysis

- 3.9 Total cost of ownership (TCO) analysis

- 3.9.1 Hardware acquisition costs

- 3.9.2 Implementation and integration costs

- 3.9.3 Operational and maintenance costs

- 3.9.4 Training and support costs

- 3.10 Patent analysis

- 3.10.1 Patent portfolio analysis by technology area

- 3.10.2 Patent filing trends and innovation activity

- 3.10.3 Competitive patent intelligence

- 3.11 Sustainability and environmental aspects

- 3.11.1 Sustainable practices

- 3.11.2 Waste reduction strategies

- 3.11.3 Energy efficiency in production

- 3.11.4 Eco-friendly initiatives

- 3.12 Carbon footprint considerations

- 3.13 Customer journey mapping

- 3.13.1 Awareness and discovery phase

- 3.13.2 Evaluation and selection phase

- 3.13.3 Implementation and integration phase

- 3.13.4 Operation and optimization phase

- 3.14 Return on investment (ROI) framework

- 3.14.1 ROI calculation methodologies

- 3.14.2 Payback period analysis

- 3.14.3 Net present value (NPV) models

- 3.14.4 Risk-adjusted returns

- 3.15 Investment and funding analysis

- 3.15.1 Venture capital trends

- 3.15.2 Strategic corporate investment

- 3.15.3 Government funding programs

- 3.15.4 M&A activity and valuations

- 3.15.5 IPO market dynamics

- 3.15.6 Private equity involvement

Chapter 4 Competitive Landscape, 2024

- 4.1 Introduction

- 4.2 Company market share analysis

- 4.2.1 North America

- 4.2.2 Europe

- 4.2.3 Asia Pacific

- 4.2.4 LATAM

- 4.2.5 MEA

- 4.3 Competitive analysis of major market players

- 4.4 Competitive positioning matrix

- 4.5 Strategic outlook matrix

- 4.6 Key developments

- 4.6.1 Mergers & acquisitions

- 4.6.2 Partnerships & collaborations

- 4.6.3 New Product Launches

- 4.6.4 Expansion Plans and funding

Chapter 5 Market Estimates & Forecast, By Component, 2021 - 2034 (USD Mn, Units)

- 5.1 Key trends

- 5.2 Sensors & IoT devices

- 5.3 Edge computing devices

- 5.4 Connectivity & networking hardware

- 5.5 Actuators & control systems

- 5.6 High-performance computing / simulation hardware

Chapter 6 Market Estimates & Forecast, By Vehicle, 2021 - 2034 (USD Mn, Units)

- 6.1 Key trends

- 6.2 Passenger cars

- 6.2.1 Hatchbacks

- 6.2.2 Sedans

- 6.2.3 SUV

- 6.3 Commercial vehicles

- 6.3.1 Light commercial vehicles (LCV)

- 6.3.2 Medium commercial vehicles (MCV)

- 6.3.3 Heavy commercial vehicles (HCV)

- 6.4 Electric vehicles (EVs)

Chapter 7 Market Estimates & Forecast, By Application, 2021 - 2034 (USD Mn, Units)

- 7.1 Key trends

- 7.2 Vehicle design & development

- 7.3 Manufacturing & production optimization

- 7.4 Predictive maintenance

- 7.5 Autonomous vehicle testing

- 7.6 Supply chain & fleet management

Chapter 8 Market Estimates & Forecast, By Deployment Mode, 2021 - 2034 (USD Mn, Units)

- 8.1 Key trends

- 8.2 Cloud

- 8.3 On-premises

- 8.4 Hybrid

Chapter 9 Market Estimates & Forecast, By Region, 2021 - 2034 (USD Mn, Units)

- 9.1 Key trends

- 9.2 North America

- 9.2.1 US

- 9.2.2 Canada

- 9.3 Europe

- 9.3.1 UK

- 9.3.2 Germany

- 9.3.3 France

- 9.3.4 Italy

- 9.3.5 Spain

- 9.3.6 Russia

- 9.3.7 Nordics

- 9.4 Asia Pacific

- 9.4.1 China

- 9.4.2 India

- 9.4.3 Japan

- 9.4.4 South Korea

- 9.4.5 ANZ

- 9.4.6 Southeast Asia

- 9.5 Latin America

- 9.5.1 Brazil

- 9.5.2 Mexico

- 9.5.3 Argentina

- 9.6 MEA

- 9.6.1 South Africa

- 9.6.2 Saudi Arabia

- 9.6.3 UAE

Chapter 10 Company Profiles

- 10.1 Global Players

- 10.1.1 Siemens

- 10.1.2 DSpace

- 10.1.3 NVIDIA

- 10.1.4 PTC

- 10.1.5 IBM

- 10.1.6 Bosch

- 10.1.7 Intel

- 10.1.8 NXP Semiconductors

- 10.1.9 General Electric

- 10.2 Regional Players

- 10.2.1 Keysight Technologies

- 10.2.2 Altair Engineering

- 10.2.3 ETAS

- 10.2.4 Vector Informatik

- 10.2.5 National Instruments

- 10.2.6 Ansys

- 10.2.7 Qualcomm

- 10.2.8 Continental

- 10.2.9 Molex

- 10.3 Emerging Players

- 10.3.1 Threedy

- 10.3.2 Neural Concept

- 10.3.3 Applied Intuition

- 10.3.4 Cognata

- 10.3.5 Luminar Technologies

- 10.3.6 Mobileye Global