|

市場調查報告書

商品編碼

1766185

電動車軸承市場機會、成長動力、產業趨勢分析及 2025 - 2034 年預測Electric Vehicle Bearings Market Opportunity, Growth Drivers, Industry Trend Analysis, and Forecast 2025 - 2034 |

||||||

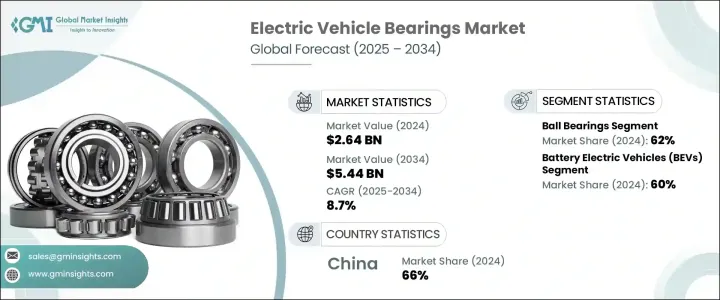

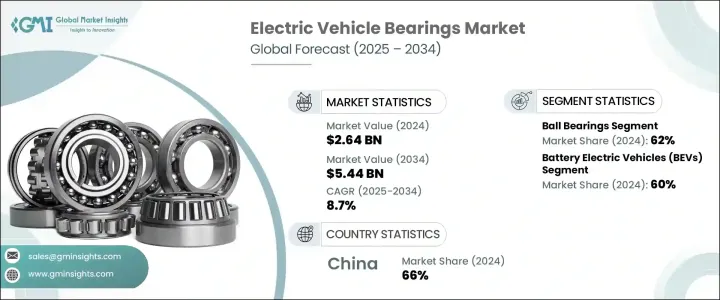

2024年,全球電動車軸承市場規模達26.4億美元,預計到2034年將以8.7%的複合年成長率成長,達到54.4億美元。電動車的快速發展加速了對先進軸承技術的需求,這些技術旨在提高電動傳動系統的效率、耐用性和性能。市場擴張的主要驅動力是市場對節能、低摩擦零件的需求不斷成長,這些零件能夠承受高負荷,並有助於延長車輛和電池的使用壽命。隨著電動車在各大汽車市場的普及,針對電動車獨特機械應力和熱應力而設計的專用軸承的需求也迅速成長。

世界各國政府正透過財政誘因和更嚴格的環境法規來強化這項轉型,促使汽車製造商優先考慮輕量化、精密設計的軸承解決方案。此外,高階電動車產量的不斷成長,也推動了對超可靠、降噪部件的需求,這些部件能夠提供無縫銜接、精緻的駕駛體驗。隨著電動車傳動系統架構的不斷發展——包括多速系統和整合式電橋——軸承供應商需要提供能夠在嚴苛環境下運作的高性能解決方案。為此,領先的製造商不斷推動設計創新,以滿足汽車行業日益成長的期望。

| 市場範圍 | |

|---|---|

| 起始年份 | 2024 |

| 預測年份 | 2025-2034 |

| 起始值 | 26.4億美元 |

| 預測值 | 54.4億美元 |

| 複合年成長率 | 8.7% |

2024年,滾珠軸承類別佔據電動車軸承市場62%的主導地位,預計在預測期內的複合年成長率將超過9.8%。該細分市場之所以能夠保持領先地位,是因為它能夠支援大量生產、保持一致的質量,並滿足電動傳動系統的嚴苛運作需求。滾珠軸承以其最小的摩擦力和最高的可靠性而聞名,並被廣泛整合到各種電動車零件中,包括電動馬達、變速箱和輪轂。隨著原始設備製造商 (OEM) 加速推出涵蓋電氣化、ADAS 和資訊娛樂技術的下一代汽車系統,汽車製造商也日益尋求能夠滿足其獨特性能和耐用性需求的先進工程服務和零件。

2024年,純電動車 (BEV) 佔據了60%的市場佔有率,穩居領先地位。 BEV 需要高精度零件來支援更高的能源效率、高速運行和降低噪音,從而從根本上重塑了電動車軸承的格局。 BEV 系統的特性要求軸承能夠承受更大的熱波動和更長的運作週期,同時保持最佳性能。隨著 BEV 在全球範圍內的持續普及,軸承製造商正在投資開發先進的解決方案,以滿足高速馬達不斷變化的技術規格,並確保產品的長期可靠性。

亞太地區電動車軸承市場佔66%的市場佔有率,2024年市場規模達9.397億美元。作為電動車生產和出口的全球領導者,中國受益於強力的政策支持、不斷擴展的供應鏈以及快速成長的本土汽車製造商數量。為了滿足這項需求,中國本土軸承製造商正在加強研發力度,並擴大生產專為高效能電動傳動系統量身定做的高性能軸承解決方案。中國積極參與軸承技術進步,彰顯了其在全球電動車軸承市場的核心地位。

推動全球電動車軸承產業創新和競爭的關鍵公司包括舍弗勒、斯凱孚、捷太格特、恩梯恩、那智不二越、日本精工和鐵姆肯。為了鞏固市場地位,電動車軸承製造商正在採取多項重點策略。其中包括投入巨資研發針對電動傳動系統最佳化的高速、低摩擦和熱穩定軸承技術。企業也與汽車製造商建立長期合作夥伴關係,共同開發客製化解決方案,順應轉向整合式電動出行平台的趨勢。擴大在主要電動車市場的製造足跡,尤其是在亞洲和北美,是另一個關鍵策略。此外,企業正在透過提供緊湊、輕巧和耐用的設計來增強產品組合,以滿足不斷發展的傳動系統架構,同時提高能源效率並延長維修間隔。

目錄

第1章:方法論

- 市場範圍和定義

- 研究設計

- 研究方法

- 資料收集方法

- 資料探勘來源

- 全球的

- 地區/國家

- 基礎估算與計算

- 基準年計算

- 市場評估的主要趨勢

- 初步研究和驗證

- 主要來源

- 預測模型

- 研究假設和局限性

第2章:執行摘要

第3章:行業洞察

- 產業生態系統分析

- 供應商概況

- 利潤率

- 成本結構

- 每個階段的增值

- 影響價值鏈的因素

- 中斷

- 產業衝擊力

- 成長動力

- 在政府獎勵措施的支持下,電動車在全球的普及率不斷提高

- 輕量化和智慧軸承技術的進步提高了效率和耐用性

- 新興市場電動車製造的擴張

- 透過感測器軸承整合預測性維護。

- 產業陷阱與挑戰

- 初始成本高

- 安裝維護複雜

- 市場機會

- 全球電動車產量激增

- 研發以及與原始設備製造商的共同開發

- 成長動力

- 成長潛力分析

- 監管格局

- 波特的分析

- PESTEL分析

- 技術和創新格局

- 當前的技術趨勢

- 新興技術

- 專利分析

- 價格趨勢

- 按地區

- 按組件

- 生產統計

- 生產中心

- 消費中心

- 匯出和匯入

- 成本細分分析

- 永續性和環境方面

- 永續實踐

- 減少廢棄物的策略

- 生產中的能源效率

- 環保舉措

- 碳足跡考量

第4章:競爭格局

- 介紹

- 公司市佔率分析

- 北美洲

- 歐洲

- 亞太地區

- 拉丁美洲

- 中東和非洲

- 主要市場參與者的競爭分析

- 競爭定位矩陣

- 戰略展望矩陣

- 關鍵進展

- 併購

- 夥伴關係與合作

- 新產品發布

- 擴張計劃和資金

第5章:市場估計與預測:按類型,2021 - 2034 年

- 主要趨勢

- 滾珠軸承

- 滾子軸承

- 其他

第6章:市場估計與預測:依車型,2021 - 2034 年

- 主要趨勢

- 純電動車(BEV)

- 插電式混合動力電動車(PHEV)

- 混合動力電動車(HEV)

- 燃料電池電動車(FCEV)

第7章:市場估計與預測:依資料,2021 - 2034 年

- 主要趨勢

- 鋼製軸承

- 陶瓷軸承

- 聚合物軸承

- 其他

第8章:市場估計與預測:依銷售管道,2021 - 2034 年

- 主要趨勢

- 原始設備製造商

- 售後市場

第9章:市場估計與預測:依軸承尺寸,2021 - 2034 年

- 主要趨勢

- 小軸承

- 中型軸承

- 大型軸承

第10章:市場估計與預測:按地區,2021 - 2034 年

- 主要趨勢

- 北美洲

- 美國

- 加拿大

- 歐洲

- 英國

- 德國

- 法國

- 義大利

- 西班牙

- 俄羅斯

- 北歐人

- 亞太地區

- 中國

- 印度

- 日本

- 韓國

- 澳新銀行

- 東南亞

- 拉丁美洲

- 巴西

- 墨西哥

- 阿根廷

- MEA

- 阿拉伯聯合大公國

- 沙烏地阿拉伯

第 11 章:公司簡介

- ILJIN

- BRK

- C&U Group

- Fersa

- IKO Nippon Thompson

- JTEKT

- Luoyang LYC Bearing

- MinebeaMitsumi

- Nachi-Fujikoshi

- NBC

- NMB Technologies

- NSK

- NSK-Warner

- NTN

- RBC Bearings

- Schaeffler

- SKF

- The Timken

- THK

- ZWZ

The Global Electric Vehicle Bearings Market was valued at USD 2.64 billion in 2024 and is estimated to grow at a CAGR of 8.7% to reach USD 5.44 billion by 2034. The rising shift toward electric mobility is accelerating the need for advanced bearing technologies that enhance the efficiency, durability, and performance of electric drivetrains. Market expansion is largely driven by rising demand for energy-efficient, low-friction components that can withstand high loads and contribute to prolonged vehicle and battery life. With the growing adoption of EVs across major automotive regions, demand for specialized bearings designed to address the unique mechanical and thermal stresses of electric vehicles is increasing rapidly.

Governments worldwide are reinforcing this transition with financial incentives and tighter environmental regulations, prompting automakers to prioritize lightweight, precision-engineered bearing solutions. Additionally, the rising production of premium electric vehicles is fueling the demand for ultra-reliable, noise-reducing components that deliver seamless and refined driving experiences. As EV drivetrain architectures evolve-incorporating multi-speed systems and integrated e-axles-bearing suppliers are required to offer high-performance solutions capable of operating in demanding environments. In response, leading manufacturers continue to push design innovation to meet the growing expectations of the automotive sector.

| Market Scope | |

|---|---|

| Start Year | 2024 |

| Forecast Year | 2025-2034 |

| Start Value | $2.64 Billion |

| Forecast Value | $5.44 Billion |

| CAGR | 8.7% |

In 2024, the ball bearings category led the EV bearings market with a dominant 62% share and is expected to expand at a CAGR exceeding 9.8% during the forecast timeline. The segment holds its position due to its ability to support high-volume manufacturing, maintain consistent quality, and meet the demanding operational needs of electric drivetrains. Known for offering minimal friction and maximum reliability, ball bearings are widely integrated into various EV components, including electric motors, transmissions, and wheel hubs. As original equipment manufacturers (OEMs) accelerate the rollout of next-gen vehicle systems-spanning electrification, ADAS, and infotainment technologies-automakers increasingly seek advanced engineering services and components tailored to their unique performance and durability needs.

Battery electric vehicles (BEVs) accounted for a 60% share in 2024, securing the leading segment share. BEVs are fundamentally reshaping the electric vehicle bearings landscape by requiring high-precision components that support enhanced energy efficiency, high-speed operation, and noise minimization. The nature of BEV systems demands bearings that can handle greater thermal fluctuations and extended operating cycles while maintaining optimal performance. As BEVs continue to gain popularity globally, bearing manufacturers are investing in the development of advanced solutions that meet the evolving technical specifications of high-speed electric motors and ensure long-term product reliability.

Asia Pacific Electric Vehicle Bearings Market held a 66% share and generated USD 939.7 million in 2024. As a global leader in EV production and export, China benefits from strong policy support, an expanding supply chain, and a rapidly growing number of domestic automakers. Local bearing manufacturers are responding to this demand by ramping up R&D and scaling production of high-performance bearing solutions tailored for high-efficiency electric drivetrains. The country's active involvement in advancing bearing technologies underscores its position as a central player in the global EV bearings market.

The key companies driving innovation and competition in the Global Electric Vehicle Bearings Industry include Schaeffler, SKF, JTEKT, NTN, Nachi-Fujikoshi, NSK, and Timken. To strengthen their market foothold, electric vehicle-bearing manufacturers are adopting several focused strategies. These include heavy R&D investment to develop high-speed, low-friction, and thermally stable bearing technologies optimized for electric drivetrains. Companies are also forging long-term partnerships with automakers to co-develop custom solutions, aligning with the shift toward integrated e-mobility platforms. Expanding manufacturing footprints in key EV markets, particularly across Asia and North America, is another key approach. In addition, firms are enhancing product portfolios by offering compact, lightweight, and durable designs that meet evolving drivetrain architectures while improving energy efficiency and extending service intervals.

Table of Contents

Chapter 1 Methodology

- 1.1 Market scope and definition

- 1.2 Research design

- 1.2.1 Research approach

- 1.2.2 Data collection methods

- 1.3 Data mining sources

- 1.3.1 Global

- 1.3.2 Regional/Country

- 1.4 Base estimates and calculations

- 1.4.1 Base year calculation

- 1.4.2 Key trends for market estimation

- 1.5 Primary research and validation

- 1.5.1 Primary sources

- 1.6 Forecast model

- 1.7 Research assumptions and limitations

Chapter 2 Executive Summary

- 2.1 Industry 360° synopsis

- 2.2 Key market trends

- 2.2.1 Regional

- 2.2.2 Product

- 2.2.3 End Use

- 2.3 TAM Analysis, 2025-2034

- 2.4 CXO perspectives: Strategic imperatives

- 2.4.1 Key decision points for industry executives

- 2.4.2 Critical success factors for market players

- 2.5 Future Outlook and Strategic Recommendations

Chapter 3 Industry Insights

- 3.1 Industry ecosystem analysis

- 3.1.1 Supplier Landscape

- 3.1.2 Profit Margin

- 3.1.3 Cost structure

- 3.1.4 Value addition at each stage

- 3.1.5 Factor affecting the value chain

- 3.1.6 Disruptions

- 3.2 Industry impact forces

- 3.2.1 Growth drivers

- 3.2.1.1 Increasing global adoption of electric vehicles supported by government incentives

- 3.2.1.2 Advancements in lightweight and smart bearing technologies improve efficiency and durability

- 3.2.1.3 Expansion of EV manufacturing in emerging markets

- 3.2.1.4 Integration of predictive maintenance through sensor-enabled bearings.

- 3.2.2 Industry pitfalls & challenges

- 3.2.2.1 High initial costs

- 3.2.2.2 Complex installation and maintenance

- 3.2.3 Market opportunities

- 3.2.3.1 Surging global EV production

- 3.2.3.2 R&D and co-development with OEMs

- 3.2.1 Growth drivers

- 3.3 Growth potential analysis

- 3.4 Regulatory landscape

- 3.5 Porter's analysis

- 3.6 PESTEL analysis

- 3.7 Technology and innovation landscape

- 3.7.1 Current technological trends

- 3.7.2 Emerging technologies

- 3.8 Patent analysis

- 3.9 Price trends

- 3.9.1 By region

- 3.9.2 By component

- 3.10 Production statistics

- 3.10.1 Production hubs

- 3.10.2 Consumption hubs

- 3.10.3 Export and import

- 3.11 Cost breakdown analysis

- 3.12 Sustainability and environmental aspects

- 3.12.1 Sustainable practices

- 3.12.2 Waste reduction strategies

- 3.12.3 Energy efficiency in production

- 3.12.4 Eco-friendly initiatives

- 3.12.5 Carbon footprint considerations

Chapter 4 Competitive Landscape, 2024

- 4.1 Introduction

- 4.2 Company market share analysis

- 4.2.1 North America

- 4.2.2 Europe

- 4.2.3 Asia Pacific

- 4.2.4 Latin America

- 4.2.5 Middle East & Africa

- 4.3 Competitive analysis of major market players

- 4.4 Competitive positioning matrix

- 4.5 Strategic outlook matrix

- 4.6 Key developments

- 4.6.1 Mergers & acquisitions

- 4.6.2 Partnerships & collaborations

- 4.6.3 New Product Launches

- 4.6.4 Expansion Plans and funding

Chapter 5 Market Estimates & Forecast, By Type, 2021 - 2034 ($Mn, Units)

- 5.1 Key trends

- 5.2 Ball bearings

- 5.3 Roller bearings

- 5.4 Others

Chapter 6 Market Estimates & Forecast, By Vehicle, 2021 - 2034 ($Mn, Units)

- 6.1 Key trends

- 6.2 Battery electric vehicles (BEVs)

- 6.3 Plug-in hybrid electric vehicles (PHEVs)

- 6.4 Hybrid electric vehicles (HEVs)

- 6.5 Fuel cell electric vehicles (FCEVs)

Chapter 7 Market Estimates & Forecast, By Material, 2021 - 2034 ($Mn, Units)

- 7.1 Key trends

- 7.2 Steel bearings

- 7.3 Ceramic bearings

- 7.4 Polymer bearings

- 7.5 Others

Chapter 8 Market Estimates & Forecast, By Sales Channel, 2021 - 2034 ($Mn, Units)

- 8.1 Key trends

- 8.2 OEMs

- 8.3 Aftermarket

Chapter 9 Market Estimates & Forecast, By Bearing Size, 2021 - 2034 ($Mn, Units)

- 9.1 Key trends

- 9.2 Small bearings

- 9.3 Medium bearings

- 9.4 Large bearings

Chapter 10 Market Estimates & Forecast, By Region, 2021 - 2034 ($Mn, Units)

- 10.1 Key trends

- 10.2 North America

- 10.2.1 U.S.

- 10.2.2 Canada

- 10.3 Europe

- 10.3.1 UK

- 10.3.2 Germany

- 10.3.3 France

- 10.3.4 Italy

- 10.3.5 Spain

- 10.3.6 Russia

- 10.3.7 Nordics

- 10.4 Asia Pacific

- 10.4.1 China

- 10.4.2 India

- 10.4.3 Japan

- 10.4.4 South Korea

- 10.4.5 ANZ

- 10.4.6 Southeast Asia

- 10.5 Latin America

- 10.5.1 Brazil

- 10.5.2 Mexico

- 10.5.3 Argentina

- 10.6 MEA

- 10.6.1 UAE

- 10.6.2 Saudi Arabia

Chapter 11 Company Profiles

- 11.1 ILJIN

- 11.2 BRK

- 11.3 C&U Group

- 11.4 Fersa

- 11.5 IKO Nippon Thompson

- 11.6 JTEKT

- 11.7 Luoyang LYC Bearing

- 11.8 MinebeaMitsumi

- 11.9 Nachi-Fujikoshi

- 11.10 NBC

- 11.11 NMB Technologies

- 11.12 NSK

- 11.13 NSK-Warner

- 11.14 NTN

- 11.15 RBC Bearings

- 11.16 Schaeffler

- 11.17 SKF

- 11.18 The Timken

- 11.19 THK

- 11.20 ZWZ