|

市場調查報告書

商品編碼

1773338

BOPET 包裝薄膜市場機會、成長動力、產業趨勢分析及 2025 - 2034 年預測BOPET Packaging Films Market Opportunity, Growth Drivers, Industry Trend Analysis, and Forecast 2025 - 2034 |

||||||

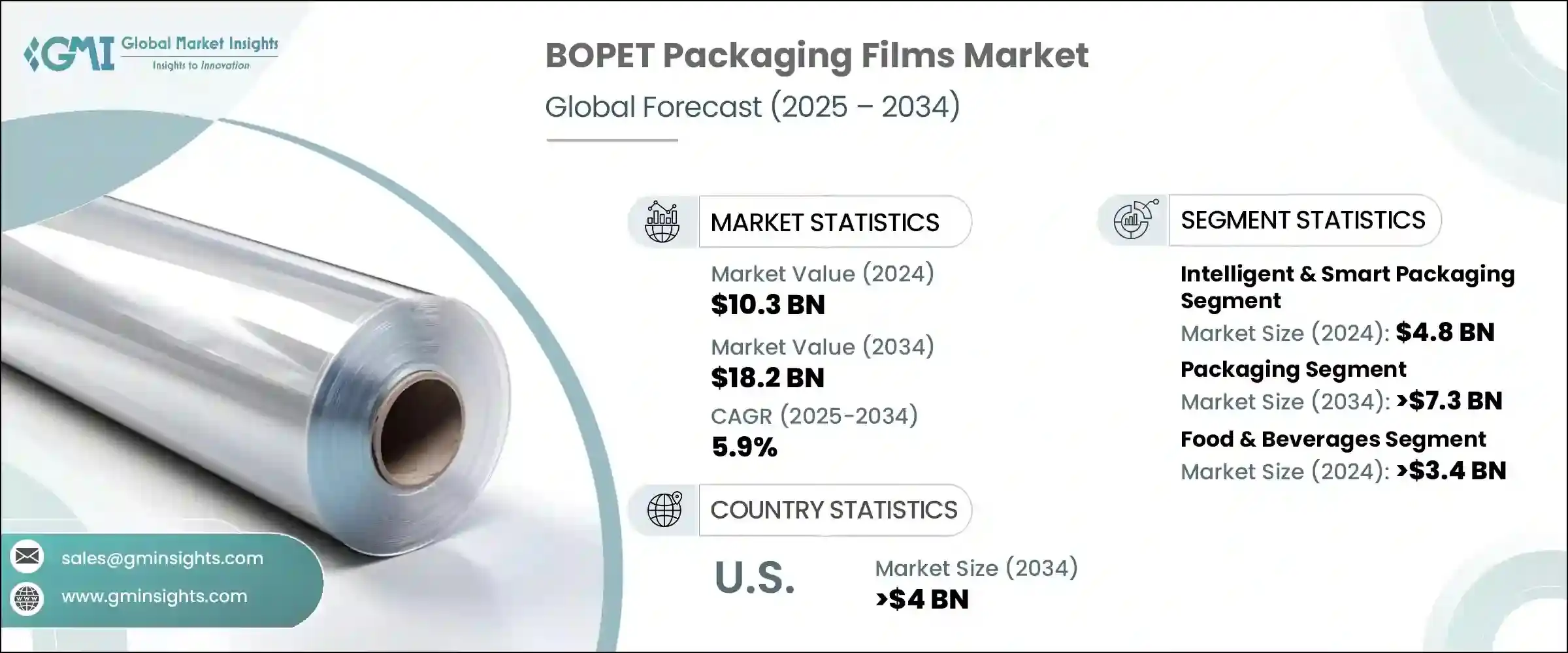

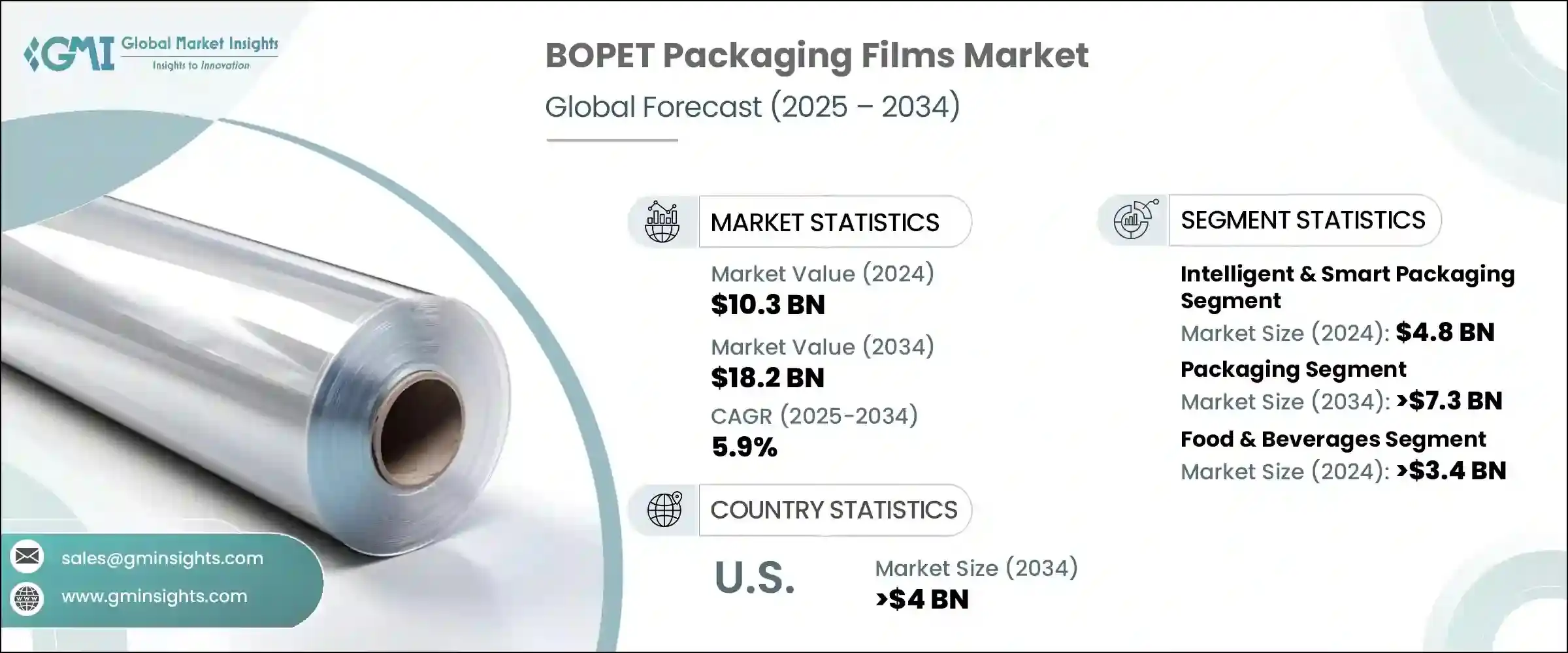

2024年,全球BOPET包裝薄膜市場規模達103億美元,預計到2034年將以5.9%的複合年成長率成長,達到182億美元。這項成長主要得益於電商平台和「最後一公里」配送系統的快速發展,以及更嚴格的永續發展要求和推廣環保包裝材料的法規。該市場面臨國際貿易緊張局勢的挑戰,尤其是川普政府推出的報復性關稅,增加了進口製造業投入的成本。由於該行業的許多主要參與者嚴重依賴進口原料,關稅迫使製造商要么將增加的成本轉嫁給消費者,要么尋找更具成本效益的國內替代品。

儘管面臨諸多不利因素,對輕量化、經濟高效且軟性包裝的需求仍在持續成長。 BOPET 薄膜相較於硬質包裝具有顯著優勢,因為它們能夠高度適應不同的產品尺寸,有助於減輕體積重量並最佳化運輸效率。消費者驅動的期望和超本地化配送趨勢進一步推動了輕量化包裝設計的創新。全球對可回收、防篡改和長保存期限包裝的需求日益成長,也推動了 BOPET 薄膜在食品、藥品、電子和個人護理行業的應用。

| 市場範圍 | |

|---|---|

| 起始年份 | 2024 |

| 預測年份 | 2025-2034 |

| 起始值 | 103億美元 |

| 預測值 | 182億美元 |

| 複合年成長率 | 5.9% |

隨著對兼具耐用性和柔韌性的保護性包裝的需求日益成長,BOPET 薄膜的市場持續受到青睞,遠超硬質薄膜。這些薄膜尤其因其能夠貼合各種產品形狀和尺寸而備受青睞,有助於減少運輸量,並最終降低物流成本。這一趨勢與全球對符合法規和消費者期望的環保包裝日益成長的需求相符。

BOPET 薄膜作為智慧和活性包裝技術的理想基材,也日益受到青睞。 2024 年,智慧包裝市場規模達 48 億美元。這些創新包裝解決方案包含除氧劑、抗菌劑和濕度調節劑等功能性成分,它們與包裝內部環境相互作用,以保持產品的新鮮度和安全性。 BOPET 薄膜憑藉其高熱穩定性、優異的阻隔性和耐化學性,能夠有效支持這些應用。這些特性使其成為食品飲料、醫療保健和化妝品等產品的首選,因為這些行業的產品壽命和完整性至關重要。

預計到2034年,更廣泛的包裝應用領域將達到73億美元。 BOPET薄膜憑藉其卓越的機械強度、透明度以及防潮防氣性能,在該領域佔據主導地位。它們非常適合多層軟包裝系統,尤其是在製藥、食品和個人護理等高性能要求較高的行業。食品安全法規的日益嚴格、消費者對永續性的意識日益增強以及對可回收解決方案的需求,加速了BOPET材料在初級包裝和次級包裝中的應用。此外,全球線上零售的擴張也推動了對確保產品安全並延長保存期限的包裝的需求。

預計2034年,美國BOPET包裝薄膜市場規模將達40億美元。聯邦物流、製藥、食品和電子等行業的需求持續推動軟包裝的創新。美國製造商正面臨越來越大的壓力,需要轉向可回收和生物基材料,以滿足消費者的期望和永續發展目標。這些不斷變化的需求正推動先進解決方案的開發,例如輕質軟性郵寄袋和可回收緩衝包裝。像三菱聚酯薄膜有限公司這樣的全球製造商正引領業界潮流,打造專為全通路零售模式設計的環保包裝,同時兼顧性能和永續性。

全球 BOPET 包裝膜市場的主要參與者包括三菱聚酯薄膜有限公司 (Mitsubishi Polyester Film GmbH)、SKC、SRF Limited、Polyplex 和 UFlex Limited。為了鞏固市場地位,BOPET 包裝膜產業的公司專注於垂直整合、投資永續產品開發以及建立策略合作夥伴關係。領先的公司正在提高產能並本地化供應鏈,以減少對進口的依賴並減輕關稅影響。創新發揮關鍵作用,研發團隊致力於開發可回收、可生物分解且輕質的薄膜解決方案,以滿足不斷變化的監管要求和消費者需求。公司也與電商和快速消費品品牌結盟,共同開發適合快速交付系統的特殊包裝形式。

目錄

第1章:方法論與範圍

第2章:執行摘要

第3章:行業洞察

- 產業生態系統分析

- 川普政府關稅

- 對貿易的影響

- 貿易量中斷

- 報復措施

- 對產業的影響

- 供應方影響(原料)

- 主要材料價格波動

- 供應鏈重組

- 生產成本影響

- 需求面影響(售價)

- 價格傳導至終端市場

- 市佔率動態

- 消費者反應模式

- 供應方影響(原料)

- 受影響的主要公司

- 策略產業反應

- 供應鏈重組

- 定價和產品策略

- 政策參與

- 展望與未來考慮

- 對貿易的影響

- 產業衝擊力

- 成長動力

- 食品飲料和製藥業的成長

- 在高性能絕緣和層壓應用中的使用日益增多

- 對靈活輕量包裝解決方案的需求不斷成長

- 永續和可回收包裝材料激增

- BOPET 薄膜具有優異的阻隔水分和氣體性能

- 產業陷阱與挑戰

- 多層薄膜結構所帶來的回收挑戰

- 原物料價格波動(例如 PTA 和 MEG)

- 成長動力

- 成長潛力分析

- 監管格局

- 技術格局

- 未來市場趨勢

- 差距分析

- 波特的分析

- PESTEL分析

第4章:競爭格局

- 介紹

- 公司市佔率分析

- 主要市場參與者的競爭分析

- 競爭定位矩陣

- 策略儀表板

第5章:市場估計與預測:按類型,2021 - 2034 年

- 智慧包裝

- 活性包裝

第6章:市場估計與預測:按應用,2021 - 2034 年

- 包裝

- 工業的

- 電氣和電子

- 影像學

- 其他

第7章:市場估計與預測:依最終用途,2021 - 2034 年

- 食品和飲料

- 製藥

- 個人護理和化妝品

- 消費性電子產品

- 其他

第8章:市場估計與預測:按地區,2021 - 2034 年

- 主要趨勢

- 北美洲

- 美國

- 加拿大

- 歐洲

- 德國

- 英國

- 法國

- 西班牙

- 義大利

- 荷蘭

- 亞太地區

- 中國

- 印度

- 日本

- 澳洲

- 韓國

- 拉丁美洲

- 巴西

- 墨西哥

- 阿根廷

- 中東和非洲

- 沙烏地阿拉伯

- 南非

- 阿拉伯聯合大公國

第9章:公司簡介

- Amcor PLC

- Avery Dennison

- BASF SE

- CCL Industries Inc.

- Checkpoint Systems, Inc

- DuPont Teijin Films

- Klockner Pentaplast

- Sealed Air Corporation

- Sonoco Products Company

- Tetra Pak International SA

The Global BOPET Packaging Films Market was valued at USD 10.3 billion in 2024 and is estimated to grow at a CAGR of 5.9% to reach USD 18.2 billion by 2034. This growth is largely fueled by the rapid development of e-commerce platforms and last-mile delivery systems, along with stricter sustainability mandates and regulations promoting eco-friendly packaging materials. The market faces challenges from international trade tensions, particularly the retaliatory tariffs introduced by the Trump administration, which have increased the cost of imported manufacturing inputs. Since many major players in this sector depend heavily on imported raw materials, the tariffs have forced manufacturers to either pass the increased costs on to consumers or find cost-effective domestic alternatives.

Despite these headwinds, the demand for lightweight, cost-effective, and flexible packaging continues to grow. BOPET films offer a distinct advantage over rigid formats, as they are highly adaptable to different product dimensions, helping reduce volumetric weight and optimizing shipping efficiency. Consumer-driven expectations and hyperlocal delivery trends are further encouraging innovation in lightweight packaging design. The expanding global push for recyclable, tamper-evident, and extended-shelf-life packaging is also pushing the use of BOPET films across food, pharmaceuticals, electronics, and personal care industries.

| Market Scope | |

|---|---|

| Start Year | 2024 |

| Forecast Year | 2025-2034 |

| Start Value | $10.3 billion |

| Forecast Value | $18.2 billion |

| CAGR | 5.9% |

The growing need for protective packaging that combines durability with flexibility continues to favor BOPET film formats over rigid alternatives. These films are especially valued for their ability to conform to various product shapes and sizes, which helps in reducing shipping volumes and, ultimately, logistics costs. This trend is in line with the increasing global demand for environmentally friendly packaging that meets both regulatory and consumer expectations.

BOPET films are also gaining popularity as ideal substrates for intelligent and active packaging technologies. In 2024, the smart packaging segment reached USD 4.8 billion. These innovative packaging solutions include functional components such as oxygen scavengers, antimicrobial agents, and moisture regulators, which interact with the internal package environment to preserve product freshness and safety. BOPET films support these applications effectively due to their high thermal stability, excellent barrier resistance, and chemical durability. These qualities make them a preferred choice for sectors such as food and beverage, healthcare, and cosmetics, where product longevity and integrity are critical.

The broader packaging application segment is forecasted to reach USD 7.3 billion by 2034. Within this space, BOPET films dominate due to their superior mechanical strength, transparency, and moisture and gas barrier capabilities. They are highly suitable for multilayer and flexible packaging systems, especially in industries demanding high performance, such as pharmaceuticals, food, and personal care. Stricter food safety laws, growing consumer awareness regarding sustainability, and the need for recyclable solutions have accelerated the use of BOPET materials in both primary and secondary packaging. Additionally, the expansion of global online retail is boosting demand for packaging that ensures product security and extends shelf life.

United States BOPET Packaging Films Market is projected to reach USD 4 billion by 2034. Demand from sectors such as federal logistics, pharmaceuticals, food, and electronics continue to drive innovation in flexible packaging. US manufacturers are under increasing pressure to shift toward recyclable and bio-based materials to align with consumer expectations and sustainability goals. These evolving demands are inspiring the development of advanced solutions such as lightweight flexible mailers and recyclable cushioning formats. Manufacturers like Mitsubishi Polyester Film GmbH worldwide are leading the charge in creating eco-friendly packaging designed for omnichannel retail models while balancing performance and sustainability.

Key players in the Global BOPET Packaging Films Market include Mitsubishi Polyester Film GmbH, SKC, SRF Limited, Polyplex, and UFlex Limited. To strengthen their market foothold, companies in the BOPET packaging films industry focus on vertical integration, investment in sustainable product development, and strategic partnerships. Leading firms are ramping up production capacities and localizing supply chains to reduce dependency on imports and mitigate tariff impacts. Innovation plays a key role, with R&D teams developing recyclable, biodegradable, and lightweight film solutions to meet shifting regulatory requirements and consumer demands. Companies are also forming alliances with e-commerce and FMCG brands to co-develop specialized packaging formats tailored for fast-moving delivery systems.

Table of Contents

Chapter 1 Methodology and Scope

- 1.1 Market scope and definitions

- 1.2 Research design

- 1.2.1 Research approach

- 1.2.2 Data collection methods

- 1.3 Base estimates and calculations

- 1.3.1 Base year calculation

- 1.3.2 Key trends for market estimation

- 1.4 Forecast model

- 1.5 Primary research and validation

- 1.5.1 Primary sources

- 1.5.2 Data mining sources

Chapter 2 Executive Summary

- 2.1 Industry 3600 synopsis

Chapter 3 Industry Insights

- 3.1 Industry ecosystem analysis

- 3.2 Trump administration tariffs

- 3.2.1 Impact on trade

- 3.2.1.1 Trade volume disruptions

- 3.2.1.2 Retaliatory measures

- 3.2.2 Impact on the industry

- 3.2.2.1 Supply-side impact (raw materials)

- 3.2.2.1.1 Price volatility in key materials

- 3.2.2.1.2 Supply chain restructuring

- 3.2.2.1.3 Production cost implications

- 3.2.2.2 Demand-side impact (selling price)

- 3.2.2.2.1 Price transmission to end markets

- 3.2.2.2.2 Market share dynamics

- 3.2.2.2.3 Consumer response patterns

- 3.2.2.1 Supply-side impact (raw materials)

- 3.2.3 Key companies impacted

- 3.2.4 Strategic industry responses

- 3.2.4.1 Supply chain reconfiguration

- 3.2.4.2 Pricing and product strategies

- 3.2.4.3 Policy engagement

- 3.2.5 Outlook and future considerations

- 3.2.1 Impact on trade

- 3.3 Industry impact forces

- 3.3.1 Growth drivers

- 3.3.1.1 Growth in food & beverage and pharmaceutical industries

- 3.3.1.2 Increasing use in high-performance insulation and lamination applications

- 3.3.1.3 Rising demand for flexible and lightweight packaging solutions

- 3.3.1.4 Surge in sustainable and recyclable packaging materials

- 3.3.1.5 Excellent barrier properties of BOPET films against moisture and gases

- 3.3.2 Industry pitfalls and challenges

- 3.3.2.1 Recycling challenges due to multi-layer film structures

- 3.3.2.2 Volatility in raw material prices (e.g., PTA and MEG)

- 3.3.1 Growth drivers

- 3.4 Growth potential analysis

- 3.5 Regulatory landscape

- 3.6 Technology landscape

- 3.7 Future market trends

- 3.8 Gap analysis

- 3.9 Porter's analysis

- 3.10 PESTEL analysis

Chapter 4 Competitive Landscape, 2024

- 4.1 Introduction

- 4.2 Company market share analysis

- 4.3 Competitive analysis of major market players

- 4.4 Competitive positioning matrix

- 4.5 Strategy dashboard

Chapter 5 Market estimates & forecast, By Type, 2021 - 2034 (USD Billion)

- 5.1 Intelligent & smart packaging

- 5.2 Active packaging

Chapter 6 Market estimates & forecast, By Application, 2021 - 2034 (USD Billion)

- 6.1 Packaging

- 6.2 Industrial

- 6.3 Electrical and electronics

- 6.4 Imaging

- 6.5 Others

Chapter 7 Market estimates & forecast, By End Use, 2021 - 2034 (USD Billion)

- 7.1 Food & beverages

- 7.2 Pharmaceuticals

- 7.3 Personal care & cosmetics

- 7.4 Consumer electronics

- 7.5 Others

Chapter 8 Market estimates and forecast, By Region, 2021 - 2034 (USD Billion)

- 8.1 Key trends

- 8.2 North America

- 8.2.1 U.S.

- 8.2.2 Canada

- 8.3 Europe

- 8.3.1 Germany

- 8.3.2 UK

- 8.3.3 France

- 8.3.4 Spain

- 8.3.5 Italy

- 8.3.6 Netherlands

- 8.4 Asia Pacific

- 8.4.1 China

- 8.4.2 India

- 8.4.3 Japan

- 8.4.4 Australia

- 8.4.5 South Korea

- 8.5 Latin America

- 8.5.1 Brazil

- 8.5.2 Mexico

- 8.5.3 Argentina

- 8.6 Middle East and Africa

- 8.6.1 Saudi Arabia

- 8.6.2 South Africa

- 8.6.3 UAE

Chapter 9 Company Profiles

- 9.1 Amcor PLC

- 9.2 Avery Dennison

- 9.3 BASF SE

- 9.4 CCL Industries Inc.

- 9.5 Checkpoint Systems, Inc

- 9.6 DuPont Teijin Films

- 9.7 Klockner Pentaplast

- 9.8 Sealed Air Corporation

- 9.9 Sonoco Products Company

- 9.10 Tetra Pak International S.A.