|

市場調查報告書

商品編碼

1750625

點陣打標機市場機會、成長動力、產業趨勢分析及 2025 - 2034 年預測Dot Peen Marking Machines Market Opportunity, Growth Drivers, Industry Trend Analysis, and Forecast 2025 - 2034 |

||||||

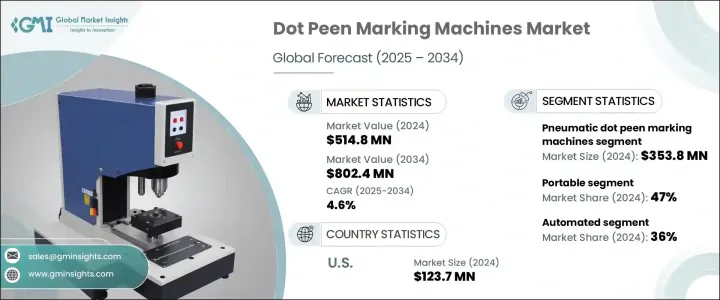

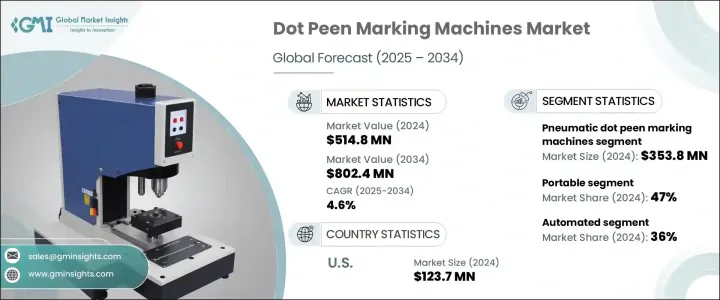

2024年,全球點陣打標機市場規模達5.148億美元,預計2034年將以4.6%的複合年成長率成長,達到8.024億美元,這得益於各行各業轉型為更自動化、更有效率的生產線。隨著工業製造規模不斷擴大和多樣化,對耐用、永久和高精度打標技術的需求也日益成長。點陣打標機的應用日益廣泛,因為它們能夠在包括金屬和塑膠在內的各種表面上提供一致且清晰的標記。隨著企業致力於減少錯誤、提高可追溯性並提升整體生產效率,向工業4.0的轉型進一步增強了自動化打標技術的吸引力。

汽車、製藥和電子等行業需要能夠確保符合可追溯性標準和品質控制的標記系統。這使得針式打標機成為生產車間的重要資產。這些行業自動化程度的提高正推動整合式和攜帶式系統得到更廣泛的應用。氣動打標機因其成本效益高且相容大批量生產,繼續佔據市場主導地位。氣動打標機能夠快速、準確地打標,廣泛應用於大量生產的組裝線。

| 市場範圍 | |

|---|---|

| 起始年份 | 2024 |

| 預測年份 | 2025-2034 |

| 起始值 | 5.148億美元 |

| 預測值 | 8.024億美元 |

| 複合年成長率 | 4.6% |

氣動點陣打標機在2024年實現了3.538億美元的市場規模,預計到2034年將以4.4%的複合年成長率成長。其成本效益以及在大批量生產環境中始終如一的性能,使其繼續成為工業用戶的首選解決方案。這些系統在速度和精度至關重要的快節奏環境中尤其有效,並且與機械手臂和生產線自動化的兼容性進一步增強了其實用性。由於這些機器能夠以最低的營運成本和維護成本提供永久性、防篡改的標記,因此越來越受到製造商的青睞。

在安裝方面,攜帶式點陣打標系統在2024年佔據了47%的市場。其緊湊的外形、易用性以及對不同工作條件的適應性使其在造船、鐵路和建築設備等經常需要現場打標的行業中尤為重要。這些設備使操作員能夠精確地標記大型或固定的部件,無需將重物運送到固定的機器上。隨著即時可追溯識別在品質保證流程中的重要性日益提升,攜帶式機器擴大被整合到現有和遠端工作環境中。

得益於美國先進的製造能力,美國點陣打標機市場規模在2024年達到1.237億美元。航太、國防、製藥和電子等產業高度依賴可追溯性、法規遵循、產品生命週期追蹤——在這些領域,點陣系統能夠發揮巨大價值。美國製造商正在投資於能夠確保準確性、持久性以及與自動化系統整合的打標技術。

為了鞏固市場地位,日立、Pryor Technology、SIC Marking、Gravotech Group、MarkinBOX USA、Dapra Marking Systems、Technomark 和 MECCO 等主要參與者正在加大研發投入,以提高標記精度和系統整合度。 Columbia Marking Tools 和 Borries Markier-Systeme 等公司也專注於模組化和攜帶式系統開發,而 Pannier 和 COUTH 等其他公司則瞄準新興經濟體,提供可客製化、經濟高效的解決方案。策略合作夥伴關係、售後服務和自動化友善設計對於在這個不斷成長的市場中保持競爭力至關重要。

目錄

第1章:方法論與範圍

第2章:執行摘要

第3章:行業洞察

- 產業生態系統分析

- 影響價值鏈的因素。

- 利潤率分析。

- 中斷

- 未來展望

- 製成品

- 經銷商

- 供應商格局

- 技術格局

- 重要新聞和舉措

- 監管格局

- 衝擊力

- 成長動力

- 工業製造業需求不斷成長

- 自動點陣打標機的採用率不斷上升

- 產業陷阱與挑戰

- 有限的標記深度和表面要求

- 新興打標機的競爭

- 成長動力

- 成長潛力分析

- 波特的分析

- PESTEL分析

第4章:競爭格局

- 介紹

- 公司市佔率分析

- 競爭定位矩陣

- 戰略展望矩陣

第5章:市場估計與預測:依產品類型,2021-2034

- 主要趨勢

- 氣動

- 電磁

第6章:市場估計與預測:按安裝量,2021-2034 年

- 主要趨勢

- 便攜的

- 桌上型

- 融合的

第7章:市場估計與預測:按營運,2021-2034

- 主要趨勢

- 自動化

- 半自動化

第 8 章:市場估計與預測:按應用,2021 年至 2034 年

- 主要趨勢

- 汽車

- 航太

- 醫療器材

- 電子產品

- 工業工具和設備

- 建造

- 其他

第9章:市場估計與預測:按配銷通路,2021-2034

- 主要趨勢

- 直銷

- 間接銷售

第10章:市場估計與預測:按地區,2021-2034

- 主要趨勢

- 北美洲

- 美國

- 加拿大

- 歐洲

- 英國

- 德國

- 法國

- 義大利

- 西班牙

- 俄羅斯

- 亞太地區

- 中國

- 印度

- 日本

- 韓國

- 澳洲

- 拉丁美洲

- 巴西

- 墨西哥

- MEA

- 阿拉伯聯合大公國

- 沙烏地阿拉伯

- 南非

第 11 章:公司簡介

- Borries Markier-Systeme

- Columbia Marking Tools

- COUTH

- Dapra Marking Systems

- Gravotech Group

- Hitachi

- Kwikmark

- MarkinBOX USA

- MECCO

- Nichol Industries

- Ostling Etchmark

- Pannier

- Pryor Technology

- SIC Marking

- Technomark

The Global Dot Peen Marking Machines Market was valued at USD 514.8 million in 2024 and is estimated to grow at a CAGR of 4.6% to reach USD 802.4 million by 2034, driven by industries' move toward more automated and efficient production lines. As industrial manufacturing continues to scale and diversify, the demand for durable, permanent, and high-precision marking technologies has intensified. Dot peen marking machines are increasingly used because they deliver consistent and legible marks on a range of surfaces, including metals and plastics. The transition to Industry 4.0 is further enhancing the appeal of automated marking technologies, as businesses aim to reduce errors, improve traceability, and enhance overall production efficiency.

Sectors such as automotive, pharmaceuticals, and electronics require marking systems that ensure compliance with traceability standards and quality control. This has made dot peen machines an asset on production floors. The rise in automation across these industries is leading to broader adoption of integrated and portable systems. Pneumatic variants continue to dominate the market due to their cost-effectiveness and compatibility with high-volume operations. With the ability to deliver fast, accurate markings, they are widely used in assembly lines for bulk production processes.

| Market Scope | |

|---|---|

| Start Year | 2024 |

| Forecast Year | 2025-2034 |

| Start Value | $514.8 Million |

| Forecast Value | $802.4 Million |

| CAGR | 4.6% |

The pneumatic dot peen marking machines brought in USD 353.8 million in 2024 and are forecasted to grow at a CAGR of 4.4% through 2034. Their cost-effectiveness, combined with consistent performance in high-volume manufacturing environments, continues to position them as a preferred solution for industrial users. These systems are particularly effective in fast-paced settings where speed and accuracy are critical, and their compatibility with robotic arms and production line automation further enhances their utility. Manufacturers increasingly favor these machines due to their ability to deliver permanent, tamper-resistant markings with minimal operational cost and maintenance.

In terms of installation, portable dot peen marking systems made up 47% share in 2024. Their compact form factor, ease of use, and adaptability to different working conditions make them especially valuable in industries such as shipbuilding, railways, and construction equipment, where components often require on-the-spot marking. These units allow operators to mark large or immobile parts with accuracy, eliminating the need to transport heavy items to stationary machines. As the importance of real-time traceable identification continues to grow in quality assurance processes, portable machines are increasingly being integrated into both established and remote work environments.

United States Dot Peen Marking Machines Market reached USD 123.7 million in 2024, driven by the country's advanced manufacturing capabilities. Sectors such as aerospace, defense, pharmaceuticals, and electronics are heavily reliant on traceability, regulatory compliance, and product lifecycle tracking-areas where dot peen systems offer significant value. American manufacturers are investing in marking technologies that ensure accuracy, permanence, and integration with automated systems.

To strengthen their market position, key players such as Hitachi, Pryor Technology, SIC Marking, Gravotech Group, MarkinBOX USA, Dapra Marking Systems, Technomark, and MECCO are investing in R&D to advance marking accuracy and system integration. Companies like Columbia Marking Tools and Borries Markier-Systeme are also focusing on modular and portable system development, while others, such as Pannier and COUTH, are targeting emerging economies with customizable, cost-effective solutions. Strategic partnerships, after-sales services, and automation-friendly designs are becoming critical to remain competitive in this growing market.

Table of Contents

Chapter 1 Methodology & Scope

- 1.1 Market scope & definitions

- 1.2 Base estimates & calculations

- 1.3 Forecast calculations.

- 1.4 Data sources

- 1.4.1 Primary

- 1.4.2 Secondary

- 1.4.2.1 Paid sources

- 1.4.2.2 Public sources

Chapter 2 Executive Summary

- 2.1 Industry synopsis, 2021-2034

Chapter 3 Industry Insights

- 3.1 Industry ecosystem analysis

- 3.1.1 Factor affecting the value chain.

- 3.1.2 Profit margin analysis.

- 3.1.3 Disruptions

- 3.1.4 Future outlook

- 3.1.5 Manufactures

- 3.1.6 Distributors

- 3.2 Supplier landscape

- 3.3 Technological landscape

- 3.4 Key news & initiatives

- 3.5 Regulatory landscape

- 3.6 Impact forces

- 3.6.1 Growth drivers

- 3.6.1.1 Increasing demand from industrial manufacturing sector

- 3.6.1.2 Rising adoption of automated dot peen marking machine

- 3.6.2 Industry pitfalls & challenges

- 3.6.2.1 Limited marking depth and surface requirements

- 3.6.2.2 Competition from emerging marking machines

- 3.6.1 Growth drivers

- 3.7 Growth potential analysis

- 3.8 Porter's analysis

- 3.9 PESTEL analysis

Chapter 4 Competitive Landscape, 2024

- 4.1 Introduction

- 4.2 Company market share analysis

- 4.3 Competitive positioning matrix

- 4.4 Strategic outlook matrix

Chapter 5 Market Estimates & Forecast, By Product Type, 2021-2034 (USD Million) (Thousand Units)

- 5.1 Key trends

- 5.2 Pneumatic

- 5.3 Electromagnetic

Chapter 6 Market Estimates & Forecast, By Installation, 2021-2034 (USD Million) (Thousand Units)

- 6.1 Key trends

- 6.2 Portable

- 6.3 Benchtop

- 6.4 Integrated

Chapter 7 Market Estimates & Forecast, By Operation, 2021-2034 (USD Million) (Thousand Units)

- 7.1 Key trends

- 7.2 Automated

- 7.3 Semi-automated

Chapter 8 Market Estimates & Forecast, By Application, 2021-2034 (USD Million) (Thousand Units)

- 8.1 Key trends

- 8.2 Automotive

- 8.3 Aerospace

- 8.4 Medical devices

- 8.5 Electronics

- 8.6 Industrial tools and equipment

- 8.7 Construction

- 8.8 Others

Chapter 9 Market Estimates & Forecast, By Distribution Channel, 2021-2034 (USD Million) (Thousand Units)

- 9.1 Key trends

- 9.2 Direct sales

- 9.3 Indirect sales

Chapter 10 Market Estimates & Forecast, By Region, 2021-2034 (USD Million) (Thousand Units)

- 10.1 Key trends

- 10.2 North America

- 10.2.1 U.S.

- 10.2.2 Canada

- 10.3 Europe

- 10.3.1 UK

- 10.3.2 Germany

- 10.3.3 France

- 10.3.4 Italy

- 10.3.5 Spain

- 10.3.6 Russia

- 10.4 Asia Pacific

- 10.4.1 China

- 10.4.2 India

- 10.4.3 Japan

- 10.4.4 South Korea

- 10.4.5 Australia

- 10.5 Latin America

- 10.5.1 Brazil

- 10.5.2 Mexico

- 10.6 MEA

- 10.6.1 UAE

- 10.6.2 Saudi Arabia

- 10.6.3 South Africa

Chapter 11 Company Profiles

- 11.1 Borries Markier-Systeme

- 11.2 Columbia Marking Tools

- 11.3 COUTH

- 11.4 Dapra Marking Systems

- 11.5 Gravotech Group

- 11.6 Hitachi

- 11.7 Kwikmark

- 11.8 MarkinBOX USA

- 11.9 MECCO

- 11.10 Nichol Industries

- 11.11 Ostling Etchmark

- 11.12 Pannier

- 11.13 Pryor Technology

- 11.14 SIC Marking

- 11.15 Technomark