|

市場調查報告書

商品編碼

1811814

航太與國防產業的全球鋼鐵需求市場:2025年~2035年Global Steel demand in Aerospace & Defense Industry market 2025 - 2035 |

||||||

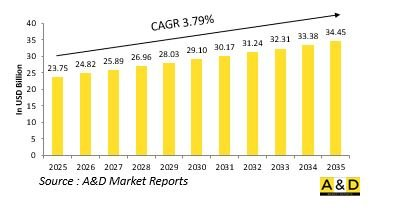

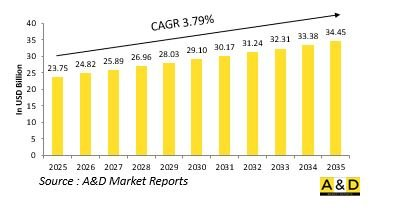

預計2025年全球航空航太和國防鋼鐵需求為237.5億美元,到2035年將成長至344.5億美元,2025年至2035年的複合年增長率 (CAGR) 為3.79%。

航空航太與國防工業市場鋼鐵需求簡介

鋼鐵仍然是航空航太和國防工業的基礎材料,尤其是在軍事平台、裝甲車輛、船舶和需要卓越強度和韌性的專用部件。儘管複合材料和先進合金材料日益興起,但鋼鐵憑藉其可靠性、成本效益和對各種應用的適應性,仍然保持其重要性。國防項目在裝甲板、結構加固和高強度緊固件等領域使用鋼鐵,這些領域優先考慮的是耐久性和防護性,而非減輕重量。該領域的鋼鐵需求與現代國防力量不斷變化的需求密切相關。隨著對生存能力的日益重視,平台需要能夠承受極端壓力、衝擊和環境條件的材料。鋼鐵的多功能性確保了其在傳統和新興國防應用中的持續重要性。從海軍船艦船體到陸地車輛的彈道系統,鋼鐵都發揮著至關重要的作用。隨著產業在現代輕量化材料和久經考驗的金屬之間取得平衡,鋼鐵繼續佔戰略地位。其成熟的供應鏈和易於加工的特性也使其在航空航太和國防生態系統中保持著持久的地位,確保了在快速變化的市場中保持穩定的需求。

科技對航太與國防市場鋼鐵需求的影響

技術進步正在重塑鋼鐵在航空航太和國防工業中的應用方式,從而推動更複雜、更專用的鋼種的開發。高強度低合金鋼如今旨在提供卓越的防護性能,同時減輕整體重量,解決了傳統上強度和機動性之間的權衡問題。這些技術進步擴展了鋼鐵在需要兼顧韌性和效率的平台中的應用,例如裝甲車輛和海軍船。先進的製造技術也為鋼鐵在國防應用領域的發展做出了重大貢獻。精密鍛造、增材製造和新型熱處理製程實現了更高的客製化程度和更優的性能。這意味著零件可以設計成具有最佳化的形狀和性能,同時保持高應力環境下所需的堅固性。此外,塗層和耐腐蝕處理的進步延長了暴露在惡劣氣候條件下(尤其是在海上作業)的鋼部件的使用壽命。技術的另一個重要影響是混合材料解決方案。鋼材正越來越多地與複合材料和合金材料相結合,形成分層防護系統和模組化設計,從而最大限度地提高強度,同時又不會過度減輕重量。這些技術發展凸顯了鋼材的適應性,並確保即使在航空航太和軍事工程領域湧現新材料的情況下,鋼材仍然是國防計畫不可或缺的一部分。

航空航太與國防市場鋼材需求的主要驅動因素

航空航太和國防工業對鋼材的需求受到戰略需求、材料優勢以及不斷變化的國防需求等多種因素的影響。其中一個關鍵驅動因素是對防護性和耐久性的持續關注。鋼材仍然是需要抗衝擊應用的首選材料,例如裝甲板、增強結構和關鍵加固部件。其經驗證的人員和設備保護能力確保了全球國防活動的穩定需求。成本效益也是關鍵因素。與先進的複合材料和特殊合金相比,鋼材價格實惠,且不會犧牲結構性能。國防預算,尤其是新興國家的國防預算,通常更青睞能夠平衡強度和價值的材料,這使得鋼材成為大型專案的首選。廣泛的鋼材供應和成熟的製造基地也有助於形成一致的採購決策。此外,隨著軍隊升級其艦隊、船艦和基礎設施,現代化計劃也推動了需求。整合重量更輕、強度更高、抗環境侵蝕能力更強的先進鋼材,使國防部隊能夠在保持可靠性的同時提高性能。其對各種製造方法的適應性以及與最新複合材料的協同作用能力,進一步鞏固了其作為國防創新關鍵推動者的地位。

航空航太與國防市場鋼鐵需求的區域趨勢

國防鋼鐵需求的區域差異反映了戰略重點、工業基礎和作戰環境的差異。在海軍力量強大的地區,例如沿海國家,需求集中在造船和海上防禦領域,而鋼材的耐用性和耐惡劣條件的能力在這些領域至關重要。擁有龐大軍隊的國家則重視裝甲車輛、防禦工事和支援結構的鋼材,以提高戰場生存能力。工業實力也影響區域動態。國內鋼鐵工業實力雄厚的經濟體通常優先考慮國內採購以支持其國防項目,而其他經濟體則依賴進口或國際合作來獲得先進鋼種。本地供應和製造能力影響採購策略以及專案執行的速度和規模。地緣政治緊張局勢和區域安全課題進一步影響鋼鐵需求模式。面臨日益增長的國防威脅的地區優先考慮快速擴張車輛和車輛庫存,需要堅固耐用且隨時可用的材料。相較之下,已開發國家優先考慮現代化,青睞更輕、更有效率的高性能鋼材。氣候因素也發揮作用,因為極端天氣條件下的地區需要具有優異耐腐蝕性和耐用性的鋼材。這些區域趨勢表明,全球國防鋼鐵市場既多樣化又相互關聯。

航空航太和國防項目的關鍵鋼鐵需求

據英國鋼鐵業協會稱,英國國防工業戰略 (DIS) 的發布強調了冶金業對國家安全的戰略重要性,並導致公共採購政策發生重大變化。該協會強調,新的國防戰略優先考慮鋼鐵供應鏈安全,這與國防部長期以來默認全球競爭採購的政策背道而馳。相反,該戰略著重於加強國內工業能力。

目錄

航太·國防市場的鋼鐵零件報告定義

航太·國防市場市場區隔

各零件

各流程

各地區

航空航太與國防市場鋼零件未來10年分析

航空航太與國防市場鋼部件未來10年分析詳細概述了市場成長、變化趨勢、技術採用概況以及本章將要討論的航空航太與國防市場鋼部件的整體市場吸引力。

航空航太與國防市場鋼製零件市場技術

本部分介紹了預計將影響該市場的十大技術,以及這些技術可能對整體市場產生的潛在影響。

全球航空航太與國防市場鋼製零件預測

以上部分詳細介紹了航空航太與國防市場鋼製零件的10年市場預測。

航空航太與國防市場鋼製零件各區域趨勢及預測

本部分涵蓋航空航太與國防領域鋼製零件市場的區域趨勢、驅動因素、限制因素和課題,以及政治、經濟、社會和技術方面的影響。此外,還包含詳細的區域市場預測和情境分析。區域分析最後概述了主要公司、供應商格局和公司基準。目前市場規模是基於常規情境估算。

北美

驅動因素、限制因素與課題

PEST

市場預測與情勢分析

主要企業

供應商階層的形勢

企業基準

歐洲

中東

亞太地區

南美

航空航太與國防市場鋼部件國家分析

本章涵蓋該市場的主要國防項目以及該市場的最新新聞和專利申請。本章也提供未來10年的市場預測和國家層級的情境分析。

美國

防衛計劃

最新消息

專利

這個市場上目前技術成熟度

市場預測與情勢分析

加拿大

義大利

法國

德國

荷蘭

比利時

西班牙

瑞典

希臘

澳洲

南非

印度

中國

俄羅斯

韓國

日本

馬來西亞

新加坡

巴西

航空航太與國防市場鋼製零件機會矩陣

機會矩陣幫助讀者了解該市場中高機會的細分市場。

航空航太與國防市場鋼製零件專家意見報告

我們提供對該市場潛力分析的專家意見。

結論

關於調查公司

The Global Steel demand in Aerospace & Defense Industry market is estimated at USD 23.75 billion in 2025, projected to grow to USD 34.45 billion by 2035 at a Compound Annual Growth Rate (CAGR) of 3.79% over the forecast period 2025-2035.

Introduction to Steel demand in Aerospace & Defense Industry Market:

Steel continues to be a fundamental material in the aerospace and defense industry, particularly in the development of military platforms, armored vehicles, naval vessels, and specialized components that require exceptional strength and resilience. Despite the rise of composites and advanced alloys, steel maintains its importance due to its reliability, cost-effectiveness, and adaptability to various applications. Within defense programs, steel is used in areas where durability and protection are prioritized over weight savings, such as armor plating, structural reinforcements, and high-strength fasteners. The demand for steel in this sector is closely tied to the evolving requirements of modern defense forces. With increasing emphasis on survivability, platforms need materials that can withstand extreme stress, impact, and environmental conditions. Steel's versatility ensures that it remains relevant across both traditional and emerging defense applications. From the hulls of naval ships to ballistic protection systems in land vehicles, its role is indispensable. As the industry balances modern lightweight materials with tried-and-tested metals, steel continues to occupy a strategic position. Its established supply chains and ease of fabrication also contribute to its sustained presence in the aerospace and defense ecosystem, ensuring consistent demand in a rapidly transforming marketplace.

Technology Impact in Steel demand in Aerospace & Defense Industry Market:

Technological advancements are reshaping how steel is utilized in the aerospace and defense industry, leading to the development of more sophisticated and application-specific grades. High-strength, low-alloy steels are now engineered to provide superior protection while reducing overall weight, addressing the traditional trade-off between strength and mobility. These innovations have expanded steel's usability in platforms that demand both resilience and efficiency, such as armored vehicles and naval ships. Advanced manufacturing techniques also contribute significantly to the evolution of steel in defense applications. Precision forging, additive manufacturing, and new heat-treatment processes allow for greater customization and improved performance characteristics. This means components can be designed with optimized shapes and properties while maintaining the robustness required in high-stress environments. Additionally, advances in coatings and corrosion-resistant treatments extend the service life of steel parts exposed to harsh climates, particularly in maritime operations. Another key impact of technology lies in hybrid material solutions. Steel is increasingly integrated alongside composites and alloys, creating layered protection systems or modular designs that maximize strength without excessive weight penalties. These technological developments underscore the adaptability of steel, ensuring it remains vital to defense programs even as new materials gain prominence in aerospace and military engineering.

Key Drivers in Steel demand in Aerospace & Defense Industry Market:

The demand for steel in the aerospace and defense industry is influenced by a combination of strategic needs, material advantages, and evolving defense requirements. A major driver is the continued focus on protection and durability. Steel remains the material of choice for applications requiring impact resistance, such as armor plating, fortified structures, and critical reinforcement components. Its proven ability to safeguard personnel and equipment ensures steady demand in defense operations worldwide. Cost-effectiveness is another key factor. Compared to advanced composites or exotic alloys, steel offers affordability without compromising structural performance. Defense budgets, particularly in emerging economies, often favor materials that balance strength with value, making steel a preferred option for large-scale projects. The widespread availability of steel and its established production base also contribute to consistent procurement decisions. Additionally, modernization programs are driving demand as militaries upgrade fleets, naval vessels, and infrastructure. The integration of advanced grades of steel that provide lighter weight, higher hardness, and better resistance to environmental degradation allows defense forces to improve performance while maintaining reliability. The material's adaptability to various fabrication methods and ability to work alongside modern composites further solidify its place as a critical enabler in defense innovation.

Regional Trends in Steel demand in Aerospace & Defense Industry Market:

Regional variations in defense steel demand reflect differing strategic priorities, industrial bases, and operational environments. In regions with significant naval presence, such as coastal nations, demand is concentrated on shipbuilding and maritime defense, where steel's durability and resistance to extreme conditions are crucial. Countries with extensive land forces focus more heavily on steel for armored vehicles, fortifications, and support structures that enhance battlefield survivability. Industrial capacity also shapes regional dynamics. Economies with strong domestic steel industries often emphasize indigenous sourcing to support defense programs, while others rely on imports or international collaborations to secure advanced grades. Local availability and manufacturing capabilities influence not only procurement strategies but also the speed and scale at which projects can be executed. Geopolitical tensions and regional security challenges further drive steel demand patterns. Areas facing rising defense threats prioritize rapid expansion of fleets and vehicle inventories, requiring robust and easily accessible materials. In contrast, advanced economies emphasize modernization, favoring high-performance steels engineered for lighter weight and greater efficiency. Climate considerations also play a role, as regions with extreme weather conditions demand steels with superior corrosion resistance and durability. Together, these regional trends illustrate a diverse but interconnected global market for defense steel.

Key Steel demand in Aerospace & Defense Industry Program:

The release of the British Defense Industry Strategy (DIS) marked a significant shift in public procurement policy, highlighting the strategic importance of metallurgy to national security, according to the industry body UK Steel. The association emphasized that the new DIS identifies steel as a priority for supply chain security, signaling a break from the long-standing policy of default global competition in Ministry of Defense procurement. Instead, the strategy places stronger focus on strengthening domestic industrial capacity.

Table of Contents

Steel Components In The Aerospace And Defense Market Report Definition

Steel Components In The Aerospace And Defense Market Segmentation

By Component

By Process

By Region

Steel Components In The Aerospace And Defense Market Analysis for next 10 Years

The 10-year Steel Components In The Aerospace And Defense market analysis would give a detailed overview of Steel Components In The Aerospace And Defense market growth, changing dynamics, technology adoption overviews and the overall market attractiveness is covered in this chapter.

Market Technologies of Steel Components In The Aerospace And Defense Market

This segment covers the top 10 technologies that is expected to impact this market and the possible implications these technologies would have on the overall market.

Global Steel Components In The Aerospace And Defense Market Forecast

The 10-year Steel Components In The Aerospace And Defense market forecast of this market is covered in detailed across the segments which are mentioned above.

Regional Steel Components In The Aerospace And Defense Market Trends & Forecast

The regional Steel Components In The Aerospace And Defense market trends, drivers, restraints and Challenges of this market, the Political, Economic, Social and Technology aspects are covered in this segment. The market forecast and scenario analysis across regions are also covered in detailed in this segment. The last part of the regional analysis includes profiling of the key companies, supplier landscape and company benchmarking. The current market size is estimated based on the normal scenario.

North America

Drivers, Restraints and Challenges

PEST

Market Forecast & Scenario Analysis

Key Companies

Supplier Tier Landscape

Company Benchmarking

Europe

Middle East

APAC

South America

Country Analysis of Steel Components In The Aerospace And Defense Market

This chapter deals with the key defense programs in this market, it also covers the latest news and patents which have been filed in this market. Country level 10 year market forecast and scenario analysis are also covered in this chapter.

US

Defense Programs

Latest News

Patents

Current levels of technology maturation in this market

Market Forecast & Scenario Analysis

Canada

Italy

France

Germany

Netherlands

Belgium

Spain

Sweden

Greece

Australia

South Africa

India

China

Russia

South Korea

Japan

Malaysia

Singapore

Brazil

Opportunity Matrix for Steel Components In The Aerospace And Defense Market

The opportunity matrix helps the readers understand the high opportunity segments in this market.

Expert Opinions on Steel Components In The Aerospace And Defense Market Report

Hear from our experts their opinion of the possible analysis for this market.

Conclusions

About Aviation and Defense Market Reports

List of Tables

- Table 1: 10 Year Market Outlook, 2025-2035

- Table 2: Drivers, Impact Analysis, North America

- Table 3: Restraints, Impact Analysis, North America

- Table 4: Challenges, Impact Analysis, North America

- Table 5: Drivers, Impact Analysis, Europe

- Table 6: Restraints, Impact Analysis, Europe

- Table 7: Challenges, Impact Analysis, Europe

- Table 8: Drivers, Impact Analysis, Middle East

- Table 9: Restraints, Impact Analysis, Middle East

- Table 10: Challenges, Impact Analysis, Middle East

- Table 11: Drivers, Impact Analysis, APAC

- Table 12: Restraints, Impact Analysis, APAC

- Table 13: Challenges, Impact Analysis, APAC

- Table 14: Drivers, Impact Analysis, South America

- Table 15: Restraints, Impact Analysis, South America

- Table 16: Challenges, Impact Analysis, South America

- Table 17: Scenario Analysis, Scenario 1, By Region, 2025-2035

- Table 18: Scenario Analysis, Scenario 1, By Role, 2025-2035

- Table 19: Scenario Analysis, Scenario 1, By End User, 2025-2035

- Table 20: Scenario Analysis, Scenario 1, By Equipment, 2025-2035

- Table 21: Scenario Analysis, Scenario 2, By Region, 2025-2035

- Table 22: Scenario Analysis, Scenario 2, By Role, 2025-2035

- Table 23: Scenario Analysis, Scenario 2, By End User, 2025-2035

- Table 24: Scenario Analysis, Scenario 2, By Equipment, 2025-2035

List of Figures

- Figure 1: Global Steel demand in Aerospace & Defense Industry Market Forecast, 2025-2035

- Figure 2: Global Steel demand in Aerospace & Defense Industry Market Forecast, By Region, 2025-2035

- Figure 3: Global Steel demand in Aerospace & Defense Industry Market Forecast, By Role, 2025-2035

- Figure 4: Global Steel demand in Aerospace & Defense Industry Market Forecast, By End User, 2025-2035

- Figure 5: Global Steel demand in Aerospace & Defense Industry Market Forecast, By Equipment, 2025-2035

- Figure 6: North America, Steel demand in Aerospace & Defense Industry Market, Market Forecast, 2025-2035

- Figure 7: Europe, Steel demand in Aerospace & Defense Industry Market, Market Forecast, 2025-2035

- Figure 8: Middle East, Steel demand in Aerospace & Defense Industry Market, Market Forecast, 2025-2035

- Figure 9: APAC, Steel demand in Aerospace & Defense Industry Market, Market Forecast, 2025-2035

- Figure 10: South America, Steel demand in Aerospace & Defense Industry Market, Market Forecast, 2025-2035

- Figure 11: United States, Steel demand in Aerospace & Defense Industry Market, Technology Maturation, 2025-2035

- Figure 12: United States, Steel demand in Aerospace & Defense Industry Market, Market Forecast, 2025-2035

- Figure 13: Canada, Steel demand in Aerospace & Defense Industry Market, Technology Maturation, 2025-2035

- Figure 14: Canada, Steel demand in Aerospace & Defense Industry Market, Market Forecast, 2025-2035

- Figure 15: Italy, Steel demand in Aerospace & Defense Industry Market, Technology Maturation, 2025-2035

- Figure 16: Italy, Steel demand in Aerospace & Defense Industry Market, Market Forecast, 2025-2035

- Figure 17: France, Steel demand in Aerospace & Defense Industry Market, Technology Maturation, 2025-2035

- Figure 18: France, Steel demand in Aerospace & Defense Industry Market, Market Forecast, 2025-2035

- Figure 19: Germany, Steel demand in Aerospace & Defense Industry Market, Technology Maturation, 2025-2035

- Figure 20: Germany, Steel demand in Aerospace & Defense Industry Market, Market Forecast, 2025-2035

- Figure 21: Netherlands, Steel demand in Aerospace & Defense Industry Market, Technology Maturation, 2025-2035

- Figure 22: Netherlands, Steel demand in Aerospace & Defense Industry Market, Market Forecast, 2025-2035

- Figure 23: Belgium, Steel demand in Aerospace & Defense Industry Market, Technology Maturation, 2025-2035

- Figure 24: Belgium, Steel demand in Aerospace & Defense Industry Market, Market Forecast, 2025-2035

- Figure 25: Spain, Steel demand in Aerospace & Defense Industry Market, Technology Maturation, 2025-2035

- Figure 26: Spain, Steel demand in Aerospace & Defense Industry Market, Market Forecast, 2025-2035

- Figure 27: Sweden, Steel demand in Aerospace & Defense Industry Market, Technology Maturation, 2025-2035

- Figure 28: Sweden, Steel demand in Aerospace & Defense Industry Market, Market Forecast, 2025-2035

- Figure 29: Brazil, Steel demand in Aerospace & Defense Industry Market, Technology Maturation, 2025-2035

- Figure 30: Brazil, Steel demand in Aerospace & Defense Industry Market, Market Forecast, 2025-2035

- Figure 31: Australia, Steel demand in Aerospace & Defense Industry Market, Technology Maturation, 2025-2035

- Figure 32: Australia, Steel demand in Aerospace & Defense Industry Market, Market Forecast, 2025-2035

- Figure 33: India, Steel demand in Aerospace & Defense Industry Market, Technology Maturation, 2025-2035

- Figure 34: India, Steel demand in Aerospace & Defense Industry Market, Market Forecast, 2025-2035

- Figure 35: China, Steel demand in Aerospace & Defense Industry Market, Technology Maturation, 2025-2035

- Figure 36: China, Steel demand in Aerospace & Defense Industry Market, Market Forecast, 2025-2035

- Figure 37: Saudi Arabia, Steel demand in Aerospace & Defense Industry Market, Technology Maturation, 2025-2035

- Figure 38: Saudi Arabia, Steel demand in Aerospace & Defense Industry Market, Market Forecast, 2025-2035

- Figure 39: South Korea, Steel demand in Aerospace & Defense Industry Market, Technology Maturation, 2025-2035

- Figure 40: South Korea, Steel demand in Aerospace & Defense Industry Market, Market Forecast, 2025-2035

- Figure 41: Japan, Steel demand in Aerospace & Defense Industry Market, Technology Maturation, 2025-2035

- Figure 42: Japan, Steel demand in Aerospace & Defense Industry Market, Market Forecast, 2025-2035

- Figure 43: Malaysia, Steel demand in Aerospace & Defense Industry Market, Technology Maturation, 2025-2035

- Figure 44: Malaysia, Steel demand in Aerospace & Defense Industry Market, Market Forecast, 2025-2035

- Figure 45: Singapore, Steel demand in Aerospace & Defense Industry Market, Technology Maturation, 2025-2035

- Figure 46: Singapore, Steel demand in Aerospace & Defense Industry Market, Market Forecast, 2025-2035

- Figure 47: United Kingdom, Steel demand in Aerospace & Defense Industry Market, Technology Maturation, 2025-2035

- Figure 48: United Kingdom, Steel demand in Aerospace & Defense Industry Market, Market Forecast, 2025-2035

- Figure 49: Opportunity Analysis, Steel demand in Aerospace & Defense Industry Market, By Region (Cumulative Market), 2025-2035

- Figure 50: Opportunity Analysis, Steel demand in Aerospace & Defense Industry Market, By Region (CAGR), 2025-2035

- Figure 51: Opportunity Analysis, Steel demand in Aerospace & Defense Industry Market, By Role (Cumulative Market), 2025-2035

- Figure 52: Opportunity Analysis, Steel demand in Aerospace & Defense Industry Market, By Role (CAGR), 2025-2035

- Figure 53: Opportunity Analysis, Steel demand in Aerospace & Defense Industry Market, By End User (Cumulative Market), 2025-2035

- Figure 54: Opportunity Analysis, Steel demand in Aerospace & Defense Industry Market, By End User (CAGR), 2025-2035

- Figure 55: Opportunity Analysis, Steel demand in Aerospace & Defense Industry Market, By Equipment (Cumulative Market), 2025-2035

- Figure 56: Opportunity Analysis, Steel demand in Aerospace & Defense Industry Market, By Equipment (CAGR), 2025-2035

- Figure 57: Scenario Analysis, Steel demand in Aerospace & Defense Industry Market, Cumulative Market, 2025-2035

- Figure 58: Scenario Analysis, Steel demand in Aerospace & Defense Industry Market, Global Market, 2025-2035

- Figure 59: Scenario 1, Steel demand in Aerospace & Defense Industry Market, Total Market, 2025-2035

- Figure 60: Scenario 1, Steel demand in Aerospace & Defense Industry Market, By Region, 2025-2035

- Figure 61: Scenario 1, Steel demand in Aerospace & Defense Industry Market, By Role, 2025-2035

- Figure 62: Scenario 1, Steel demand in Aerospace & Defense Industry Market, By End User, 2025-2035

- Figure 63: Scenario 1, Steel demand in Aerospace & Defense Industry Market, By Equipment, 2025-2035

- Figure 64: Scenario 2, Steel demand in Aerospace & Defense Industry Market, Total Market, 2025-2035

- Figure 65: Scenario 2, Steel demand in Aerospace & Defense Industry Market, By Region, 2025-2035

- Figure 66: Scenario 2, Steel demand in Aerospace & Defense Industry Market, By Role, 2025-2035

- Figure 67: Scenario 2, Steel demand in Aerospace & Defense Industry Market, By End User, 2025-2035

- Figure 68: Scenario 2, Steel demand in Aerospace & Defense Industry Market, By Equipment, 2025-2035

- Figure 69: Company Benchmark, Steel demand in Aerospace & Defense Industry Market, 2025-2035