|

市場調查報告書

商品編碼

1844365

雷射打標機市場機會、成長動力、產業趨勢分析及2025-2034年預測Laser Marking Machine Market Opportunity, Growth Drivers, Industry Trend Analysis, and Forecast 2025 - 2034 |

||||||

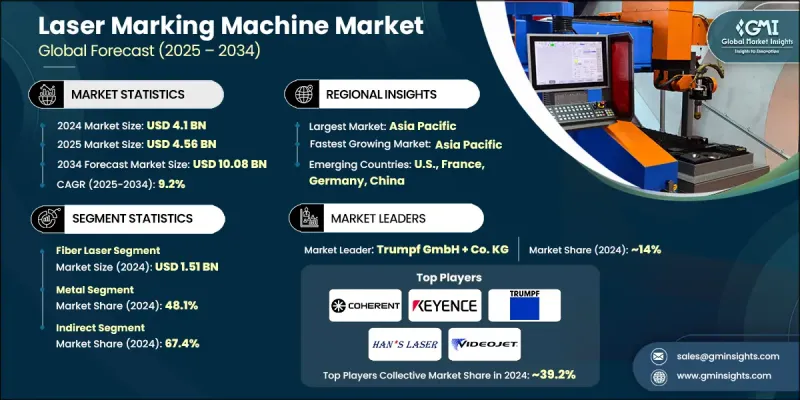

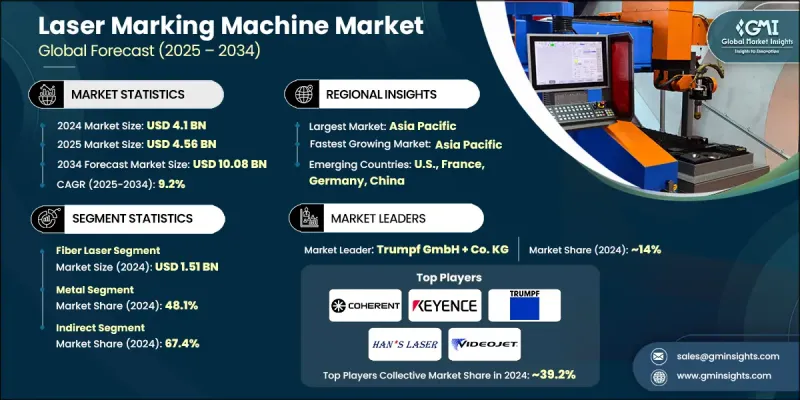

2024 年全球雷射打標機市值為 41 億美元,預計將以 9.2% 的複合年成長率成長,到 2034 年達到 100.8 億美元。

這一成長是由快速的技術進步、不斷變化的工業需求和不斷成長的國內製造業共同推動的。推動這項擴張的主要因素之一是電子、航太、製藥、醫療設備和汽車等受到嚴格監管的行業對可追溯性和合規性的要求日益成長。傳統的基於油墨的方法或不乾膠標籤不符合當今的耐用性和易讀性標準,這些標準正透過監管框架日益嚴格地執行。另一方面,雷射打標提供永久、準確和防篡改的標記,這對於安全、品質保證和防偽至關重要。向智慧製造和自動化的轉變進一步加速了需求。光纖雷射技術因其高速打標、低維護和與多種材料相容而成為主導選擇。從區域來看,亞太地區繼續引領市場成長,這得益於其大規模的工業基礎、政策驅動的製造業升級以及消費性電子和汽車行業不斷成長的需求。

| 市場範圍 | |

|---|---|

| 起始年份 | 2024 |

| 預測年份 | 2025-2034 |

| 起始值 | 41億美元 |

| 預測值 | 100.8億美元 |

| 複合年成長率 | 9.2% |

光纖雷射器市場在2024年創造了15.1億美元的市場規模,預計2025年至2034年的複合年成長率將達到10.1%。其廣泛應用得益於其高效的運作效率、卓越的光束品質以及處理多種基材的能力。光纖雷射系統具有更高的功率密度和更快的處理速度,其性能優於二氧化碳雷射和傳統的固態雷射。這些特性使其特別適用於涉及銅、鋁和不銹鋼等金屬的商業應用,這些應用對標記結果的精度、速度和耐用性有很高的要求。

金屬領域在2024年佔據了48.1%的市場佔有率,預計到2034年將以8.5%的複合年成長率成長。各行各業對金屬的使用日益增多,加上嚴格的可追溯性標準,使得雷射打標成為識別和品質控制的首選方法。金屬上的標記具有卓越的耐用性,並且耐熱、耐磨損、耐化學腐蝕,使其成為高要求應用的理想選擇。光纖雷射對金屬的吸收率高,可實現快速、清潔、精確的標記,同時對周圍表面的影響極小,兼具性能和成本效益。

美國雷射打標機市場佔82.4%的市場佔有率,2024年市場規模達8.336億美元。美國市場主導地位源自於其先進的工業生態系統,涵蓋醫療器材、航太、國防、電子和汽車等領域。這些行業高度依賴永久性標記系統來滿足法律的可追溯性標準和合規性要求。先進的雷射系統,包括紫外線和超快型號,已被廣泛應用於該地區的自動化生產線。設備識別和零件標籤方面的法規在推動雷射打標機的普及方面發揮了核心作用。

影響全球雷射打標機市場的公司包括 Lumentum Operations、LaserStar Technologies、FOBA Technology and Services、Keyence、Coherent、Han's Yueming Laser Group、Gravotech Marking、Laser Photonics、Epilog Laser、IPG Photonics、Huagong Tech、Novantata、Dana Technologyher、大恆新紀元科技、新紀元科技和 Industa Technology。這些主要的行業參與者在研發、自動化和性能驅動的系統開發方面投入了大量資金,以滿足下一代標記要求。雷射打標機市場的領先公司正在透過持續的研發投資來鞏固其地位,以開發高速、高精度且維護需求極少的系統。他們專注於光纖、紫外線和超快雷射技術的創新,以滿足電子、航太和醫療設備等領域的特定需求。正在進行策略性收購和全球擴張,以提高市場滲透率並實現產品組合多樣化。製造商還將他們的系統與智慧工廠技術和自動化平台結合,以提供交鑰匙解決方案。

目錄

第1章:方法論與範圍

第2章:執行摘要

第3章:行業洞察

- 產業生態系統分析

- 供應商格局

- 利潤率

- 每個階段的增值

- 影響價值鏈的因素

- 產業衝擊力

- 成長動力

- 電子產品小型化和精密化需求不斷提高

- 自動化/工業4.0整合

- 高需求領域的成長(電動車電池、汽車、醫療設備

- 產業陷阱與挑戰

- 雷射使用的安全和法規遵從性

- 特定材料和應用的限制

- 機會

- 光纖、皮秒/飛秒和紫外線雷射生長

- 與機器視覺、可追溯性和 IIoT 整合

- 成長動力

- 成長潛力分析

- 未來市場趨勢

- 技術和創新格局

- 當前的技術趨勢

- 新興技術

- 價格趨勢

- 按地區

- 按類型

- 監管格局(HS 編碼 -8456.11)

- 標準和合規要求

- 區域監理框架

- 波特的分析

- PESTEL分析

第4章:競爭格局

- 介紹

- 公司市佔率分析

- 按地區

- 公司矩陣分析

- 主要市場參與者的競爭分析

- 競爭定位矩陣

- 關鍵進展

- 併購

- 夥伴關係與合作

- 新產品發布

- 擴張計劃

第5章:市場估計與預測:按類型,2021 - 2034

- 主要趨勢

- 光纖雷射

- 綠色雷射

- 紫外線雷射

- Co2雷射

- Mopa雷射

- 二極體泵浦雷射

- Nd:yag雷射

- 其他

第6章:市場估計與預測:依機器類型,2021 - 2034 年

- 主要趨勢

- 2D

- 3D

第7章:市場估計與預測:依行程類型,2021 - 2034

- 主要趨勢

- 固定的

- 便攜的

第8章:市場估計與預測:按材料,2021 - 2034 年

- 主要趨勢

- 金屬

- 玻璃

- 塑膠

- 陶瓷

- 其他

第9章:市場估計與預測:按應用,2021 - 2034

- 主要趨勢

- 消融

- 退火

- 碳化

- 起泡

- 雕刻

- 其他

第 10 章:市場估計與預測:按最終用途產業,2021 - 2034 年

- 主要趨勢

- 汽車

- 電子和半導體

- 國防和航太

- 工具機

- 衛生保健

- 包裝和標籤

- 其他

第 11 章:市場估計與預測:按配銷通路,2021 年至 2034 年

- 主要趨勢

- 直接的

- 間接

第 12 章:市場估計與預測:按地區,2021 年至 2034 年

- 主要趨勢

- 北美洲

- 美國

- 加拿大

- 歐洲

- 英國

- 德國

- 法國

- 義大利

- 西班牙

- 俄羅斯

- 亞太地區

- 中國

- 印度

- 日本

- 澳洲

- 韓國

- 拉丁美洲

- 巴西

- 墨西哥

- 阿根廷

- 多邊環境協定

- 阿拉伯聯合大公國

- 南非

- 沙烏地阿拉伯

第13章:公司簡介

- Coherent

- Daheng New Epoch Technology

- Danaher

- Epilog Laser

- FOBA Technology and Services

- Gravotech Marking

- Han's Laser Technology Industry Group

- Han's Yueming Laser Group

- Huagong Tech

- IPG Photonics

- Keyence

- Laser Photonics

- LaserStar Technologies

- Lumentum Operations

- Novanta

The Global Laser Marking Machine Market was valued at USD 4.1 billion in 2024 and is estimated to grow at a CAGR of 9.2% to reach USD 10.08 billion by 2034.

The growth is driven by the combined impact of rapid technological advancements, evolving industrial demands, and rising domestic manufacturing. One of the main factors fueling this expansion is the growing requirement for traceability and compliance across highly regulated sectors such as electronics, aerospace, pharmaceuticals, medical equipment, and automotive. Traditional ink-based methods or adhesive labels do not meet today's durability and legibility standards, which are increasingly enforced through regulatory frameworks. Laser marking, on the other hand, offers permanent, accurate, and tamper-proof marking essential for safety, quality assurance, and anti-counterfeiting. The transition toward smart manufacturing and automation has further accelerated demand. Fiber laser technologies have emerged as the dominant choice due to their high-speed marking, low maintenance, and compatibility with a wide range of materials. Regionally, Asia-Pacific continues to lead market growth, supported by its large-scale industrial base, policy-driven manufacturing upgrades, and expanding demand in consumer electronics and automotive sectors.

| Market Scope | |

|---|---|

| Start Year | 2024 |

| Forecast Year | 2025-2034 |

| Start Value | $4.1 Billion |

| Forecast Value | $10.08 Billion |

| CAGR | 9.2% |

The fiber lasers segment generated USD 1.51 billion in 2024 and is forecast to grow at a CAGR of 10.1% from 2025 to 2034. Their widespread adoption is tied to their operational efficiency, superior beam quality, and the ability to work with multiple substrates. With higher power density and faster processing speeds, fiber laser systems outperform both CO2 and traditional solid-state variants. These characteristics make them particularly suitable for commercial applications involving metals like copper, aluminum, and stainless steel, which require precision, speed, and durability in marking outcomes.

The metals segment accounted for a 48.1% share in 2024 and is projected to grow at a CAGR of 8.5% through 2034. The increasing use of metals across industries, combined with strict traceability standards, has made laser marking a preferred method for identification and quality control. Markings on metals deliver exceptional longevity and resistance to heat, abrasion, and chemicals, making them ideal for high-demand applications. Fiber lasers' strong absorption rate for metals allows for fast, clean, and precise marking with minimal impact on surrounding surfaces, offering both performance and cost-effectiveness.

U.S. Laser Marking Machine Market held an 82.4% share and generated USD 833.6 million in 2024. The country's dominance stems from its advanced industrial ecosystem spanning sectors like medical devices, aerospace, defense, electronics, and automotive. These industries rely heavily on permanent marking systems to meet legal traceability standards and compliance requirements. Advanced laser systems, including UV and ultrafast models, are widely integrated into automated production lines across the region. Regulations around device identification and part labeling have played a central role in driving laser marking machine adoption.

Companies shaping the Global Laser Marking Machine Market include Lumentum Operations, LaserStar Technologies, FOBA Technology and Services, Keyence, Coherent, Han's Yueming Laser Group, Gravotech Marking, Laser Photonics, Epilog Laser, IPG Photonics, Huagong Tech, Novanta, Danaher, Daheng New Epoch Technology, and Han's Laser Technology Industry Group. These major industry players are deeply invested in R&D, automation, and performance-driven system development to cater to next-generation marking requirements. Leading companies in the laser marking machine market are strengthening their position through sustained investments in R&D to develop high-speed, high-precision systems with minimal maintenance needs. They are focusing on innovations in fiber, UV, and ultrafast laser technologies to meet the specific demands of sectors like electronics, aerospace, and medical devices. Strategic acquisitions and global expansion are being pursued to enhance market penetration and diversify product portfolios. Manufacturers are also integrating their systems with smart factory technologies and automation platforms to offer turnkey solutions.

Table of Contents

Chapter 1 Methodology and Scope

- 1.1 Market scope and definition

- 1.2 Research design

- 1.2.1 Research approach

- 1.3 Data collection methods

- 1.4 Data mining sources

- 1.4.1 Global

- 1.4.2 Regional/Country

- 1.5 Base estimates and calculations

- 1.5.1 Base year calculation

- 1.5.2 Key trends for market estimation

- 1.6 Primary research and validation

- 1.6.1 Primary sources

- 1.7 Forecast model

- 1.8 Research assumptions and limitations

Chapter 2 Executive Summary

- 2.1 Industry 3600 synopsis

- 2.2 Key market trends

- 2.2.1 Regional

- 2.2.2 Type

- 2.2.3 Machine type

- 2.2.4 Mobility type

- 2.2.5 Material

- 2.2.6 Application

- 2.2.7 End use industry

- 2.2.8 Distribution channel

- 2.3 CXO perspectives: strategic imperatives

- 2.3.1 Key decision points for industry executives

- 2.3.2 Critical success factors for market players

- 2.4 Future outlook and strategic recommendations

Chapter 3 Industry Insights

- 3.1 Industry ecosystem analysis

- 3.1.1 Supplier landscape

- 3.1.2 Profit margin

- 3.1.3 Value addition at each stage

- 3.1.4 Factors affecting the value chain

- 3.2 Industry impact forces

- 3.2.1 Growth drivers

- 3.2.1.1 Raising electronics miniaturization & precision need

- 3.2.1.2 Automation / Industry 4.0 integration

- 3.2.1.3 Growth in high-demand segments (EV batteries, automotive, medical devices

- 3.2.2 Industry pitfalls & challenges

- 3.2.2.1 Safety & regulatory compliance for laser use

- 3.2.2.2 Material- and application-specific limits

- 3.2.3 Opportunities

- 3.2.3.1 Fiber, picosecond/femtosecond, and UV laser growth

- 3.2.3.2 Integration with machine vision, traceability & IIoT

- 3.2.1 Growth drivers

- 3.3 Growth potential analysis

- 3.4 Future market trends

- 3.5 Technology and innovation landscape

- 3.5.1 Current technological trends

- 3.5.2 Emerging technologies

- 3.6 Price trends

- 3.6.1 By region

- 3.6.2 By Type

- 3.7 Regulatory landscape (HS code -8456.11)

- 3.7.1 standards and compliance requirements

- 3.7.2 Regional regulatory frameworks

- 3.8 Porter’s analysis

- 3.9 PESTEL analysis

Chapter 4 Competitive Landscape, 2024

- 4.1 Introduction

- 4.2 Company market share analysis

- 4.2.1 By region

- 4.2.1.1 North America

- 4.2.1.2 Europe

- 4.2.1.3 Asia Pacific

- 4.2.1.4 Latin America

- 4.2.1.5 Middle East and Africa

- 4.2.1 By region

- 4.3 Company matrix analysis

- 4.4 Competitive analysis of major market players

- 4.5 Competitive positioning matrix

- 4.6 Key developments

- 4.6.1 Mergers & acquisitions

- 4.6.2 Partnerships & collaborations

- 4.6.3 New Product Launches

- 4.6.4 Expansion Plans

Chapter 5 Market Estimates & Forecast, By Type, 2021 - 2034 ($Bn, Thousand Units)

- 5.1 Key trends

- 5.2 Fiber laser

- 5.3 Green laser

- 5.4 UV laser

- 5.5 Co2 laser

- 5.6 Mopa laser

- 5.7 Diode-pumped laser

- 5.8 Nd:yag laser

- 5.9 Others

Chapter 6 Market Estimates & Forecast, By Machine Type, 2021 - 2034 ($Bn, Thousand Units)

- 6.1 Key trends

- 6.2 2D

- 6.3 3D

Chapter 7 Market Estimates & Forecast, By Mobility Type, 2021 - 2034 ($Bn, Thousand Units)

- 7.1 Key trends

- 7.2 Fixed

- 7.3 Portable

Chapter 8 Market Estimates & Forecast, By Material, 2021 - 2034 ($Bn, Thousand Units)

- 8.1 Key trends

- 8.2 Metal

- 8.3 Glass

- 8.4 Plastics

- 8.5 Ceramics

- 8.6 Others

Chapter 9 Market Estimates & Forecast, By Application, 2021 - 2034 ($Bn, Thousand Units)

- 9.1 Key trends

- 9.2 Ablation

- 9.3 Annealing

- 9.4 Carbonizing

- 9.5 Foaming

- 9.6 Engraving

- 9.7 Others

Chapter 10 Market Estimates & Forecast, By End use Industry, 2021 - 2034 ($Bn, Thousand Units)

- 10.1 Key trends

- 10.2 Automotive

- 10.3 Electronics & semiconductor

- 10.4 Defense & aerospace

- 10.5 Machine tool

- 10.6 Healthcare

- 10.7 Packaging & labeling

- 10.8 Others

Chapter 11 Market Estimates & Forecast, By Distribution Channel, 2021 - 2034 ($Bn, Thousand Units)

- 11.1 Key trends

- 11.2 Direct

- 11.3 Indirect

Chapter 12 Market Estimates & Forecast, By Region, 2021 - 2034 ($Bn, Thousand Units)

- 12.1 Key trends

- 12.2 North America

- 12.2.1 U.S.

- 12.2.2 Canada

- 12.3 Europe

- 12.3.1 UK

- 12.3.2 Germany

- 12.3.3 France

- 12.3.4 Italy

- 12.3.5 Spain

- 12.3.6 Russia

- 12.4 Asia Pacific

- 12.4.1 China

- 12.4.2 India

- 12.4.3 Japan

- 12.4.4 Australia

- 12.4.5 South Korea

- 12.5 Latin America

- 12.5.1 Brazil

- 12.5.2 Mexico

- 12.5.3 Argentina

- 12.6 MEA

- 12.6.1 UAE

- 12.6.2 South Africa

- 12.6.3 Saudi Arabia

Chapter 13 Company Profiles

- 13.1 Coherent

- 13.2 Daheng New Epoch Technology

- 13.3 Danaher

- 13.4 Epilog Laser

- 13.5 FOBA Technology and Services

- 13.6 Gravotech Marking

- 13.7 Han's Laser Technology Industry Group

- 13.8 Han's Yueming Laser Group

- 13.9 Huagong Tech

- 13.10 IPG Photonics

- 13.11 Keyence

- 13.12 Laser Photonics

- 13.13 LaserStar Technologies

- 13.14 Lumentum Operations

- 13.15 Novanta