|

市場調查報告書

商品編碼

1833668

電動建築設備市場機會、成長動力、產業趨勢分析及2025-2034年預測Electric Construction Equipment Market Opportunity, Growth Drivers, Industry Trend Analysis, and Forecast 2025 - 2034 |

||||||

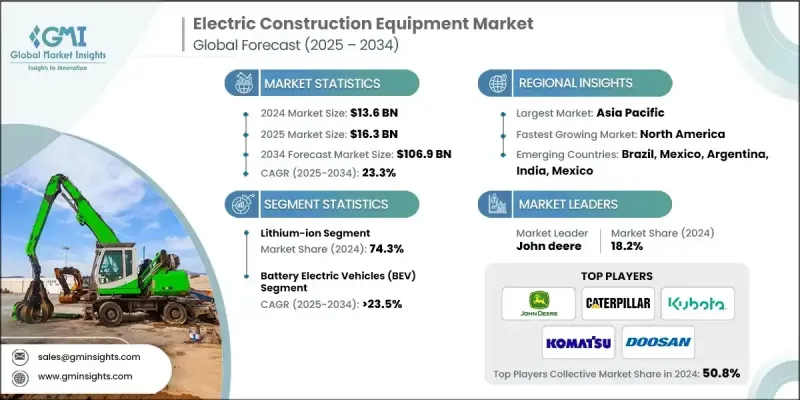

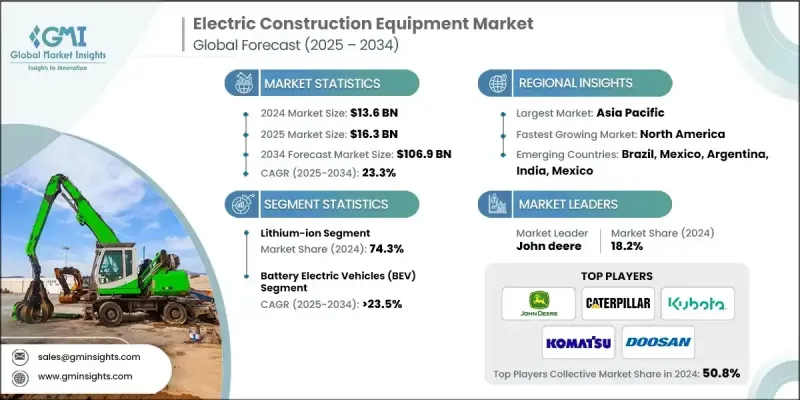

根據 Global Market Insights Inc. 發布的最新報告,2024 年全球電動建築設備市場規模估計為 136 億美元,預計將從 2025 年的 163 億美元成長到 2034 年的 1,069 億美元,複合年成長率為 23.3%。

歐洲、北美和亞洲部分地區的政府正在日益嚴格非道路移動機械(包括建築設備)的排放標準。這些法規旨在控制氮氧化物 (NOx)、粒狀物 (PM) 和二氧化碳 (CO2) 等有害污染物的排放,這些污染物是造成空氣污染和氣候變遷的主要因素。

| 市場範圍 | |

|---|---|

| 起始年份 | 2024 |

| 預測年份 | 2025-2034 |

| 起始值 | 136億美元 |

| 預測值 | 1069億美元 |

| 複合年成長率 | 23.3% |

鋰離子電池的普及率不斷上升

鋰離子電池憑藉其高能量密度、更長的使用壽命和快速充電能力,在2024年佔據了相當大的佔有率。企業之所以重視鋰離子技術,是因為它能夠提供高要求施工任務所需的可靠電力,同時減輕設備整體重量。隨著技術創新和規模經濟的推動,電池成本持續下降,鋰離子電池正成為製造商和最終用戶的首選。

電動車需求不斷成長

受全球推動零排放解決方案的推動,純電動車 (BEV) 將在 2025 年至 2034 年間實現顯著成長。這些車輛兼具減少噪音污染和消除廢氣排放的雙重優勢,使其成為城市和室內建築工地的理想選擇。開發 BEV 的公司優先考慮電池技術的進步,以延長營運時間並減少充電停機時間。

亞太地區將崛起為利潤豐厚的地區

2024年,亞太地區電動建築設備市場佔據了相當大的佔有率,這得益於快速的城市化、基礎設施建設以及政府推行的清潔能源應用支援政策。中國、日本和韓國等國家正引領這一趨勢,在電動車隊的研發和部署方面投入大量資金。該地區建築業的蓬勃發展,加上環保意識的不斷增強,正在加速對兼具性能和永續性標準的電動機械的需求。

電動建築設備產業的主要參與者有利勃海爾、久保田、斗山工程機械、Mecalac、約翰迪爾、柳工機械、Caterpillar、小松、曼尼通和日立建築。

為了在不斷發展的電動建築設備市場中站穩腳跟,各公司正在採取多方面的策略。產品創新仍然是核心重點,公司投入大量資金用於開發續航時間更長的電池、改進的能源管理系統以及涵蓋各種設備類別的多功能電動型號。與電池製造商和科技公司建立策略合作和合資企業有助於公司加速創新並縮短產品上市時間。此外,擴大售後服務網路並投資客戶教育計畫對於建立信任並簡化從柴油機械到電動機械的過渡至關重要。

目錄

第1章:方法論與範圍

第2章:執行摘要

第3章:行業洞察

- 產業生態系統分析

- 原物料供應商

- 零件製造商

- 設備製造商

- 分銷商和經銷商

- 售後市場供應商

- 產業衝擊力

- 成長動力

- 嚴格的排放法規

- 都市化和智慧城市項目

- 節省成本和提高效率

- OEM和租賃採用

- 產業陷阱與挑戰

- 前期成本高

- 充電基礎設施缺口

- 市場機會

- 政府激勵和補貼

- 電池技術的進步

- 智慧工地整合

- 綠色基礎設施項目

- 成長動力

- 成長潛力分析

- 專利分析

- 監管格局

- 北美洲

- 歐洲

- 亞太地區

- 拉丁美洲

- 中東和非洲

- 波特的分析

- PESTEL分析

- 技術整合和標準化挑戰

- 充電基礎設施相容性和標準

- 連接器標準和互通性問題

- 通訊協定和資料交換

- 跨製造商相容性挑戰

- 遺留系統整合與遷移成本

- 車隊管理系統整合

- 多品牌車隊管理的複雜性

- 數據整合和分析平台

- 遠端資訊處理和遠端監控系統

- 維護計劃和最佳化

- 數位轉型和物聯網整合

- 連接標準和協議

- 3資料安全和隱私要求

- 邊緣運算和即時分析

- 數位孿生技術與仿真

- 多供應商整合的複雜性

- 跨品牌充電連接器相容性問題

- 車隊管理系統整合挑戰(15+個平台)

- 資料格式標準化和互通性差距

- 服務診斷工具需求和培訓

- 充電基礎設施相容性和標準

- 3 能源管理與電網整合

- 智慧充電和負載管理系統

- 動態負載平衡和削峰

- 使用時間最佳化和成本降低

- 電網穩定性和需量反應整合

- 人工智慧和機器學習應用

- 再生能源整合

- 太陽能和風能整合的優勢

- 儲能和電池系統

- 微電網發展與孤島能力

- 減少碳足跡和永續發展

- 車輛到電網 (V2G) 和雙向充電

- 電網服務和收入機會

- 技術要求和標準

- 商業模式開發與實施

- 規範架構和市場壁壘

- 智慧充電和負載管理系統

- 服務網路準備評估

- 地理服務涵蓋分析

- 服務覆蓋差距識別(40% 的市場服務不足)

- 區域服務密度和反應時間分析

- 農村與城市服務可用性差異

- 緊急服務反應能力

- 技術人員認證和培訓基礎設施

- 高壓認證計劃的可用性

- 培訓能力與瓶頸分析

- 技能發展時間表和要求

- 認證成本及投資分析

- 診斷設備和工具要求

- 專業診斷工具投資

- 軟體平台整合和更新

- 多品牌相容性和標準化

- 技術升級和淘汰管理

- 地理服務涵蓋分析

- 零件供應和供應鏈支持

- 電子元件供應鏈成熟度

- 電池更換和服務基礎設施

- 緊急零件供應和交貨時間

- 區域供應鏈發展與本地化

- 服務模式創新與數位融合

- 遠端診斷和預測性維護

- 擴增實境和數位服務工具

- 服務即服務模式與訂閱

- 客戶自助服務和數位平台

- 專利分析

- 永續性和環境方面

- 永續實踐

- 減少廢棄物的策略

- 生產中的能源效率

- 環保舉措

- 碳足跡考慮

- 用例

- 最佳情況

第4章:競爭格局

- 介紹

- 公司市佔率分析

- 北美洲

- 歐洲

- 亞太地區

- 拉丁美洲

- 多邊環境協定

- 主要市場參與者的競爭分析

- 競爭定位矩陣

- 戰略展望矩陣

- 關鍵進展

- 併購

- 夥伴關係與合作

- 新產品發布

- 擴張計劃和資金

第5章:市場估計與預測:按設備,2021 - 2034 年

- 主要趨勢

- 挖土機

- 裝載機

- 推土機

- 起重機

- 自卸卡車

- 滾筒

- 其他

第6章:市場估計與預測:依電池容量,2021 - 2034 年

- 主要趨勢

- 少於50度

- 50度電至200度

- 超過200度

第7章:市場估計與預測:按電池技術,2021 - 2034 年

- 主要趨勢

- 鉛酸電池

- 鋰離子

- 鎳氫電池

第8章:市場估計與預測:依電源分類,2021 - 2034 年

- 主要趨勢

- 純電動車(BEV)

- 插電式混合動力電動車(PHEV)

第9章:市場估計與預測:依最終用途,2021 - 2034

- 主要趨勢

- 建造

- 礦業

- 物料搬運

- 農業

- 其他

第 10 章:市場估計與預測:按地區,2021 年至 2034 年

- 主要趨勢

- 北美洲

- 美國

- 加拿大

- 歐洲

- 英國

- 德國

- 法國

- 義大利

- 西班牙

- 俄羅斯

- 北歐人

- 亞太地區

- 中國

- 印度

- 日本

- 澳洲

- 韓國

- 東南亞

- 拉丁美洲

- 巴西

- 墨西哥

- 阿根廷

- 多邊環境協定

- 南非

- 沙烏地阿拉伯

- 阿拉伯聯合大公國

第 11 章:公司簡介

- 全球參與者

- Caterpillar

- CNH Industrial

- Hitachi Construction Machinery

- JCB

- John Deere

- Komatsu

- Komatsu

- Liebherr

- 區域參與者

- Develon

- Doosan Infracore

- Hyundai Construction Equipment

- LiuGong Machinery

- Manitou

- Mecalac

- SDLG

- 新興玩家

- Avant Tecno

- Elematic

- Kramer-Werke

- Sunward Intelligent Equipment

- Zoomlion Heavy Industry Science & Technology

The global electric construction equipment market was estimated at USD 13.6 billion in 2024 and is expected to grow from USD 16.3 billion in 2025 to USD 106.9 billion by 2034 at a CAGR of 23.3%, according to the latest report published by Global Market Insights Inc.

Governments across Europe, North America, and parts of Asia are increasingly tightening emission standards for non-road mobile machinery, including construction equipment. These regulations aim to curb harmful pollutants such as nitrogen oxides (NOx), particulate matter (PM), and carbon dioxide (CO2), which are major contributors to air pollution and climate change.

| Market Scope | |

|---|---|

| Start Year | 2024 |

| Forecast Year | 2025-2034 |

| Start Value | $13.6 Billion |

| Forecast Value | $106.9 billion |

| CAGR | 23.3% |

Rising Adoption of Lithium-Ion

The lithium-ion battery segment held a significant share in 2024, owing to its high energy density, longer lifecycle, and rapid charging capabilities. Companies emphasize lithium-ion technology because it provides the reliable power needed for demanding construction tasks while reducing overall equipment weight. As battery costs continue to decline, driven by technological innovation and economies of scale, lithium-ion batteries are becoming the preferred choice for both manufacturers and end-users.

Increasing Demand for Battery Electric Vehicles

The battery electric vehicles (BEVs) are witnessing significant growth from 2025 to 2034, fueled by a global push toward zero-emission solutions. These vehicles offer the dual benefits of minimizing noise pollution and eliminating tailpipe emissions, making them ideal for urban and indoor construction sites. Companies developing BEVs are prioritizing advancements in battery technology to extend operational hours and reduce charging downtime.

Asia Pacific to Emerge as a Lucrative Region

Asia Pacific electric construction equipment market held a sizeable share in 2024, driven by rapid urbanization, infrastructure development, and supportive government policies promoting clean energy adoption. Countries such as China, Japan, and South Korea are leading the charge with substantial investments in research and development and the deployment of electric fleets. The region's expanding construction industry, coupled with rising environmental awareness, is accelerating demand for electric machinery that meets both performance and sustainability criteria.

Major players operating in the electric construction equipment industry are Liebherr, Kubota, Doosan Infracore, Mecalac, John Deere, LiuGong Machinery, Caterpillar, Komatsu, Manitou, and Hitachi Construction.

To secure and strengthen their foothold in the evolving electric construction equipment market, companies are adopting multifaceted strategies. Product innovation remains a core focus, with investments funneled into developing longer-lasting batteries, improved energy management systems, and versatile electric models that cover various equipment categories. Strategic collaborations and joint ventures with battery manufacturers and technology firms help companies accelerate innovation and reduce time-to-market. Furthermore, expanding after-sales service networks and investing in customer education initiatives are critical to building trust and easing the transition from diesel to electric machinery.

Table of Contents

Chapter 1 Methodology & Scope

- 1.1 Market scope and definition

- 1.2 Research design

- 1.2.1 Research approach

- 1.2.2 Data collection methods

- 1.3 Data mining sources

- 1.3.1 Global

- 1.3.2 Regional/Country

- 1.4 Base estimates and calculations

- 1.4.1 Base year calculation

- 1.4.2 Key trends for market estimation

- 1.5 Primary research and validation

- 1.5.1 Primary sources

- 1.6 Forecast model

- 1.7 Research assumptions and limitations

Chapter 2 Executive Summary

- 2.1 Industry 3600 synopsis, 2021 - 2034

- 2.2 Key market trends

- 2.2.1 Regional

- 2.2.2 Equipment

- 2.2.3 Battery Capacity

- 2.2.4 Battery Technology

- 2.2.5 Power Source

- 2.2.6 End Use

- 2.3 TAM Analysis, 2025-2034

- 2.4 CXO perspectives: Strategic imperatives

- 2.4.1 Executive decision points

- 2.4.2 Critical success factors

- 2.5 Future outlook and strategic recommendations

Chapter 3 Industry Insights

- 3.1 Industry ecosystem analysis

- 3.1.1 Raw material suppliers

- 3.1.2 Component manufacturers

- 3.1.3 Equipment manufacturers

- 3.1.4 Distributors and dealers

- 3.1.5 Aftermarket suppliers

- 3.2 Industry impact forces

- 3.2.1 Growth drivers

- 3.2.1.1 Stringent emission regulations

- 3.2.1.2 Urbanization & smart city projects

- 3.2.1.3 Cost savings & efficiency

- 3.2.1.4 OEM and rental adoption

- 3.2.2 Industry pitfalls and challenges

- 3.2.2.1 High upfront costs

- 3.2.2.2 Charging infrastructure gaps

- 3.2.3 Market opportunities

- 3.2.3.1 Government incentives & subsidies

- 3.2.3.2 Advancements in battery tech

- 3.2.3.3 Smart jobsite integration

- 3.2.3.4 Green infrastructure projects

- 3.2.1 Growth drivers

- 3.3 Growth potential analysis

- 3.4 Patent analysis

- 3.5 Regulatory landscape

- 3.5.1 North America

- 3.5.2 Europe

- 3.5.3 Asia Pacific

- 3.5.4 Latin America

- 3.5.5 Middle East & Africa

- 3.6 Porter's analysis

- 3.7 PESTEL analysis

- 3.8 Technology Integration and Standardization Challenges

- 3.8.1 Charging Infrastructure Compatibility and Standards

- 3.8.1.1 Connector Standards and Interoperability Issues

- 3.8.1.2 Communication Protocols and Data Exchange

- 3.8.1.3 Cross-Manufacturer Compatibility Challenges

- 3.8.1.4 Legacy System Integration and Migration Costs

- 3.8.2 Fleet Management System Integration

- 3.8.2.1 Multi-Brand Fleet Management Complexity

- 3.8.2.2 Data Integration and Analytics Platforms

- 3.8.2.3 Telematics and Remote Monitoring Systems

- 3.8.2.4 Maintenance Scheduling and Optimization

- 3.8.3 Digital Transformation and IoT Integration

- 3.8.3.1 Connectivity Standards and Protocols

- 3.8.3.2 3Data Security and Privacy Requirements

- 3.8.3.3 Edge Computing and Real-Time Analytics

- 3.8.3.4 Digital Twin Technology and Simulation

- 3.8.4 Multi-Vendor Integration Complexity

- 3.8.4.1 Charging Connector Compatibility Issues Across Brands

- 3.8.4.2 Fleet Management System Integration Challenges (15+ Platforms)

- 3.8.4.3 Data Format Standardization and Interoperability Gaps

- 3.8.4.4 Service Diagnostic Tool Requirements and Training

- 3.8.1 Charging Infrastructure Compatibility and Standards

- 3.9 3 Energy Management and Grid Integration

- 3.9.1 Smart Charging and Load Management Systems

- 3.9.1.1 Dynamic Load Balancing and Peak Shaving

- 3.9.1.2 Time-of-Use Optimization and Cost Reduction

- 3.9.1.3 Grid Stability and Demand Response Integration

- 3.9.1.4 AI and Machine Learning Applications

- 3.9.2 Renewable Energy Integration

- 3.9.2.1 Solar and Wind Power Integration Benefits

- 3.9.2.2 Energy Storage and Battery Systems

- 3.9.2.3 Microgrid Development and Islanding Capabilities

- 3.9.2.4 Carbon Footprint Reduction and Sustainability

- 3.9.3 Vehicle-to-Grid (V2G) and Bidirectional Charging

- 3.9.3.1 Grid Services and Revenue Opportunities

- 3.9.3.2 Technology Requirements and Standards

- 3.9.3.3 Business Model Development and Implementation

- 3.9.3.4 Regulatory Framework and Market Barriers

- 3.9.1 Smart Charging and Load Management Systems

- 3.10 Service Network Readiness Assessment

- 3.10.1 Geographic Service Coverage Analysis

- 3.10.1.1 Service Coverage Gap Identification (40% Markets Underserved)

- 3.10.1.2 Regional Service Density and Response Time Analysis

- 3.10.1.3 Rural vs Urban Service Availability Disparities

- 3.10.1.4 Emergency Service Response Capabilities

- 3.10.2 Technician Certification and Training Infrastructure

- 3.10.2.1 High-Voltage Certification Program Availability

- 3.10.2.2 Training Capacity and Bottleneck Analysis

- 3.10.2.3 Skill Development Timeline and Requirements

- 3.10.2.4 Certification Cost and Investment Analysis

- 3.10.3 Diagnostic Equipment and Tool Requirements

- 3.10.3.1 Specialized Diagnostic Tool Investment

- 3.10.3.2 Software Platform Integration and Updates

- 3.10.3.3 Multi-Brand Compatibility and Standardization

- 3.10.3.4 Technology Upgrade and Obsolescence Management

- 3.10.1 Geographic Service Coverage Analysis

- 3.11 Parts Availability and Supply Chain Support

- 3.11.1 Electric Component Supply Chain Maturity

- 3.11.2 Battery Replacement and Service Infrastructure

- 3.11.3 Emergency Parts Availability and Lead Times

- 3.11.4 Regional Supply Chain Development and Localization

- 3.12 Service Model Innovation and Digital Integration

- 3.12.1 Remote Diagnostics and Predictive Maintenance

- 3.12.2 Augmented Reality and Digital Service Tools

- 3.12.3 Service-as-a-Service Models and Subscriptions

- 3.12.4 Customer Self-Service and Digital Platforms

- 3.13 Patent analysis

- 3.14 Sustainability and environmental aspects

- 3.14.1 Sustainable practices

- 3.14.2 Waste reduction strategies

- 3.14.3 Energy efficiency in production

- 3.14.4 Eco-friendly Initiatives

- 3.14.5 Carbon footprint considerations

- 3.15 Use cases

- 3.16 Best-case scenario

Chapter 4 Competitive Landscape, 2024

- 4.1 Introduction

- 4.2 Company market share analysis

- 4.2.1 North America

- 4.2.2 Europe

- 4.2.3 Asia Pacific

- 4.2.4 LATAM

- 4.2.5 MEA

- 4.3 Competitive analysis of major market players

- 4.4 Competitive positioning matrix

- 4.5 Strategic outlook matrix

- 4.6 Key developments

- 4.6.1 Mergers & acquisitions

- 4.6.2 Partnerships & collaborations

- 4.6.3 New product launches

- 4.6.4 Expansion plans and funding

Chapter 5 Market Estimates & Forecast, By Equipment, 2021 - 2034 ($Bn, Units)

- 5.1 Key trends

- 5.2 Excavators

- 5.3 Loaders

- 5.4 Bulldozers

- 5.5 Cranes

- 5.6 Dump Trucks

- 5.7 Roller

- 5.8 Others

Chapter 6 Market Estimates & Forecast, By Battery Capacity, 2021 - 2034 ($Bn, Units)

- 6.1 Key trends

- 6.2 Less than 50 kWh

- 6.3 50 kWh to 200 kWh

- 6.4 More than 200 kWh

Chapter 7 Market Estimates & Forecast, By Battery Technology, 2021 - 2034 ($Bn, Units)

- 7.1 Key trends

- 7.2 Lead-acid

- 7.3 Lithium-ion

- 7.4 Nickel-metal hydride

Chapter 8 Market Estimates & Forecast, By Power Source, 2021 - 2034 ($Bn, Units)

- 8.1 Key trends

- 8.2 Battery Electric Vehicles (BEV)

- 8.3 Plug-in Hybrid Electric Vehicles (PHEV)

Chapter 9 Market Estimates & Forecast, By End Use, 2021 - 2034 ($Bn, Units)

- 9.1 Key trends

- 9.2 Construction

- 9.3 Mining

- 9.4 Material Handling

- 9.5 Agriculture

- 9.6 Others

Chapter 10 Market Estimates & Forecast, By Region, 2021 - 2034 ($Bn, Units)

- 10.1 Key trends

- 10.2 North America

- 10.2.1 US

- 10.2.2 Canada

- 10.3 Europe

- 10.3.1 UK

- 10.3.2 Germany

- 10.3.3 France

- 10.3.4 Italy

- 10.3.5 Spain

- 10.3.6 Russia

- 10.3.7 Nordics

- 10.4 Asia Pacific

- 10.4.1 China

- 10.4.2 India

- 10.4.3 Japan

- 10.4.4 Australia

- 10.4.5 South Korea

- 10.4.6 Southeast Asia

- 10.5 Latin America

- 10.5.1 Brazil

- 10.5.2 Mexico

- 10.5.3 Argentina

- 10.6 MEA

- 10.6.1 South Africa

- 10.6.2 Saudi Arabia

- 10.6.3 UAE

Chapter 11 Company Profiles

- 11.1 Global Players

- 11.1.1 Caterpillar

- 11.1.2 CNH Industrial

- 11.1.3 Hitachi Construction Machinery

- 11.1.4 JCB

- 11.1.5 John Deere

- 11.1.6 Komatsu

- 11.1.7 Komatsu

- 11.1.8 Liebherr

- 11.2 Regional Players

- 11.2.1 Develon

- 11.2.2 Doosan Infracore

- 11.2.3 Hyundai Construction Equipment

- 11.2.4 LiuGong Machinery

- 11.2.5 Manitou

- 11.2.6 Mecalac

- 11.2.7 SDLG

- 11.3 Emerging Players

- 11.3.1 Avant Tecno

- 11.3.2 Elematic

- 11.3.3 Kramer-Werke

- 11.3.4 Sunward Intelligent Equipment

- 11.3.5 Zoomlion Heavy Industry Science & Technology