|

市場調查報告書

商品編碼

1740970

軟管灌裝機市場機會、成長動力、產業趨勢分析及 2025 - 2034 年預測Tube Filling Machine Market Opportunity, Growth Drivers, Industry Trend Analysis, and Forecast 2025 - 2034 |

||||||

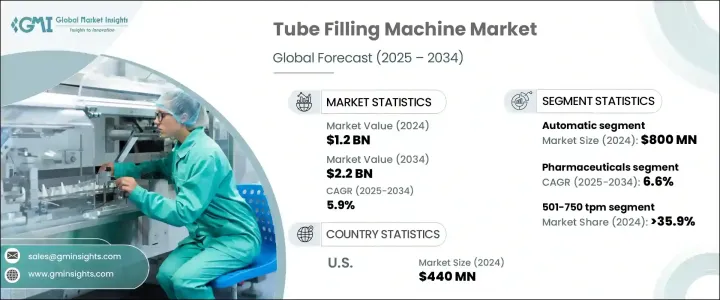

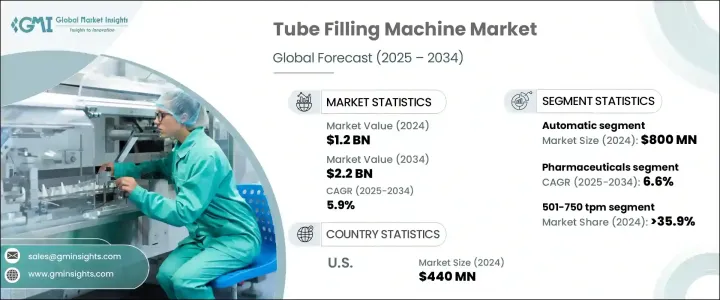

2024年,全球軟管灌裝機市場規模達12億美元,預計2034年將以5.9%的複合年成長率成長至22億美元。這一成長主要得益於各行各業對自動化日益成長的需求以及包裝技術的進步。消費品產業尤其推動著這一轉變,因為企業正在尋求採用更精確、更有效率、更具可擴展性的製造流程。軟管灌裝機對於滿足這些需求至關重要,它能夠靈活地包裝各種產品,包括個人護理用品、藥品和食品。這些機器不僅提高了生產效率,還能透過確保精確填充來最大限度地減少浪費,最終降低營運成本。此外,消費者對衛生、單劑量和攜帶式包裝解決方案的日益青睞,也推動了軟管灌裝系統的需求成長。這一趨勢在食品和飲料等各個行業都很明顯,其中定量調味品和一次性牙膏正變得越來越受歡迎。隨著軟管包裝產品需求的成長,軟管灌裝機市場也不斷擴大。

2024年,自動軟管灌裝機市場營收達8億美元,預計到2034年複合年成長率將達到6.2%。自動化轉型勢頭強勁,尤其是在食品、製藥和化妝品等高速、大量生產至關重要的產業。自動軟管灌裝機在灌裝、密封和貼標等過程中最大限度地減少人機交互,在提高生產效率方面發揮關鍵作用。這不僅可以確保更快的生產速度,還能提高一致性並減少錯誤。這些機器配備了自動軟管進料和精確填充控制等先進功能,可協助製造商提高生產效率並降低人力成本。自動化系統日益普及也得益於創新技術,這些創新技術使這些機器能夠處理各種尺寸和材質的軟管,進一步提升了其在各個領域的吸引力。

| 市場範圍 | |

|---|---|

| 起始年份 | 2024 |

| 預測年份 | 2025-2034 |

| 起始值 | 12億美元 |

| 預測值 | 22億美元 |

| 複合年成長率 | 5.9% |

光是製藥業,2024 年就從軟管灌裝機創造了 5 億美元的收入,預計到 2034 年的複合年成長率為 6.6%。製藥業對軟管灌裝機的需求尤其強勁,因為該行業對精準無菌包裝的需求至關重要。軟管灌裝機確保乳膏、軟膏和凝膠等產品在無菌環境中準確填充,這對於維護產品品質和安全至關重要。全自動系統在製藥製造業的應用簡化了作業流程,降低了污染風險,並提高了整體生產效率。隨著產業持續將安全和品質放在首位,軟管灌裝機也不斷發展,以滿足更嚴格的監管標準和消費者期望。

2024 年,每分鐘 501-750 支管 (tpm) 細分市場佔據了軟管灌裝機市場的 35.9% 以上,預計到 2034 年將以 6.1% 的速度成長。這個細分市場因其能夠適應各種產品、軟管尺寸和黏度而受到青睞,對於生產各種產品或計劃向市場推出新產品的公司來說,這使其成為理想之選。 501-750 tpm 機器在生產能力和成本效率之間取得了平衡,為希望最佳化軟管填充操作的中型企業提供了一個有吸引力的選擇。雖然大容量機器可以提供更快的吞吐量,但它們的價格不菲,對某些公司來說可能難以負擔。相較之下,501-750 tpm 機器經濟可行,無需過多資源即可提高產量。

北美,尤其是美國,以2024年4.4億美元的估值引領市場,預計2025年至2034年的複合年成長率將達到7%。美國擁有龐大且高度自動化的消費品包裝產業,該產業嚴重依賴軟管灌裝機來包裝盥洗用品、化妝品和藥品等產品。製造業自動化是該地區發展的關鍵驅動力,越來越多的企業投資於機器人軟管填充系統,該系統可自動裝載、填充、密封和噴碼軟管。這些自動化系統對於提高生產效率和降低人力成本至關重要。

幾家關鍵企業主導軟管灌裝機產業,佔據15-20%的市場。為了保持競爭優勢,這些公司專注於研發和產品創新。此外,永續發展趨勢日益成長,一些製造商優先考慮環保機器設計,以減少對環境的影響。隨著自動化和永續發展的不斷進步,軟管灌裝機市場將持續擴張,為企業提供所需的工具,以滿足各行各業對高品質、高效包裝產品日益成長的需求。

目錄

第1章:方法論與範圍

第2章:執行摘要

第3章:行業洞察

- 產業生態系統分析

- 川普政府關稅分析

- 對貿易的影響

- 貿易量中斷

- 報復措施

- 對產業的影響

- 供應方影響(原料)

- 主要材料價格波動

- 供應鏈重組

- 生產成本影響

- 需求面影響(售價)

- 價格傳導至終端市場

- 市佔率動態

- 消費者反應模式

- 受影響的主要公司

- 策略產業反應

- 供應鏈重組

- 定價和產品策略

- 政策參與

- 展望與未來考慮

- 對貿易的影響

- 供應商格局

- 定價分析

- 技術與創新格局

- 重要新聞和舉措

- 監管格局

- 製造商

- 經銷商

- 零售商

- 衝擊力

- 成長動力

- 跨產業自動化

- 包裝產業的技術進步

- 不斷擴張的製藥和化妝品產業

- 工業4.0技術的融合

- 產業陷阱與挑戰

- 高成本投資

- 定期維護

- 成長動力

- 技術與創新格局

- 成長潛力分析

- 監管格局

- 定價分析

- 波特的分析

- PESTEL分析

第4章:競爭格局

- 介紹

- 公司市佔率分析

- 競爭定位矩陣

- 戰略展望矩陣

第5章:市場估計與預測:按類型,2021 年至 2034 年

- 主要趨勢

- 半自動

- 自動的

第6章:市場估計與預測:依產能,2021 年至 2034 年

- 主要趨勢

- 低於 250 tpm

- 251-500 轉/分

- 501-750 噸/分鐘

- 750 tpm 以上

第7章:市場估計與預測:按應用,2021 年至 2034 年

- 主要趨勢

- 製藥

- 化妝品

- 食品和飲料

- 化學品

第8章:市場估計與預測:按地區,2021 年至 2034 年

- 主要趨勢

- 北美洲

- 美國

- 加拿大

- 歐洲

- 德國

- 英國

- 法國

- 義大利

- 西班牙

- 亞太地區

- 中國

- 印度

- 日本

- 韓國

- 澳洲

- 拉丁美洲

- 巴西

- 墨西哥

- MEA

- 沙烏地阿拉伯

- 阿拉伯聯合大公國

- 南非

第9章:公司簡介

- Accutek Packaging Equipment Company

- Advanced Dynamics

- Aligned Machinery

- APACKS Packaging

- Axomatic

- BellatRx

- Bischoff & Munneke

- Blenzor India

- Busch Machinery

- Caelsons Industries

- GGM Group

- Gustav Obermeyer

- Harish Pharma Engineering

- Makwell Machinery

- ProSys Servo Filling Systems

The Global Tube Filling Machine Market was valued at USD 1.2 billion in 2024 and is estimated to grow at a CAGR of 5.9% to reach USD 2.2 billion by 2034. This growth is fueled by the increasing demand for automation across industries, as well as advancements in packaging technology. The consumer goods sector, in particular, is driving this shift as businesses seek to adopt more precise, efficient, and scalable manufacturing processes. Tube filling machines are critical in meeting these demands, offering flexibility in packaging a wide range of products, including personal care items, pharmaceuticals, and food products. These machines not only improve production efficiency but also minimize waste by ensuring precise filling, ultimately reducing operational costs over time. Additionally, the rising consumer preference for hygienic, single-dose, and portable packaging solutions is contributing to the growing demand for tube-filling systems. This trend is evident across various sectors, including food and beverages, where portion-controlled dressings and single-serve toothpaste are becoming increasingly popular. As the demand for tube-packaged products grows, the market for tube filling machines is expanding in response.

In 2024, the automatic tube filling machine segment generated a revenue of USD 800 million and is expected to experience a CAGR of 6.2% through 2034. The shift toward automation is gaining momentum, particularly in industries like food, pharmaceuticals, and cosmetics, where high-speed, high-volume production is essential. Automatic tube filling machines play a key role in enhancing production efficiency by minimizing human interaction during processes like filling, sealing, and labeling. This not only ensures a faster production pace but also improves consistency and reduces errors. These machines are equipped with advanced features, such as automatic tube feeding and precise filling control, which help manufacturers achieve higher productivity and lower labor costs. The growing adoption of automated systems is also fueled by innovations that allow these machines to handle a wide range of tube sizes and materials, further boosting their appeal in various sectors.

| Market Scope | |

|---|---|

| Start Year | 2024 |

| Forecast Year | 2025-2034 |

| Start Value | $1.2 Billion |

| Forecast Value | $2.2 Billion |

| CAGR | 5.9% |

The pharmaceutical sector alone generated USD 500 million in revenue from tube filling machines in 2024, with an expected CAGR of 6.6% through 2034. The demand for tube filling machines is particularly strong in the pharmaceutical industry, where the need for precise and sterile packaging is critical. Tube filling machines ensure that products such as creams, ointments, and gels are filled accurately in sterile environments, which is crucial for maintaining product quality and safety. The adoption of fully automated systems in pharmaceutical manufacturing has streamlined operations, reduced the risk of contamination, and improved overall production efficiency. As the industry continues to prioritize safety and quality, tube filling machines are evolving to meet stricter regulatory standards and consumer expectations.

The 501-750 tubes per minute (tpm) segment accounted for more than 35.9% of the tube filling machine market in 2024 and is expected to grow at a rate of 6.1% until 2034. This segment is favored due to its ability to accommodate a broad range of products, tube sizes, and viscosities, making it ideal for companies that produce various products or are planning to introduce new items to the market. The 501-750 tpm machines strike a balance between production capacity and cost efficiency, offering an attractive option for mid-sized businesses looking to optimize their tube-filling operations. While high-capacity machines offer faster throughput, they come with a significant price tag, which can be prohibitive for some companies. In contrast, the 501-750 tpm machines are economically viable and offer improved production without requiring excessive resources.

North America, particularly the United States, leads the market with a valuation of USD 440 million in 2024 and is expected to grow at a CAGR of 7% from 2025 to 2034. The U.S. has a large and highly automated consumer packaged goods industry, which is heavily reliant on tube filling machines for packaging products like toiletries, cosmetics, and medicines. Automation in manufacturing is a key driver in the region, with companies increasingly investing in robotic tube filling systems that offer automatic loading, filling, sealing, and coding of tubes. These automated systems are integral to increasing production efficiency and reducing labor costs.

Several key players dominate the tube filling machine industry, holding 15-20% of the market share. To maintain a competitive edge, these companies are focusing on research and development and product innovation. There is also a growing trend toward sustainability, with some manufacturers prioritizing eco-friendly machine designs to reduce environmental impact. With the ongoing advancements in automation and sustainability, the tube filling machine market is set to continue expanding, offering businesses the tools they need to meet the growing demand for high-quality, efficiently packaged products across various sectors.

Table of Contents

Chapter 1 Methodology & Scope

- 1.1 Research design

- 1.1.1 Research approach

- 1.1.2 Data collection methods

- 1.2 Base estimates and calculations

- 1.2.1 Base year calculation

- 1.2.2 Key trends for market estimates

- 1.3 Forecast model

- 1.4 Primary research & validation

- 1.4.1 Primary sources

- 1.4.2 Data mining sources

- 1.5 Market definitions

Chapter 2 Executive Summary

- 2.1 Industry 3600 synopsis, 2021 - 2034

Chapter 3 Industry Insights

- 3.1 Industry ecosystem analysis

- 3.2 Trump administration tariffs analysis

- 3.2.1 Impact on trade

- 3.2.1.1 Trade volume disruptions

- 3.2.1.2 Retaliatory measures

- 3.2.2 Impact on the industry

- 3.2.2.1 Supply-side impact (raw materials)

- 3.2.2.2 Price volatility in key materials

- 3.2.2.3 Supply chain restructuring

- 3.2.2.4 Production cost implications

- 3.2.2.5 Demand-side impact (selling price)

- 3.2.2.6 Price transmission to end markets

- 3.2.2.7 Market share dynamics

- 3.2.2.8 Consumer response patterns

- 3.2.3 Key companies impacted

- 3.2.4 Strategic industry responses

- 3.2.4.1 Supply chain reconfiguration

- 3.2.4.2 Pricing and product strategies

- 3.2.4.3 Policy engagement

- 3.2.5 Outlook and future considerations

- 3.2.1 Impact on trade

- 3.3 Supplier landscape

- 3.4 Pricing analysis

- 3.5 Technology & innovation landscape

- 3.6 Key news & initiatives

- 3.7 Regulatory landscape

- 3.8 Manufacturers

- 3.9 Distributors

- 3.10 Retailers

- 3.11 Impact forces

- 3.11.1 Growth drivers

- 3.11.1.1 Automation across industries

- 3.11.1.2 Technological advancement in packaging industry

- 3.11.1.3 The expanding pharmaceutical and cosmetics industries

- 3.11.1.4 Integration of Industry 4.0 technologies

- 3.11.2 Industry pitfalls & challenges

- 3.11.2.1 High-cost investment

- 3.11.2.2 Regular maintenance

- 3.11.1 Growth drivers

- 3.12 Technology & innovation landscape

- 3.13 Growth potential analysis

- 3.14 Regulatory landscape

- 3.15 Pricing analysis

- 3.16 Porter's analysis

- 3.17 PESTEL analysis

Chapter 4 Competitive Landscape, 2024

- 4.1 Introduction

- 4.2 Company market share analysis

- 4.3 Competitive positioning matrix

- 4.4 Strategic outlook matrix

Chapter 5 Market Estimates & Forecast, By Type, 2021 – 2034, (USD Million) (Thousand Units)

- 5.1 Key trends

- 5.2 Semi-automatic

- 5.3 Automatic

Chapter 6 Market Estimates & Forecast, By Capacity, 2021 – 2034, (USD Million) (Thousand Units)

- 6.1 Key trends

- 6.2 Less than 250 tpm

- 6.3 251-500 tpm

- 6.4 501-750 tpm

- 6.5 Above 750 tpm

Chapter 7 Market Estimates & Forecast, By Application, 2021 – 2034, (USD Million) (Thousand Units)

- 7.1 Key trends

- 7.2 Pharmaceutical

- 7.3 Cosmetics

- 7.4 Food & beverages

- 7.5 Chemicals

Chapter 8 Market Estimates & Forecast, By Region, 2021 – 2034, (USD Million) (Thousand Units)

- 8.1 Key trends

- 8.2 North America

- 8.2.1 U.S.

- 8.2.2 Canada

- 8.3 Europe

- 8.3.1 Germany

- 8.3.2 UK

- 8.3.3 France

- 8.3.4 Italy

- 8.3.5 Spain

- 8.4 Asia Pacific

- 8.4.1 China

- 8.4.2 India

- 8.4.3 Japan

- 8.4.4 South Korea

- 8.4.5 Australia

- 8.5 Latin America

- 8.5.1 Brazil

- 8.5.2 Mexico

- 8.6 MEA

- 8.6.1 Saudi Arabia

- 8.6.2 UAE

- 8.6.3 South Africa

Chapter 9 Company Profiles

- 9.1 Accutek Packaging Equipment Company

- 9.2 Advanced Dynamics

- 9.3 Aligned Machinery

- 9.4 APACKS Packaging

- 9.5 Axomatic

- 9.6 BellatRx

- 9.7 Bischoff & Munneke

- 9.8 Blenzor India

- 9.9 Busch Machinery

- 9.10 Caelsons Industries

- 9.11 GGM Group

- 9.12 Gustav Obermeyer

- 9.13 Harish Pharma Engineering

- 9.14 Makwell Machinery

- 9.15 ProSys Servo Filling Systems