|

市場調查報告書

商品編碼

1716618

雷射焊接機市場機會、成長動力、產業趨勢分析及2025-2034年預測Laser Welding Machine Market Opportunity, Growth Drivers, Industry Trend Analysis, and Forecast 2025 - 2034 |

||||||

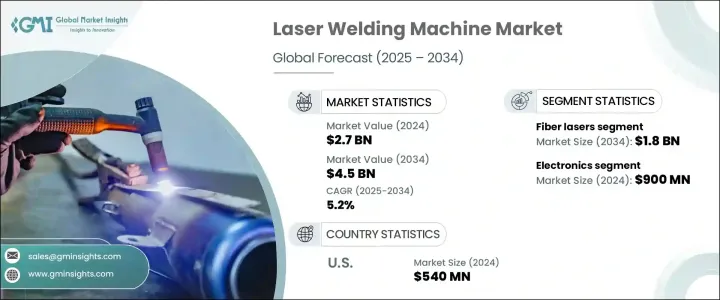

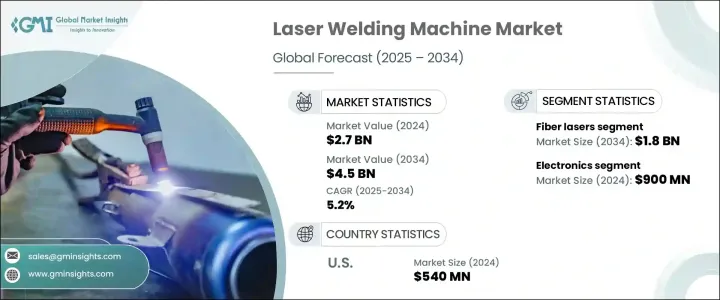

2024 年全球雷射焊接機市場規模達到 27 億美元,預計 2025 年至 2034 年期間的複合年成長率為 5.2%。隨著汽車、航太、電子和醫療設備等行業繼續採用先進的焊接解決方案,對高精度製造流程的需求不斷成長,推動了該市場的快速擴張。雷射焊接技術因其無與倫比的精度、速度以及在不損害材料完整性的情況下形成耐用焊縫的能力,已成為現代製造業的重要組成部分。隨著電動和自動駕駛汽車產量的激增,對提供精度和效率的先進焊接系統的需求比以往任何時候都更加強烈。

隨著公司專注於提高生產能力和減少停機時間,雷射焊接機正在成為實現無縫、高品質製造的關鍵部件。此外,各個行業,尤其是電子和醫療設備的小型化趨勢日益成長,促使製造商採用非接觸式焊接解決方案,因為傳統方法往往無法滿足下一代產品的精度要求。隨著製造商尋求簡化流程並提高生產力,自動化創新加上工業 4.0 的進步也推動了雷射焊接機的採用。製造業越來越重視永續性和能源效率,這是鼓勵業界轉向雷射焊接技術的另一個重要因素,因為雷射焊接技術能夠減少浪費、最佳化材料使用並提供一致的結果。

| 市場範圍 | |

|---|---|

| 起始年份 | 2024 |

| 預測年份 | 2025-2034 |

| 起始值 | 27億美元 |

| 預測值 | 45億美元 |

| 複合年成長率 | 5.2% |

雷射焊接技術因其卓越的精度、效率和適應性而比傳統焊接方法受到廣泛青睞。市場按雷射技術細分,其中光纖雷射、二氧化碳雷射、二極體雷射和其他變體構成核心產品類型。其中,光纖雷射佔據主導地位,2024 年價值 12 億美元,預計到 2034 年將達到 18 億美元。光纖雷射器因其卓越的光束品質、能源效率和降低的營運成本而受到各行各業的青睞。這些雷射器能夠焊接複雜且精密的零件而不會造成變形,這使得它們在汽車、醫療設備製造和電子等精度至關重要的領域中不可或缺。

此外,市場根據最終用途行業進行細分,包括汽車、醫療、電子、航太和珠寶。電子產業在 2024 年的價值為 9 億美元,預測期內的複合年成長率將達到 3.8%,這主要得益於半導體、電路板和微電子等緊湊複雜組件的精密焊接需求。

美國雷射焊接機市場預計在 2024 年創造 5.4 億美元的產值,在自動化、電動車製造和半導體生產進步的推動下,2025 年至 2034 年期間的複合年成長率將達到 5.3%,使美國成為光纖雷射技術的領先中心。

目錄

第1章:方法論與範圍

第2章:執行摘要

第3章:行業洞察

- 產業生態系統分析

- 影響價值鏈的因素

- 利潤率分析

- 中斷

- 未來展望

- 製造商

- 經銷商

- 零售商

- 衝擊力

- 成長動力

- 汽車產業的擴張

- 製造業活動激增

- 雷射焊接的技術進步

- 產業陷阱與挑戰

- 初期投資及維護成本高

- 操作和程式設計的熟練勞動力有限

- 成長動力

- 技術與創新格局

- 成長潛力分析

- 監管格局

- 定價分析

- 波特的分析

- PESTEL分析

第4章:競爭格局

- 介紹

- 公司市佔率分析

- 競爭定位矩陣

- 戰略展望矩陣

第5章:市場估計與預測:依技術分類,2021 年至 2034 年

- 主要趨勢

- 光纖雷射

- 二氧化碳雷射

- 二極體雷射

- 其他

第6章:市場估計與預測:依最終用途,2021 年至 2034 年

- 主要趨勢

- 汽車

- 醫療的

- 電子產品

- 航太與國防

- 珠寶

- 其他

第7章:市場估計與預測:按配銷通路,2021 年至 2034 年

- 主要趨勢

- 直接的

- 間接

第8章:市場估計與預測:按地區,2021 年至 2034 年

- 主要趨勢

- 北美洲

- 美國

- 加拿大

- 歐洲

- 德國

- 英國

- 法國

- 義大利

- 西班牙

- 俄羅斯

- 亞太地區

- 中國

- 印度

- 日本

- 韓國

- 澳洲

- 拉丁美洲

- 巴西

- 墨西哥

- MEA

- 沙烏地阿拉伯

- 阿拉伯聯合大公國

- 南非

第9章:公司簡介

- CHIRON Group

- Coherent

- Emerson Electric

- Han's Laser Technology Industry Group

- Huagong Laser Engineering

- IPG Photonics

- Jenoptik

- KEYENCE

- Laser Technologies

- Laser line

- Laser Star Technologies

- Penta Laser

- Precitec

- TRUMPF

The Global Laser Welding Machine Market reached USD 2.7 billion in 2024 and is projected to grow at a CAGR of 5.2% between 2025 and 2034. The rising demand for high-precision manufacturing processes is driving the rapid expansion of this market, as industries such as automotive, aerospace, electronics, and medical devices continue to adopt advanced welding solutions. Laser welding technology has become an essential part of modern manufacturing for its unmatched accuracy, speed, and ability to create durable welds without compromising material integrity. With the surge in electric and autonomous vehicle production, the need for advanced welding systems that offer precision and efficiency is stronger than ever.

As companies focus on improving production capabilities and reducing downtime, laser welding machines are emerging as a critical component in enabling seamless, high-quality manufacturing. Moreover, the growing trend of miniaturization across various industries, especially electronics and medical devices, is pushing manufacturers to adopt non-contact welding solutions, as traditional methods often fall short of meeting the precision demands of next-generation products. Innovations in automation, coupled with Industry 4.0 advancements, are also fueling the adoption of laser welding machines, as manufacturers seek to streamline processes and enhance productivity. The increasing emphasis on sustainability and energy efficiency in manufacturing operations is another significant factor encouraging industries to shift toward laser welding technologies, given their ability to reduce waste, optimize material usage, and deliver consistent results.

| Market Scope | |

|---|---|

| Start Year | 2024 |

| Forecast Year | 2025-2034 |

| Start Value | $2.7 Billion |

| Forecast Value | $4.5 Billion |

| CAGR | 5.2% |

Laser welding technology is widely preferred over conventional welding methods for its superior precision, efficiency, and adaptability. The market is segmented by laser technology, with fiber lasers, CO2 lasers, diode lasers, and other variants forming the core product types. Among these, fiber lasers held a dominant share, valued at USD 1.2 billion in 2024, and are projected to reach USD 1.8 billion by 2034. Fiber lasers are highly favored across industries for their exceptional beam quality, energy efficiency, and reduced operational costs. These lasers are capable of welding intricate and delicate components without causing distortions, making them indispensable in sectors like automotive, medical device manufacturing, and electronics where precision is paramount.

Additionally, the market is segmented based on end-use industries, including automotive, medical, electronics, aerospace, and jewelry. The electronics segment, valued at USD 0.9 billion in 2024, is set to grow at a CAGR of 3.8% during the forecast period, driven by the demand for precision welding in compact and complex components such as semiconductors, circuit boards, and microelectronics.

The U.S. laser welding machine market, generating USD 540 million in 2024, is forecast to expand at a CAGR of 5.3% between 2025 and 2034, fueled by advancements in automation, electric vehicle manufacturing, and semiconductor production, making the U.S. a leading hub for fiber laser technology.

Table of Contents

Chapter 1 Methodology & Scope

- 1.1 Market scope & definition

- 1.2 Base estimates & calculations

- 1.3 Forecast parameters

- 1.4 Data sources

- 1.4.1 Primary

- 1.4.2 Secondary

- 1.4.2.1 Paid sources

- 1.4.2.2 Public sources

Chapter 2 Executive Summary

- 2.1 Industry 3600 synopsis, 2021 - 2034

Chapter 3 Industry Insights

- 3.1 Industry ecosystem analysis

- 3.1.1 Factors affecting the value chain

- 3.1.2 Profit margin analysis

- 3.1.3 Disruptions

- 3.1.4 Future outlook

- 3.1.5 Manufacturers

- 3.1.6 Distributors

- 3.1.7 Retailers

- 3.2 Impact forces

- 3.2.1 Growth drivers

- 3.2.1.1 Expansion of the automotive industry

- 3.2.1.2 Surge in manufacturing activities

- 3.2.1.3 Technological advancements in laser welding

- 3.2.2 Industry pitfalls & challenges

- 3.2.2.1 High initial investment and maintenance costs

- 3.2.2.2 Limited skilled workforce for operation and programming

- 3.2.1 Growth drivers

- 3.3 Technology & innovation landscape

- 3.4 Growth potential analysis

- 3.5 Regulatory landscape

- 3.6 Pricing analysis

- 3.7 Porter's analysis

- 3.8 PESTEL analysis

Chapter 4 Competitive Landscape, 2024

- 4.1 Introduction

- 4.2 Company market share analysis

- 4.3 Competitive positioning matrix

- 4.4 Strategic outlook matrix

Chapter 5 Market Estimates & Forecast, By Technology, 2021 – 2034, (USD Billion) (Million Units)

- 5.1 Key trends

- 5.2 Fiber lasers

- 5.3 CO2 lasers

- 5.4 Diode lasers

- 5.5 Others

Chapter 6 Market Estimates & Forecast, By End Use, 2021 – 2034, (USD Billion) (Million Units)

- 6.1 Key trends

- 6.2 Automotive

- 6.3 Medical

- 6.4 Electronics

- 6.5 Aerospace & defense

- 6.6 Jewelry

- 6.7 Others

Chapter 7 Market Estimates & Forecast, By Distribution Channel, 2021 – 2034, (USD Billion) (Million Units)

- 7.1 Key trends

- 7.2 Direct

- 7.3 Indirect

Chapter 8 Market Estimates & Forecast, By Region, 2021 – 2034, (USD Billion) (Million Units)

- 8.1 Key trends

- 8.2 North America

- 8.2.1 The U.S.

- 8.2.2 Canada

- 8.3 Europe

- 8.3.1 Germany

- 8.3.2 UK

- 8.3.3 France

- 8.3.4 Italy

- 8.3.5 Spain

- 8.3.6 Russia

- 8.4 Asia Pacific

- 8.4.1 China

- 8.4.2 India

- 8.4.3 Japan

- 8.4.4 South Korea

- 8.4.5 Australia

- 8.5 Latin America

- 8.5.1 Brazil

- 8.5.2 Mexico

- 8.6 MEA

- 8.6.1 Saudi Arabia

- 8.6.2 UAE

- 8.6.3 South Africa

Chapter 9 Company Profiles (Business Overview, Financial Data, Product Landscape, Strategic Outlook, SWOT Analysis)

- 9.1 CHIRON Group

- 9.2 Coherent

- 9.3 Emerson Electric

- 9.4 Han's Laser Technology Industry Group

- 9.5 Huagong Laser Engineering

- 9.6 IPG Photonics

- 9.7 Jenoptik

- 9.8 KEYENCE

- 9.9 Laser Technologies

- 9.10 Laser line

- 9.11 Laser Star Technologies

- 9.12 Penta Laser

- 9.13 Precitec

- 9.14 TRUMPF