|

市場調查報告書

商品編碼

1784309

4680電池技術的開發趨勢與預測(2025年)<2025> 4680 Battery Technology Development Trend and Outlook |

||||||

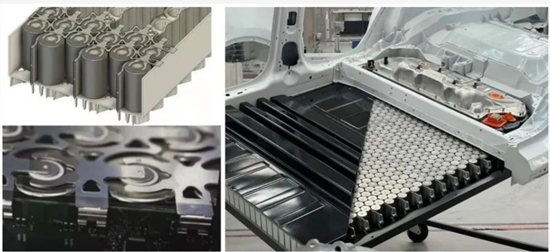

4680電池是一種大尺寸圓柱形鋰離子電芯,直徑46毫米,長度80毫米。自2020年特斯拉電池日首次亮相以來,它已成為一種標誌性的電芯形態,引領著全球電池和電動車產業的技術創新。與現有的2170/1865規格相比,4680電池具有許多優勢,包括更高的能量密度、更少的電芯數量、更佳的熱管理效率以及更低的成本。

因此,不僅特斯拉,松下、LG Energy Solution、三星SDI、寧德時代和EVE Energy等主要電芯製造商也在競相爭奪4,680電池的產能。

4680電池特別融合了許多創新技術,例如電芯到底盤(CtC)設計,該設計可提高電動車平台的結構效率;以及無極電極結構,可實現更高的充放電性能。這些進步使4680電池成為大幅提升電動車效率和成本競爭力的關鍵技術。

4680電池最顯著的特徵是無極電極結構,將集流極耳分佈在整個電極上,而不是將其佈置在電芯邊緣。這使得電流更均勻,電阻分佈減少,發熱得到抑制,散熱效果更好,從而防止高功率條件下的局部過熱。此外,它簡化了製造工藝,無需電極片連接,提高了良率。雖然這種架構在軟包或方形電池中難以實現,但在圓柱形電池(尤其是大型電池)中,其優勢得到了最大化。特斯拉的自有電池積極地將這種結構與乾電極塗層技術結合使用。

同時,特斯拉嘗試將其透過收購Maxwell Technologies獲得的乾電極塗層技術應用於4680。這種方法使用高速壓機將固體電極材料黏合到集流體上,無需使用溶劑,是一種環保(不含NMP)的製程。無需乾燥工序,縮短了生產時間,從而可以生產更厚更緻密的電極,從而提高能量密度。然而,大規模生產仍然存在課題,例如均勻的塗層厚度和穩定的界面結合力。因此,一些公司正在開發基於濕式製程的替代高速塗層解決方案。

為了最大限度地提高能量密度,高能量活性材料正在被廣泛應用。正極材料採用高鎳(鎳含量超過 88%)NCM/NCA,以提高密度和使用壽命。負極材料採用矽石墨複合材料 (Si-C) 或全矽基設計,以增強快速充電能力。電解質採用高壓穩定添加劑或凝膠電解質,以提高耐久性和穩定性。矽負極尤其面臨膨脹控制和導電性的課題,這些問題透過奈米複合材料技術、碳基質結構和界面穩定添加劑來解決。

隨著容量的增加,熱失控和安全措施也變得至關重要。由於 4680 擁有大型電池,單一電池故障可能迅速蔓延至整個模組。因此,正在開發諸如熱障、內建 PTC/熱熔斷器、阻燃電池外殼和分散式冷卻路徑等安全技術。由於結構分析比軟包或方形電池更複雜,基於模擬的結構、熱和電氣一體化設計正在不斷擴展。

特斯拉率先提出了這個概念,目前韓國、日本和中國正在開發46Phi大型電池。特斯拉正在德州超級工廠和柏林工廠量產4,680型電池,預計到2024年產量將超過1億塊。該公司計劃將第二代Cybercell應用於Cybertruck,以提高充電速度和性能,並在2026年前開發至少四款新車型,包括基於乾法塗層的NC05。松下正在其位於日本和歌山縣和美國內華達州的工廠進行試生產和供貨,並已完成位於堪薩斯州的大型4680工廠的翻新。此外,該公司也正在向特斯拉以外的OEM廠商提供樣品和批准。

本報告調查並分析了全球4,680個市場,提供了發展趨勢、電池和電池組細分報告的詳細分析、市場規模和產量預測以及材料和技術的回顧。

目錄

第1章 4680日元筒形電池概要

- 特斯拉電池日(2020 年 9 月 22 日)總結及主要發現

- 電池單元設計

- 電池單元製造工藝

- 矽負極材料

- 高鎳正極材料

- 電池到車輛整合

- 降低電池成本

- 4680 電池開發

- 全球 46xx 電池產能

第2章 4680電池電池單元的開發

- 降低成本、提高效率的策略

- 加強安全要求(熱管理升級)

- 快速充電作為未來趨勢:4680 的快充優勢

- 各大廠商市場競爭力

- 46xx 電池詳細規格:依廠商

第3章 4680電池的技術細節

- 正極材料

- 負極材料

- 其他的電池材料

- 4680製造流程的改良

第4章 4680電池的分解與分析

- 概述

- 拆解與分析流程

- 特斯拉 4680 電芯和電池組的詳細工程分析

第5章 特斯拉 4680 電池拆解與電化學研究電芯

- 總結

- 研究概述

- 前期研究

- 詳細分析

- 實驗

- 結果與討論

- 結論

第6章 4680電池的成功所需的技術

- 多極耳技術

- 極耳焊接技術

- 正極和負極材料

- 冷卻技術

第7章 4680和18650·2170比較:能量密度和降低成本

- 概要

- 4680:能量密度、快速充電與成本降低

- 高濃度電解液的使用

- 主要的4680電解液供應商

第8章 特斯拉 4680 模組電池熱管理系統 (BTMS) 設計

- 引言

- 電動車電池對 BTMS 的需求

- 冷卻方法

- 文獻綜述

- 4680 模組液冷 + 熱管:方法、結果與結論

- 擬定冷卻系統的熱分析

- 結果與討論

- 結論

第9章 4680 電芯熱管理:設計與冷卻

- 總結

- 引言

- 實驗

- 仿真模型

- 仿真結果

- 結論

第10章 圓筒型LIB電池單元的設計,特性,製造

- 概要

- 實驗材料與方法

- 實驗結果與考察

- 結論

第11章 電池尺寸與外殼材料對無平台圓柱形鋰離子電池的影響

- 總結

- 實驗

- 結果與討論

- 結論

第12章 大型圓柱形鋰離子電池的熱失控與熱傳播

- TR 和 TP 特性研究

- 引言:新設計的必要性

- 實驗

第13章 比較分析:特斯拉 4680 與比亞迪 Blade電池

- 引言

- 結果與討論

第14章 建模研究:電池尺寸與封裝對無電極圓柱形鋰離子電池的影響

- 引言

- 製程分析

- 建模

- 結果與討論

- 結論

第15章 成本比較:電極圓柱形鋰離子電池與標準電極圓柱形鋰離子電池

- 總結:特斯拉無電極圓柱形鋰離子電池設計

- 引言

- 方法

- 結果

- 結論

第16章 4680電池單元製造商情形

- Tesla

- Panasonic

- LGES

- Samsung SDI

- SK On

- EVE

- BAK

- CATL

- Gotion Hi-TECH

- SVOLT

- CALB

- Envision AESC

- LISHEN

- Easpring (Dangsheng Technology)

- Kumyang

- BMW

- Dongwon Systems

- Sungwoo

- TCC Steel

- Dongkuk Industries

- Shinheung SEC

- Sangsin EDP

- LT Precision

- NIO

第17章 4680電池的專利分析

- 無電極電池

- 特斯拉:無電極儲能裝置及製造方法

- 特斯拉乾電極製程專利(1):顆粒狀非纖維黏合劑

- 特斯拉乾電極製程專利(2):乾電極用黏合鈍化膜組合物

- LG Energy Solution:無極板相關專利(電極組件、電池、電池組、車輛)

- 村田:無極板電池

- 江蘇中能電池

- 億緯鋰能(極耳平坦化裝置)

- 微宏科技(極耳板和繞線電池)

第18章 4680電池的市場預測

- 整體市場展望

- 4680材料與製程技術預測

- 化學工業:矽碳負極、PTFE、LiFSI等材料

- 4680政策、需求與CAPA預測

第19章 Tesla的4680電池單元生產預測

- GIGA TEXAS 產量預估

- 特斯拉 4680 電池生產時程與關鍵里程碑

- 特斯拉 4680 電池最新進展

- Tesla的4680電池電池單元的成本結構

- 效率改良和降低成本的要素

- Tesla的4680電池單元開發的現狀

- 特斯拉 4680 電池單元成本結構

- 提升效率與降低成本的因素

- 特斯拉 4680 電池單元開發現況

- 特斯拉 4680 和超級充電網路的最新進展

- 特斯拉電池製造和鋰精煉業務概要

- 4680 電池單元產能 vs. Cybertruck 產量

- 4680 年度 CAPA vs. 日產量

- 4680 CAPA vs. 生產時間趨勢

- 特斯拉超級工廠 P/P 生產線的主要組裝工序

The 4680 battery is a large cylindrical lithium-ion cell with a diameter of 46 mm and a length of 80 mm. Since Tesla first unveiled it at its 2020 Battery Day, it has emerged as a symbolic cell form factor leading technological innovation across the global battery and electric vehicle industries. Compared to the existing 2170 and 1865 formats, the 4680 highlights multidimensional advantages such as higher energy density, reduced cell assembly count, improved thermal management efficiency, and lower costs.

Accordingly, not only Tesla but also major cell manufacturers including Panasonic, LG Energy Solution, Samsung SDI, CATL, and EVE Energy are racing to secure 4680 production capacity.

The 4680 battery particularly enables enhanced structural efficiency of EV platforms through Cell-to-Chassis (CtC) design and incorporates innovations such as the tabless electrode structure, which makes it possible to achieve high charge/discharge performance. These advances position the 4680 as a key technology that can drastically improve EV efficiency and cost competitiveness.

The most distinctive feature of the 4680, the tabless electrode structure, distributes the current-collecting tabs across the entire electrode instead of placing them at the cell's edges. This leads to more uniform current flow, reducing resistance distribution, suppressing heat generation, and improving thermal diffusion efficiency, thereby preventing localized overheating under high-power conditions. Additionally, the simplified manufacturing process eliminates the need for electrode-tab connection steps, boosting yield. While this architecture is difficult to implement in pouch or prismatic cells, in cylindrical cells-especially large ones-its advantages are maximized. Tesla's in-house cells actively leverage this structure along with dry electrode coating.

Meanwhile, Tesla sought to apply the dry electrode coating technology introduced via its acquisition of Maxwell Technologies to the 4680. This method, which attaches solid electrode materials to the current collector by high-speed pressing without using solvents, is an environmentally friendly (NMP-free) process. It shortens production time by eliminating drying, allows thicker and denser electrodes, and thereby improves energy density. However, challenges remain in mass production, such as ensuring coating thickness uniformity and interfacial adhesion stability. Some companies are therefore developing alternative high-speed coating solutions based on wet processes.

To maximize energy density, high-energy active materials are being applied: cathodes employ high-nickel (Ni > 88%) NCM/NCA to enhance both density and lifespan; anodes use silicon-composite graphite (Si-C) or fully silicon-based designs to boost fast-charging capability; electrolytes incorporate high-voltage stabilizing additives or gel electrolytes to improve durability and stability. In particular, silicon anodes face expansion control and conductivity challenges, tackled by nanocomposite technologies, carbon-matrix architectures, and interfacial stabilization additives.

As capacity increases, so does the need for thermal runaway and safety countermeasures. Due to the large-cell nature of the 4680, a single-cell failure can quickly cascade across the module. Accordingly, safety technologies such as thermal barriers, built-in PTC/thermal fuses, flame-retardant cell casings, and dispersed cooling pathways are being developed. Since structural analysis becomes more complex than in pouch or prismatic cells, simulation-based integrated structural-thermal-electrical design is expanding.

Although Tesla pioneered the concept, development of 46-Phi large-format cells is now actively underway in Korea, Japan, and China. Tesla is mass-producing 4680 cells at its Texas Gigafactory and Berlin plant, surpassing 100 million units in 2024. The company has applied the second-generation "Cybercell" to the Cybertruck to improve charging speed and performance, and by 2026 plans to develop at least four new variants-including the NC05-based on dry coating. Panasonic is conducting pilot production and supply from its Wakayama (Japan) and Nevada (U.S.) facilities, and has completed renovations for a large 4680 plant in Kansas. It is also undergoing sampling and approval processes with OEMs beyond Tesla.

Among Korean "K-3" companies: LG Energy Solution began pilot production at Ochang in August 2024 and is preparing for mass production at its new Arizona plant by the first half of 2026. Samsung SDI, starting in Q1 2025, will apply 46-Phi cells in micromobility packs and expand adoption with European OEMs such as BMW. Meanwhile, Chinese companies including CATL and EVE are testing 46-series cells for structural compatibility, while BYD is developing similar large cells based on LFP chemistry.

Ultimately, while the 4680 holds strong potential in terms of high capacity, high density, and cost reduction, the keys remain mass-production stabilization and technological maturity. The period between 2025 and 2026 is expected to be a watershed, as Tesla and Panasonic accumulate production experience while Korean firms build out full-scale supply systems.

Competition, however, is diversifying. Rivalry with other battery technologies such as LFP, the completion of dry processes, yield improvements, and levels of localization will shape the industry landscape. For the 4680 to truly establish itself as a game-changer in the EV market, the trifecta of technical completeness, cost competitiveness, and supply chain stability must be achieved.

This report by SNE systematically compiles scattered data from corporate announcements, teardown studies, and performance tests related to the 4680. It also reviews key academic papers to assess the actual effectiveness and performance improvements of the 4680, summarizes the status and main products of manufacturers, and presents correlations between Gigafactory scale, Cybertruck production volumes, and cell output-providing valuable insights on manufacturability for researchers and stakeholders.

The strong points of this report are as follows:

- 1. Comprehensive consolidation of development trends and information on the 4680, enabling easy overall understanding

- 2. Detailed analysis of 4680 cell and pack teardown reports, enhancing comprehension

- 3. Market and production outlook analysis for the 4680, clarifying market size and growth rates

- 4. In-depth review of materials and technologies applied in the 4680, based on academic papers

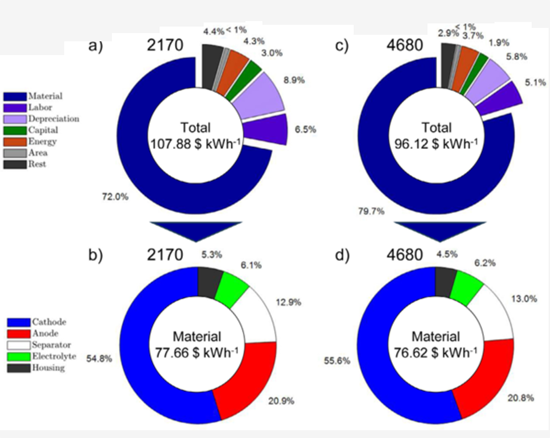

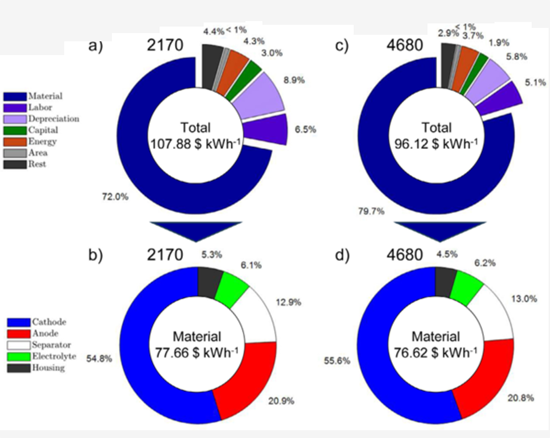

(a)(c) The total cost is classified into material costs, labor costs, depreciation, capital costs, energy costs, plant area costs, and other expenses, with their respective proportions shown. Material cost accounts for the largest share (72.0%).

(b)(d) Detailed material cost analysis of 2170 cells vs. 4680 cells. This donut chart breaks down material costs into anode, cathode, separator, electrolyte, and housing. It clearly shows that cathode and anode materials are the main cost drivers.

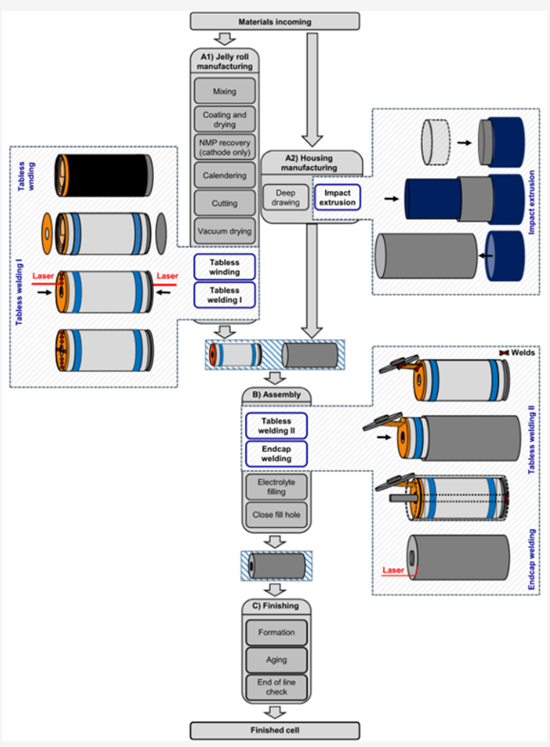

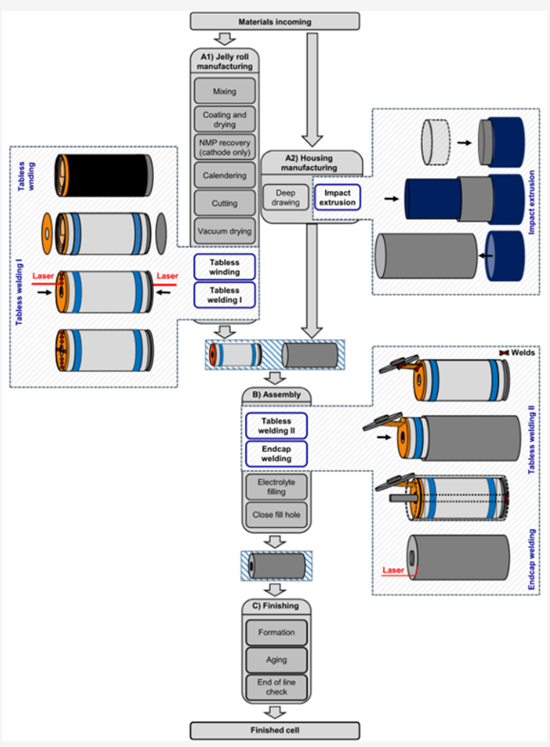

Manufacturing process of large tabless cylindrical lithium-ion cells (including can and end cap).

This figure visually illustrates the key steps of cell manufacturing:

- Top left: Tabless jelly-roll fabrication (A1) - shows how the jelly roll is formed together with the current collector plate. Laser welding is indicated.

- Top right: Can deep drawing (steel) or impact extrusion (aluminum) (A2) - illustrates the process of forming the housing.

- Center: Cell assembly (B) - the jelly roll is inserted into the housing and assembled through various welding processes. Laser and ultrasonic welding are indicated.

- Bottom: Finishing (C) - the fully assembled cell undergoes final inspection and treatment.

Table of Contents

1. Overview of 4680 Cylindrical Battery

- 1.1. Summary and Key Findings of Tesla Battery Day (Sep 22, 2020)

- 1.2. Battery Cell Design

- 1.3. Battery Cell Manufacturing Process

- 1.3.1. Coating Process

- 1.3.2. Winding Process

- 1.3.3. Assembly Process

- 1.3.4. Formation Process

- 1.4. Silicon Anode Material

- 1.5. High-Nickel Cathode Material

- 1.6. Cell-to-Vehicle Integration

- 1.7. Battery Cost Reduction

- 1.8. 4680 Battery Development

- 1.8.1. Specifications of 4680 Battery

- 1.8.2. Tesla Battery Suppliers

- 1.8.3. Global Development and Production Status of 4680 Batteries

- 1.9. Global 46xx Battery Production Capacity

- 1.9.1. Advantages and Disadvantages of New 46xx Cell Design

2. Development of 4680 Battery Cells

- 2.1. Cost Reduction and Efficiency Enhancement Strategy

- 2.2. Increasing Safety Requirements (Thermal Management Upgrade)

- 2.3. Fast Charging as a Future Trend: Advantages of 4680's High Charging Speed

- 2.4. Market Entry Competition Among Leading Companies

- 2.5. Detailed Specifications of 46xx Batteries by Company

3. Detailed Technology of 4680 Battery

- 3.1. Cathode Materials

- 3.1.1. Ultra High-Nickel Application

- 3.1.2. Production Capacity Expansion

- 3.1.3. Manufacturing Technology Upgrade

- 3.2. Anode Materials

- 3.2.1. Silicon-Based Development

- 3.2.2. Silicon Development Timeline

- 3.2.3. Silicon Anode Modifications: Nanostructuring, Carbon Composites, Pre-lithiation

- 3.2.4. Commercialization Acceleration of Silicon Anode

- 3.3. Other Battery Materials

- 3.3.1. SWCNT Conductive Additives

- 3.3.2. Steel Battery Can

- 3.3.3. Aluminum Battery Can

- 3.3.3.1. Al Housing Cell Design Concept

- 3.3.3.2. 46xx Large Cylindrical Cell

- 3.3.3.3. 46xx Jelly Roll Concept

- 3.3.3.4. Jelly Roll Thermal Transfer and Distribution

- 3.3.3.5. Thermal Simulation of Jelly Roll Concept

- 3.3.3.6. Cooling Performance Enhancement for 46xx Cells

- 3.4. Improvements in 4680 Manufacturing Process

- 3.4.1. Process Technologies for 4680

- 3.4.2. Differentiation in Production Process

- 3.4.2.1. Dry Electrode Coating

- 3.4.2.2. Example Dry Process (Huaqi New Energy)

- 3.4.2.3. Integrated Electrode and Tab Cutting

- 3.4.2.4. Increased Laser Welding Difficulty

- 3.4.2.5. Integrated Die Casting and CTC

4. 4680 Battery Teardown and Analysis

- 4.1. Overview

- 4.2. Teardown and Analytical Process

- 4.3. Detailed Engineering Analysis of Tesla 4680 Cells and Packs

- 4.3.1. Tesla 4680 Cell Design Data (w/o Tab)

- 4.3.2. Pack Structure (Cell Orientation)

- 4.3.3. Proposed Assembly Methods for 4680 Pack

- 4.3.4. Analysis of 4680 Pack for Model 3: Expected Charge Time, Power, and Dimensions

- 4.3.4.1. Summary of Pack Analysis

- 4.3.4.2. Thermal Dissipation Discussion

- 4.3.5. Current Collector for Model 3 Battery

5. Teardown and Electrochemical Study of Tesla 4680 Cell

- 5.1. Summary

- 5.2. Study Overview

- 5.3. Previous Research

- 5.4. Detailed Analysis

- 5.5. Experiments

- 5.5.1. Overview of Test Cell

- 5.5.2. Cell Disassembly and Material Extraction

- 5.5.3. Structural and Elemental Analysis

- 5.5.4. Three-Electrode Analysis

- 5.5.5. Electrical Characteristics

- 5.5.6. Thermal Investigation

- 5.6. Results & Discussion

- 5.6.1. Cell and Jelly Roll Structure

- 5.6.2. Electrode Design

- 5.6.3. Material Properties

- 5.6.4. Three-Electrode Analysis

- 5.6.5. Capacity and Impedance Analysis

- 5.6.6. Quasi-OCV, DVA and ICA

- 5.6.7. HPPC (Hybrid Pulse Power Characterization)

- 5.6.8. Thermal Characterization at Cell Level

- 5.7. Conclusion

6. Technologies Required for 4680 Battery Success

- 6.1. Multi-Tab Technology

- 6.2. Tab Welding Technology

- 6.3. Cathode & Anode Materials

- 6.4. Cooling Technology

7. Comparison of 4680 with 18650 & 2170: Energy Density and Cost Reduction

- 7.1. Overview

- 7.2. 4680: Energy Density, Fast Charging, and Cost Reduction

- 7.2.1. Energy Density vs. Blade & Prismatic Hi-Ni Batteries

- 7.2.2. Improvement in Fast Charging Speed

- 7.2.3. Dry Electrode: Production Standardization and Cost Down

- 7.3. Use of High-Concentration Electrolyte

- 7.3.1. Electrolyte Reduction per GWh

- 7.3.2. High-Concentration Electrolyte with LiFSI Additive

- 7.3.3. Fluorinated Solvent (FEC): Performance Boost in NCM811/SiOx

- 7.4. Major Electrolyte Companies for 4680

8. Design of Battery Thermal Management System (BTMS) for Tesla 4680 Module

- 8.1. Introduction

- 8.2. Need for BTMS in EV Batteries

- 8.3. Cooling Methods

- 8.4. Literature Review

- 8.5. Liquid Cooling + Heat Pipe for 4680 Module: Method, Results, Conclusion

- 8.6. Thermal Analysis of Proposed Cooling System

- 8.7. Results & Discussion

- 8.8. Conclusion

9. Thermal Management of 4680 Cells: Design and Cooling

- 9.1. Overview

- 9.2. Introduction

- 9.2.1. Previous Research

- 9.2.2. Contributions of This Study

- 9.3. Experimental

- 9.3.1. Reference Cell

- 9.3.2. Thermal Battery Test Bench

- 9.3.3. Test Procedure

- 9.4. Simulation Model

- 9.4.1. Housing & Cooler

- 9.4.2. Jelly Roll

- 9.4.3. Cathode and Anode Tabs

- 9.4.4. Model Calibration and Validation

- 9.5. Simulation Results

- 9.5.1. Impact of Tab Design

- 9.5.2. Impact of Housing Materials

- 9.5.3. Interaction between Tab Design and Housing Material

- 9.6. Conclusion

10. Design, Properties, and Manufacturing of Cylindrical LIB Cells

- 10.1. Overview

- 10.2. Experimental Materials and Methods

- 10.2.1. Cell Design

- 10.2.2. Cell Properties

- 10.3. Experimental Results and Discussion

- 10.3.1. Design of Cylindrical LIB Cell

- 10.3.2. Jelly Roll Design

- 10.3.2.1. Geometry

- 10.3.3. Tab Design

- 10.3.4. Cell Characteristics

- 10.3.4.1. Energy Density

- 10.3.4.2. Cell Resistance

- 10.3.4.3. Thermal Behavior

- 10.3.5. Jelly Roll Manufacturing

- 10.4. Conclusion

11. Effects of Cell Size and Housing Materials in Tabless Cylindrical LIB Cells

- 11.1. Overview

- 11.2. Experiment

- 11.2.1. Reference Cell

- 11.2.2. Modeling

- 11.2.2.1. Geometrical Modeling

- 11.2.2.2. Jelly Roll Electrode Layers

- 11.2.2.3. Hollow Core

- 11.2.2.4. Tabless Design

- 11.2.3. Cell Housing

- 11.2.4. Thermo-Electrochemical Framework

- 11.2.4.1. Boundary Conditions and Discretization

- 11.3. Results and Discussion

- 11.3.1. Energy Density

- 11.3.1.1. Effect of Diameter

- 11.3.1.2. Effect of Height

- 11.3.1.3. Effect of Housing Material

- 11.3.2. Fast Charging Performance

- 11.3.2.1. Heat Transfer Algorithm

- 11.3.2.2. Effect of Axial Cooling (Height/Housing)

- 11.3.2.3. Effect of Axial Cooling (Diameter/Housing)

- 11.3.2.4. Tab Design & Series Resistance Scaling

- 11.3.2.5. Overall Effect on Fast Charging

- 11.3.1. Energy Density

- 11.4. Conclusion

12. Thermal Runaway & Propagation in Large Tabless Cylindrical LIB Cells

- 12.1. Study on TR & TP Characteristics

- 12.2. Introduction: Need for New Design

- 12.2.1. Test Cell & Innovations

- 12.2.2. Limitations of Al Housing

- 12.2.3. TR Test Methods

- 12.2.4. Potting Compounds

- 12.2.5. Future Research

- 12.3. Experiment

- 12.3.1. Tabless Cell Investigation

- 12.3.2. Trigger Methods in Al Housing

- 12.3.2.1. China Safety Standards

- 12.3.2.2. FTRC Comparison

- 12.3.2.3. Large Cell Triggering Limits

- 12.3.2.4. Rupture Mechanism & Short Circuit

- 12.3.2.5. Axial Nail Penetration

- 12.3.2.6. Trigger Parameters & Geometry

- 12.3.2.7. Accelerated Calorimetry (EV-ARC)

- 12.3.2.8. Pressure Chamber Bench

- 12.3.2.9. Small Module TP Test

- 12.3.2.10. Radial Nail & Plate Test

- 12.3.2.11. Mechanical Triggering

- 12.3.3. EV-ARC Evaluation

- 12.3.3.1. Decomposition & Detection Temp

- 12.3.3.2. Reaction Mechanism

- 12.3.3.3. Dispersion Analysis

- 12.3.3.4. Temperature Distribution

- 12.3.3.5. Enthalpy Estimation

- 12.3.3.6. Voltage & Venting

- 12.3.3.7. Post-TR Mass Mapping

- 12.3.3.8. TR Cell Characteristics

13. Comparative Analysis: Tesla 4680 vs. BYD Blade Cell

- 13.1. Introduction

- 13.2. Results & Discussion

- 13.2.1. Mechanical Design & Process

- 13.2.2. Cell Housing

- 13.2.3. Electrode Composition

- 13.2.4. Contact Technology

- 13.2.5. Electrode Structure & Measurement

- 13.2.6. Manufacturing Process Flow

- 13.2.7. Materials & Cost Analysis

- 13.2.8. Electrical Performance

- 13.2.9. Thermal Efficiency & Resistance

- 13.2.10. Thermal Analysis

14. Modeling Study: Cell Size & Housing Impact in Tabless Cylindrical LIB

- 14.1. Introduction

- 14.2. Process Analysis

- 14.2.1. Manufacturing Impact

- 14.2.2. Reference Cell

- 14.2.3. Manufacturing Classification

- 14.2.3.1. Tabless Jelly Roll

- 14.2.3.2. Housing

- 14.2.3.3. Assembly

- 14.3. Modeling

- 14.3.1. Process-Based Cost Model

- 14.3.2. Geometrical Model

- 14.3.3. Process Model

- 14.3.4. Operations Model

- 14.3.5. Financial Model

- 14.4. Results & Discussion

- 14.4.1. Validation

- 14.4.2. Cell Size Effects

- 14.4.2.1. Diameter

- 14.4.2.2. Height

- 14.4.2.3. Cell Count

- 14.4.3. Housing Material Effects

- 14.5. Conclusion

15. Cost Comparison: Tabless vs. Standard Electrode Cylindrical LIB

- 15.1. Summary: Tesla's Tabless Design

- 15.2. Introduction

- 15.2.1. Design Comparison & Process Considerations

- 15.3. Methodology

- 15.3.1. Cost Modeling

- 15.3.2. Included Elements

- 15.3.3. Parameterization

- 15.4. Results

- 15.4.1. Output Calculation

- 15.4.2. Baseline Cost Analysis

- 15.4.3. Sensitivity Analysis

- 15.5. Conclusion

16. Status of 4680 Cell Manufacturers

- 16.1. Tesla

- 16.2. Panasonic

- 16.3. LGES

- 16.4. Samsung SDI

- 16.5. SK On

- 16.6. EVE

- 16.7. BAK

- 16.8. CATL

- 16.9. Gotion Hi-TECH

- 16.10. SVOLT

- 16.11. CALB

- 16.12. Envision AESC

- 16.13. LISHEN

- 16.14. Easpring (Dangsheng Technology)

- 16.15. Kumyang

- 16.16. BMW

- 16.17. Dongwon Systems

- 16.18. Sungwoo

- 16.19. TCC Steel

- 16.20. Dongkuk Industries

- 16.21. Shinheung SEC

- 16.22. Sangsin EDP

- 16.23. LT Precision

- 16.24. NIO

17. Patent Analysis on 4680 Batteries

- 17.1. Battery with Tabless Electrode

- 17.2. Tesla: Tabless Energy Storage Devices and Manufacturing Methods

- 17.3. Tesla Dry Electrode Process Patent (1): Fine Particle Non-Fibrous Binder

- 17.4. Tesla Dry Electrode Process Patent (2): Adhesive Passivation Film Composition for Dry Electrodes

- 17.5. LG Energy Solution: Tabless-Related Patents (Electrode Assembly, Battery, Battery Pack, and Vehicle)

- 17.6. Murata: Tabless Battery

- 17.7. Jiangsu Zenergy Battery

- 17.8. EVE Energy (Tab Flattening Device)

- 17.9. Microvast Inc. (Tab Plate & Wound Battery)

18. Market Outlook for 4680 Batteries

- 18.1. Overall Market Outlook

- 18.2. Materials and Process Technology Forecast for 4680

- 18.3. Chemical Industry: Silicon-Carbon Anode, PTFE, LiFSI, and Other Materials

- 18.3.1. Silicon-Carbon Anode Materials

- 18.3.2. PTFE, LiFSI, and Other Additives

- 18.3.3. Non-Ferrous Metals: Lithium, Cobalt, Nickel Demand

- 18.3.4. Hi-Ni Cathode + Silicon-Based Anode

- 18.4. Policy, Demand, and CAPA Forecasts Surrounding 4680

- 18.4.1. 4680 Cylindrical Battery Industry Chain

- 18.4.2. Analysis of China's 4680 Battery Industry Status

- 18.4.3. Market Structure of 4680 Cylindrical Batteries

- 18.4.4. Declining Trend in Cylindrical Battery Adoption

- 18.4.5. New Form Factor Development by Battery Manufacturers

- 18.4.6. Development and Production Forecast for 4680 (46xxx) Batteries

- 18.4.7. Development Trend of China's 4680 Battery Industry

- 18.4.8. Demand Forecast for EV 46xx Batteries

19. Forecast of Tesla 4680 Cell Production

- 19.1. Estimated Production at GIGA TEXAS

- 19.2. Tesla 4680 Battery Production Timeline and Key Milestones

- 19.3. Summary of Latest Tesla 4680 Battery Program

- 19.4. Cost Structure of Tesla 4680 Battery Cells

- 19.5. Efficiency Improvements and Cost Reduction Factors

- 19.6. Current Status of Tesla 4680 Cell Development

- 19.7. Recent Developments in Tesla 4680 and Supercharger Network

- 19.8. Summary of Tesla's Battery Production and Lithium Refining Business

- 19.9. 4680 Cell Production Capacity vs. Cybertruck Output

- 19.10. Annual 4680 CAPA vs. Daily Production Output

- 19.11. 4680 CAPA vs. Production Time Trends

- 19.12. Major Assembly Processes at Tesla Giga Factory P/P Line